Now Clean 3 to 6-inch Pipe Up to 125 Feet; Wall-to-wall clean with capabilities of simultaneous pipe inspection RIDGID® is giving plumbers even more cleaning power and diagnostic capabilities in large-scale commercial or residential jobs with the addition of the K9-306 to its line of FlexShaftTM Drain Cleaning Machines. Designed to clean 3 to 6-inch diameter Read more

Toolbox

Now Clean 3 to 6-inch Pipe Up to 125 Feet; Wall-to-wall clean with capabilities of simultaneous pipe inspection

RIDGID® is giving plumbers even more cleaning power and diagnostic capabilities in large-scale commercial or residential jobs with the addition of the K9-306 to its line of FlexShaftTM Drain Cleaning Machines. Designed to clean 3 to 6-inch diameter drain lines up to 125 feet, the K9-306 clears blockages with astonishing speed, while the ability to inspect with a camera simultaneously maximizes efficiency and lets you literally complete two jobs at once.

Purpose-built for the professional, the K9-306 quickly clears grease buildup, roots and heavy scale in larger pipes. It features a professional 1.5 HP internal universal motor for maximum power and longevity; a fully enclosed drum to minimize setup and cleanup time; and a retractable handle with multiple wheels and grab points to make loading, unloading, transporting and storage easy.

“The positive response to our first two RIDGID FlexShaft Drain Cleaning Machines last year was overwhelming, with contractors wanting a similar product to clear wider and longer lines. The RIDGID K9-306 FlexShaft Drain Cleaning Machine is the answer to that request,” said Tim Dunphy, marketing director, Global Underground Technologies, RIDGID. “With the K9-306’s ability to clean wider pipes and reach up to 125 feet, it lets contractors clean larger lines all the way out to the main.”

The K9-306 has the highest capacity of the RIDGID FlexShaft machine models; each utilizes various chain knockers that are spun at high speeds and expand to quickly clear the entire circumference of a pipe for a more thorough and longer lasting wall-to-wall clean. The flexible, fully enclosed nylon-sheathed cable can be easily wiped clean as it is pulled from the line. It also eliminates splatter, cutting down on jobsite cross- contamination.

“Our range of plain and carbide tipped chain knockers for the K9-102 and K9-204 models have proven their worth in the field, and pros have told us how much they value the cleaning power they offer, particularly when getting into grease and scale,” Dunphy said. “When designing the K9-306, we also continued to innovate and expand our chain knocker lineup, adding a new option featuring a carbide tipped penetrating head. These new chain knockers will be available for all FlexShaft models and will help the pro more efficiently engage and clear tough full line blockages.”

“As municipalities deal with older pipe lines and the tough roots of established vegetation, the K9-306’s ability to power through 3 to 6-inch diameter pipes will be a must-have for contractors today. Alongside the proven performance of our K9-102 and K9-204 models, it’s a great addition to our FlexShaft machine line,” said Wyatt Kilmartin, vice president and general manager, Global Underground Technologies, RIDGID.

FlexShaft machines are backed by the RIDGID Full Lifetime Warranty.

To purchase or learn more about FlexShaft machines or other drain cleaning solutions, contact your local

distributor for an in-person demo, visit RIDGID.com, or call toll-free: 1-800-4RIDGID.

Milwaukee Tool continues to expand ONE-KEY™, the industry’s largest and most robust asset management platform and tracking and security network, with the introduction of Asset ID Tags. ONE-KEY™ Asset ID Tags allow users to easily manage their tool and equipment inventories. Scanning these durable tags with any camera-equipped mobile device automatically records time and location Read more

Milwaukee Tool continues to expand ONE-KEY™, the industry’s largest and most robust asset management platform and tracking and security network, with the introduction of Asset ID Tags. ONE-KEY™ Asset ID Tags allow users to easily manage their tool and equipment inventories. Scanning these durable tags with any camera-equipped mobile device automatically records time and location information within the ONE-KEY™ app, providing users with instant documentation as assets are transferred between jobsites and users.

“Since first launched in 2016, ONE-KEY™ has grown to be the industry’s largest tool and equipment tracking network. With more than 40 connected solutions and counting, we continue to pioneer the evolution of smart tools and equipment. However, many of our users want to be able to take advantage of the ONE-KEY™ inventory management platform even with tools and equipment that are not Bluetooth™ enabled. The TICK™ will remain the ideal Bluetooth™ tracker for larger equipment while these new Asset ID Tags will be a perfect fit for smaller equipment and tools, and for users who don’t require the advanced capabilities of TICK™,” said Andrew Lambert, Group Product Manager for Milwaukee Tool.

