The son of an arcade owner, you could say that business ran in his blood. Born into an entrepreneurial family, Terence Chan (@the_impetus), owner, Impetus Plumbing and Heating LTD, Vancouver, British Columbia, Canada, practices networking and customer service daily to grow his business. But it didn’t come easy, at first. With a goal of becoming Read more

Featured Articles

The son of an arcade owner, you could say that business ran in his blood. Born into an entrepreneurial family, Terence Chan (@the_impetus), owner, Impetus Plumbing and Heating LTD, Vancouver, British Columbia, Canada, practices networking and customer service daily to grow his business.

But it didn’t come easy, at first. With a goal of becoming an engineer, Chan found himself in the “slumps,” after dropping out of the local university. “I didn’t know what I wanted to do and my parents told me to try plumbing,” says Chan. “Instead of just playing video games all day and waiting for something to happen, I decided to take on that challenge and try working with my hands,” says Chan.

Chan ended up really liking the trade—more so because he found out how plumbing and heating is so important in everyone’s day-to-day lives—and he was adamant about being the best out there, and his sights were set on owning his own business one day. “My goal was to get all types of experience before I start my business; commercial, residential, construction, service and sales,” say Chan.

In fact, Chan worked in commercial construction, working on high rises, schools and low rises. He then moved over to a sales position learning how to sell, diagnose boilers/heating issues, inside/outside sales and customer relations. From there, Chan moved over to a service company that did commercial service for restaurants and multi-complex buildings. After a stint doing residential construction for custom homes, Chan had the final experience of working for a full-service company doing residential/commercial service to finish his plan of starting a business with the experience he had built.

“Basically, I was able to change jobs each year to get the experience that I needed. Fast forward to this day, I have my own business, freedom, and I challenge myself to change the trade daily,” says Chan.

Six years later and Impetus is a leader in Vancouver area, receiving multiple awards for plumbing and customer service. “Even through all the years, the biggest thing I’d say in running a successful business is customer service. I may not know everything, but I sure as hell know what it takes to provide good service. Service goes a long way—learn and master it!” says Chan.

The Next Generation

The Next Generation

According to Chan, the industry should invest more in marketing to the next generation. The industry should continue to create scholarships, giveaways, recognition, anything captivating for plumbing so that younger generations can see it as a feasible career path. “It needs to provide more interest to the next generation so that they want to come into the trade. For the longest time, everyone believes the trade to be butt cracks and the uneducated. That was not true back then nor is it true now, especially now,” says Chan. “There is so much technology and so much change that we need younger people to work on the equipment. Everything can be connected to a phone, everything is automated. So much has changed, a plumbing job is almost like an IT job,” says Chan.

As for taking on the role of being a role model? “100%. I try to be the role model to show them that someone young can make the difference—showing everyone that if someone young can do this, so can they. I want to show that trades can be fun and rewards in all aspects,” says Chan.

And how about attracting more diversity to the trades? “Social marketing would be my answer. The more we get everyone on there and flood the world with plumbing content, the more people will eventually see it. Quantity is key in my opinion,” says Chan.

As for social media, “it has opened an unimaginable number of new doors for me,” says Chan. “From new friends, to learning, to connecting, to networking and to sponsorships, all of that came from the power of social media. It has been an amazing ride and I believe it has just started, there is a lot more to come and a lot more to share,” says Chan.

In fact, Chan says that the closest thing to a mentor would be Instagram. “On the platform, I’ve met so many awesome people and learned so much from others just by watching and observing—accounts like Mechanical Hub, my BC plumbers, people from overseas, there are just so many to mention,” says Chan.

Getting Personal

If you’ve followed Chan on Instagram lately (@the_impetus), you’ll know that a lot of his work gets done in the bathroom—not just plumbing. “Don’t ask for more information than that,” says Chan.

A lot of that has to do with work on the phone. “I carry two phones with me, one company and one personal. But both of them impact my day to day hugely. People would think, ‘well isn’t he a plumber: what about wrenches and other things?’ Of course, I have all that stuff and use that from day to day, but I’m more of a business guy,” says Chan.

A lot of that has to do with work on the phone. “I carry two phones with me, one company and one personal. But both of them impact my day to day hugely. People would think, ‘well isn’t he a plumber: what about wrenches and other things?’ Of course, I have all that stuff and use that from day to day, but I’m more of a business guy,” says Chan.

