In 1818, a coppersmith named William Heiss built a four-story home on the banks of the Delaware River in Bristol, Pa. Captain Joseph Hutchinson bought the home in 1934, then expanded it. William Grundy, a successful wool entrepreneur, purchased the property in 1884. He and his wife, Mary, further expanded and remodeled the home and Read more

Featured Articles

In 1818, a coppersmith named William Heiss built a four-story home on the banks of the Delaware River in Bristol, Pa. Captain Joseph Hutchinson bought the home in 1934, then expanded it. William Grundy, a successful wool entrepreneur, purchased the property in 1884. He and his wife, Mary, further expanded and remodeled the home and raised their two children, Joseph and Margaret, along the banks of the placid river.

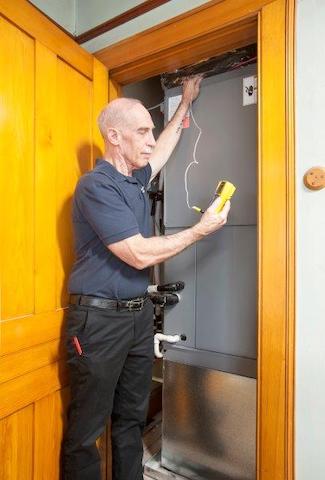

Ray Perotti, owner of RHR Mechanical Contractors, Inc., and his son, Ray Perotti Jr., look over the HVAC design for the museum installation.

Joseph Grundy grew up to become a successful business icon and in 1929 was appointed to the U.S. Senate. He and his sister Margaret were philanthropists, and much of the development in the Bristol area is owed to their generosity and community-focused mindset. Margaret founded a library adjacent to the family mansion, which was replaced with a new one following the terms of Joseph’s will after his death in 1961.

Today, the home museum and library are operated by the Grundy Foundation, each named in Margaret’s honor, and stand for the Grundy family’s values: love of their hometown, civic participation, devotion to family, respect for hard work and commitment to education. By establishing the Grundy Foundation, Senator Grundy wanted to ensure the ongoing well-being of the residents of Bristol Borough and its surroundings in Bucks County, Pa.

Foundation assets have assured for proper care of the 5,000-sq.-ft. museum, and in 2019, discussions about adding air conditioning and upgrading the heating system began.

“As part of a three-year renovation of the structure, AC and improved heating were major additions that the foundation deemed necessary,” said Geoff Webster, museum curator. “We are directly on the river, so it’s very muggy in summer. We weren’t able to open the windows, and the museum grew incredibly hot. Full tours typically take an hour, but our summer tours were limited to 20 minutes because staff and visitors simply couldn’t tolerate the heat. The humidity also isn’t good for the collections, artifacts, and antique woodwork.”

Local talent

Ray Perotti, a lifelong resident of the Bristol area, lives just down the street from the Grundy Museum, and is well known in the community. He owns RHR Mechanical Contractors, Inc. The 25-person commercial/industrial firm is known for their work on large, challenging projects between Wilmington, DE, and New York City. They’re trusted by a wide range of commercial firms, schools, and occasional high-end residential customers. In 2019, when they were contacted by the Grundy Foundation for a design-build solution, RHR had installed many mini-split systems, but had installed only a few VRF systems.

“I knew that either Fujitsu Halcyon mini-splits or a VRF were going to be the solution on this project, due to the challenges of addressing the needs of the building without detracting from the facility’s historical nature,” said Perotti. “My concern with mini-splits—later confirmed—would be the high number of outdoor units needed. As for the VRF option, that left us with some uncertainty about the brand of system best-suited to the task. The level of support we were offered by Ed Peterson, technical service advisor at Johnstone Supply, and Jim McBride, at Harry Eklof, made it an easy decision.”

“I knew that either Fujitsu Halcyon mini-splits or a VRF were going to be the solution on this project, due to the challenges of addressing the needs of the building without detracting from the facility’s historical nature,” said Perotti. “My concern with mini-splits—later confirmed—would be the high number of outdoor units needed. As for the VRF option, that left us with some uncertainty about the brand of system best-suited to the task. The level of support we were offered by Ed Peterson, technical service advisor at Johnstone Supply, and Jim McBride, at Harry Eklof, made it an easy decision.”

Peterson and McBride toured the facility with Perotti, spoke with staff at the museum, and designed a Fujitsu Airstage V2 VRF system that would meet all of the needs and ease any concerns about maintaining the building’s historic integrity. Even thermostats were to be hidden. Being RHR Mechanical Contractors’ first Airstage VRF installation, Perotti sent two lead technicians to Johnstone Supply for VRF training.

A solution for sensitive space

Meetings at the museum resulted in a design that required a lot of creativity. There was some ductwork already available; tin, from the 1960s. This had either been abandoned or was still currently in use for hot water coils connected to the building’s oil boiler. Without the option to add new ductwork, RHR cleaned and camera’d the ductwork before determining that it could be retrofitted with new VRF air handlers.

“Building new soffit to hide ductwork wasn’t acceptable to the Board of Directors,” said Webster. “Also, almost every interior wall in the museum was once a brick exterior wall, so new penetrations had to be kept at an absolute minimum.”

Most of the museum (minus the two basements and the third story attic) could be served by the old ductwork, with one zone upstairs and one downstairs. Even the old brass registers were polished and re-installed. Two Airstage air handlers in the basement provide the heating and cooling, meeting the need with one four-ton vertical and one four-ton horizontal unit.

The only space on the first floor that doesn’t receive sufficient airflow from the ductwork is the dining room. Here, a small horizontal air handler is hidden inside an original radiator cabinet, which needed to be carefully disassembled and rebuilt. Instead of brazing refrigerant lines, ZoomLock flame-free fittings were used.

The only space on the first floor that doesn’t receive sufficient airflow from the ductwork is the dining room. Here, a small horizontal air handler is hidden inside an original radiator cabinet, which needed to be carefully disassembled and rebuilt. Instead of brazing refrigerant lines, ZoomLock flame-free fittings were used.

“The slim duct unit that was used within the wood cabinet could be mounted vertically without the need for a riser,” said Peterson. “The competitor’s unit required a riser, meaning it wouldn’t have fit the dimensions of the old cabinet.”

There were spaces in the building where maintaining historical integrity wasn’t a key concern. The 1,300 square-foot caretaker’s quarters in the daylight basement received three wall-hung units, an office in the attic now has a small horizontal air handler, and two air handlers in the attic connect to new ductwork. This space was conditioned simply to protect items that are kept in storage. In all, the museum now has eight zones of heating and cooling.

“The compact footprint of Fujitsu’s Airstage systems was a big advantage on this project,” said Peterson. “We were very limited by where we could set the condensing units. We were able to install them on a small porch between the museum and the library, out of sight from the road and from visitors.”

Physical size was only half the equation. Per code, the occupied space of the museum could only be served by a single system containing 26 pounds of refrigerant per 1,000 cubic feet. Peterson and McBride suggested installing one six-ton and one eight-ton system instead of a single 14-ton unit. This not only split the refrigerant charge between two systems, but also provides a level of redundancy for the museum.

Constant humidity and simple control

“On the control side of the project, there were two things that the foundation was adamant about,” explained Peterson. First, the humidity had to remain constant year ‘round, and would require constant monitoring. They actually have to report humidity levels to the Board of Directors. Second, they wanted a very user-friendly control platform. This was made slightly more complicated because of the firewalls within the system that communicates between the museum and the library, but we had a solution.”

If not for the security measures in the existing communication system, the Fujitsu Airstage controls would’ve been sufficient to provide the data collection and logging the museum required. With that added complexity, Peterson suggested using a Honeywell RedLINK system, coupled to the Airstage controls via Fujitsu’s third party adapter.

If not for the security measures in the existing communication system, the Fujitsu Airstage controls would’ve been sufficient to provide the data collection and logging the museum required. With that added complexity, Peterson suggested using a Honeywell RedLINK system, coupled to the Airstage controls via Fujitsu’s third party adapter.