The Asset ID Tags can be affixed to non-ONE-KEY™ compatible assets to better track movement and flow across jobsites and crews. Using any smart mobile device with an integrated camera and the ONE-KEY™ app installed, users can simply scan the Tags to record time and location data.

The Asset ID Tags can be affixed to non-ONE-KEY™ compatible assets to better track movement and flow across jobsites and crews. Using any smart mobile device with an integrated camera and the ONE-KEY™ app installed, users can simply scan the Tags to record time and location data.

Available in both small (0.69” x 1”) and large (1.5” x 2”), the Tags come in sets of up to 200 that are designed to adhere to either plastic or metal surfaces. The Tags made for plastic surfaces, such as power tools, are made with Velvet Lexan, while the Tags made for metal surfaces, such as hand tools, are made with anodized aluminum.

Fully embodying the Milwaukee promise of “Nothing but HEAVY DUTY,” each Tag is built to withstand the harshest jobsite conditions, with resistance to water and chemical exposure, fade-protection from UV light, scratch-resistance, and can maintain adhesion through significant fluctuations in temperature.

Since the launch of ONE-KEY™, Milwaukee® has worked to solve a problem that plagues the construction industry: downtime. Delivering connected solutions, Milwaukee helps trade professionals improve efficiency, smooth timeliness, and reduce risk. With this unwavering commitment to the trades and continued investment in software development, Milwaukee pioneers innovation in the construction industry and continues to work toward building a smarter jobsite. For more information on ONE-KEY™ please visit https://onekey.milwaukeetool.com/.

RELEASE DATE: JUNE 2020

ONE-KEY™ Asset ID Tag Offering

- ONE-KEY™ Asset ID Tag – Small Plastic Surface 200 count (48-21-0001) – $79

- ONE-KEY™ Asset ID Tag – Large Plastic Surface 100 count (48-21-0002) – $119

- ONE-KEY™ Asset ID Tag – Small Metal Surface 100 count (48-21-0003) – $129

- ONE-KEY™ Asset ID Tag – Large Metal Surface 25 count (48-21-0004) – $129

The new 18V Connected-Ready Lithium-Ion 16 Amp Battery Turbo Charger with Power Boost repowers CORE18V 8.0Ah batteries from 0 to 50 percent in 15 minutes. Boost your power tool productivity and performance while minimizing downtime with Bosch’s new “HELL-ION” 18V high-powered 16-amp turbo charger, which delivers eight times the charging current of its standard counterparts Read more

The new 18V Connected-Ready Lithium-Ion 16 Amp Battery Turbo Charger with Power Boost repowers CORE18V 8.0Ah batteries from 0 to 50 percent in 15 minutes.

Boost your power tool productivity and performance while minimizing downtime with Bosch’s new “HELL-ION” 18V high-powered 16-amp turbo charger, which delivers eight times the charging current of its standard counterparts.

The GAL18V-160C 16-Amp Battery Turbo Charger offers fast and faster lithium-ion battery charging to get the user back to work. The charger offers Power Boost Mode, which charges a CORE18V 8.0Ah Lithium-ion battery to 50 percent charge in 15 minutes or to 80 percent in 26 minutes. It is compatible with Bosch 18V lithium-ion batteries.

The GAL18V-160C 16-Amp Battery Turbo Charger offers fast and faster lithium-ion battery charging to get the user back to work. The charger offers Power Boost Mode, which charges a CORE18V 8.0Ah Lithium-ion battery to 50 percent charge in 15 minutes or to 80 percent in 26 minutes. It is compatible with Bosch 18V lithium-ion batteries.

“Our existing CORE18V batteries set the bar high for power tool performance. Now, there’s a charger that delivers fast and faster charging all while minimizing the downtime associated with the tedious, but necessary task of charging batteries,” Bosch Power Tools product manager Chris Gregory said. “We are confident that our HELL-ION 18V Turbo Charger has all the bells and whistles professionals need to harness the full power of the tools and batteries in their everyday lineup.”