Chan’s personal phone is for taking videos, answering emails, answering calls from his guys to troubleshoot and editing videos. His other work phone is for taking calls, forwarding calls, taking videos, tracking jobs through his Jobber app, and also acts as an extra battery, in case the other phone dies.

“Without my phones, I wouldn’t be able to operate my business at all, as I start moving up and doing less plumbing work, managing a business becomes crucial. Communication becomes key,” says Chan.

And let’s not forget about his computer. That’s where the quotes happen, that’s where the approvals happen, that’s where the networking happens and that’s where the learning comes from.”

As far as balancing his work with leisure? “I don’t. I let them balance out themselves. I do what makes me happy on a daily basis. It sounds greedy and selfish but my true belief is that you can only make people around you happy by being happy yourself,” says Chan.

But there is some personal time mixed in, and that includes golf, lots of golf. In addition, Chan enjoys hanging out with his friends and his team, going out to eat new food at new places he’s never been before, and shopping for tools or golf stuff. “But all of it revolves around work,” says Chan.

Full Circle

It always comes back to customer service, however. “The most rewarding thing about my job is being able to help a customer with their issue. It always feels like I’m a hero and that I actually made a difference in someone’s life. It’s so rewarding to have a happy customer knowing that you solved something essential in their life while getting paid. It doesn’t get any better!” says Chan.

In the end it’s about being satisfied with yourself and your work. “If I were to enter a business or a job that I don’t like. I wouldn’t be doing it. I’m all about being happy with everything I do. Unluckily, having my own business, I have to do everything so I don’t bother hating or not liking anything because I love what I do every day,” says Chan.

No doubt about it, COVID-19 quickly changed the way we work, and play. Travel and in person visits came to a screeching halt. Professional offices, suppliers, even many working shops closed their doors to visitors. Training in the not to distant past was done, for the most part, in person. Conveniently, most trainers adapted quickly Read more

No doubt about it, COVID-19 quickly changed the way we work, and play. Travel and in person visits came to a screeching halt. Professional offices, suppliers, even many working shops closed their doors to visitors. Training in the not to distant past was done, for the most part, in person. Conveniently, most trainers adapted quickly to offer online training options. Many of the companies in our industry were already familiar with platforms like Go To meeting. This made the switch to virtual training fairly easy for those trainers.

Some trainers I met through the ESCO group devised hybrid virtual training events. With a few cameras, one that would follow you around a room they kept the hands on training available also.

An instructor in front of a piece of equipment would be led through the troubleshooting in real time, clever and almost like being there.

The question remains, what happens going forward in the training world. In some cases offices that made the change to virtual workspaces plan on staying that way. In some larger cities’ that has created office space vacancies and those building owners are scrambling to repurpose those spaces to get the rent rolling back in.

In cities like San Francisco it was a tough slog to see more than two engineering firms in a day due to traffic and parking logistics. With online, virtual sessions you can present to their entire staff as well as any locations they have scattered around the world.

I’ve started limited travel myself for training events. I doubt cramming 30 or more folks into a hotel meeting room will ever be attractive anymore. In some cases moving the training into the shop area, parking lot or a large cafeteria area is a good option to allow attendees to spread out more.

I doubt anyone knows for sure how this will shake out or what “bug” will hit us next that makes people want to avoid crowded rooms and spaces, but plan on having options. Come up with new ways to engage the attendees. Not being able to see faces, expressions and not getting that in person feedback changes the game for a trainer. Add polls to your training to get some interaction and a feel for the groups. Consider multiple speakers or trainers to get some back and forth conversation in your online trainings.

The need for having a trained workforce is critical. Equipment is becoming more sophisticated and specific, so factory training will march forward. We would love to hear from all the players in the industry, thoughts suggestions, what we can do to keep you’ all coming back.

Let’s rid the ‘VID and get back to the normal face to face that we all crave.

