Program is in beta test with industrial users both on the jobsite and off When Bosch introduced its Bluehound asset tracking solution to select customers, the focus was on builders on the jobsite. That’s still the case. But a great beta test site has turned out to be a rental equipment and supply house that Read more

Toolbox

Program is in beta test with industrial users both on the jobsite and off

When Bosch introduced its Bluehound asset tracking solution to select customers, the focus was on builders on the jobsite. That’s still the case. But a great beta test site has turned out to be a rental equipment and supply house that works with its customers.

Cole Breese, inventory warehouse manager, 365 Equipment and Supply, Barrington, Ill., knows an advantage when he sees one. “We’re always looking to get better,” said Breese of the company’s decision to test Bluehound. “We’ve been testing this out on a big project for about seven months. We need to see where equipment has been so that we can optimize asset availability, verify quantity access and monitor records tied to individual assets.”

Getting the Jobsite Running

365 rents everything from power tools and work platforms to cranes and front loaders, in a market area that stretches from Chicagoland to Milwaukee. The company is a one-stop shop for contractors, sub-contractors and municipalities. 365 also sells power tool accessories to support its rentals.

365 rents everything from power tools and work platforms to cranes and front loaders, in a market area that stretches from Chicagoland to Milwaukee. The company is a one-stop shop for contractors, sub-contractors and municipalities. 365 also sells power tool accessories to support its rentals.

Ryan Braschko, warehouse manager at 365 Equipment and Supply, says there are 7,800 pieces of equipment in the company’s fleet. Up to this point, the company has relied on traditional methods to track when products were rented, when they left a site and when they were returned. If a product stays in the field, the 365 team has limited information as it moves from jobsite to jobsite.

With Bosch Bluehound, Braschko can accurately track every job an item has served, as well as duration and status. While 365 hasn’t implemented the entire Bosch solution, the pair notes that Bluehound has been able to complement and enhance their current system. Bosch tracking tags can be placed on every piece of equipment so it’s easier to see where an item is in real time. The 365 goal is to replace the manual tracking/static bar code-following computer software system that captures tool serial number, jobsite name and contact information for the foreman at a single jobsite.

Efficiency of Asset Flow

Bluehound development has pushed the Bosch research team to consult with everyone from jobsite managers to company owners, from site owners and general contractors to developers and sub-contractors. Bosch has also talked to distributors about how sales representatives find products when they’re in the field.

Even with the diverse feedback Bosch has gathered, there’s no test site quite like 365 Equipment and Supply. “Most of the adjustments we’ve made to Bluehound were influenced by our experience at 365,” said Eli Share, mobile and IoT lead, Bosch Power Tools. “We’re working to be the software link between the tool crib and the jobsite. We’ve seen the influence this technology can have here.”

Even with the diverse feedback Bosch has gathered, there’s no test site quite like 365 Equipment and Supply. “Most of the adjustments we’ve made to Bluehound were influenced by our experience at 365,” said Eli Share, mobile and IoT lead, Bosch Power Tools. “We’re working to be the software link between the tool crib and the jobsite. We’ve seen the influence this technology can have here.”

Share notes that one of the biggest challenges for their customers is that tools and equipment walk from jobsite to jobsite. Nothing has been stolen, but no one in the organization knows which site has what products and equipment. There’s no clear reporting, yet some companies generate thousands of pages of paperwork. He observed that many man-hours of manually checking and verifying records doesn’t prevent lost and stolen items.

What’s clear is that companies want to know where tools and equipment are located all the time, including small tools. One of the things that makes Bluehound attractive is that users can immediately tell if a product is lost or stolen due to manual status updates in the system. And that’s related to the tag.

“On the jobsite, people see the tag – that’s a theft deterrent to start,” said Braschko. “But the real value is that it saves time by showing equipment location on a map.” And any discrepancy about tool location can potentially be cleared up with a single phone call.

The Service Angle

In the case of 365, it’s less expensive to repair serviceable tools rather than having to replace them on a regular basis. With Bosch Bluehound, users know what the maintenance history is so repairs can be completed in a proactive manner. The system also reduces the reliance on manual maintenance administration.