The new charger is also the first of its kind to offer battery diagnostics via connectivity. It can connect via Bluetooth Connectivity Module (GCY42 sold separately) to a smart device to enable more control over charging preferences and allow the user to monitor charging levels and status. Two additional charging functions – Max Lifetime and Storage modes – are available through Bosch’s Toolbox App to help pros get the most out of each battery’s lifetime. With the help of the connectivity module, a user has to option to stay notified and informed on all charging activities.

The new charger is also the first of its kind to offer battery diagnostics via connectivity. It can connect via Bluetooth Connectivity Module (GCY42 sold separately) to a smart device to enable more control over charging preferences and allow the user to monitor charging levels and status. Two additional charging functions – Max Lifetime and Storage modes – are available through Bosch’s Toolbox App to help pros get the most out of each battery’s lifetime. With the help of the connectivity module, a user has to option to stay notified and informed on all charging activities.

The Bosch GAL 18V-160 C 18V Connected-Ready Lithium-Ion 16 Amp Battery Turbo Chargers with Power Boost are available now.

Milwaukee Tool announces a new accessory, CABLE DRIVE™, for the groundbreaking M18 FUEL™ SWITCH PACK™ Sectional Drum System, the first drain cleaning solution that combines the benefits of sectional and drum machines to create the single most versatile and mobile machine on the market. The SWITCH PACK™ CABLE DRIVE™ Assembly provides users with the ability Read more

Milwaukee Tool announces a new accessory, CABLE DRIVE™, for the groundbreaking M18 FUEL™ SWITCH PACK™ Sectional Drum System, the first drain cleaning solution that combines the benefits of sectional and drum machines to create the single most versatile and mobile machine on the market. The SWITCH PACK™ CABLE DRIVE™ Assembly provides users with the ability to automatically feed and retract cables through 1-1/4” to 4” lines at up to 15-20 feet per minute.

Milwaukee Tool announces a new accessory, CABLE DRIVE™, for the groundbreaking M18 FUEL™ SWITCH PACK™ Sectional Drum System, the first drain cleaning solution that combines the benefits of sectional and drum machines to create the single most versatile and mobile machine on the market. The SWITCH PACK™ CABLE DRIVE™ Assembly provides users with the ability to automatically feed and retract cables through 1-1/4” to 4” lines at up to 15-20 feet per minute.

The SWITCH PACK™ CABLE DRIVE™ Assembly quickly attaches to any SWITCH PACK™ drum with the mounting plate installed. A twist lock feature allows the CABLE DRIVE™ assembly to be easily swapped between drums. This means users only need one CABLE DRIVE™ Assembly for all the SWITCH PACK™ Drums they own.

A ratcheting lever automatically adjusts for Milwaukee® 5/16”, 3/8”, and 1/2″ inner core drain cleaning cables and 5/8” open wind cables. The assembly is equipped with a RAPID STOP™ button that releases the steel bearings to provide a quick way to release the cable once a blockage is reached, preventing the cable from binding.

Tackling the most frequent challenge of any drain cleaning application, getting the machine onto the job, the M18 FUEL™* SWITCH PACK™ System utilizes a modular design with backpack straps for the easiest transport to any roof, drain, crawl space, or cleanout. The tool-free drum connection allows users to quickly interchange between cable sizes, or add a second drum to reach a length of 100’. SWITCH PACK™ drums are fully enclosed to provide the best protection and containment of the mess.

The System combines three exclusive innovations—the POWERSTATE™ brushless motor, REDLITHIUM™ battery pack, and REDLINK PLUS™ intelligence. The POWERSTATE™ Brushless Motor delivers up to 2X more clearing power than corded competitors for tough jobs through 4” drain lines.

The M18 FUEL™ SWITCH PACK™ Sectional Drain System is fully compatible with the entire M18™ line, now offering more than 200 power tool products.

Milwaukee Tool is committed to providing drain cleaning professionals with the most portable and versatile drain cleaning solutions. The company is dedicated to continuing investments in technology to build solutions from the ground-up that provide these users with an easier way to get on and off the job, with less mess, so they can service more calls. Currently, Milwaukee offers the only completely cordless drain cleaning lineup for fixtures to sewer lateral lines, as well as premium cables with the maneuverability and durability to tackle the clogs.

*M18 FUEL™ is engineered for the most demanding tradesmen in the world. Delivering unrivaled performance, all M18 FUEL™ products feature three Milwaukee®-exclusive innovations—The POWERSTATE™ Brushless Motor, REDLITHIUM™ Battery Pack and REDLINK PLUS™ Intelligence Hardware and Software—that deliver unmatched power, run-time and durability on the jobsite. Simply put, M18 FUEL™ tools are the most powerful 18V cordless tools in their class.