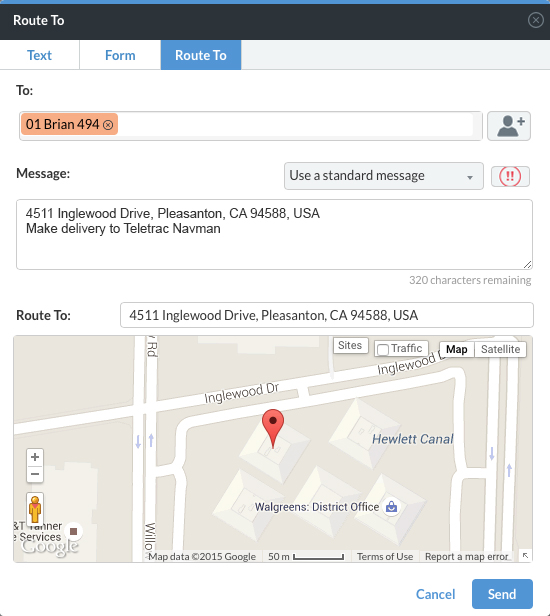

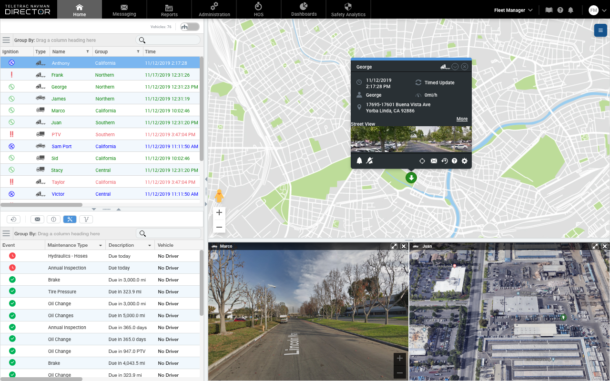

Wireless network technology is continuing to evolve, and members of the transportation industry who have come to rely on 3G networks for telematics in their connected vehicles have to consider how they’re going to keep up, lest they get left behind. Driven by ever-growing demands for more and faster data, major network providers are working Read more

Wireless network technology is continuing to evolve, and members of the transportation industry who have come to rely on 3G networks for telematics in their connected vehicles have to consider how they’re going to keep up, lest they get left behind.

Driven by ever-growing demands for more and faster data, major network providers are working ceaselessly on their respective rollouts of the fifth generation of mobile network capabilities, known as 5G, promising greatly reduced latency along with incredible speed and the ability to transmit large amounts of data in much reduced time. At the same time, the 3G networks are being phased out, with most networks set to go offline next year. Current 3G hardware is incompatible with the newer networks, and fleets that don’t upgrade in time will find themselves in the dark before long.

3G’s Clock is Ticking

Fortunately for fleet owners, there is still time to make the transition. Of the biggest providers, only AT&T is currently set to sunset 3G early next year – in February – with both Sprint and Verizon planning their shutdowns for December 2022.

Those dates come with a caveat, however: depending on the region, existing 3G infrastructure isn’t guaranteed to last until the sunset date, as regular maintenance may be dropped in favor of implementing hotly demanded 4G and 5G infrastructure instead.

Faced with uncertainty, fleet owners would be wise to get ahead of this technological leap. This is especially true for fleets that are using electronic logging devices (ELD). No fleets are more at risk of being negatively impacted by this change than those mandated to use ELDs. If these fleets fall offline, the systems will no longer be accurately tracking hours of service, and the drivers will be non-compliant, introducing a risk of those vehicles being pulled from service. To make this jump correctly, companies must carefully craft an internet of things (IoT) strategy that accounts for these newer, high-speed networks. Doing so will require implementation planning, cost analysis and training, giving all the more reason to act quickly.

The Benefits of Modern Hardware

Newer technology introduces greater functionality that will undoubtedly come in handy in the regular operation of a fleet. Even going from one step from 3G to 4G, the improvement will be immediately noticeable. Further futureproofing for 5G will ensure fleet owners stay at the forefront of technology for decades to come, all while enjoying the smoothest experience possible as the new networks roll out. The perks of being on a cutting-edge network are myriad, but highlights include:

- Faster speed and a wider network mean more reliable connections, particularly in areas where the wireless network is congested.

- Improved latency allows for sending a large mass of data such as alerts and events, including data-heavy content such as video.

- Communications between connected vehicles and the surrounding infrastructure is far more reliable and operate in close to real-time on high-speed connections providing instant information from the fleet and drivers.

- Massive amounts of data can be fed into AI-enabled telematics systems, turning real-time data into actionable safety, efficiency and compliance gains.

The key takeaway is that moving to new hardware isn’t a needless burden, but a net gain for a fleet’s drivers, customers and bottom line. Owners who get ahead now will avoid challenges down the line and reap the benefits above in the meantime.

The Road Ahead

Adopting 4G and 5G capable hardware is both an exciting opportunity and a growing requirement as older networks sunset, but the biggest reason for fleet owners to get started sooner is to make sure they have time to do it right. In the coming months, owners will want to take the following steps:

- Determine how many devices are still on the 3G network, and how many need to be migrated.

- Understand what kind of lifecycle to expect from new telematics equipment.

- Research modern telematics speed- and data-focused features made possible by new hardware, including AI and machine learning options, and consider how they can improve the fleet’s operation.

- Discuss the upgrade with the fleet’s telematics provider and learn about modern telematics and future facing solutions.

- Discover whether or not the telematics provider is charging their current customers for this type of upgrade, this can give you a glimpse into how they will handle related future tech refreshes.

- Ensure the new hardware is properly certified and has a pathway to helping companies with their regulatory requirements such as ELD or other regional specific programs

- Schedule the necessary vehicle downtime to make the upgrade with the minimum possible impact on downtime.

- Once everything is in place, implement a migration plan well ahead of your wireless network provider’s 3G sunset period.

These steps will take time, and fleet owners will want to feel confident in every step of the process. As such, waiting until the last minute to get started on the transition is ill-advised. Moving up from 3G isn’t as easy as flipping a switch. However, those owners who do put in the effort will avoid having to worry about their telematic systems potentially going out on them, crippling their essential dataflow for safety, compliance and business efficiency.

Now is the time to check with your telematics provider about the imminent 3G sunsetting or find a new vendor who can handle the inevitable upgrade.

Guest Blog By Andrew Rossington

Guest Blog By Andrew Rossington

Andrew Rossington joined Teletrac Navman in February 2016, working first as Vice President of Transtech (Division) before becoming Vice President, Transport Solutions in February 2018 then onto becoming Chief Product Officer in October 2020. In this role, Andrew is responsible for all transport industry solutions, including product development, go to market, team development and financial responsibilities. Since joining the business, he has overseen year-on-year growth in the transport vertical across the Australia/New Zealand region of Teletrac Navman. Prior to this, Andrew was the Chief Executive Officer for Transtech, which was acquired by Teletrac Navman. He has spent the last 20 years focused on transport industry solutions and has extensive experience managing software development teams and implementing key business systems for some of Australia’s largest transport operators and software companies, including Toll, ComTech and Dimensions Data. He is passionate about the transport industry and using technology to enable successful business outcomes.

If you buy an ECM circulator later this summer, you’re likely to see something new stuck to it: an Efficiency Rating label courtesy of the Hydraulic Institute. The labeling represents independent, third-party verification of each circulator’s overall electrical efficiency. That sounds pretty cool, but what does it all mean? Well, for starters, it means you Read more

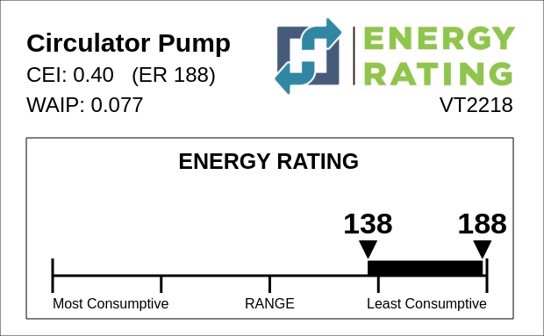

If you buy an ECM circulator later this summer, you’re likely to see something new stuck to it: an Efficiency Rating label courtesy of the Hydraulic Institute. The labeling represents independent, third-party verification of each circulator’s overall electrical efficiency.

That sounds pretty cool, but what does it all mean?

Well, for starters, it means you don’t have to rely on marketing claims or sales mumbo-jumbo to determine who has the most advanced and efficient circulators. And you don’t have to rely on vague math to determine how much less an ECM circulator will cost to run compared to its standard efficiency counterpart.

In other words, it’s there in black and white.

There’s a lot to unpack here, so let’s get started.

First Off, Just What Is the Hydraulics Institute?

The Hydraulics Institute, or HI for short, touts itself as the global authority on pumps since 1917. It’s an industry association working on behalf of the pump industry and works with the U.S. Department of Energy to establish guidelines and regulations for pumps of all types and sizes. Most recently, its efforts with the DOE led to commercial pump efficiency regulations that went into effect in January of 2020, covering all pumps 1 H.P. and above.

The new labeling on ECM’s under 1 HP can be considered a pre-cursor to DOE regulations that will ultimately phase out standard efficiency circulators. However, don’t expect those regulations to go into effect for at least two, maybe three more years.

The new labeling on ECM’s under 1 HP can be considered a pre-cursor to DOE regulations that will ultimately phase out standard efficiency circulators. However, don’t expect those regulations to go into effect for at least two, maybe three more years.

While HI is an organization made up of pump and circulator manufacturers, it’s important to note that all of its guidelines and regulations are set in concert with the DOE. In its most basic form, the DOE says, “this is what you have to do.” HI, in turn, develops guidelines, test procedures and processes manufacturers need to follow in order to be rated.

HI also certifies each manufacturer’s test lab, and it fully audits all test results. Yes, manufacturers test their own pumps, but only if their test lab is certified. HI creates all testing procedures and guidelines, including machinery calibration, personnel training and record keeping. Labs are periodically inspected, and all test results are reviewed and audited.

The whole process is set up so there’s no scamming the system. The results are the results.

But What About the Ratings?

You’ve no doubt seen those ubiquitous yellow EnergyGuide stickers on just about every appliance under the sun. They’re not only on fridges, dryers and other everyday items, they’re also on boilers, furnaces, A/C units and heat pumps. The Federal Trade Commission requires those stickers to give consumers an idea of relative energy efficiency compared to similar units.

The new HI Energy Rating stickers on circulators are pretty much the same thing, only different.

Instead of giving you an estimated yearly energy cost, the new HI Energy Rating stickers give each circulator an Energy Rating score, or an ER. It’s a pretty easy rating to decipher: the higher the number, the more efficient the circulator.

For example, an ECM circulator with an ER of 188 consumes 10 percent less energy than a circulator with an ER of 178.

By comparison, a common standard efficiency circulator, such as a Taco 007 or a Grundfos 1558, would have an ER in the neighborhood of 48 to 50.

The math to calculate the ER is fairly detailed, so it would take someone way smarter than me to walk you through it. The ultimate value of ER, however, is to provide a simple way to show a customer how much less an ECM circulator will cost to operate compared to its standard efficiency counterpart based on independent, third-party testing.

Let’s Do THAT Math!

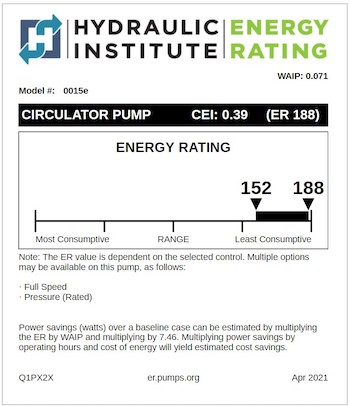

Let’s look at the ER label for the Taco 0015e3. The 0015e3 is a variable speed Delta-P circulator with three settings, two for constant pressure and one for full-speed, fixed speed. It’s the perfect pump to use for zone valve applications and does a dandy job as a zone circulator as well.

As you can see, the 0015e3 has an ER ranging from 152 in its least efficient mode, which is that full speed, fixed speed setting. In its most efficient operating mode setting – variable speed, constant pressure Delta-P – the ER goes to 188.

And not for nothing, Taco has four circulators with 188 ratings (and a fifth rated at 187). Those are the highest rated circulators on the HI database (Armstrong also has a circulator rated at 188. No one else is within six ER points). You can access the HI database here.

The full ratings label provides you with the math to determine how much a particular circulator will save. You first multiply ER by something called WAIP, which stands for Weighted Average Input Power. WAIP represents the average input power in horsepower for an ECM circulator without controls:

188 x 0.071 = 13.348

Next, to convert horsepower to watts, you’d multiply by 7.46:

13.348 x 7.46 = 99.58 watts

From here on it, it’s a simple kWh/cost calculation. To convert watts to kilowatts, you divide by 1000, and then multiply by the estimated number of run hours over a heating season. For this example, we’ll use 2500.

99.58 ÷ 1000 = 0.09958 kilowatts

0.09958 kW x 2500 hours = 248.95 kWh

Last, multiply kWh by your cost per kilowatt hour. That will tell you how much less the 0015e3 would cost to operate compared to a 007 or 1558:

248.95 kWh x 0.15 per kWh = $37.34

Is that a Lot?

