In the “new to me” category I’ve picked Rothenberger’s RENOL 65008 High-Performance Cutting Oil spray for my number 9 pick. I’ve been using this spray all year in place of an oiler bucket while cutting threads on both black iron and galvanized pipe. We typically have only a few threads to cut and most of Read more

ShopTalk

In the “new to me” category I’ve picked Rothenberger’s RENOL 65008 High-Performance Cutting Oil spray for my number 9 pick. I’ve been using this spray all year in place of an oiler bucket while cutting threads on both black iron and galvanized pipe.

We typically have only a few threads to cut and most of our threading is done for either repairs or quick additions to existing systems. We have yet to invest in a set of press rings for the new M18 Force Logic tool so the old reliable 200 & 300 machines are our go-to’s for threading mobile. This spray is great, in my opinion.

The RENOL spray comes in a 20oz aerosol can. Its a mineral-based oil and provides lubricant and a high level of cooling for the dies and pipe as the threads are cut. Rothenberger claims longer die life and cleaner threads. I can’t say I have found this spray to be anything but a great performer all around. Of course its propelled out of the can so, unlike an oiler, its going to be a little messier but I haven’t found that to be an issue. The amount of space and time it save me is noticeable. No longer lugging around a messy oil bucket and hose is perfect for the amount of cutting we do.

Top Tools 2016: #10

Taking a look back on 2016 – the new tools & old favorites. My #10 favorite this year would have be the M18 FUEL One-Key recip saw. The One-Key system is a mesh of software and hardware working together to make our jobs easier by wirelessly connecting to a smart phone to customize, track and Read more

Taking a look back on 2016 – the new tools & old favorites. My #10 favorite this year would have be the M18 FUEL One-Key recip saw.

The One-Key system is a mesh of software and hardware working together to make our jobs easier by wirelessly connecting to a smart phone to customize, track and manage a tool’s performance and location. One-Key offers up some killer application settings for the sawzall that will definitely change how you think about one of the most violent and powerful tools we use daily.

One cool feature is “Triggered Ramp Up” which controls how fast the saw goes from a standstill to the cutting speed you’ve selected when you pull the trigger all the way. This allows you to start a cut in a more controlled manner. It takes a few cuts to reprogram you brain into realizing the slow start is normal and oh so useful. No more skating blades.

One cool feature is “Triggered Ramp Up” which controls how fast the saw goes from a standstill to the cutting speed you’ve selected when you pull the trigger all the way. This allows you to start a cut in a more controlled manner. It takes a few cuts to reprogram you brain into realizing the slow start is normal and oh so useful. No more skating blades.

Speed control, speed control and speed control. This program setting gets you dialed in to the proper blade speed that best matches the material you’re cutting. This is more important than you might think because its specifically intended to lengthen your blade life. Good blades aren’t cheap. Period. This function is legit.

The third customizable parameter is the Cut Brake. This one also changes the way you use the saw because it allows you to run thru the end of a cut at full blade speed. No throttling needed and that’s sweet, bro. The tool senses when you break through the cut and automatically stops the blade even if you are still squeezing the trigger. You’ll like this when working in tight spots and around easily damaged materials.

The third customizable parameter is the Cut Brake. This one also changes the way you use the saw because it allows you to run thru the end of a cut at full blade speed. No throttling needed and that’s sweet, bro. The tool senses when you break through the cut and automatically stops the blade even if you are still squeezing the trigger. You’ll like this when working in tight spots and around easily damaged materials.