Specifications

CABLE DRIVE™ Assembly

- Feed Speed: Up to 15-20 ft per minute

- Ratcheting Lever

- RAPID STOP™

- Twist Lock Attachment

- Steel Bearings

- Compatible with: Milwaukee® 5/16”, 3/8”, 1/2″ Inner Core and 5/8” Open Wind Cables

M18 FUEL™ SWITCH PACK™ Sectional Drum System (2775-211)

- Drain Line Capacity: Up to 100”

- Recommended Pipe Sizes: 1-1/4” – 4”

- SWITCH PACK™ Drum Capacity:

- 5/16” x 75’ Inner Core

- 3/8” x 50’ Inner Core

- 1/2” x 50’ Inner Core

- 5/8” x 50’ Open Wind

- Backpack Straps: Yes

- Removable Drum: Tool-Free

- Cable Spin Speed: 250 RPM

- Electronic Foot Pedal: Yes

- Integrated Drum Brake: Yes

- Length: 15.75”

Includes 2775-20 SWITCH PACK™ Powered Base, SWITCH PACK™ Drum w/ Anchor Cable, M18 REDLITHIUM XC 5.0 Battery Pack and Charger (cable not included)

Additional kit options, accessory cables, and attachment heads available. Check www.milwaukeetool.com for a full listing.

Additional Accessories:

47-53-2773 Mounting Plate

47-53-2776 Guide Hose

Makita’s new Impact XPS™ is the industry’s new leading line of bits and fastening accessories. The new Impact XPS insert and power bits are designed to handle the high-torque demands of professional users in all trades, lasting up to 90-times longer than standard bits. For plumbing and mechanical contractors, Impact XPS is ideal for fixture Read more

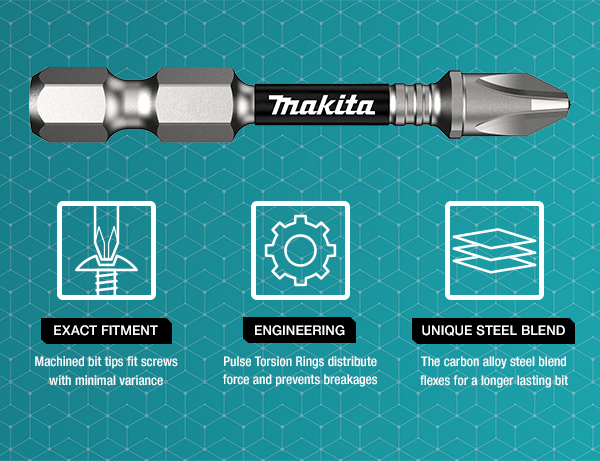

Makita’s new Impact XPS™ is the industry’s new leading line of bits and fastening accessories. The new Impact XPS insert and power bits are designed to handle the high-torque demands of professional users in all trades, lasting up to 90-times longer than standard bits. For plumbing and mechanical contractors, Impact XPS is ideal for fixture installation, precise tightening of couplings, and mounting brackets.

Expertly engineered with exact fitment and a unique steel blend, Impact XPS bits are the ideal bit collection. They can withstand the hardest hitting impact drivers, drills and screwdrivers. Three unique features help eliminate common pain points of bits:

- Exact Fitment – Precision machined bit tips fit screws with minimal variance, thereby minimizing wear on the bit and screw. This helps prevent screw head stripping (cam-outs).

- Pulse Torsion Rings and Zone – Makita is the leading innovator of torsion zone technology in insert bits. The specially engineered pulse torsion rings and torsion zone help prevent the screwdriver bit from snapping.

Pulse torsion rings disperse impact energy through the torsion zone and off the bit tip. The torsion zone has been optimized to flex under load to transfer impact energy for improved bit life. The length combined with diameter is the special formula to create an optimized torsion zone.

- Unique Steel Blend – The unique steel composition is engineered for increased durability to minimize stripping of screwdriver tips. The Impact XPS bits also feature a matte nickel surface for corrosion resistance.

The entire Impact XPS collection includes insert bits, bit holders, power bits, extensions, magnetic nutsetters, sockets, and socket adapters.

For more information, please visit makitatools.com/impactxps.