This solution gathers information from the 20 sensors hidden throughout the museum, stores the data, and provides simple access for museum personnel.

Summertime humidity is controlled by the AC function of the VRF system. During the dry winter, a Honeywell humidifier is used on the first floor and second floor duct systems. Because of concern about a leak, the attic system does not feature a humidifier. The use of the humidifiers protects paintings, wooden fixtures and trim, tapestries, etc.

From first contact to commissioning, the project took over two years to complete. The sweeping museum renovation that was ongoing in 2019 extended the timeline considerably, as did the COVID lockdowns. A full year was lost to health precautions. The system was operational for a year before final commissioning.

From first contact to commissioning, the project took over two years to complete. The sweeping museum renovation that was ongoing in 2019 extended the timeline considerably, as did the COVID lockdowns. A full year was lost to health precautions. The system was operational for a year before final commissioning.

“This is one of the oldest buildings in the area,” said Peterson. “Marrying it with cutting edge technology, invisibly, was gratifying. We’ve proven that we can think outside the box to provide an extremely comfortable, efficient system, and museum personnel are thrilled.”

Larger square footage houses that feature hydronic heating normally require an architect and a contractor to be on the same page. What is the menu or choice of items offered? By Norman Hall Granite vs. marble: casement vs. double-hung: paint vs. stain. The architect or builder proposes a variety of choices to the person building Read more

Larger square footage houses that feature hydronic heating normally require an architect and a contractor to be on the same page. What is the menu or choice of items offered?

By Norman Hall

Granite vs. marble: casement vs. double-hung: paint vs. stain. The architect or builder proposes a variety of choices to the person building a new home. One question that may not be asked is, do you want a comfortable temperature in the home or not? Architects and contractors may want to offer choices when it comes to hydronic heating.

Do We Offer New Home Buyers the Right Choices?

I live in Michigan where most homes are heated by single zone furnaces. Hydronic heating is rarely a suggestion unless the home is over 6,000-7,000 sq. ft. When I explain hydronic heating to friends in smaller homes, they wonder why it was not offered to them as an option. Architects, builders and contractors may be missing a great opportunity to create extremely satisfied customers by offering choices in an area most buyers do not even know about.

We are guilty of being too close to the industry. I recently asked a few people about heating system choices. Most of the couples I spoke to were in their mid-30s with two professional incomes. They were first- or second-time homeowners of homes in the 3,000 to 4,000-sq.-ft. range. I asked if they knew the term hydronic heating. There were a variety of responses but nothing close to correct. The best I heard was one couple who knew you could put separate furnaces in for the upstairs and downstairs.

I asked the following questions:

- Would you like separate temperatures upstairs and downstairs? Maybe there are rooms you do not want to heat too much when not in use. How about separate temperatures in specific rooms?

- How about warm bathroom floors on a cold morning?

- Are you interested in mobile conductivity? Checking and setting temperatures by your mobile device? (Note: many thermostats, boilers, and even pumps have this capability)

- Have a swimming pool or hot tub? The home heating boiler can be used through a heat exchanger. This removes the ugly pool heater.

- Worried about snow in the walkways? The heating system can take care of that.

I coupled the conversation with a price tag of 5 to 7% more for the price of the newly constructed home. Every one of them were interested.

You get the idea. The list and the marketing pieces to present the offerings are up to the contractor or architect. The important thing is to recognize that most home purchasers are not even aware these things exist.

Do Not Get Stuck in Yesterday’s Design

Bell & Gossett PL series circulator

I laugh at times when I think of what we, in the HVAC world, think of as new. I still refer to products introduced 10 years ago as new. I mentioned mobile conductivity. This is very important to the buyer who uses this technology all day long. Thermostats can be monitored and programmed remotely. Stopping there might miss a “new” value to offer. Whether controls, condensing boilers, or even the ECM hydronic heating pump, technology catches attention.

Today, you can install a smart ECM circulator instead of yesterday’s technology. Look at the two pumps below. Both the red PL series circulator and the black ecocirc 20-18+ are provided by Xylem Bell & Gossett.

