MX FUEL Threading Machine The following information was provided to MH directly from Milwaukee Tool. MILWAUKEE, WI – Milwaukee Tool is resetting the standard in pipe threading performance with the industry’s first cordless threading machine. The new MX FUEL™ Pipe Threading Machine harnesses the power of MX FUEL™ Equipment System’s* REDLITHIUM™ batteries to detach operators Read more

Toolbox

MX FUEL Threading Machine

The following information was provided to MH directly from Milwaukee Tool.

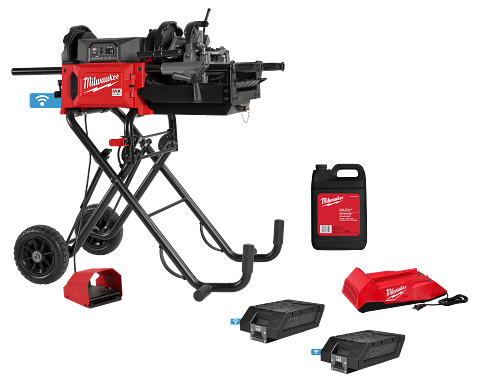

MILWAUKEE, WI – Milwaukee Tool is resetting the standard in pipe threading performance with the industry’s first cordless threading machine. The new MX FUEL™ Pipe Threading Machine harnesses the power of MX FUEL™ Equipment System’s* REDLITHIUM™ batteries to detach operators from power outlets on the job site, allowing threads to be made wherever its most convenient. In addition to the improved design, this new cordless pipe threading machine enables the easiest transportation and fastest set up to clean up, even in remote sections of the jobsite.

“Through our relentless user research, we found clear inefficiencies and significant opportunities to improve job site workflow on jobs requiring large amounts of threading,” said John Karl Jarzombek, Product Manager for Milwaukee Tool. “Historically, corded machines have forced operators to setup and stay near a power source, wasting time walking back and forth on the job site. With the MX FUEL™ Pipe Threading Machine we have freed operators from a power source while also optimizing the design for onsite transportation to enable contractors to move the machine with them as they work. The durable job site cart makes it easier than ever to thread at each point of install or remote areas of the job site and having a self-contained oil reservoir eliminates the need to move messy bucket oilers separate from the machine. All of these innovations ultimately provide operators increased efficiency and the most productive onsite threading experience.”

The MX FUEL™ Pipe Threading Machine comes equipped with the new Milwaukee NPT Pipe Threading Die Head with Micro-Adjust which enables the easiest, most controlled die adjustments and the auto release mechanism controls the thread length. The pipe threading machine is ideal for use with Milwaukee’s new line of Universal Pipe Threading Dies and compatible with other universal style dies.

For easy transportation onto and around the job site, the MX FUEL™ Pipe Threading Machine features a collapsible cart, built with gas springs to assist the tool up to working height and the integrated wheels allow for easy transportation over uneven surfaces. When moving the machine, the self-contained oil reservoir keeps oil within the basin and eliminates the need to drain the oil. Additionally, the reservoir minimizes the mess created by the threading process by removing the need for a bucket oiler, providing the cleanest threading experience available. For jobs requiring threading and grooving, the machine’s rear hammer chuck enables a quick transition and connection of roll grooving attachments without teardown or use of additional adapters. Milwaukee’s pipe threading machine reduces set up and clean up time to under one minute.

Once set up on site, the pipe threading machine provides the power to thread up to 2” black iron pipe, stainless steel, rigid metal conduit (RMC) and more. When paired with the included MX FUEL™ REDLITHIUM™ XC406 battery packs, the threading machine allows for all day runtime, delivering up to (140) cut, reamed, and threaded ¾” pipe ends per pack. Once the job is complete, the machine can be stored upright without spilling, reducing the overall storage footprint.

The MX FUEL™ Pipe Threading Machine joins Milwaukee’s pipe threading tools as another industry first. The machine eliminates inefficient steps of onsite threading and allows the operator to streamline their workflow. The new MX FUEL™ Pipe Threading Machine is fully compatible with the entire MX FUEL™ Equipment System and is a true testament to Milwaukee’s focus on investing in game-changing technology that truly delivers breakthrough solutions for users.

The MX FUEL™ Pipe Threading Machine joins Milwaukee’s pipe threading tools as another industry first. The machine eliminates inefficient steps of onsite threading and allows the operator to streamline their workflow. The new MX FUEL™ Pipe Threading Machine is fully compatible with the entire MX FUEL™ Equipment System and is a true testament to Milwaukee’s focus on investing in game-changing technology that truly delivers breakthrough solutions for users.

In addition, Milwaukee introduces their new line of Universal Pipe Threading Dies, designed for consistent quality threads in pipes. The pipe threading dies are stamped with size markings and alignment numbers for easy identification and allow for quick installation when placed into the die head, maximizing productivity on the jobsite. Offered in alloy, high speed, and high speed for stainless, the Milwaukee Universal Pipe Threading Dies are ideal for use with the Milwaukee® NPT Pipe Threading Die Head w/ Micro-Adjust and the MX FUEL™ Pipe Threading Machine, as well as compatible with other universal die heads.

*The MX FUEL™ Equipment System: This groundbreaking cordless system revolutionizes the light equipment market by delivering the performance, run-time, and durability demanded by the trades without the hazards associated with emissions, noise, vibration, and the frustrations of gas maintenance. Each of the solutions on the MX FUEL™ System go beyond the limitations of gasoline and power-cord units and operate off one completely compatible system all on the same battery. This is Equipment Redefined.

Specifications

MX FUEL™ Pipe Threading Machine (MXF512-2XC)

- Battery System: MX FUEL™

- Pipe Capacity: 1/8” – 2”

- Housing Material: All Metal Construction

- Collapsible Cart: Yes

- Dual Hammer Chucks: Yes

- Micro-Adjust Die Head: Yes

- Self-Contained Oil Reservoir: Yes

- Self-Oiling: Yes

- Equipment Warranty: 2 years

- Battery Warranty: 2 years

- ONE-KEY™ Compatible: Track and Manage

Kit Includes: (1) MX FUEL™ Pipe Threading Machine, (2) MX FUEL™ REDLITHIUM™ XC406 Battery Pack (MSFSC406), (1) MX FUEL™ Charger (MXFC), (1) Gallon Milwaukee Dark Thread Cutting Oil (49-08-5100), (1) NPT Pipe Threading Die Head w/ Micro-Adjust (49-16-5100), (1) ½”-¾” High Speed NPT Universal Pipe Threading Die (48-36-1203), (1) 1”-2” High Speed NPT Universal Pipe Threading Die (48-36-1204)

Milwaukee® Universal Pipe Threading Dies

½”-¾” ALLOY NPT Universal Pipe Threading Dies 48-36-1201

1”-2” ALLOY NPT Universal Pipe Threading Dies 48-36-1202

½”-¾” HIGH SPEED NPT Universal Pipe Threading Dies 48-36-1203

1-2″ HIGH SPEED NPT Universal Pipe Threading Dies 48-36-1204

½”-¾” HIGH SPEED FOR STAINLESS NPT Universal Threading Dies 48-36-1205

1”-2” HIGH SPEED FOR STAINLESS NPT Universal Pipe Threading Dies 48-36-1206

Cutter Wheels for Universal Pipe Threading (4pc) 48-36-1401

Additional Accessories

NPT Pipe Threading Micro Adjust Die Head 49-16-5100

BSPT Pipe Threading Micro Adjust Die Head 49-16-5103

Dark Thread Cutting Oil 49-08-5100

Threading Jaw Inserts for Coated Pipe 49-16-5102

Threading Jaw Inserts 49-16-5104

An Axe to Chop Trees, Dig Dirt and Much More For nearly 170 years, Warwood Tool has forged the tools that have helped build America. The company’s sledges, hammers, chisels, mauls, and more have been the choice of hard-working people who rely on their tools to get the job done. Continuing that prized legacy, Warwood Read more

An Axe to Chop Trees, Dig Dirt and Much More

For nearly 170 years, Warwood Tool has forged the tools that have helped build America. The company’s sledges, hammers, chisels, mauls, and more have been the choice of hard-working people who rely on their tools to get the job done. Continuing that prized legacy, Warwood Tool’s Pulaski Axe has been called “the supreme fire tool” since 1911 when it was developed by the legendary U.S. Forest Service ranger and firefighter, Ed Pulaski. Now nearly synonymous with wildland firefighting, the Pulaski Axe is equally adept at chopping trees and wood and digging in hard or root-bound dirt, making it the right choice for anyone needing a reliable and top-quality axe.

For nearly 170 years, Warwood Tool has forged the tools that have helped build America. The company’s sledges, hammers, chisels, mauls, and more have been the choice of hard-working people who rely on their tools to get the job done. Continuing that prized legacy, Warwood Tool’s Pulaski Axe has been called “the supreme fire tool” since 1911 when it was developed by the legendary U.S. Forest Service ranger and firefighter, Ed Pulaski. Now nearly synonymous with wildland firefighting, the Pulaski Axe is equally adept at chopping trees and wood and digging in hard or root-bound dirt, making it the right choice for anyone needing a reliable and top-quality axe.

“At Warwood Tool, we could not be prouder of the effort and care we put into forging each and every tool we make, just like this company has been doing for almost 170 years,” said Chris Azur, president. “And our Pulaski Axe is a particular point of pride for us. We know that it is a prized tool, not only for firefighters, but also for homeowners, farmers, landscapers, and others. It is an axe built with pride and designed to last for our hard-working customers.”

