Dedicated to introducing productivity-focused dust collection solutions for compliance with the new Occupational Safety and Health Administration (OSHA®) regulation on respirable crystalline silica dust*, Milwaukee Tool is excited to announce the industry’s first OSHA® compliance solution that doesn’t require the use of a vacuum – the Milwaukee® SDS Plus DUST TRAP™ Drilling Shroud. Ideal for Read more

Toolbox

Dedicated to introducing productivity-focused dust collection solutions for compliance with the new Occupational Safety and Health Administration (OSHA®) regulation on respirable crystalline silica dust*, Milwaukee Tool is excited to announce the industry’s first OSHA® compliance solution that doesn’t require the use of a vacuum – the Milwaukee® SDS Plus DUST TRAP™ Drilling Shroud. Ideal for overhead drilling applications, and with a universal fit to work with all SDS Plus rotary hammers, the DUST TRAP™ is an OSHA® objective data compliance solution that doesn’t require the use of a vacuum. The accessory is also OSHA® Table 1** compliant when used in conjunction with a proper dust extractor.

Dedicated to introducing productivity-focused dust collection solutions for compliance with the new Occupational Safety and Health Administration (OSHA®) regulation on respirable crystalline silica dust*, Milwaukee Tool is excited to announce the industry’s first OSHA® compliance solution that doesn’t require the use of a vacuum – the Milwaukee® SDS Plus DUST TRAP™ Drilling Shroud. Ideal for overhead drilling applications, and with a universal fit to work with all SDS Plus rotary hammers, the DUST TRAP™ is an OSHA® objective data compliance solution that doesn’t require the use of a vacuum. The accessory is also OSHA® Table 1** compliant when used in conjunction with a proper dust extractor.

“As employers continue to equip themselves with the accessories needed to be compliant, it can be difficult to quickly and efficiently ensure full compliance amid the high costs of many solutions and the limited availability of cordless options that offer a universal fit,” said Iris Horn, Product Manager for Milwaukee Tool. “The Milwaukee ® SDS Plus DUST TRAP™ Drilling Shroud is the answer to these frustrations. A cost-effective and completely universal accessory, the DUST TRAP™ offers an efficient and flexible way for users to adjust to the daily demands of the jobsite while remaining compliant.”

The DUST TRAP™ is built with a clear sleeve which provides visibility when lining up the hole and during the drilling application. Once attached to the front of the rotary hammer, it keeps dust contained throughout the duration of the drilling process. Afterwards the sleeve can be emptied, and the entire unit easily collapses and locks for storage. The compact, collapsible design is ideal for hard-to-reach places, providing superior productivity to the user.

The universal fit of the DUST TRAP™ allows it to work with all SDS Plus rotary hammer brands and styles and all SDS Plus drill bits up to 8” in length, including stop bits and other anchor installation tools.

Milwaukee® is committed to improving productivity by providing performance-driven and trade-focused solutions so users can perform an entire day’s work. As employers work to be compliant with the new OSHA® regulation, Milwaukee Tool is dedicated to continuing to expand its Dust Extraction System.

* Enforcement of the new OSHA regulation on respirable crystalline silica dust (29 CFR 1926.1153) for construction trades began on September 23, 2017. This regulation reduces the Permissible Exposure Limit (PEL) to 50 µg/m3 over an 8-hour period and affects jobsites nationwide.

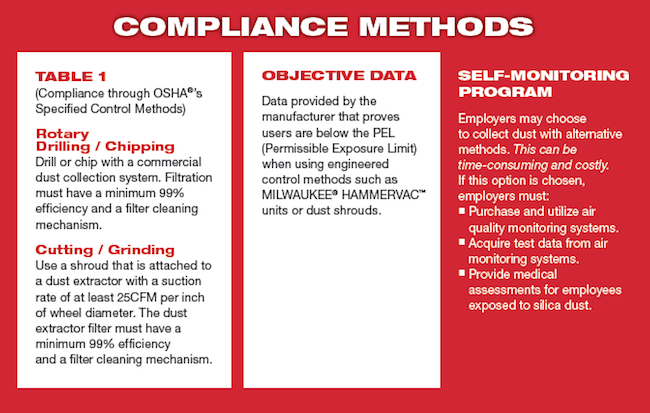

** In order to be compliant with the new regulation* companies prove they are under the PEL by following Table 1 standards, demonstrating objective data, or conducting their own self-monitoring programs, as laid out by OSHA.

