Earlier this summer Milwaukee Tool sent us their latest addition to the FUEL lineup of the M12 cordless tools, an all new M12 FUEL Hackzall compact cordless reciprocating saw. After about two months of having this on the Aune Plumbing truck I’d like to tell you little about what may be your next favorite tool Read more

ShopTalk

Earlier this summer Milwaukee Tool sent us their latest addition to the FUEL lineup of the M12 cordless tools, an all new M12 FUEL Hackzall compact cordless reciprocating saw. After about two months of having this on the Aune Plumbing truck I’d like to tell you little about what may be your next favorite tool.

There have been a ton of Milwaukee FUEL developments over the last couple years. In case you’re not familiar, the FUEL moniker indicates the POWERSTATE™ brushless motor and REDLINK PLUS™ circuitry inside that supply constant power and overload protection using a total system communication operation that keeps the motor cooler and the battery performing at full capacity until the end. On the job site this means faster cutting/drilling/grinding and much longer battery life every time. I have been using the FUEL series impact driver, drill, circular saw, recip. saw and now the Hackzall for a little over a year now and Milwaukee’s claims on tough build and long battery life have proven true in my experience.

Specifications

▪ 5/8″ stroke length

▪ 0-3,000 SPM (Strokes Per Minute)

▪ Quick-Lok tool-free universal blade clamp

▪ 13.25″ length

▪ 4.1 lbs

▪ Blade can be mounted upside down

▪ Fuel Gauge

▪ M12™ REDLITHIUM™ XC4.0 Battery Pack (3yr warranty)

▪ LED Light

Milwaukee’s claim to be the fastest cutting and most powerful saw in its class have had me looking for the next cut this thing cannot handle. The Hackzall wasn’t made to replace the cordless sawzall but in many instances it does. If you’re cutting plastic pipe for boiler, furnace or water heater venting load it with a 6” blade. Metal or plastic conduit? Not a problem. The same for copper, demo work, threaded rod and more. Short of major lumber removal, I have reached for this over my cordless sawzall almost every time. It has made my life easier, tasks faster and has not let me down. The only question I have now is what will Milwaukee FUEL-ify next?

https://www.youtube.com/watch?v=y9_SvJaXN94

Every once in a while a “head slapping” tool comes across my radar. This simple but versatile MPT Tester by Palmer Wahl Instrumentation Group is one of the better ideas I have seen in some time. It was invented by a plumber to replace the homemade or one sized test gauges assemblies commonly found on Read more

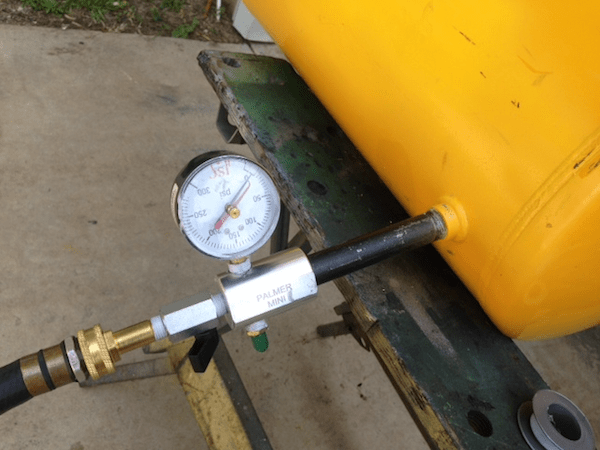

Every once in a while a “head slapping” tool comes across my radar. This simple but versatile MPT Tester by Palmer Wahl Instrumentation Group is one of the better ideas I have seen in some time. It was invented by a plumber to replace the homemade or one sized test gauges assemblies commonly found on the suppliers shelves.

I have worn through dozens of the standard, off the shelf test gauge assemblies. They often crack—and plug the gauge or Schrader valve from rust—when used on water testing over and over.

The patented MPT Tester eliminates special testing apparatus and makeshift manifolds for rough and finish inspections — making them more economical, less labor intensive and easier.

The unique feature of the MPT multi-thread pressure tester is its ability to fit a range of pipe sizes, without requiring additional fittings or reducers. The stepped “cone” design also allows it to accommodate 1/8, ½, and ¾ on the mini and ½- 2” on the pro version. The construction is high-quality aluminum, and the thick wall should provide a long lasting assembly the will not crack or strip easily. Aluminum construction will also eliminate the rust build up common with the steel-type test gauge sets.

Several kits are available, with a choice of sizes and accessories. The adapters and gauges included are also high-quality construction. Two gauges with a low range 35oz. and a 5 psi are packed in the foam lined case. A standard ¼ npt connection allows you to use other gauges. I added a “lazy hand,” telltale gauge for my testing. Air hose and garden hose adapters are another nice feature included in the case, along with a mini ball valve.

If you pride yourself in owning and wrangling high-quality, tools that will last a lifetime, the MPT is one that you will want to add to your collection.

For information, www.palmerwahl.com.

Hot Rod is currently the training and education manager for Caleffi North America. He owned his own contracting company, Show Me Radiant Heat & Solar, Rogersville, Mo. He has been a plumbing and heating contractor since 1978.

Hot Rod is currently the training and education manager for Caleffi North America. He owned his own contracting company, Show Me Radiant Heat & Solar, Rogersville, Mo. He has been a plumbing and heating contractor since 1978.

hilmor Orbital Flare Tool Hand tools are the lifeblood of any mechanic. Whether installing HVAC jobs, servicing plumbing or hydronics a solid tool inventory is a must for us contractors. According to their website, hilmor began in 1926 with only a tube bender. In January of 2013 we here at The Hub learned they were Read more

hilmor Orbital Flare Tool

Hand tools are the lifeblood of any mechanic. Whether installing HVAC jobs, servicing plumbing or hydronics a solid tool inventory is a must for us contractors. According to their website, hilmor began in 1926 with only a tube bender. In January of 2013 we here at The Hub learned they were in the US market with a complete HVAC/R tool lineup. We’ve had their Orbital Flare Tool for a few months now, taking it on multiple job sites and putting it to the test. Here’s our report:

The warranty of all the hilmor tubing tools states:

“At hilmor we have put the highest priority on thoughtful product design and manufacturing quality.

That is why we guarantee our tube-working tools, including benders, flaring and swaging tools to be free of material and workmanship defects for the lifetime of the tool.”

From the rugged tool body to the sleek and well-machined and thought out “tubing rail” this orbital flaring tool seems to stack-up or pass other tool mainstays in the industry.

A couple features the hilmor flare tool has that I have not seen on others is the spring-loaded “tubing rail” and the spring-loaded alignment system that aligns the tool head perfectly every time. The first couple uses of the tool had me somewhat fumbling to figure it out (tubing placement and tool alignment) but in a short time (4-5 flares) the necessary order of operations seemed intuitive and simple. One simple feature to note is the tubing stop guide that, when slid in place over the tubing in preparation for a flare acts as a depth guide. This tube stop guide will allow for the perfect size flare each time; similar tools on the market have left the tube depth to your best guess and flare size completely random.

Soft-Copper, Steel, Aluminum and Brass tubing can be flared using this tool. Tubing sizes include:(O.D.) 3/16″, 1/4″, 5/16″, 3/8″, 1/2″, 5/8″, 3/4″

For more info about the hilmor Orbital Flare Tool click here.

After dozens, if not over one hundred flares with our tool I would give hilmor a high grade on the Orbital Flaring Tool; if quality and durability with repeatable end results are what you’re looking for I feel this tool is a good investment. Other hilmor tools on our radar are their digital manifolds, service hand tools and electronics. If you have anything to add please leave a comment below.

