A.O. Smith, a leading water heater manufacturer, has donated 200 water heaters for Waverly, Tenn. flood relief efforts. The units will be provided to flood victims who are still rebuilding eight months after storms ripped through the town on Aug. 21, 2021. “At A. O. Smith, we are deeply committed to supporting our local communities,” Read more

ShopTalk

A.O. Smith, a leading water heater manufacturer, has donated 200 water heaters for Waverly, Tenn. flood relief efforts. The units will be provided to flood victims who are still rebuilding eight months after storms ripped through the town on Aug. 21, 2021.

“At A. O. Smith, we are deeply committed to supporting our local communities,” said David Chisolm, vice president of marketing and customer experience. “Hot water is such a basic life necessity. We hope the donation of these units will allow this community to rebuild more quickly while lessening the financial burden. We also hope that this will inspire other companies to step forward with additional donations to assist in rebuilding the Waverly community.”

In August 2021, treacherous storms swept through the Waverly community claiming 20 lives, including several children. Hundreds of homes were damaged, and some residents have even had to purchase trailers and RVs to live in while their homes are being repaired. Of the homes that were destroyed or severely damaged, 80% of them are owned by people ages 70 or older, and most of those homeowners are living on social security wages.

“The past eight months since the flood have been incredibly difficult, but Waverly is a resilient town,” said Waverly resident, Susan Hodges. “When our family began rebuilding, we had no idea how long the process would take or just how expensive it would be. We’re grateful for the money we’ve saved by not having to purchase a water heater, but the impact of A. O. Smith’s donation goes beyond that—it’s a huge step toward making our home livable once again, and it’s raised our spirits along the way.”

FEMA helped support the community at the beginning of its redevelopment phase immediately after the flooding, but the extensive damage has continued to put pressure on homeowners. Community members have worked relentlessly to help their neighbors, friends and family in the area recover from the devastation. Hodges has two adult children living in Waverly whose houses were destroyed by the flood. She has spent the last eight months assisting them in their complete home renovations.

“The Waverly community has worked tirelessly to help neighbors and friends rebuild from this tragedy. We are so thankful for the water heater donation from A. O. Smith,” said Kaye Thomas of First Baptist Church Relief Efforts. “Water heaters are an essential item that many of our homeowners could not afford without the help from A. O. Smith. This donation truly gave the Waverly community a renewed sense of hope in what continues to be a long road to recovery. It will allow our community to continue to push forward in recovery efforts as we rebuild.”

The units were delivered to the First Baptist Church in Waverly earlier this year, and roughly 100 units have already been distributed to families in need. Distribution and installation will continue in the coming months.

When RLS (Rapid Locking System) introduced the first press-to-connect fittings for HVAC/R back in 2015, some contractors were understandably skeptical of the new technology. So it took some time for RLS fittings to gain acceptance from the industry. Fast forward to 2022 and now the fittings are in widespread use. Why? Here are three key Read more

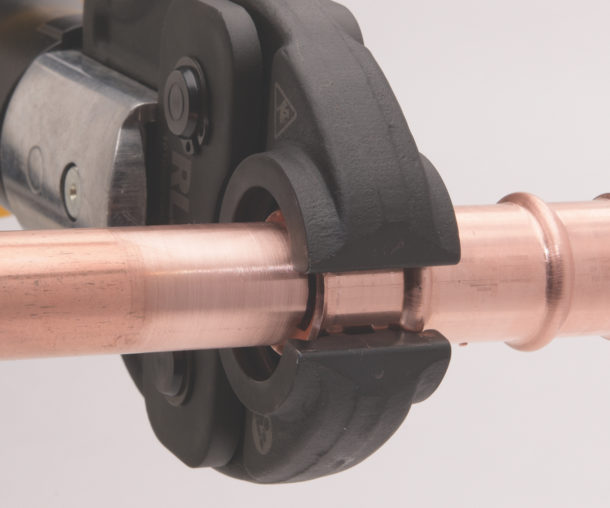

When RLS (Rapid Locking System) introduced the first press-to-connect fittings for HVAC/R back in 2015, some contractors were understandably skeptical of the new technology. So it took some time for RLS fittings to gain acceptance from the industry. Fast forward to 2022 and now the fittings are in widespread use. Why? Here are three key reasons:

Proven reliability

The first thing most industry veterans said when RLS fittings were introduced was, “Sure they hold pressure now. But we’ll see if they leak in a few years.” Well, a few years passed…and then a few more…and the reports of leaking fittings that were predicted by the skeptics never materialized. And with each passing year, the industry in general becomes more and more comfortable with the idea of press fittings for HVAC/R.

Labor shortages

Let’s face it, it’s tough to find and keep good workers right now. So many companies are short staffed, but still have plenty of work. That means they need to get more work done with less people – which is exactly what RLS press fittings can help them do. Since the fittings connect in about 10 seconds, each joint can be completed much faster than with brazing. Especially on larger commercial projects, the time savings can really add up.

Increase in tool/jaw options

To use RLS fittings back in 2015, contractors had to first invest in a new press tool and jaws. But with the addition of RLS-compatible jaws from RIDGID and Milwaukee – for use with a wide range of tools up to 32 kN – it’s now easier than ever to get into pressing for HVAC. If you already own a press tool of any brand or size, there’s a good chance you will only need to buy the jaws (and only in the sizes you use) to start enjoying the time-saving benefits of RLS fittings.

To learn more about RLS press fittings, visit rapidlockingsystem.com or take their online training at training.rapidlockingsystem.com.

This Central Pennsylvania family wanted to improve the indoor air quality in their home to ease their daughter’s allergy symptoms. Their teenage daughter, Julia, had suffered from seasonal allergies for years. Julia’s allergies were so severe they once led to walking pneumonia. Julia’s allergies were most notable in the fall and early winter. She would Read more

This Central Pennsylvania family wanted to improve the indoor air quality in their home to ease their daughter’s allergy symptoms. Their teenage daughter, Julia, had suffered from seasonal allergies for years. Julia’s allergies were so severe they once led to walking pneumonia. Julia’s allergies were most notable in the fall and early winter. She would wake up stuffy and congested and have a constant cough.

Jessica and her husband understood the health benefits of installing indoor air quality technology in their home. When they researched the many different technologies available on the market, though, they quickly learned not all technologies use the same air cleaning process, and not all technologies are validated as safe. They learned some technologies could actually produce harmful by-products, such as ozone. They also learned not all technologies have the same maintenance needs or costs. Most of the technologies they reviewed required periodic maintenance, including the preplanned replacement of expensive components.

A family friend recommended Phenomenal Aire. They scheduled a visit with a local HVAC company to learn more about this technology.

Jessica noted that the technician who showed up was friendly and knowledgeable. He explained how the technology worked in easy, understandable terms. The technician verified there were no maintenance issues to worry about or ongoing costs associated with expensive replacement parts.

When Jessica was asked why her family chose Phenomenal Aire, she said, “When we were looking at indoor air technologies, we wanted to make sure they were safe and effective for our family. It’s important to me as a mom to know the technology can address harmful things like viruses, bacteria, and mold. We felt Phenomenal Aire was a great investment for the health of our family.”

Additionally, daughter Julia shared that, “The worst part of my allergies was

getting walking pneumonia, missing school and sports, and not being able to hang out with my friends.”

Severe Seasonal Allergies

National data on allergies and immunology indicate about 50 million people in the United States suffer from allergies. Indoor and outdoor allergies can be seasonal or chronic. Many allergy sufferers often are allergic to multiple allergens. The most common indoor and outdoor allergy triggers include tree, grass, and weed pollens; mold spores; dust; and cat or dog dander.

After installing Phenomenal Aire, Julia and her family noticed a change in the indoor air within just a day or two. The family described the indoor air as feeling fresher and cleaner. Most of all, Julia noticed she was able to breathe easier. She was no longer waking up stuffy and congested. When the fall season arrived, her cough did not.

To learn more about Phenomenal Aire go to CleaningAirNaturally.com

The FabricAir® Rack Flow System prevents microclimates within multi-tier racks and boasts the grow industry’s highest CFM/watt energy efficiency FabricAir® Inc, Lawrenceville, Georgia, the original manufacturer of fabric HVAC duct, introduces the FabricAir Rack Flow System, the agricultural industry’s only air delivery system for multi-tier grow racks that doesn’t use sheet metal duct or plenums Read more

The FabricAir® Rack Flow System prevents microclimates within multi-tier racks and boasts the grow industry’s highest CFM/watt energy efficiency

FabricAir® Inc, Lawrenceville, Georgia, the original manufacturer of fabric HVAC duct, introduces the FabricAir Rack Flow System, the agricultural industry’s only air delivery system for multi-tier grow racks that doesn’t use sheet metal duct or plenums.

Rack Flow consists of fabric duct, high efficiency fans, variable speed controllers, and a suspension system of stainless steel cables and powder-coated mounting brackets. The system is designed for multi-tier cannabis growing as it delivers conditioned ambient air through the racking into the plant canopy to prevent yield-restricting microclimates.

Rack Flow is the only multi-tier rack air delivery system designed by an air distribution manufacturer. The lightweight system is adaptable to all rack brands and compatible with any lighting grid. FabricAir guarantees the grow industry’s highest CFM/watt efficiency. The system serves racks up to 64-feet-long.

Rack Flow ducts are supplied with conditioned ambient air from two high-efficiency, ETL-listed, Energy Star® fans. Growers can adjust the air flow to accommodate different stages of grow cycles. Fans come standard with variable speed digital controllers, are easily integrated with grow automation systems (GAS) and are compatible with feedback controls. Rack Flow’s fans are controllable using 0-10V or pulse wave modulation (PWM) formats. Rack Flow uses two premium antimicrobial, flame-retardant and durable fabric cloud ducts that span the length of the rack.