Available Models

SDS Plus DUST TRAP™ Drilling Shroud 48-03-3035

*Replacement sleeves available

For more info, www.milwaukeetool.com.

Under-sink plumbing just got easier with the new RIDGID®EZ Change Faucet Tool, a multipurpose tool for installation and removal of faucets and sink strainers. The EZ Change Faucet Tool is used to fasten and remove tab mounting nuts and supply line nuts.It has a short body for easy access in tight spaces and includes a Read more

Under-sink plumbing just got easier with the new RIDGID®EZ Change Faucet Tool, a multipurpose tool for installation and removal of faucets and sink strainers.

The EZ Change Faucet Tool is used to fasten and remove tab mounting nuts and supply line nuts.It has a short body for easy access in tight spaces and includes a shut-off valve wrench to assist with stubborn valves.

“Tight quarters underneath sinks can be a major source of frustration for professional plumbers and DIYers alike and the new RIDGID EZ Change Faucet Tool helps eliminate that frustration,” said Sara Porosky, RIDGID Product Manager. “It’s a simple, purpose-built tool that makes a great addition to any toolbox.”

“Tight quarters underneath sinks can be a major source of frustration for professional plumbers and DIYers alike and the new RIDGID EZ Change Faucet Tool helps eliminate that frustration,” said Sara Porosky, RIDGID Product Manager. “It’s a simple, purpose-built tool that makes a great addition to any toolbox.”

The tool features a unique cubed insert that is compatible witha variety of common nut sizes and is ideal for most common 2-, 3-, 4-and 6-tabmounting nuts. In addition, it has a retainer for three or four slot strainer baskets and a 5/8” deep welled socket is ideal for single-hole mountings.

The EZ Change Faucet Tool comes with the RIDGID Full Lifetime Warranty.

To learn more about the EZ Change Faucet Tool contact your local distributor, visit RIDGID.com, or call toll-free: 1-800-769-7743.

Want to purchase this or other RIDGID tools? Click here to buy.

The only tool on the market that lets contractors press black steel pipe between two-and-a-half and four inches, the new RIDGID® Press Booster for use with Viega® MegaPress® XL Jaws and Rings, builds on the power of the RIDGID RP 340, attaching to the tool to multiply its output for fast connections on larger diameter Read more

The only tool on the market that lets contractors press black steel pipe between two-and-a-half and four inches, the new RIDGID® Press Booster for use with Viega® MegaPress® XL Jaws and Rings, builds on the power of the RIDGID RP 340, attaching to the tool to multiply its output for fast connections on larger diameter pipe.

The only tool on the market that lets contractors press black steel pipe between two-and-a-half and four inches, the new RIDGID® Press Booster for use with Viega® MegaPress® XL Jaws and Rings, builds on the power of the RIDGID RP 340, attaching to the tool to multiply its output for fast connections on larger diameter pipe.

“We heard from contractors that they wanted to leverage our current Standard Tool platform to make press connections on black pipe over 2 inches,” said Marcus Borman, RIDGID Global Marketing Manager. “The MegaPress XL Booster & Rings provide the ideal solution. The new tool will make press connections on 2.5”, 3”, and 4” black pipe in under 25 seconds—welding those same connections can take over 30 minutes. We worked closely with Viega to develop a program that would meet the strict demands of the contractors we serve. As market leaders in pressing, we’re both truly proud to introduce yet another industry-first.”

MegaPress XL makes connections in under 25 seconds, saving time and enhancing efficiency. Simply attach the booster to the end of the RP 340, press the trigger on the tool three times, and you have a secure press connection. Hard-to-reach angles are a breeze with an actuator that can rotate 180-degrees on the press ring.

Weighing less than 22 pounds and coming with built-in carrying handle and strap, the MegaPress XL Booster is designed for portability and easy transport between jobs. The primary kit includes the XL Booster, 2.5” ring, 3” ring, 4” ring, and high quality carrying case.

After success in Europe, RIDGID and Viega introduced ProPress® to North America in 1999 and continue to have a strong partnership to this day, resulting in continuous tool innovation and design. RIDGID press tools are unsurpassed in making quick and reliable connections on copper, stainless steel, black steel, PEX and multi-layer tubing.