Bell & Gossett ecocirc

Both will do the job of providing water flow to terminal units. The ecocirc 20-18+ offers features that align with your prospective customer. Let me mention just three of them.

- The Variable speed pump with an ECM motor saves money and reduces electrical energy waste compared with most pumps.

- Bluetooth conductivity to a mobile device

- Internal protection against damage if the homeowner closes a valve to stop the flow.

Architects and contractors should get together to market the option of hydronic heating in new homes. Make sure the options include the latest technology for their fast moving and totally connected customers.

Norman Hall is an engineer and leader at the R. L. Deppmann Company, a manufacturer’s representative, in Michigan and Ohio. Norm has assisted in the design and troubleshooting of hydronic and steam systems for 45 years.

Norman Hall is an engineer and leader at the R. L. Deppmann Company, a manufacturer’s representative, in Michigan and Ohio. Norm has assisted in the design and troubleshooting of hydronic and steam systems for 45 years.

Ongoing training is an essential pillar of the skilled trades. Trades professionals who proactively engage with opportunities to learn about new processes and new technology deliver better experience and workmanship, make more educated decisions, complete more work in less time and establish trust with customers. In short, ongoing training helps create the right conditions for Read more

Ongoing training is an essential pillar of the skilled trades. Trades professionals who proactively engage with opportunities to learn about new processes and new technology deliver better experience and workmanship, make more educated decisions, complete more work in less time and establish trust with customers.

In short, ongoing training helps create the right conditions for positive business growth.

Unfortunately, for a variety of reasons, our industry has not traditionally made non-required continuing training a priority. Many skilled tradespeople are reluctant to pursue the opportunities made available by professional organizations, trade associations and manufacturers. Business owners and leadership teams often fail to invest in training for their technicians and office staff. Additionally, the current COVID-19 crisis has had an enormous impact on the nature of training in the industry.

Virtual training offers convenience and accessibility, but in-person, hands-on engagement has proven to be the most effective and preferred method of training for skilled trades professionals. While the best examples of virtual training can replicate some of the elements of live, personal interaction by providing opportunities for direct feedback and questions, the vast majority of virtual training options are pre-recorded. The effective elimination of live training by safety concerns, travel restrictions and social distancing is yet another huge COVID-19-related challenge our industry faces.

What training is and isn’t

Our industry may be short on training, but we use the word a lot. In fact, it’s one of the most overused terms in the skilled trades professions, primarily because we apply it to many things that aren’t training.

Training is not just information sharing. Training involves both the sharing of information and action.

When you’re weight training, you don’t watch it on a screen. You might review proper form and execution, but weight training is an action. It’s exactly the same for professional technical training in the trades. Training involves watching and then doing, learning through hands-on experience. Many people have pursued a career in the trades because they like to work with their hands and learn by doing.

Many trades professionals have demonstrated initiative and embraced the virtual training that has sprung up in the last year. Video tutorials and webinars have value in introducing technicians to new equipment, processes and concepts, but that’s only half of the full training experience. Following up virtual training with hands-on practice is essential for fully translating information into actionable skill. As the pandemic slows, expect in-person training to boom as agents look to validate the practices and concepts seen on the screen. Trades people are looking forward to mixing it up, getting back to their roots and making things happen.

A “traditional” industry

If you surveyed the skilled trades right now and asked what the biggest barrier to training is right now, most professionals would say they’re too busy and don’t have enough people. It’s true that the labor shortage is a lasting challenge, but there may be deeper reasons for training hesitance.

In my early days as an HVAC technician, I learned the ropes working with a specific manufacturer. I was loyal to that manufacturer, but I had less confidence working with other companies’ products. We do what we know how to do. A related fact is that we don’t like to admit to ourselves or others what we don’t know or are unsure about. Many people in today’s world, not just in the skilled trades, feel incredible pressure to already know everything they need to know.