The Pulaski Axe combines an axe on one end of the head and a mattock blade on the other. Adhering to the time-honored Forest Service specifications, the Pulaski Axe is designed with a 3-3/4 lb. head and an overall head length of 13”. Made with a drop-forged, carbon steel head and a 36” American Hickory handle, the axe is finished with a classic black paint. And unlike many imports and lesser alternatives, the head of the Pulaski Axe is not simply “twisted” 90 degrees to form the mattock end. Warwood Tool takes pride in hand-forging the Pulaski Axe from U.S.-sourced steel in the same way all Warwood tools have been made since 1854.

The Pulaski Axe combines an axe on one end of the head and a mattock blade on the other. Adhering to the time-honored Forest Service specifications, the Pulaski Axe is designed with a 3-3/4 lb. head and an overall head length of 13”. Made with a drop-forged, carbon steel head and a 36” American Hickory handle, the axe is finished with a classic black paint. And unlike many imports and lesser alternatives, the head of the Pulaski Axe is not simply “twisted” 90 degrees to form the mattock end. Warwood Tool takes pride in hand-forging the Pulaski Axe from U.S.-sourced steel in the same way all Warwood tools have been made since 1854.

Warwood Tool Pulaski Axe – MSRP – $100.00

For more information: Pulaski Axe | Warwood Tool

Fujitsu General America has partnered with Intelligent Mobile Support to offer contractors Sales Builder Pro professional HVAC sales software for greater productivity and increased sales in less time. The app includes all AIRSTAGE H-Series and Fujitsu Unitary product. Sales Builder Pro is an in-home sales app that allows HVAC salespeople to provide customers with a Read more

Fujitsu General America has partnered with Intelligent Mobile Support to offer

contractors Sales Builder Pro professional HVAC sales software for greater productivity and increased sales in less time. The app includes all AIRSTAGE H-Series and Fujitsu Unitary product.

Sales Builder Pro is an in-home sales app that allows HVAC salespeople to provide customers with a professional presentation, including company background, available products and a proposal with good-better-best options.

Ductless design tools within the app streamline the design process. Instantly-generated proposals include all accessories for the job and provide product brochures and videos, all presented on a custom-branded layout.

Include clipping path for tablet and screen. Isolated on white. XXXL size, ultra quality.

The app provides integration of Payment Option Programs, and does not require Wi-Fi. Sales Builder Pro app also offers a Site Survey tool to capture job site pictures and data. The Site Survey prevents unplanned job rollovers. This improves profitability and leads to more five-star customer reviews, in turn leading to more referrals.

Setup of additional unitary brands or ServiceTitan integration are optional

enhancements.

For more information, please visit www.mobilesupport.com/schedule-a-demo

Second generation of “advanced” and easy to use stud finder utilizes multiple sensors and sophisticated signal processing to filter out false positives. For decades, stud finders have been designed based on capacitive technology that identifies changes in density behind the walls. While this technology can indicate the location of wood stud framing, it also discovers Read more

Second generation of “advanced” and easy to use stud finder utilizes multiple sensors and sophisticated signal processing to filter out false positives.

For decades, stud finders have been designed based on capacitive technology that identifies changes in density behind the walls. While this technology can indicate the location of wood stud framing, it also discovers metal, plastic, wiring, and other objects in walls just as easily. Hypersensitive “deep scanning” modes further increase the potential for “false positives,” objects inaccurately identified as studs. The result is that traditional stud finders frequently chirp or flash LED lights – often to the point of distraction – to indicate something was sensed. But what exactly?

Now new, more advanced technology is being introduced to this popular tool category that promises to redefine and even reset the standards for stud finder performance and accuracy. These next-generation “intelligent” models incorporate multiple sensors and sophisticated signal processing technology to filter out “false positives.”

In doing so, these technologically advanced stud finders locate wood studs – as intended – and also recognize and filter out non-wood objects such as plumbing, conduit, straps, brackets, screws, protector plates, ductwork, plastic pipe, PEX tubing, and wiring behind the walls.

For professionals and DIYers, this innovative technology will provide a more accurate representation of what is behind the wall and significantly improve confidence that what is detected is truly a wood stud. The benefits are significant: minimized rework, less damage created, and increased safety.

And yes, it’s about time.

A common experience

Today, the challenge is only increasing. In addition to metal plumbing and wiring, there is more behind the walls than ever, including network cabling, plastic pipes, and tubing. Complicating matters, wood framing in homes, old or new, can be inconsistent at best. Not all construction follows standard stud spacing practices of 16” or 24” on-center, and there are often additional support beams, fire blocks, and other framing features that can further muddy the picture.