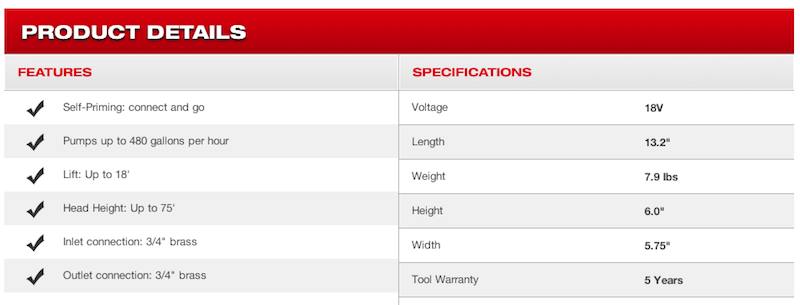

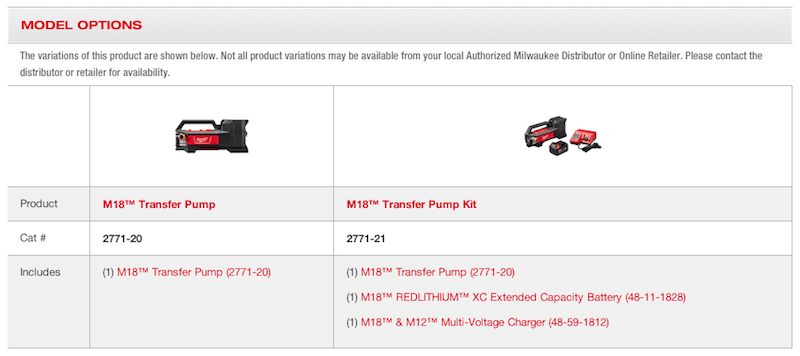

One of the biggest hits at this year’s Milwaukee Tool New Product Symposium—from the plumbing department—was the new, self-priming M18 Transfer Pump. The Hub shot a Facebook Live video from the event and received more than 8,000 views within the first couple of hours of seeing a Read more

One of the biggest hits at this year’s Milwaukee Tool New Product Symposium—from the plumbing department—was the new, self-priming M18 Transfer Pump. The Hub shot a Facebook Live video from the event and received more than 8,000 views within the first couple of hours of seeing a demo for the first time.

Our ProStaffers were chomping at the bit to get their hands on one, so we sent it out to Bob ‘Hot Rod’ Rohr; Andy Mickelson, owner, Mickelson Plumbing & Heating; and the Hub’s Eric Aune, owner, Aune Plumbing LLC, for testing and review.

According to Rohr, the pump is well built and has nice fit and finish. “If weight—7.9 lbs.— equals quality, and the tool is properly used and maintained, this should be a coveted, long-lasting tool,” says Rohr. Aune and Mickelson agree, “The pump is lightweight compared to typical transfer pumps used on the job—cast iron usually,” says Aune.

“The weight is a big plus, as we are frequently packing our equipment though a house. This unit easily fits in a 5-gallon bucket with hoses for transportation,” says Mickelson.

The pump has a nice balance when carrying and using with one hand. Yet, says Aune, while the carry handle protects on/off switch, the handle makes it somewhat difficult to access the button. Rohr’s solution? If you hold the tool with your right hand, index finger towards the battery, “I found you can use the tip of your thumb to activate the switch. This frees up your left hand, and allows one-handed operation.”

The battery is protected under a hinged, tight fitting cover. Warranty is a generous—5 years. Performance on 5.0 battery, washer hoses, draining 50-gal H2O heater, for instance: 12 minutes—that’s fast, would be faster with larger hoses. Runtime on 9ah battery increases by almost 2x. “When paired with the 9.0 battery I see this being a very versatile tool, providing an exceptional run time for a cordless tool,” says Mickelson.

And, no additional cord to plug in is added value and makes jobs easier/faster.

Rohr says that he did not see any pump curve information included in the box. The spec sheet indicates 18’ maximum lift and up to 75’ head, or about 35 psi. (144 gallons per battery charge, about 20 minutes.)

The pump does run much louder when it is pumped dry, indicating it is time to power it down. Milwaukee indicates not over 10 seconds of dry run. The pump should shut down after 1 minute of dry run, via the battery technology.

Rohr considers the pump a flexible impeller style of pump, a design around since 1800s. Some refer to this style as a positive displacement-style pump also. Mickelson continues that even with mild system back pressure the pump does not spin backwards when turned off, acting as check valve almost. And Aune says that the impeller is replaceable. If left to run dry, it will need replaced at some point.