There are a myriad of condensing boiler options available on the market today. NTI, or NY Thermal Inc. has been manufacturing boilers since 1968 and condensing boilers since 1997, and is considered by many to be a pioneer in the condensing boiler market. One of the many quality products manufactured by NTI is the Trinity Read more

There are a myriad of condensing boiler options available on the market today. NTI, or NY Thermal Inc. has been manufacturing boilers since 1968 and condensing boilers since 1997, and is considered by many to be a pioneer in the condensing boiler market.

One of the many quality products manufactured by NTI is the Trinity Lx series of condensing boilers. Having extensive installation and service experience with many of the hydronic heating systems made available by NTI, from the first generation T & Ti series boilers, to the Matrix furnace system, which comprises of a high efficiency condensing boiler, hydronic air handler, tankless hot water production and an available integral HRV unit to the Lx series of condensing boilers, I can vouch for the quality and reliability of these units.

One of the many quality products manufactured by NTI is the Trinity Lx series of condensing boilers. Having extensive installation and service experience with many of the hydronic heating systems made available by NTI, from the first generation T & Ti series boilers, to the Matrix furnace system, which comprises of a high efficiency condensing boiler, hydronic air handler, tankless hot water production and an available integral HRV unit to the Lx series of condensing boilers, I can vouch for the quality and reliability of these units.

The Trinity Lx uses a stainless burner with a metal fiber coating to produce extremely high modulating rates. The interior view of the combustion chamber illustrates the water tube heat exchanger, which is constructed of 316L stainless steel.

With its advanced touchscreen LCD display and Sola control package, this boiler is available in sizes ranging from 150 up to 800 MBH. This model can be used as a closed system boiler in a central heating system or models from the Lx 200 and up can be used as a water heater in conjunction with a storage tank, producing almost endless amounts of hot water for such high hot water consumption needs of restaurants, hotels and car washes to name a few. Capable of producing three separate temperature demands for today’s modern multi-temp hydronic systems with fan coil, DHW and high or low temperature space heating requirements.

Outdoor reset and multi boiler master/slave capable these boilers can detect other Lx boilers in the cascade sequence eliminating the need for an external multi boiler control. Easily set up and programmed using the 7″ touchscreen display all operational parameters can be accessed through the various status screens and menu options.

The NTI Trinity Lx is a quality choice in the highly competitive condensing boiler marketplace of today. Offering flexibility, easy installation and years of energy efficiency in a compact floor or wall mount design.

James Rolfe, Calgary Hydronics Solutions

James Rolfe has been in the plumbing and heating industry for 20+ years, working in the Calgary, Alberta, Canada area. After having worked for numerous plumbing and heating contractors over the years James went out on his own in 2009 to form his own company primarily to specialize in Hydronics. From the design stage to final system commissioning he enjoys the challenge of properly designed and installed hydronic heating systems. His bread and butter so to speak is in the service and repair field. Calgary Hydronics Solutions install about eight to 10 new systems annually, most in the retro fit market. The bulk of our business is repair, maintenance, hydronic system consultation, evaluations and system upgrades. James emphasizes energy efficiency in all hydronic installations which includes proven and reliable equipment choices for installation and repair. James enjoys the opportunity to compile blogs based on his observations and experiences in the Hydronic and HVAC industry. He welcomes any comments or feedback from others in the industry and any opportunity to answer questions. James can be reached at 403-796-4768 or at jamesrolfe@calgaryhydronicssolutions.com.

James Rolfe has been in the plumbing and heating industry for 20+ years, working in the Calgary, Alberta, Canada area. After having worked for numerous plumbing and heating contractors over the years James went out on his own in 2009 to form his own company primarily to specialize in Hydronics. From the design stage to final system commissioning he enjoys the challenge of properly designed and installed hydronic heating systems. His bread and butter so to speak is in the service and repair field. Calgary Hydronics Solutions install about eight to 10 new systems annually, most in the retro fit market. The bulk of our business is repair, maintenance, hydronic system consultation, evaluations and system upgrades. James emphasizes energy efficiency in all hydronic installations which includes proven and reliable equipment choices for installation and repair. James enjoys the opportunity to compile blogs based on his observations and experiences in the Hydronic and HVAC industry. He welcomes any comments or feedback from others in the industry and any opportunity to answer questions. James can be reached at 403-796-4768 or at jamesrolfe@calgaryhydronicssolutions.com.