Well, it depends. If you’re trying to justify replacing four perfectly good and not terribly old circulators with four ECMs, you’ll save just under $150 per heating season. Depending on how much you charge for the swap out, it might be a hard sell. And there’s nothing “green” about dumping four perfectly good circulators before their time.

However, if you’re trying to show a customer (or yourself, for that matter) that replacing a dead circulator with a more expensive ECM is worth it, you now have something to sink your teeth into.

However, if you’re trying to show a customer (or yourself, for that matter) that replacing a dead circulator with a more expensive ECM is worth it, you now have something to sink your teeth into.

Say a standard efficiency 007 or 1558 dies and you want to replace it with a 0015e3. Yes, the 0015e3 costs more. But just channel your inner Cosmo Castorini from Moonstruck and tell them, “it costs money, because it saves money.”

Without getting into wholesale costs, profit margins and selling prices (those are your business), it’s fair to say that based on a $37.34 annual savings, the 0015e3’s higher selling price will be offset in less than two heating seasons. After that, the homeowner pockets the rest.

And if you want to talk about how a properly programmed ECM, particularly one that operates on a fixed Delta-T, will help the overall system work better, let’s make an Outlook appointment. There’s a LOT more to discuss.

What’s the Point?

So, why HI is doing this labeling thing in the first place? Simple: to give the industry an easy—and independent—way to show the value of converting from standard efficiency to ECM.

In markets where local utilities do not offer incentive rebates to drive conversion, ECM conversion has been snail’s pace slow. Some of it is a little of the “if it ain’t broke, don’t fix it,” mindset. Some of it has been ridiculous claims of “magic” and the misguided promise that these circulators somehow mean you don’t have to know how to size a pump. No one with half a mind believes that nonsense.

And some of it is, to put it gently, giving new technology a healthy—and distant —respect.

But for the most part, it’s been price resistance.

What the ER label does is give you an easy way to show a customer a fundamental truth: they’re going to be paying for the ECM circulator one way or another. The only question is whether they actually get it or not.

Remember Cosmo’s words.

Engineering and construction (E&C) is one of the largest industries in the world, and yet, it has been one of the slowest to embrace digital change. The entire ecosystem represents 13% of global GDP, but the industry has seen meager productivity growth of 1% annually for the past two decades—and this is where disruptive technologies Read more

Engineering and construction (E&C) is one of the largest industries in the world, and yet, it has been one of the slowest to embrace digital change. The entire ecosystem represents 13% of global GDP, but the industry has seen meager productivity growth of 1% annually for the past two decades—and this is where disruptive technologies can make a difference. In 2021, construction contractors and engineering firms are starting to heavily invest in digital transformation to create new value across the entire supply chain and Kenny Ingram, VP of Engineering, Construction & Infrastructure at IFS, explains the four forces driving this shift.

According to an IDC study, digital transformation investment will increase to $6.8 trillion by 2023 as companies build on existing strategies and investments to become digital-at-scale future enterprises—and the E&C sector is no exception. Despite the global pandemic, the traditional brick-and-mortar industry is ready to enter the digital age—and an IFS study conducted in 2020 found that, despite regional differences, digital transformation spending among construction and engineering companies was surprisingly more robust than among companies from other industries.

Engineering and construction companies are now investing in disruptive technologies including building information management (BIM), artificial intelligence (AI), the internet of things (IoT) and innovative new mobile software solutions to replace legacy back-office systems and inject new value across the entire supply chain. According to McKinsey, E&C business are increasing productivity and value delivery, so they can outcompete their rivals, regardless of how quickly the market returns to or exceeds previous activity levels.

This digitalization of operational processes across engineering and construction companies is set to drive greater connectivity, and four key factors can be accredited for the increase in digital transformation investment.

Innovation in crisis – market changes require greater business adaptability

The E&C industry is particularly vulnerable to economic cycles—and the global economic changes caused by the COVID-19 pandemic has made digital investments more urgent, as companies try to find new ways to create and deliver value more efficiently.

Since the start of the pandemic, the industry’s traditional on-site workflows, which rely on paper trails and outdated communication methods, have not been able to mitigate the impact of lockdown and social distancing measures on construction activity. For instance, the RICS’ Global Construction Activity Index shows that 25% of projects have been put on hold, of which only 20% of projects on hold are expected to restart immediately with an average 131-day delay anticipated—costing projects, time and money. To combat the continuation of economic uncertainty, many companies are starting to realize that digital technologies provide the solution.

