Designed to use one-third the electricity of traditional residential electric water heaters, new product ensures dependable, efficient hot-water delivery. Noritz America, a leader in tankless water heaters and high-efficiency combination boilers, recently previewed its new, ENERGY STAR-certified Hybrid Electric Heat Pump Water Heater for residential domestic hot water applications. Making its debut in Chicago at Read more

Product Spotlight

Designed to use one-third the electricity of traditional residential electric water heaters, new product ensures dependable, efficient hot-water delivery.

Noritz America, a leader in tankless water heaters and high-efficiency combination boilers, recently previewed its new, ENERGY STAR-certified Hybrid Electric Heat Pump Water Heater for residential domestic hot water applications.

Making its debut in Chicago at the 2024 AHR Expo in January, this newest addition to the Noritz offering consumes up to one-third of the electricity required by a standard residential electric water heater with a resistive element, yet maintains the same level of hot-water delivery. The “hybrid” designation denotes the inclusion of dual 4.5-kilowatt electric elements positioned at the top and bottom of the tank to provide backup water heating or accelerate recovery times when necessary.

Set for an official launch on July 1, the new Hybrid Electric Heat Pump unit efficiently transfers heat from air to water, resulting in substantial energy savings for consumers seeking to reduce their utility bills. The Hybrid Electric Heat Pump is eligible for government rebates of up to $3,000, the kind of incentive that has made heat pump installations so attractive for both contractors and homeowners.

Set for an official launch on July 1, the new Hybrid Electric Heat Pump unit efficiently transfers heat from air to water, resulting in substantial energy savings for consumers seeking to reduce their utility bills. The Hybrid Electric Heat Pump is eligible for government rebates of up to $3,000, the kind of incentive that has made heat pump installations so attractive for both contractors and homeowners.

Handling hot water temperatures ranging from 50°F to 160°F, the product will be available in four sizes, with the model numbers here indicating the gallon storage volumes: (NHP50, NHP65, NHP80, and NHP120). The 120-gallon model, still a rarity in today’s market, is available by special order. UEF (Uniform Energy Factor) ratings range up to 3.48, highlighting its energy efficiency when compared to similar products in the market.

“At Noritz, our dedication to providing our customers with diverse water heating solutions drives our innovation,” explains Jason Fleming, Executive Vice President and General Manager of Noritz America. “The introduction of the Hybrid Electric Heat Pump not only addresses recent market and regulatory shifts nationwide, but also offers a product designed to save energy, lower maintenance and operating expenses for customers, and streamline installations and servicing for contractors.”

Key Features

- Cement lining: The specially formulated cement lining of the unit’s storage tank is designed to prevent the corrosive effects of hot water. By negating the need for a sacrificial anode rod, the lining all but eliminates maintenance requirements and the necessity for regular checks. (Neglecting to replace the anode rod can lead to premature tank failure in a conventional electric water heater.)

- Five operating modes: The Hybrid Electric Heat Pump offers users five different ways to operate the unit, depending upon user demand and current conditions: hybrid (standard), electric only, heat pump only, super (for high-demand situations), and vacation.

- First Hour Rating: The Hybrid Electric Heat Pump Water Heater’s first hour ratings are 58 gallons (NHP50), 70 gallons (NHP65), 86 gallons (NHP80), and 105 (NHP120).

- High-pressure rating: The unit has a pressure rating of 150 pounds per square inch (psi) WP and 300 psi TP. A temperature and pressure relief valve comes with the unit, pre-installed.

- Warranties: The cement-lined tank and all parts are covered by ten years of protection, plus a one-year warranty on reasonable labor.

- Approvals include AHRI, UL1995, CSA 22.2 No. 236, Low Lead.

For more information on the new Hybrid Electric Heat Pump Water Heater, visit: https://noritz.com/heatpump/

Powers®, a Watts® brand, has released IntelliStation 2 digital mixing valve, setting a new standard in water control technology. The IntelliStation 2 provides unmatched versatility and efficiency. IntelliStation 2 is designed with an advanced valve for consistent temperatures across a wide range of flows from high to low demand . Enhancements include a sophisticated touchscreen Read more

Powers®, a Watts® brand, has released IntelliStation 2 digital mixing valve, setting a new standard in water control technology. The IntelliStation 2 provides unmatched versatility and efficiency.

IntelliStation 2 is designed with an advanced valve for consistent temperatures across a wide range of flows from high to low demand . Enhancements include a sophisticated touchscreen interface and user-friendly design, alongside built-in Nexa Equipment connectivity for unparalleled system insights. This advanced connectivity ensures seamless integration and monitoring, providing users with critical data at their fingertips. Pre-piped options are available.

IntelliStation 2 supports BACnet and Modbus protocols through both IP and RS485, allowing for smooth integration with existing systems.

A highlight of IntelliStation 2 is its industry-leading five-year warranty, activated upon connecting the unit to Nexa. This extended warranty underscores Powers’ commitment to quality and customer satisfaction.

IntelliStation 2 replaces the Powers IntelliStation and IntelliStation Jr. models. To support existing installations, Powers will continue to offer parts and kits for the previous models, helping to ensure uninterrupted service for current customers.

To learn more, visit watts.com/IntelliStation2.