Time and time again, contractors and DIYers often think they’ve found a wood stud only to drill into empty voids or attempt to insert fasteners and meet resistance in the form of false positives, such as copper pipes or metal protector plates. Worse yet, a pop and a spark might indicate the discovery of plastic-sheathed wiring.

The abundance of false positives detected can be frustrating enough that some users opt to leave stud finders in the toolbox in favor of techniques such as rapping on walls or drilling pilot holes.

Still, knowing the location of pipes, wires, and other dangerous obstacles behind the wall is just as valuable as knowing the location of the wood stud. Heavy items need to be mounted securely into the center of studs or they can fall, causing damage or even injury. Likewise, drilling into water lines can lead to costly repairs, and attempting to insert fasteners through live electrical wiring can result in significant safety issues.

For professionals and DIYers alike, the consequences can be considerable rework, loss of time, and decreased productivity.

Innovation in the Stud Finder Category

Today, basic models at varying price points are available from big name brands better known for products in other tool categories.

Zircon Corporation, however, has been in the stud finder game for more than 40 years. In 1980, the company manufactured the original StudSensor™ stud finder and invented the category. The Silicon Valley-based company produces more than just stud finders, to be clear. They design and manufacture an extended range of sensor technologies in electronic hand tools spanning wall scanners, metal detectors, circuit breaker finders, drill guides, water detectors, and leveling tools.

With this background, the company continues to lead the path to innovation in the category. The latest invention is Wood Stud SuperScan® with Target Control® Technology + FILTERz™. By analyzing the complex data streams from multiple sensors and controlling the result using sophisticated intelligence, the stud finder finds wood studs and filters out metallic objects, such as plumbing, conduit, straps, brackets, screws, protector plates, or ductwork in the wall. Additionally, the technology alerts the user to the presence of other low signal-strength, non-metallic targets, like plastic pipe, PEX tubing, and wiring.

To simplify the delivery of this seemingly complex information to users, Zircon invested extensive time and research to understand the user experience. A new and improved user interface provides an intuitive “go/no go” indication in response to what is being sensed. With a new haptic vibration and a patented SpotLite® Pointer that shines an arrow-shaped beam on the wall, users can clearly understand the target’s location and areas to avoid.

By filtering out false positives, users can be confident they have located a wood stud and not something else. Given the opportunity for a much clearer picture of what is behind the wall, contractors and DIYers would do well to upgrade their existing stud finder with an affordable, next-generation model that is sure to become the new standard in scanning. It would be the “intelligent” decision.

For more information, call Zircon Corporation at (408) 963-4550, e-mail: info@zircon.com, or visit www.zircon.com.

Engineered for strength, reach and measuring control, CONTROL-LOCK™ tapes provide maximum durability on the jobsite STANLEY®, the leading tapes manufacturer in the world and a Stanley Black & Decker brand, today announced the launch of CONTROL-LOCK™ tape measures designed for strength, reach and measuring control. STANLEY CONTROL-LOCK™ tapes range from 12-Ft. to 30-Ft. and feature a Read more

Engineered for strength, reach and measuring control, CONTROL-LOCK™ tapes provide maximum durability on the jobsite

STANLEY®, the leading tapes manufacturer in the world and a Stanley Black & Decker brand, today announced the launch of CONTROL-LOCK™ tape measures designed for strength, reach and measuring control. STANLEY CONTROL-LOCK™ tapes range from 12-Ft. to 30-Ft. and feature a rugged, yet lightweight compact design equipped with an integrated finger brake,* providing users with maximum control and protection when extending and retracting the blade.

“As the leading tapes manufacturer, we know that professionals demand tapes they can trust. That is why we are consistently innovating STANLEY tapes to enhance the user experience,” said Peter Gabriele, Group Product Manager of Tapes at Stanley Black & Decker. “STANLEY CONTROL-LOCK™ tapes are engineered to strike the perfect balance between size, performance and comfort – empowering tradespeople to tackle any job with confidence and ease.”

STANLEY CONTROL-LOCK™ tapes are ideal for use on professional jobsites and include the following features:

- A lightweight, compact and ergonomic design for maximum comfort and usability

- An integrated finger brake that provides improved control of the blade when measuring and retracting*

- Pro-grade performance 1-In. blade width and 12-Ft. max reach**

- Protective rubber over-molded casing

- BladeArmor® coating treated to the first 3-In. for durability and abrasion resistance

The STANLEY CONTROL-LOCK™ line-up comprises of 12-Ft., 16-Ft., 25-Ft., 8M/26-Ft and 30-Ft., tapes sold in recyclable packaging, marking an important step forward in minimizing single use plastic from this packaging style.

The STANLEY CONTROL-LOCK™ range is available on www.homedepot.com and at other independent retailers where STANLEY products are sold.