As E&C companies, particularly in North America, explore new ways to unlock operational efficiencies with reduced manpower, recent developments in 5G are having a significant impact on the industry. For instance, the network slicing capability of 5G enables data collection, capture and analysis to increase the visibility over the health, location, status and specifications of assets and projects. This can improve on-site monitoring to better inform decision-making across all stages of a project and minimize issues and changes during construction. 5G has the potential to create fully connected construction sites that can navigate the challenges of the current climate—and E&C companies are starting to respond with investment in cutting edge technologies.

Enhancing productivity with transformational technology

A separate McKinsey report found that firms which introduced digital systems for procurement, supply-chain management, better on-site operations and increased automation had improved productivity by 50% over firms that relied on analog solutions. Some of these transformational technologies include AR/VR, AI, IoT and machine learning, which according to the IFS study, will increase in importance in the next two years.

Construction projects are often impacted by time and cost overruns, but with this tech, companies can modernize each operational stage, from planning to execution. AR/VR, for instance, may already be helping companies deal with the challenges of project delivery during the pandemic by providing a dynamic format for BIM. In the field, the related technology of remote assistance is growing in popularity in field service settings like those a mechanical contractor may face in discharging maintenance agreements, or an EPCI contractor may encounter as they support projects in the field. Research indicates that this trend will continue as AR/VR is expected to become a key component in most construction projects within 10 years.

The digital workplace can make or break the employee experience

Given recent technological advancements and changes in consumer behavior, E&C companies are recognizing that digital technologies will help retain in-house expertise and play a crucial role in creating a more connected and engaged workplace. In fact, that 60% of enterprises will invest heavily in digitalizing the employee experience in 2021.

Across the supply chain, E&C companies traditionally operate in deeply entrenched business siloes, and survey data has shown that a large proportion of reworks are caused by miscommunication between teams. For instance, site workers will often not notify the supplier of any defective products, which means that on-site workers will need to either fix the products or wait for replacements—this can increase labor costs and create further projects delays.

This is where investment in digital technologies can create opportunities for greater collaboration and keep more projects on track and within budget. Cloud-connected mobile apps, for example, can be used to send feedback between teams and tag defects against specific elements in the BIM model before storing the information in a centralized data system. This input can significantly help companies reduce defects and the likelihood of unplanned rework—helping to improve operational efficiencies and the employee experience.

Industry sophistication is not a given, but country-dependent

Unlike other industries, most construction and engineering work is performed in-country and heavily influenced by cultural factors. This has led to stark regional differences in the degree of technological and business sophistication across the industry. In the UK for instance, government policy to improve construction productivity has led to heavy investment in building information management (BIM), while across the Atlantic there is no equivalent progress being made. According to a McKinsey report, economic value lost by the United States construction industry is the largest in the world at $58 billion versus $46 billion for all of Europe—and experts believe a lack of systems to effectively tackle the problems of the business is responsible for this variation.

Similarly, the adoption of modular or off-site construction across the industry is having a significant impact on how E&C companies invest in digital transformation. In this type of construction, companies rely on enterprise systems to reduce the cost and risk of projects, while increasing productivity, quality and safety. However, some countries have made further progress than others, particularly in the offsite building of new single-family homes. According to Boston Consulting Group research, only 2% of new homes in the United States were built offsite in comparison to 11% in the United Kingdom, and 20% in Germany and Japan respectively.

The digital roadmap for E&C is set and its incumbents must respond to thrive

The E&C industry, most notably in the United States, is well-known for its conservative stance on tech investment, but companies are starting to realize that this reality has the potential to compromise their future survival. Construction projects are increasing in both complexity and scale, and therefore require this sector to adopt new ways of thinking and working with digital technologies.

Construction and engineering companies that don’t take risks when it comes to their digital transformation and carry on as they are will cease to exist in five years. It is no longer a matter of if or when construction will be affected—change is already here and digital transformation investment is an essential component.

To take advantage of the increase in demand for construction services, E&C companies can no longer ignore the radical changes that are taking place within the industry. Digital technologies have become the new building blocks for optimizing operational efficiencies and securing competitive advantage—and this development is coming a lot more quickly due in part to the immediate demand and supply shocks of the pandemic.