The Veto Pro Pac line of tool bags has been designed for the true professional and any job site that may be in his/her work week. Roger Brouard, Owner of VETO PRO PAC decided after 25 years of carpentry work that the bags/bins/buckets he had for carrying tools onto and around the job were just Read more

The Veto Pro Pac line of tool bags has been designed for the true professional and any job site that may be in his/her work week. Roger Brouard, Owner of VETO PRO PAC decided after 25 years of carpentry work that the bags/bins/buckets he had for carrying tools onto and around the job were just not made well enough to hold up to the rigors of the job site. Add to that the failed attempt by other brands at offering tool organizing and he decided he’s had enough. That was in 1998. Fast forward to 2014 and imagine my excitement when I first learned there may be a tool bag that can handle what a real job site throws at it.

I have been working in the plumbing and hydronic heating trade for nearly my whole life. From digging trenches in basements for Grandpa’s plumbing company at the ripe young age of 13 to hanging copper fin-tube baseboard for my uncles in high school; from the beginning I have been in search of a tool box/bag that will last through anything I throw at it and allow me to keep my tools organized and ready to grab. I have tried most everything along the way as you likely have too. Well, my search may be over. And in case your wondering, I’m not getting paid to write this. It’s my own personal opinion based off of my own personal experience with the two Veto bags I now own. This first review will cover the details of the “Tech XL” bag.

Just one of many trips to the mechanical room. The Tech XL organizes my tools and testing equipment very nicely. There are tons of pockets and a lot of space.

The Tech XL bag has 80 interior and exterior pockets of various sizes, 2 Large, 3 Medium and 9 Small Neoprene pockets (for bits or memory sticks), 4 large and 5 small D-Rings, 8” Electrical Tape Strap and a Stainless Steel Tape Clip. Measuring in at 9.5″w X 16.5″l X 20.75″ t this bag has some serious tool carrying capacity! Add to all those features the padded shoulder strap and extra tough carry handle and you’ve got a bag that not only can store a ton of tools for your service work but, you’ll be able to handle this bag comfortably and with ease.

The carry handle for this bag is positioned in the center of the two-sided storage compartments making the over-moulded rubber grip a solid anchoring spot to maneuver the bag while carrying or pulling off the truck or toward you while working in front of a boiler or the like.

The handle is great, the pockets are plenty but the whole bag is built upon a solid injection molded waterproof base. I noticed right away how solid the base was compared to my previous bag. It stays cleaner because its not made of cloth and slides a little easier when I pull it out of the back of my truck. Make no mistake though, the bag stays put when traveling but more importantly I have already had the bag sitting in an inch or so of water because of a broken boiler and a major spill. The bag and my tools were dry.

Some other features of the Veto bags are the heavy duty zippers and marine grade rivets and snaps all of which are held together by industrial strength nylon stitching, PVC impregnated 1200-1800 denier body fabric. Although I have only had the bag for a little over a month there has been few surfaces it has not came into contact with. I have little doubt the canvas fabric will have a hard time standing up to whatever I may demand of it. In my opinion, it looks good too.

As with other product reviews here on The Hub, I base what I write off of my own real world experience. I use tools everyday and when I have the occasion to test something out [like the Veto bags] I approach the task seriously. I take notes and ask questions about durability, performance, ergonomics, improvement over previous designs, whether it will help me do my job better in the field and more. The “Tech XL” tool bag by Veto Pro Pac is one of those tools that will help me better perform my job. If you have a tool or bag that you would like to have reviewed, send it to us! (info@mechanical-hub.com)

- Cost: $169-200 as seen on amazon.com

- Availability: Now

- Warranty: “Veto Pro Pac warrants that its merchandise will be free from defects in materials and workmanship for a period of five (5) years after date of original retail purchase.” –vetopropac.com/warranty-policy