Businesses can cut costs and consume energy more intelligently by making a few smart changes with their HVAC system retrofits, upgrades and other carbon footprint programs. Over the years, our team at Atlantic Westchester, Inc., has developed programs to offer continuous energy monitoring services to optimize HVAC system performance and ensure that many aspects of Read more

Featured Articles

Businesses can cut costs and consume energy more intelligently by making a few smart changes with their HVAC system retrofits, upgrades and other carbon footprint programs. Over the years, our team at Atlantic Westchester, Inc., has developed programs to offer continuous energy monitoring services to optimize HVAC system performance and ensure that many aspects of energy consumption in buildings are addressed.

Below, are some tips on how to consume energy intelligently which will lead to saving money in the long run:

1) Companies can consume energy intelligently with their HVAC system

HVAC systems in typical commercial buildings can be responsible for up to 41% of total U.S. energy use, according to the U.S. Dept. of Energy’s Office of Energy Efficiency and Renewable Energy—so keeping those systems running at peak efficiency is key to managing your energy usage and cost. To consume energy intelligently, buildings can raise or lower the thermostat two degrees, or as much as comfort allows, to reduce HVAC system run time. Tax and utility incentives are available to help offset the cost.

2) Maintaining a building’s HVAC system is important

2) Maintaining a building’s HVAC system is important

Clean, well-operating systems will provide reliable, efficient service during the extreme weather days. Dirty or old, worn out systems will breakdown more often and continually become less efficient with age. Dirty equipment will also have a direct effect on your utility bill as the cost to operate will be higher. Performing a continuous professional and periodic maintenance ensures that the equipment is clean and running at optimum levels.

3) Implementing LED lighting is a quick solution to save energy

LED lighting technology has come a long way in the last few years and the cost to implement has dropped substantially. The replacement lights operate at a cooler temperature than the lights they replace thereby reducing the heat load during cooling season. By implementing LED lighting in offices, companies will reduce their energy costs immediately. Adding LED lights in an office is quick and simple to calculate saved energy consumption. According to Energy Saver, the U.S. Department of Energy’s (DOE) consumer resource.

4) Adding solar panels will reduce electricity consumption:

Installing solar panels to a building are an excellent addition if space and layout is favorable. Tax rebates and utility incentives have made it such that installing solar system can be very cost effective. By adding solar panels, the building will generate supplemental electricity allowing the average cost per kilowatt to decrease.

Each building situation is unique, so we develop a cost-effective customized plan that’s tailored to fit your facility. At Atlantic Westchester, we offer system benchmarking, usage assessment, as well as continuous energy monitoring. Make sure your building’s HVAC system is working effectively and most importantly, saving energy year-round.

Bud Hammer is President of Atlantic Westchester, Inc., a commercial and industrial HVAC business located in Bedford Hills, N.Y.

Bud Hammer is President of Atlantic Westchester, Inc., a commercial and industrial HVAC business located in Bedford Hills, N.Y.

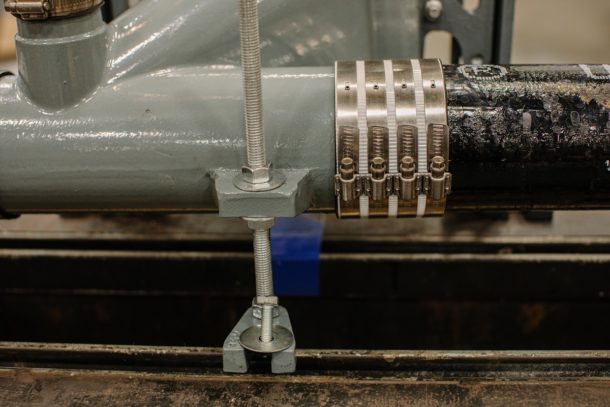

Every plumbing & heating contractor could give you a list of their favorite products to install or service but what goes into those installs? Here’s a walk-thru from The Hub’s Eric Aune, owner of Aune Plumbing & Heating, of a recent heating boiler installation, please take a look! https://youtu.be/Ot5NCm8JcMQ Read more

Every plumbing & heating contractor could give you a list of their favorite products to install or service but what goes into those installs?

Here’s a walk-thru from The Hub’s Eric Aune, owner of Aune Plumbing & Heating, of a recent heating boiler installation, please take a look!