In the trades, an unfortunate result is that too many professionals wrongly calculate that by exposing themselves to training, they’re also revealing what they don’t know. Getting them to understand that it’s OK not to know something is a major obstacle for trainers and business owners.

Many trades people value their personal experience in the industry over formal ongoing training. While experience on the job is critical, so is continuing engagement with new technology and processes.

The critical carrot

We know why training is important. We know what it can be worth. How do you convince the industry to commit to training as a critical element of our industry?

You have to have a carrot.

There has to be something at the end that makes it worthwhile, whether it’s recognition within the company, financial reward or added benefits. The difference in experience and training is reflected in the different labor rates for a master plumber and a journeyman. The recognizable difference in skills and knowledge typically sets a master apart.

The more relevant the carrot is to the training, the more effective it will be in the long run. More training can put a technician in position to earn more money as a local expert, and that’s a gift that keeps on giving.

Confidence is at the very top of the list of advantages resulting from quality training. When technicians have a solid foundation of up-to-date skills, customers end up paying for service they’re satisfied with. Confident techs deliver better experience and build relationships.

The better trained a contractors’ team is, the fewer mistakes they’ll make. With training, techs work more quickly and more accurately and in the end are more cost effective.

Dustin Bowerman is director of corporate training and product support for Bradford White Corporation, a full-line manufacturer of residential, commercial and industrial products for water heating, space heating, combination heating and storage applications. For more information, visit www.bradfordwhitecorporation.com.

Dustin Bowerman is director of corporate training and product support for Bradford White Corporation, a full-line manufacturer of residential, commercial and industrial products for water heating, space heating, combination heating and storage applications. For more information, visit www.bradfordwhitecorporation.com.

https://youtu.be/Il6vlVrsmQA Milwaukee has added to the FORCE Logic family with the addition of the M18 Press Tool w/ ONE-Key 2922-20. The standard size press tool is available now as a kit and bare tool. The M18 FORCE Logic press tool w/ ONE-Key is compatible with over 20 fitting systems. Typically called a “ProPress” tool [a Read more

Milwaukee has added to the FORCE Logic family with the addition of the M18 Press Tool w/ ONE-Key 2922-20.

The standard size press tool is available now as a kit and bare tool. The M18 FORCE Logic press tool w/ ONE-Key is compatible with over 20 fitting systems.

Typically called a “ProPress” tool [a brand or trademarked name owned by Viega] the M18 is fully capable of pressing up to 4″ copper pipe and iron pipe fittings of various manufacturers.

In the video above Eric Aune shows the new press tool next to its brushless predecessor, the 2773-20 M18 FORCE Logic press tool.

When I asked Sean Debnath, VP of Sales and Marketing, Viega, about the short-term economy earlier this year, he said, “The uptick in business that we all experienced gradually through Q3 and Q4 of 2020, seems to be continuing in to Q1 2021. But we choose not to take that trend for granted with all Read more

When I asked Sean Debnath, VP of Sales and Marketing, Viega, about the short-term economy earlier this year, he said, “The uptick in business that we all experienced gradually through Q3 and Q4 of 2020, seems to be continuing in to Q1 2021. But we choose not to take that trend for granted with all that is happening around us, and deal with it a month and a quarter at a time. Viega has taken steps with frequent testing and tracing to ensure we keep our factories and distribution centers running.”

Through all of this uncertainty and one month-at-a-time mentality, making the transition to a new CEO can be difficult enough. But through a pandemic? Mechanical Hub recently talked with Viega’s new CEO, Markus Brettschneider, about his vision for the company, and navigating through these uncertain times.

Through all of this uncertainty and one month-at-a-time mentality, making the transition to a new CEO can be difficult enough. But through a pandemic? Mechanical Hub recently talked with Viega’s new CEO, Markus Brettschneider, about his vision for the company, and navigating through these uncertain times.

MH: How has Viega navigated through the pandemic and what does the path moving forward look like as we start to normalize?

Brettschneider: Since the beginning of the pandemic, the health and safety of our people has come first. We put into place regular testing and safety measures at the facilities where in-person work was required. Moving forward, health and safety will continue to be our focus. Our other big focus is our customers, and we have done all we can to keep production and distribution as normal as possible. With all of the challenges in the logistical side, it’s a tense period. But we haven’t shied away from spending money to keep things running smoothly. We hope in the coming months to get colleagues back to the office and find new ways of working in various setups. We very much look forward to meeting our customers once again face-to-face, while at the same time being very careful and keeping everyone safe. So far this year, the outlook is positive.

Viega’s interactive displays in Broomfield, Colo.

MH: Has the company learned anything during the pandemic that will be implemented more into the business plan (virtual trainings, less travel, etc.)

Brettschneider: I think we have learned that virtually, a lot is possible. There are even certain benefits when it comes to training as well as new ways of engaging with customers. It will be interesting to see how things like trade shows and other events evolve in the future, but in 2020 we reallocated most of those funds into other channels to make the most of what we could. We didn’t cut any funding. Instead, we trained our own people to be capable in this digital environment, and have excelled with virtual education and customer events. We know there have been changes in buying behavior in the past year, and we remain open to this ever-changing business landscape.

MH: What are some of your top initiatives for the company?

Brettschneider: Our biggest priorities right now are safety and supply to the customers. We’re looking at things like raw materials, logistics and the availability of workforce. We are continuously investing in our company footprint through automation, digitization and robotization. This is all important to help drive growth with our customers. We also know how important it is to invest in virtual and online marketing, as well as launch additional customer training activities.

Viega’s Seminar Center in Broomfield, Colo., comes with a view.

MH: What has impressed you the most since joining the company?

Brettschneider: The people—our colleagues, the customers and the Viega family ownership. I’m extremely impressed with the products as well as the relationship we have with our customers and the opportunity to grow in our space. I’m also impressed with the commitment of the Viegener family to the company globally as well as its strong commitment to Viega LLC (the North American market) specifically. I’ve found the company is willing to constantly invest in order to grow the business, and the ownership’s passion and commitment is impressive.

MH: Explain Viega’s commitment to the supply chain and wholesale channels.

Brettschneider: We have proven our commitment to the supply chain, especially over the last few years . During that time, we grew the manufacturing and distribution presence in McPherson, Kansas, and we invested heavily in the workforce within the supply chain. We hired additional people to ensure our commitment in the U.S. is as strong as it always has been, and will continue. It’s important for us to invest for continual growth, and we know that our distribution and logistical centers are a key part of the business.

Training is paramount with Viega, and getting contractors back into the facilities, safely, is the goal.

A good example of our commitment was after the record cold snap in Texas and other southern states. We prioritized shipments and looked at unique ways to get products to the area that was so desperately in need of help. We are eager to work with our partners to drive growth, and are currently adding points of distribution throughout the U.S. We are a strong believer in wholesaler business and remain absolutely committed to our wholesaler distribution setup.

MH: What are some things you’ve learned throughout your career that will help you in your new position?

Brettschneider: Simply put, there is nothing more important than your own people and building great relationships with customers. Those ideas are central to a successful business.

MH: How do you see the short-term economy?

Brettschneider: Between the Covid relief package, some of the American population having more disposable income than ever, lower fixed-interest rates and potential infrastructure packages, we’re optimistic. We’ll see bumps here and there, I’m sure, because of the uncertainty of a global pandemic, but the fast-pace rollout of the Covid vaccination is giving us all a more positive outlook for the short-term U.S. economy.

A McPherson, Kansas, facility.

MH: Provide an update of the McPherson locations — expansions, new innovations, etc.

Brettschneider: We have invested heavily in that location over the past few years, in both infrastructure and people. This year we are focused mostly on hiring people. It’s important to recognize we are investing not to just maintain, but to grow. Our plan has been to build for significant growth so that we are ready when there are sudden spikes in demand (such as the Texas cold snap). In terms of infrastructure, the expansion in logistics was completed early in 2020 and is fully operational. The new ProPress building is completed, with some machines in operation, while others will be arriving later this year (delayed due to Covid).