Rack Flow far outperforms all other rack air delivery systems because of the following advantages:

- Uses a proprietary linear venting that produces uniform, predictable airflow and velocities

- Doesn’t use metal plenums or ductwork that are labor intensive to install and clean

- ECM Fans cut power consumption by up to half versus conventional AC fans

- Fans conform to UL–507 and CSA C22.2 standards

- Can be quickly disassembled, laundered and reassembled up to six times faster than conventional systems

Other benefits of Rack Flow are:

- Environments, as reported by GAS sensors, can be modified or improved via variable speed fan capabilities

- Mounting system is adaptable to hanging from sides or middle of the rack

- Comes with easy-to-wire TRRS jacks/cables for connecting to the GAS or FabricAir provided controller

- simple and quick installation

FabricAir also has extensive experience in overhead fabric air dispersion systems for delivering conditioned HVAC unit air for grow environments. FabricAir has been an international leader in HVAC fabric duct manufacturing for all building environments since 1973.

For more details on Rack Flow, visit www.//na.fabricair.com/en/rackflow. For more information on FabricAir duct products and accessories, visit www.fabricair.com, email sales-US@fabricair.com or contact customer and technical support departments at (502) 493-2210.

With enhanced brightness and the longest working range offered in the market, Bosch’s green-beam laser goes farther for leveling and grading accuracy Bosch Power Tools, a global leader for power tools and power tool accessories, adds to its robust line of grading and leveling solutions with the introduction of its 18V REVOLVE 4000 Connected Green-Beam Read more

With enhanced brightness and the longest working range offered in the market, Bosch’s green-beam laser goes farther for leveling and grading accuracy

Bosch Power Tools, a global leader for power tools and power tool accessories, adds to its robust line of grading and leveling solutions with the introduction of its 18V REVOLVE 4000 Connected Green-Beam Self-Leveling Rotary Laser (GRL4000-90CHVG). Providing users with a superior experience during a range of heavy-duty tasks, the new laser features higher visibility up to four-times brighter than traditional red beams, extended leveling range, and additional ADS settings, ideal for varied work sites. The 18V REVOLVE 4000 offers users the additional accuracy, precision, and customization to get the job done right.

“Our goal was to design a laser that could adapt to any jobsite condition, ensuring that professionals working on projects ranging from landscaping to framing and anything in between can have the leveling flexibility they need all in one product,” said Brooke Corbin, Product Manager for Bosch Power Tools. “This new green-beam laser is setting a high bar for other tools in this sector with its 4,000-foot measurement range, Dual axis Dial-In Slope and its easy user calibration (uCAL) capabilities, allowing for advanced real-time precision adjustments while on the job.”

Features and Benefits

The 18V REVOLVE 4000 elevates the user experience with the addition of a wide range of new features to ensure the laser is properly setup for internal and external projects. With its comprehensive display, professionals can easily adjust the tool to fit their real-time needs.

- Slope Memory Data Storage: In addition to its durable design, the laser offers an added level of convenience with its slope memory feature that saves slope entry profiles on the tool for up to four entries.

- Long Working Range Accuracy: The long working range also provides measurement accuracy up to ±1/16 inches at 100 feet, in its horizontal mode and ±1/8 inches at 100 feet, in vertical mode adding extra precision to each entry.

- Self-Leveling and Slope Measurement: For additional reading accuracy, electronic self-leveling allows for easy setup. The Dual Dial-In Slope feature allows for angle adjustment on both axes when the laser lies on varying surfaces.

- Bluetooth® Connectivity: Connectivity to the Bosch Leveling Remote App is just a click away with the added Bluetooth® features, simplifying laser control and minimizing disturbances to the laser level during the workday.

- Increased Run Time: For projects requiring long power stretches of endurance, the laser offers an extended runtime of up to 60 hours with the option of a 4.0 Ah CORE18V battery or a battery adapter included with four D-cell batteries.

Specifications

The 18V REVOLVE 4000 Green-Beam Rotary Laser specifications include:

- 4,000 ft. range with receiver

- 230 ft. range without receiver

- IP68 rating

- 18V Li-Ion/Alkaline battery compatibility

- 6 ft. Tripod Tip-Over drop rating

- Bare weight: 8.2 lbs.

The Bosch 18V REVOLVE 4000 Green-Beam Rotary Laser kit offers quality accessories, supporting the tools endurance on the job. Product package includes: LR40G green-beam rotary laser receiver with mounting bracket, BT170HD tripod, GR13 grade rod, BA1 battery adapter, GBA18V40 18V CORE18V Lithium-Ion 4.0 Ah compact battery, GAL18V-40 18V charger, RC5 remote, WM6 wall mount, carrying case, (2) AA batteries and (4) D-Cell batteries.

The 18V REVOLVE 4000 Green-Beam Rotary Laser comes with a limited lifetime warranty and will be available online and in stores for purchase nationwide winter of 2022.