As we head into Q2 for 2021, according to Michael Luz, President and Chief Executive Officer, Viessmann Manufacturing US, the markets in our industry have made a strong turnaround, leading to an optimistic short-term outlook. We continue with our forecast series with major players in the industry. The following is an exclusive Q&A with Luz Read more

Michael Luz

As we head into Q2 for 2021, according to Michael Luz, President and Chief Executive Officer, Viessmann Manufacturing US, the markets in our industry have made a strong turnaround, leading to an optimistic short-term outlook. We continue with our forecast series with major players in the industry. The following is an exclusive Q&A with Luz regarding the economy:

MH: What does the short-term economy look like as it relates to Viessmann?

LUZ: Our short-term outlook for the year is quite optimistic; so far for the first quarter we are trending around 30% higher in revenue in comparison to 2020. We do see a lot of home renovation activity on the residential side driving demand. At the same time, we have not experienced a slowdown in commercial activity this year and right now it is quoting and shipping season in the construction markets.

What do we look at for indicators? We look at trends related to order intake year over year. We look at economic indicators including forecasts on U.S. manufacturing and durable goods wholesaler indices.

MH: How does (has) Viessmann positioned itself from the “fallout” of COVID-19?

LUZ: We expect some levels of normalcy to return to the U.S. and our industry in the second half of this year 2021. Although the pandemic has impacted our sales last year, we have seen a strong rebound that started in Q4 of last year and has continued into the first quarter of this year. Viessmann has not missed a beat supporting its customer base during the pandemic, being available in person where appropriate and needed as well as virtually for technical support, customer training and marketing. As an essential business, our logistics operation has been open continuously through the entire pandemic with all necessary safety protocols in place.

MH: Is the only certainty heading into early 2021 uncertainty? How do you forecast and budget for such uncertainty? (Or is it fairly certain at this point during the pandemic?)

LUZ: As a business we are very much used to operating in an uncertain environment, taking into account many factors that could impact our business starting with raw material prices, potential supply bottlenecks on certain components, potential transportation capacity issues to quickly changing customer preferences. From many years of experience, we take all of those into account and give it our best to produce an accurate forecast. Was it particularly challenging doing this during a once-in-a-generation pandemic? Yes. Did we always get it right? No. Lucky for us and our industry, our markets turned around fairly quickly and have come back strongly.

MH: Without getting overly political, does a change at the presidential level (and congress) change the outlook for your company, if at all? (Infrastructure, regulations, green energy initiatives, etc.)

LUZ: Listening to our economic advisors and their analysis of historical data, federal governments with the same party controlling the White House, the Senate and the House of Representatives have always been phases of solid growth for the U.S. economy. Looking at some of the green initiatives that the current administration is pushing, we are ready for those and very well positioned as a company in the HVAC sector with a vision of “Creating living spaces for generations to come.”

And now, starting for the Los Angeles Lakers, a 5’ 10” forward from South Pasadena, Krikor Chiranian! [cheers and a loud applause ring throughout the Forum.] “Hey, as a young boy I loved basketball and my dream was to play professionally in the NBA,” says Krikor. But with most young kids dreaming of becoming a Read more

Koko working hard on the jobsite.

And now, starting for the Los Angeles Lakers, a 5’ 10” forward from South Pasadena, Krikor Chiranian! [cheers and a loud applause ring throughout the Forum.] “Hey, as a young boy I loved basketball and my dream was to play professionally in the NBA,” says Krikor.

But with most young kids dreaming of becoming a professional athlete, reality sets in at some point, and fortunately for Koko, he got a taste of the trades early on, and there was no looking back.

Fun Fact: How do most of you know Krikor as Koko? Koko Drains (@koko.drains) was named after Krikor’s nickname. “My given name is Krikor, and since I can remember, my family would only call me Koko. In my career in drain cleaning, everyone has always known me as, and called me by, Koko. So, it really stuck with me,” says Koko.

One of Koko’s techs finds a treasure.

Starting in the trades at the age of 20, Koko went on a call for a kitchen sink drain stoppage with his father, a veteran of the plumbing trade for nearly 50 years. “My father had to call on a man named Ole Bugarin to clear the drain stoppage. Ole came out with his Gorlitz Go 50 1/2” cable and cleaned the kitchen drain from the clean out, and I looked at my dad and said, ‘That’s what I want to do.’ There was just something about that moment while watching Ole clear the drain. It opened my eyes to a new part of plumbing that I found appealing and satisfying. I asked Ole if he would hire and teach me, and he did,” says Koko.