“Everything we need is there in Bluehound,” said Breese. “The system was raw when it first came in, but the team has built up a hierarchy of asset tracking, locations and other details. Initially, we didn’t know what to expect, but we knew this was an opportunity to improve our business.”

“Everything we need is there in Bluehound,” said Breese. “The system was raw when it first came in, but the team has built up a hierarchy of asset tracking, locations and other details. Initially, we didn’t know what to expect, but we knew this was an opportunity to improve our business.”

The lifecycle for products at 365 is remarkably consistent: small tools, three-to-five years; larger tools, five years; laser measuring tools, seven to eight years. Efficiency and cost savings come when Breese and Braschko know where tools are located all the time rather than having to purchase replacements.

Today, 365 Equipment and Supply buys more tools than it takes in return, but that’s now a product of growth. Throughout the course of its short history, 365 has seen its business grow and become balanced season to season. With Bluehound, the company has been able to optimize asset availability, quantity access and records tied to individual assets. And these functions can be done from anywhere.

“This is the first time we’ve used a live tracker,” said Braschko. “It’s been good.”

The Plumber’s Third Hand tool makes installing and removing garbage disposals an easy, one-person job. This patented tool eliminates all the aggravation and challenges of installing garbage disposals saving you time and money. It holds the disposer and parts in place, leaving two hands free for installation. The installation tool offers a universal fit for Read more

The Plumber’s Third Hand tool makes installing and removing garbage disposals an easy, one-person job. This patented tool eliminates all the aggravation and challenges of installing garbage disposals saving you time and money. It holds the disposer and parts in place, leaving two hands free for installation. The installation tool offers a universal fit for residential and commercial disposers.

The tool allows the weight of the disposal to hold down the flange while installing the mounting hardware and raises disposal off of the ground so both hands are free to complete the installation of the garbage disposal. Simple threaded shaft and spin down locking wing nut can be used by one person in crowded installation spaces and works with all standard garbage disposal designs.

For more on the Plumber’s Third Hand Tool, visit the website.

Jones Stephens, a World and Main Company, has launched a new disposable test plug which fits their existing line of residential shower drains. This test plug enables code required pressure testing of the drain- waste-vent system and wet testing of the shower liner membrane without the need of a separate testing device. Andy Yanka, Jones Read more

Jones Stephens, a World and Main Company, has launched a new disposable test plug which fits their existing line of residential shower drains. This test plug enables code required pressure testing of the drain- waste-vent system and wet testing of the shower liner membrane without the need of a separate testing device.

Jones Stephens, a World and Main Company, has launched a new disposable test plug which fits their existing line of residential shower drains. This test plug enables code required pressure testing of the drain- waste-vent system and wet testing of the shower liner membrane without the need of a separate testing device.

Andy Yanka, Jones Stephens’ Senior Director of Product Management shares, “our new product development team is laser focused on finding ways to save plumbers time and money and this innovation embodies that approach. We want plumbers to know that Jones Stephens products are designed specifically to make their lives better.”

The preinstalled plug is secured in place by the spud during construction and testing. Once all testing is complete and the finishing touches are being placed on the bathroom, the plug is easily removed with pliers and discarded.

Jones Stephens 2”x3” residential shower drains have many options available. Plastic and brass spuds, round and square snap-in or screw-in strainers, plus many different finish options.

To find out more information, visit www.jonesstephens.com

Milwaukee Tool introduces a unique new professional-grade solution for making fast and accurate cuts through a wide array of materials—the M12 FUEL™ 3” Compact Cut Off Tool. By harnessing the power, performance and run-time of M12 FUEL™ technology*, the new tool can tackle materials ranging from metal and steel, to drywall, cement board, and tile Read more

Milwaukee Tool introduces a unique new professional-grade solution for making fast and accurate cuts through a wide array of materials—the M12 FUEL™ 3” Compact Cut Off Tool. By harnessing the power, performance and run-time of M12 FUEL™ technology*, the new tool can tackle materials ranging from metal and steel, to drywall, cement board, and tile. Its one-handed, in-line design provides exceptional control and visibility through cuts, and it is the only cordless tool of its kind with reversible blade rotation.