All RIDGID press tools come backed by the RIDGID Full Lifetime Warranty.

To purchase or learn more about MegaPress XL or other pressing solutions contact your local distributor, visit RIDGID.com.

General Pipe Cleaners’ award-winning Gen-Eye Micro-Scope® compact inspection tool offers outstanding versatility when inspecting small drain lines and hard-to-reach places – like duct work, furnaces, and crawl spaces. General is offering a special limited-time $100 rebate* with the purchase of the 30 ft. model (Cat # GMC) or 100 ft. model (Cat # GMG) from January Read more

General Pipe Cleaners’ award-winning Gen-Eye Micro-Scope® compact inspection tool offers outstanding versatility when inspecting small drain lines and hard-to-reach places – like duct work, furnaces, and crawl spaces.

General is offering a special limited-time $100 rebate* with the purchase of the 30 ft. model (Cat # GMC) or 100 ft. model (Cat # GMG) from January 1 to March 31, 2018.

The Micro-Scope Command Module sports a bright 3.5″ LCD screen and built-in SD card reader with one-touch record button to record job photos or videos. It also includes digital zoom, rotatable picture, voice-over recording, and LED brightness controls. On-screen status indicators include date and time, SD card capacity, and battery strength. The rechargeable battery powers the unit for up to four hours.

The Micro-Scope Command Module sports a bright 3.5″ LCD screen and built-in SD card reader with one-touch record button to record job photos or videos. It also includes digital zoom, rotatable picture, voice-over recording, and LED brightness controls. On-screen status indicators include date and time, SD card capacity, and battery strength. The rechargeable battery powers the unit for up to four hours.

The Micro-Scope Command Module attaches to the reel with an adjustable mount for optimal viewing angles. And the reel holds up to 100 ft. of micro push-rod with color camera, giving you the ability to inspect 1-1/2″ to 3″ drain lines and most toilet traps.

The three-foot probe rod with color camera lets you check hard-to-reach places. And three handy attachments help adjust your viewing angle – or retrieve objects.

For details, contact the Drain Brains® at General Pipe Cleaners at 800-245-6200 or 412-771-6300, or visit www.drainbrain.com/geneye.

*Product Note: The $100 rebate is in US currency. Purchase must be made between Jan. 1 and March 31, 2018, and Rebate Card, copy of bill of sale, and Warranty Card must be returned to General Pipe Cleaners no later than April 30, 2018 to qualify for rebate.

DEWALT® launches its Jobsite WiFi Access Points (DCT100) which are Made in the USA with global materials. First announced in May 2017 at ENR FutureTech, where leading construction teams learn about today’s innovative applications of technology, DEWALT Jobsite WiFi Access Points are built to withstand tough construction site conditions. Reliable internet access is a necessity Read more

DEWALT® launches its Jobsite WiFi Access Points (DCT100) which are Made in the USA with global materials. First announced in May 2017 at ENR FutureTech, where leading construction teams learn about today’s innovative applications of technology, DEWALT Jobsite WiFi Access Points are built to withstand tough construction site conditions.

Reliable internet access is a necessity on residential and commercial construction sites large and small. DEWALT Jobsite WiFi Access Points utilize the user’s existing ISP to provide jobsite wireless internet coverage. With an operating temperature of -4°F to 122°F, the Access Points are IP67 rated to protect against dust and water submersion. In addition, the Jobsite WiFi mobile app, coming soon, will provide detailed steps to guide users through the simple setup process without requiring a technician. With both vertical and horizontal mounting options, DEWALT Jobsite WiFi Access Points can be installed to a user’s optimal orientation on a carabiner, anchor, tripod, or wall mount (not included). As the jobsite changes and progresses, the DEWALT Jobsite WiFi Access Points self-heal and adapt, retaining connectivity on site and helping to keep users connected to their data.

DEWALT Jobsite WiFi Access Points provide increased productivity and profitability* by providing access to 3D models, construction software, RFI’s, change orders, punch lists, collaboration tools, and photo documentation. Each Access Point operates off of 120V AC power and provides WPA2 encryption via SSL interfaces for security. One DEWALT Jobsite WiFi Access Point is available for $1,499 MSRP. For more information, visit dewalt.com/jobsitewifi.

*Based on actual case study findings.