What about glycol? The instructions mentions clear water use only—note the 140°F maximum fluid temperature—so check with Milwaukee regarding glycols or GEO fluids. It is rated only for water but Aune Plumbing has pumped straight undiluted glycol and rinsed pump without problem. Mickelson pumped thick cold glycol with the pump and had great results thus far. “Perhaps if the pump is flushed with clear water after use this will be acceptable. Milwaukee mentions flushing with clear water should ‘anything but clear water be accidently pumped.’ For plumbing and HVAC use it needs to be able to handle the typical, clean heat transfer fluid, in my opinion,” says Rohr.

Funky Fittings?

If you want full performance from this pump, I’d suggest a 5/8 or 3/4” hoses, says Rohr. I did need to use a pliers to get a new hose to seal tightly, the threads seem a bit tight, time may wear these in so hand tightening is all that is required. Aune did notice some issues with the connections. “The hose fittings are odd in that some of my hoses will not tighten properly without wrench and effort,” says Aune.

UPDATE:

Since the original posting of this review Milwaukee has taken our concerns about the hose fittings to the product engineering team for a solution. Effective immediately all new transfer pumps have been fitted with hose adapters that work with a wider variety of hose connections.

On the Job

Hot Rod perched it on top of a 6-foot ladder and pumped from an open 5-gallon bucket. The pump primed instantly, first time out of the box. My first test was with a common washing machine-type hose, about 3/8 actual hose inside diameter. The operation manual does suggest a ¾” ID hose.

It took just under two minutes to empty the bucket, with the restrictive, off-the-shelf wash machine hoses. Pumping straight out of the pump, no hose on the discharge.

He then switched to a hose with a full 5/8” ID and the bucket emptied in 37 seconds! So at 6-ft. lift, wide-open discharge I measured just under 8 gallons per minute flow rate.

His first job was to re-prime a siphon hose that fills a stock watering tank. The inlet end hose plugs with debris from the pond source from time to time. Rohr pumped clean water from a 5-gallon bucket into the siphon line to get the system flowing gain. This is one of the many tasks Rohr sees this cordless pump being used for around the shop.

His first job was to re-prime a siphon hose that fills a stock watering tank. The inlet end hose plugs with debris from the pond source from time to time. Rohr pumped clean water from a 5-gallon bucket into the siphon line to get the system flowing gain. This is one of the many tasks Rohr sees this cordless pump being used for around the shop.

Mickelson has flushed two tankless water heaters with this pump and he loves the self-prime feature. “The rubber impeller seems to be holding up nicely with the acid solution we use to clean the heaters. It also has shown no ill effects of pumping glycol or acid solutions.”

The techs at Mickelson Plumbing and Heating were able to pressurize a heating system with 33% propylene glycol to roughly 22 PSI with the pump. During this process we had pumped 30 gallons of fluid into the heating system, and purged the air out of the system with the pump for an additional 25 minutes, and the 9.0 battery still had 2 bars left on it!

The verdict

• Rohr: This should be a homerun for Milwaukee Tool. With the versatile M-18 battery pack, this useful pump should find it way on many service trucks.

• Aune: Easily the handiest pump for cleaning/flushing tankless water heaters I’ve ever used. Slam-dunk design and performance for the money. It’s not inexpensive but fits perfectly within the M18 platform, which is very popular in the plumbing/HVAC trades

• Mickelson — This model, less the battery is less money than the current transfer pumps that we use. Will be buying more cordless versions very shortly.

Finally, for the HVAC contractor, Rohr suggests this as a transfer pump for filling or topping off hydronic, geothermal or solar systems. Plumbers may find it ideal for empting water heaters, assuming the drain cock is not plugged. If so add a PEX dip tube from the top of the tank to prevent pulling sediment from the bottom drain valve.