“While multi-material cutting tools are not new to the market, there are only a select few that have been engineered to withstand the demands of the trades, and none of the cordless options provide the level of performance that these users require,” said Tyson Apfelbeck, Senior Product Manager for Milwaukee Tool. “The M12 FUEL™ 3” Compact Cut Off Tool changes all that by being the first dedicated cordless multi-material cutting tool designed with the performance needed by the trades. Completely optimized for one-handed use, this tool’s cutting performance and versatility allow it to easily replace many cutting tools that require two hands.”

The M12 FUEL™ 3” Compact Cut Off Tool’s POWERSTATE™ Brushless Motor delivers 20,000 RPM. When this motor is paired with Milwaukee’s REDLINK™ Intelligence and REDLITHIUM™ XC4.0 Battery Pack, the tool has the cutting performance and speed to tackle various materials without bogging down. For example, it can make 12” cuts in 26ga sheet metal in under 10 seconds and 3” cuts in 3/8” ceramic tile in under 9 seconds.

As the only tool of its kind capable of reversible blade rotation, users can easily control where they eject debris and can optimize the blade for the application at hand. Its in-line design also provides exceptional control in cutting applications while improving line of sight to the material.

Ideal for cutting light to medium gauge metals and various non-metal building materials (tile, drywall, fiber cement, PVC/Plastic, etc.) the M12 FUEL™ 3” Cut Off Tool is the most capable compact cut off tool. Due to its incredible versatility, the tool will come complete with the necessary blade accessories for these applications, so users can get to work quickly and easily.

Available September 2018, the new M12 FUEL™ 3” Compact Cut Off Tool joins the largest sub-compact cordless system in the industry, now offering more than 90 professional solutions focused on power, productivity, and portability.

* M12 FUEL™ power tools are designed, engineered, and built to deliver extreme performance and productivity. All M12 FUEL™ products feature three Milwaukee®-exclusive innovations—the POWERSTATE™ Brushless Motor, REDLITHIUM™ Battery Pack and REDLINK PLUS™ Intelligence Hardware and Software—that deliver unmatched power, run-time and durability on the jobsite. Simply put, M12 FUEL™ tools are the most powerful sub-compact cordless tools in their class

Specifications

M12 FUEL™ 3” Compact Cut Off Tool Kit (2522-21XC)

Blade Size: 3”

RPM: 20,000

Arbor Size: 3/8”

Cut Depth: 0.64”

Length: 8.9”

Width: 4.7”

Height: 3.5”

Weight (w/ XC4.0 battery): 2.4 lbs

Includes M12 FUEL™ 3” Compact Cut Off Tool, (1) M12™ REDLITHIUM™ XC4.0™ Battery Pack, M12™ Charger, Dust Accessory Shoe, (3) Accessory Blades (Metal Cut Off, Carbide Abrasive, Diamond Tile), Blade Wrench, and Contractor Bag.

*Also available as a Bare Tool (2522-20)

** Metal Cut-Off Wheel, Carbide Abrasive Blade, Diamond Tile Blade also sold separately

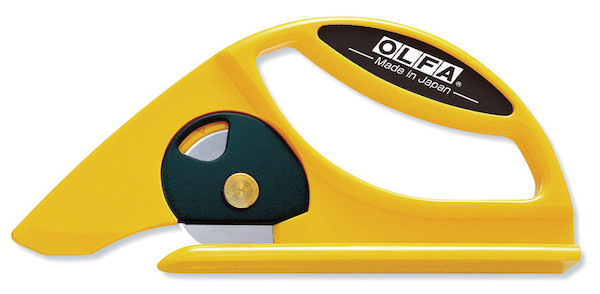

OLFA’s Rolled Materials Cutter is preloaded with an enclosed 45mm rotary blade that offers 12 cutting positions per blade for longer blade life. The solid base prevents users from damaging the surface under the cutter, making the tool perfect for cutting anything on a roll – from paper and linoleum to carpet and turf. The Read more

OLFA’s Rolled Materials Cutter is preloaded with an enclosed 45mm rotary blade that offers 12 cutting positions per blade for longer blade life. The solid base prevents users from damaging the surface under the cutter, making the tool perfect for cutting anything on a roll – from paper and linoleum to carpet and turf. The Rolled Materials Cutter slices easily through the toughest materials. This cutter has an ergonomic handle design with a large handhold allowing for a sturdy and comfortable grip.