Koko worked for a single company for 11 years specializing in drain and sewer cleaning, and became adept to the work very quickly. “With the experience gained my confidence grew.” Says Koko. “One thing led to another, and I was eventually able to go on my own at age 31. As time passed, we became busier, leading to the hiring of my wife and two technicians. I’ve been self-employed for eight years now with plans for continued growth.”

Now, owner of Koko Drains, South Pasadena, Calif., Krikor Chiranian has been self-employed for the past eight years running a successful drain and sewer cleaning business with a side of waste drainage repair and replacement. In addition, Koko also provides camera inspections with marked pipe location, repairs and cleans of drains or sewer pipes by way of cabling and hydro jetting, as well as toilet and garbage disposal installations. As mentioned, Koko also repairs or replaces waste drainage piping, clean-out installation, pipe descaling, as well as trenchless rehabilitation services, and more. His go-to tool is his sewer inspection camera. “The camera tells all within an underground drain pipe, allowing proper diagnosis,” says Koko. Another daily go-to tool is Koko’s hydro jetter, which allows Koko to move a blockage out of a pipe, and, at the same time, cleans the drain or sewer pipe.”

Now, owner of Koko Drains, South Pasadena, Calif., Krikor Chiranian has been self-employed for the past eight years running a successful drain and sewer cleaning business with a side of waste drainage repair and replacement. In addition, Koko also provides camera inspections with marked pipe location, repairs and cleans of drains or sewer pipes by way of cabling and hydro jetting, as well as toilet and garbage disposal installations. As mentioned, Koko also repairs or replaces waste drainage piping, clean-out installation, pipe descaling, as well as trenchless rehabilitation services, and more. His go-to tool is his sewer inspection camera. “The camera tells all within an underground drain pipe, allowing proper diagnosis,” says Koko. Another daily go-to tool is Koko’s hydro jetter, which allows Koko to move a blockage out of a pipe, and, at the same time, cleans the drain or sewer pipe.”

While Ole was instrumental in mentoring Koko early in his career in drain cleaning and other plumbing essentials “teaching him everything he knows,” does Koko himself consider himself a role model for the younger generation entering the trades?

Diggin’ in the dirt, working hard and gettin’ it done.

“Absolutely,” says Koko. “We pave the way for future generations. People are influenced mostly by not only what they see, but also by what they hear. To have a successful plan, it’s very important to stop and think before we act—teaching the younger generations the way to honestly and properly accomplish tasks is critical.”

According to Koko, the industry could do a better job promoting more women or minority contractors in the trades, “allowing for the attraction and eventual growth of a more diversified workforce, especially in leadership positions,” says Koko.

Being self-employed and the owner of a business makes it a bit easier to balance work/family time. “My wife schedules our work and personal life events; therefore, my wife schedules time off for me to spend with my family,” says Koko.

The free time is spending time with family, listening to and reading self-development audiobooks/books, and thinking of new ways to improve and grow the business. And, there’s social media. “Social media has allowed us to share our knowledge with others, and we can learn new ways of doing a job through other tradespeople’s perspective,” says Koko. “With social media, the new tools and equipment that are available to contractors are displayed, and they have brought new ideas for our company to utilize and grow. Also, we have made many new friends and customers through social media, building a network of reliable and respectable people.”

In the end, what does Koko love most about his job? “The gratitude our customers show us for getting the job done is the most rewarding. Also, the ability to be in the field, seeing new faces and places. In the trade, we are always seeing and learning something new.”

Southland Industries was founded in Long Beach, California, in 1949 as a Southern California-based supplier of residential heating solutions. After years of growing organically and expanding their services and capabilities, they are now one of the nation’s largest MEP (mechanical/electrical/plumbing) building systems experts. Today, Southland has 3,200 employees who serve most of the East and Read more

Southland Industries was founded in Long Beach, California, in 1949 as a Southern California-based supplier of residential heating solutions. After years of growing organically and expanding their services and capabilities, they are now one of the nation’s largest MEP (mechanical/electrical/plumbing) building systems experts.

