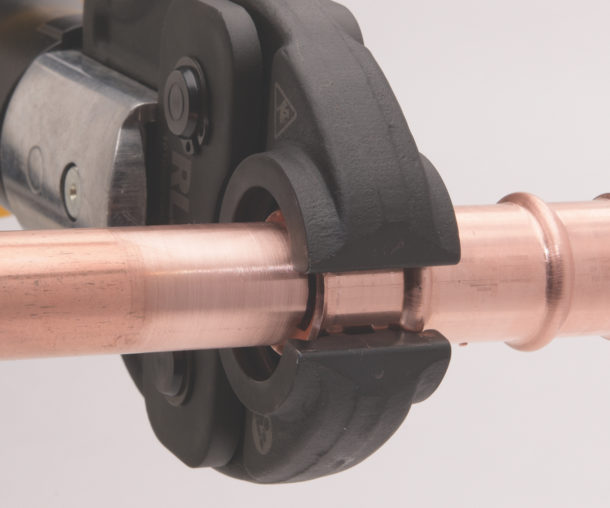

When RLS (Rapid Locking System) introduced the first press-to-connect fittings for HVAC/R back in 2015, some contractors were understandably skeptical of the new technology. So it took some time for RLS fittings to gain acceptance from the industry. Fast forward to 2022 and now the fittings are in widespread use. Why? Here are three key reasons:

Proven reliability

The first thing most industry veterans said when RLS fittings were introduced was, “Sure they hold pressure now. But we’ll see if they leak in a few years.” Well, a few years passed…and then a few more…and the reports of leaking fittings that were predicted by the skeptics never materialized. And with each passing year, the industry in general becomes more and more comfortable with the idea of press fittings for HVAC/R.

Labor shortages

Let’s face it, it’s tough to find and keep good workers right now. So many companies are short staffed, but still have plenty of work. That means they need to get more work done with less people – which is exactly what RLS press fittings can help them do. Since the fittings connect in about 10 seconds, each joint can be completed much faster than with brazing. Especially on larger commercial projects, the time savings can really add up.

Increase in tool/jaw options

To use RLS fittings back in 2015, contractors had to first invest in a new press tool and jaws. But with the addition of RLS-compatible jaws from RIDGID and Milwaukee – for use with a wide range of tools up to 32 kN – it’s now easier than ever to get into pressing for HVAC. If you already own a press tool of any brand or size, there’s a good chance you will only need to buy the jaws (and only in the sizes you use) to start enjoying the time-saving benefits of RLS fittings.

To learn more about RLS press fittings, visit rapidlockingsystem.com or take their online training at training.rapidlockingsystem.com.

Join the conversation: