As we work out our first few installs of the the ADEY MagnaCleanse I wanted to share a few quick videos ProStaff’er Andy Mickelson has posted on his Instagram account. Andy has a older radiant system he’s been working on in Montana that has thousands of feet of Onyx tubing and some major corrosion with Read more

ShopTalk

As we work out our first few installs of the the ADEY MagnaCleanse I wanted to share a few quick videos ProStaff’er Andy Mickelson has posted on his Instagram account. Andy has a older radiant system he’s been working on in Montana that has thousands of feet of Onyx tubing and some major corrosion with a terrible buildup of iron oxide within the heating solution.

The ADEY products; the MagnaClean magnetic filter, MagnaCleanse magnetic filter flush station and chemicals all work together to filter an entire hydronic system of efficiency-robbing elements. The magnetic sludge, as you’ll see in the short 60 second video posts can cause failure of system components such as circulators, valves, air eliminators and flow controls; depending on the type of heat-exchanger used at the heat source the debris can even cause total failure from restricted flow and over-heating. Please watch for future posts here on The Hub and our social media pages as I will be installing and using the ADEY products on some of my installs as well.

The Milwaukee 3pc Close Quarters Tubing Cutter set #48-22-4263 has been available for about a year now, I recently added it to my tool bag. The cutters can be bought separately but I definitely have a need for all three sizes (1/2″, 3/4″ & 1″) so the kit made the most sense for me. I Read more

The Milwaukee 3pc Close Quarters Tubing Cutter set #48-22-4263 has been available for about a year now, I recently added it to my tool bag. The cutters can be bought separately but I definitely have a need for all three sizes (1/2″, 3/4″ & 1″) so the kit made the most sense for me.

I purchased the kit at the Milwaukee factory service center here in the Twin Cities for about $50, a price point I would expect for all three sizes and a case. So far I have only used the cutters for a few weeks and I’m still on the fence. Having used similar style cutters for twenty years, I have to wonder if I didn’t get a bad set or if they simply need some “breaking in” time to exercise the tension springs. Let me explain.

The cutting wheel articulates under spring tension, this is how the cut happens. When you place the cutter on the copper tubing the wheel is spring loaded and pushing against the outside wall of the tube, as the cutter turns the wheel and spring does the cutting. My problem so far is that when the cutter is placed on the tube and not yet cutting, it tends to jump off the pipe. This is annoying. Check out the video below for a visual.

I’ve talked with dozens of other plumbers using the cutters or similar styles, some having the same issue, many who are not. I intend to continue using the set for a full month before I decide to keep them or try another cutter.

There are three things I want to highlight in this video, not all are totally flattering so please take a look: 1. The 2nd generation M12 Fuel Impact is even better than the first and that’s actually incredible because anyone who’s owned the 1st gen knows it’s a very nice tool. 2. The Smith HE2 Read more

There are three things I want to highlight in this video, not all are totally flattering so please take a look:

1. The 2nd generation M12 Fuel Impact is even better than the first and that’s actually incredible because anyone who’s owned the 1st gen knows it’s a very nice tool.

2. The Smith HE2 copper fintube baseboard is fabulous. The performance is crazy awesome and makes it the best bb on the market for mod/con & electric boilers, without a doubt. Don’t argue with me on this, I’ve tried them all and I’ve installed miles of bb. This is a fact, it’s science.

3. The Milwaukee Tool dipped gloves (I’m wearing the cut level 1 pair here) are nice but too stiff in the cold for my liking. Also, they’re supposed to have “SMARTSWIPE” index fingers but I can tell you first hand they don’t work on my iPhone 7+ at all. I’m told that this may be due to my screen protector or the angle of my finger. They did however protect my hands against the 750 million cuts I would’ve received from the razor sharp aluminum fins on the bb. They’re priced right in my opinion and I’d have no problem buying more pairs because they fit well and offer the protection I am looking for.

Hope this helps,

Eric Aune

Aune Plumbing, LLC

Mechanical Hub ProStaff

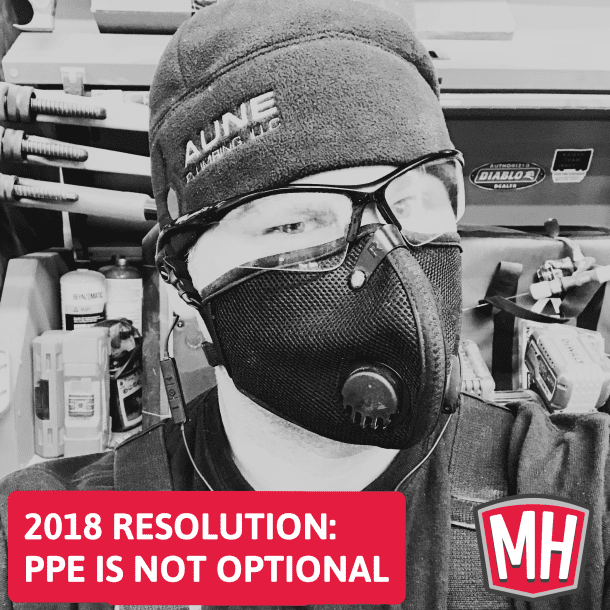

I turned 40 in 2017 so it’s official now that half my life I’ve been working as a plumber professionally. In that time I’ve completely wrecked my shoulders, hands and knees. I’m not at all proud of that, it just is the way it is At this point. That’s nothing new for anyone that’s been Read more

I turned 40 in 2017 so it’s official now that half my life I’ve been working as a plumber professionally. In that time I’ve completely wrecked my shoulders, hands and knees. I’m not at all proud of that, it just is the way it is At this point. That’s nothing new for anyone that’s been in the trades for more than 10-15 years. I’ve since made a lot of changes to how I handle materials and use tools (the right tools for the job) but I’ve also changed how I take care of myself physically. What I’ve always been lacking is a strong discipline to consistently wear appropriate PPE while working.

This is also nothing new for anyone working in the trades. I’m changing that this year. I challenge you to do so as well. I’ve been relatively lucky to this point, my eyes are both intact and strong so far but my hearing could be better. I never hit the floor without knee protection but I don’t always wear safety glasses. I have zero excuses, I own it all and none of it is out of reach or as expensive as missing a day of work or having surgery. Join me in making 2018 a safer, more productive year.