Today, Southland has 3,200 employees who serve most of the East and West Coast regions, as well as a Mountain West Division with offices in Tempe, Arizona and Las Vegas. The company’s capabilities encompass everything within each stage of the building lifecycle, including customized engineering, construction, building automation, service, and energy solutions.

“When Southland expanded to the East Coast in the mid-1990s, we were the first true design-build contractor in the area,” explained J. Gilbert, Mid-Atlantic Division plumbing supervisor. Gilbert has been with the company for 12 years and has presided over substantial growth during his tenure.

“At that time, other installers had no choice but to hire outside professional firms for design and engineering work,” continued Gilbert. “We had that capability in-house, which really set us apart from the competition. We’re now one of the largest MEP firms in the country.”

J. Gilbert, Mid-Atlantic Division plumbing supervisor.

According to Mike Dye, senior purchasing agent, much of Southland’s work in the Mid-Atlantic region includes government contracts, data centers, and pharmaceutical and educational customers. The company’s ability to bring every element of a project into consideration, including building automation and energy solutions, is a big advantage for large corporations and government agencies.

Professional plumbing

In 2017, Southland outgrew its existing offices and fabrication shop in Lorton, VA, and moved to a new facility in Laurel, MD.

The new facility, like all others owned by Southland, is a one-stop-shop for mechanical customers. The building’s 240,000 square feet is occupied by administrative offices, an engineering department, a sheet metal shop, mechanical piping (hydronic) fabrication space, plumbing, and a process piping area. It houses 100 union workers, including 30 plumbers.

“Southland Industries pre-fabricates components for every single project we’re on, and plumbing pre-fabrication is no exception,” said Gilbert. “The ability to work in a controlled environment, minimize jobsite waste, and reduce onsite labor is a huge advantage.”

One of the company’s most frequently used plumbing products are commercial water closet carriers. As one would expect, they’re used on every job. Dye purchases hundreds each year through local manufacturer’s representative, The Joyce Agency, based in Chantilly, VA.

“The QT QuickTurn™ closet carrier is one of dozens of Watts products we source through Kevin Cerretani at The Joyce Agency,” said Gilbert. “Its design expedites both the prefabrication process here at the shop and the final installation in the field.”

Plumber Joe Gencavage assembles many of the carrier systems in the fab shop. There, water supply, vent, and waste water piping is cut to length, attached to the carriers, and disassembled for later use in the field.

“The enamel finish on the QT QuickTurn carrier is great, as are the no-hub vent and wastewater connections and the dual threaded boss for supply water pipe support,” said Gencavage. “For install crews, the ability to adjust the face plate left and right makes the job easier. Same goes for the side-facing carrier support legs. It’s a nicely streamlined design.”

The new carrier system was one of several new products brought to Southland by The Joyce Agency in 2019.

Partnered for growth

“We’ve had a strong relationship with Southland for 15 years,” said Cerretani, who’s been with The Joyce Agency for 29 years. “I think that has been one source of success for both companies.”

The Joyce Agency’s plumbing division provides pipe, water closet and lavatory carriers, drainage products, flush valves, plumbing fixtures, sinks, water coolers, electric tankless water heaters, safety equipment, steam components, acid waste piping and laboratory fixtures to Southland. The agency’s main facility in Chantilly has three divisions: plumbing, architectural products, and HVAC.

“We’re very happy with the Watts products and the breadth of their line, but one of the biggest advantages of buying Watts products for us comes through our relationship with The Joyce Agency,” said Gilbert. “We can count on them to get products to us in a timely manner and provide exceptional service.”

The Joyce Agency represented a different carrier line for 23 years, switching to Watts six years ago. Cerretani has found that many of the costly options offered by other manufacturers are standard features in the Watts line.

“The epoxy coating on the carriers is one example of a Watts standard feature,” said Cerretani. “Another feature we like on the QT QuickTurn is the O-ring seal and ABS nipple. Pushing the nipple into place is much faster than threading the nipple into place.”

“The true superstars in the supply chain are the folks in our quotations group, the commercial inside sales group, and our warehouse personnel,” continued Cerretani. We have an open line of communications with the folks at Southland to streamline the process of product selection, submittals, and providing the right material on time. I’m blessed to work with the professionals at Southland, as well as my Joyce Agency associates.”

“Watts and The Joyce Agency both really set themselves apart when it comes to customer service,” said Dye. “They’re the experts, and we lean on them both during the design phase and beyond.”