Retail price:

$179.00 for bare tool

$279.00 for kit

Copper press systems have become commonplace on the job but the piping systems have expanded recently to include stainless steel piping and fittings along with fittings engineered specifically for iron pipe. As the systems have expanded so have the tool offerings by multiple manufacturers. Milwaukee entered the press tool market in 2013 with the first Read more

Copper press systems have become commonplace on the job but the piping systems have expanded recently to include stainless steel piping and fittings along with fittings engineered specifically for iron pipe. As the systems have expanded so have the tool offerings by multiple manufacturers.

Milwaukee entered the press tool market in 2013 with the first generation of M12 and M18 Force Logic press tools. 12v & 18v offering the first inline design by a major tool manufacturer available at the time. Others would soon follow with similar designs. I have owned both corded and cordless models from Ridgid and Milwaukee. My first press tools were the pistol grip type and my most recent purchase (2014) was the M12 inline design.

Last week I took delivery of the newest press tool available. The Milwaukee M18 Force Logic press tool kit [2773-22] is the first tool available with a brushless motor system.

The significance of brushless design for a press tool is high. As we’ve experienced with multiple tools already built with brushless technology smaller physical designs and faster, more powerful performance ratings are now the norm. The case here is very much the same. The new M18 press tool is not only smaller and lighter but the performance ratings published by Milwaukee are faster and longer [presses per battery charge cycle]. From using it now on two boiler change-outs its been my opinion that this is the fastest cordless press tool I’ve ever used. I’ve likely pressed 50-75 joints and have been running the new 9ah battery pack from an initial full charge and have not had to recharge. The current battery charge, according to the indicator lights is about 50% or more.

The new brushless M18 tool is capable of handling up to and including 4” on Viega’s stainless system (ProPress XL-S), and up to and including 1” on Grinnell’s stainless system (Stainless Steel G-Press). Up to and including 2” on MegaPress. The 2773-22 kit will require additional jaw sets for stainless and MegaPress. As mentioned, the kit includes copper jaws up to 2″.

When asked if competitor press jaws are compatible with the M18 tool a Milwaukee design engineer responded with a “Yes, you can use competitive jaws with the tool”.

The new FLEXVOLT system from Dewalt has opened up a whole new line of tools and possibilities for the pro contractor looking to get more done in less time. We’ve had a few of the FLEXVOLT tools at work in our shop and in the hands of the ProStaff team for a couple months now Read more

The new FLEXVOLT system from Dewalt has opened up a whole new line of tools and possibilities for the pro contractor looking to get more done in less time. We’ve had a few of the FLEXVOLT tools at work in our shop and in the hands of the ProStaff team for a couple months now and continue to be impressed. The latest is the DCB1800 Portable Power Station.

The power station is a combination 4-bank parallel battery charger and DC power inverter capable of providing 1800 watts continuous power at 15A with a peak power rating of 3600 watts 120v. That’s some serious power, this thing is sick.

There are a still a lot of tools on the job that haven’t lent well to cordless technology yet. Core drills, large demo hammers, compressors and various saws. Add to that the many contractors still using corded tools where upgrades either haven’t been in the budget or replacement of a perfectly good tool is unwarranted and you’ve got the need for portable power.

The DCB1800 power station is a portable generator running off (4) 20v MAX batteries, not a gas engine so indoor use is not a problem. The inverter is silent in comparison to any other portable power solution as well making it a non-factor where noise is a obstacle to getting the job done. This is a gamechanger for those looking to knock out some punch list items at the end of the job or quickly get in and out to complete a task with a corded tool when cordless isn’t available.

I wanted to get an idea of how much power this thing has so I loaded it up with (1) FLEXVOLT 20/60v MAX pack and (3) 20v MAX batteries, all new and fully charged and plugged my DW734 thickness planer in to it. I ran (14) 2×8 Fir boards thru the planer before losing power supply. The low power indicator lights started flashing after 10 boards, giving me four more complete before shutting down. That’s 112 feet of planing 2×8’s! I’d imagine ripping some plywood for backing or chipping with a rotary hammer for 20-30 minutes is within reach with a power supply like that. I’ll be putting this to the test on the job soon so stay tuned, for now check out video proof of my test:

https://youtu.be/bHT9eJi9cvM