Aspen Manufacturing, LLC (Aspen), one of the largest independent manufacturers of evaporator coils and air handlers for the residential and commercial heating, ventilation, and air conditioning (HVAC) marketplace in the United States and Canada, announces the introduction of the new AED and AEU family of electric heat air handlers designed for manufactured housing installations. The Read more

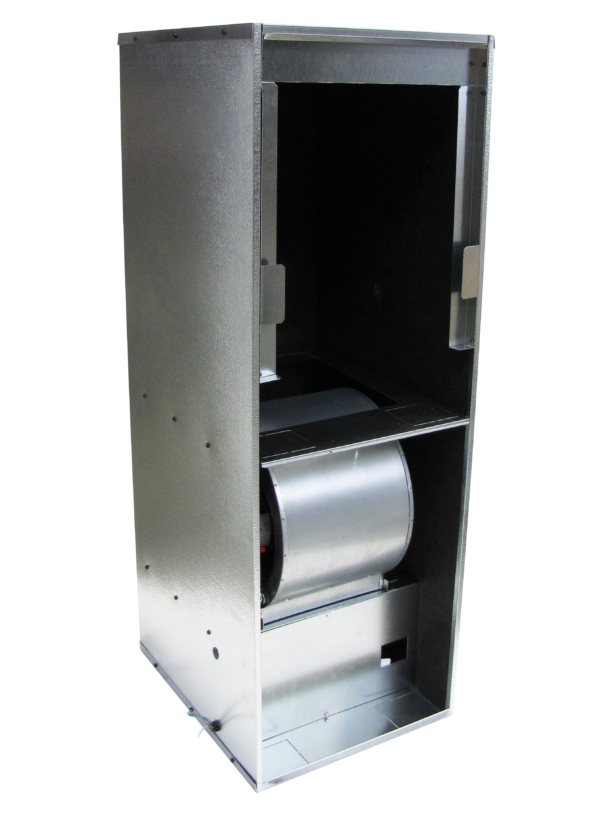

Aspen Manufacturing, LLC (Aspen), one of the largest independent manufacturers of evaporator coils and air handlers for the residential and commercial heating, ventilation, and air conditioning (HVAC) marketplace in the United States and Canada, announces the introduction of the new AED and AEU family of electric heat air handlers designed for manufactured housing installations.

The new upflow and downflow AED/AEU air handlers are designed and engineered for optimal performance in air conditioning and heat pump applications. These units stand out with their one-piece cabinet design, offering reduced weight and increased rigidity. With a low-leakage cabinet design and a larger coil area, they accommodate high-efficiency (taller) evaporator coils, meeting performance requirements in copper and aluminum tube coil designs while maintaining overall cabinet dimensions. These new units are AHRI certified with all major OEM condenser brands, meet the requirements of the Inflation Reduction Act (IRA) 25C rebates, and come with a five-year limited warranty with registration.

Additional features and benefits of the new and enhanced AED/AEU units include:

- One-piece cabinet, reducing time and effort when converting airflow orientation in the field

- Option for field-installed or factory-installed heat kits available

- Rail-mounted blower assembly is easily removed for service

- Electrical access on both sides of the cabinet

- Redesigned control panel for improved interface to wiring and components

- Sloped coil shelf for optimal condensate management

“At Aspen, we’re constantly working to develop new products and to enhance our existing products to ensure that we offer customers the highest quality possible,” said Riley Archer, Vice President of Sales and Marketing at Aspen. “The new AED/AEU units offer outstanding features for easier installation, enhanced operation, and routine maintenance.”

Order dates and lead times for the new AED/AEU units are available from your local Aspen sales representatives.”

For additional information, visit www.aspenmfg.com or email info@aspenmfg.com.

RectorSeal, a leading manufacturer of quality HVAC/R and plumbing tools and accessories, introduces GulfCoat Spray Applied Corrosion Coating – Gallon. GulfCoat Corrosion Coatings products, manufactured by Modine Coatings, provide outstanding corrosion protection from salt spray, UV rays, humidity, and other potentially harmful elements that can cause premature failure of HVAC system coils. Available in Blue Read more

RectorSeal, a leading manufacturer of quality HVAC/R and plumbing tools and accessories, introduces GulfCoat Spray Applied Corrosion Coating – Gallon. GulfCoat Corrosion Coatings products, manufactured by Modine Coatings, provide outstanding corrosion protection from salt spray, UV rays, humidity, and other potentially harmful elements that can cause premature failure of HVAC system coils.

Available in Blue and Clear, GulfCoat Spray Applied Corrosion Coating is water-based and environmentally friendly. GulfCoat sprays evenly without concern for excessive buildup or oversaturation, which can clog vital portals and air passages and reduce the system’s energy efficiency. When correctly applied, GulfCoat products penetrate coil fins deeply to provide outstanding protection. After application, a smooth, high-gloss finish limits the damaging effects of dirt and debris buildup on the coil, allowing for easy, routine equipment cleaning.

“By adding a convenient gallon-size of GulfCoat Corrosion Coating to our lineup, we provide customers with flexibility and another way to protect HVAC coils and equipment effectively,” said Karina Eureste, Product Marketing Manager at RectorSeal. “Now it’s easier than ever to have long-lasting protection for projects of any size.”

Since 1937, RectorSeal has offered products that have built a steadily growing and loyal following among contractors due to differentiated and proven product performance. Further, the company is often the first to tackle and solve challenges professional trade contractors face. In 2015, RectorSeal became part of CSW Industrials, Inc. (Nasdaq: CSWI) and leads CSWI’s Contractor Solutions segment.

Please visit www.rectorseal.com for additional details, and follow us on LinkedIn, Facebook, YouTube, Instagram, and X for the latest product enhancements and news.

Bosch Home Comfort has introduced its latest solution for a cleaner, safer home with the release of its Bosch Air Series Purifiers. Available at select retailers, Bosch Air Purifiers are helping homeowners breathe easy by removing over 99% of air impurities commonly found inside homes. “Most of us spend the majority of our time indoors Read more

Bosch Home Comfort has introduced its latest solution for a cleaner, safer home with the release of its Bosch Air Series Purifiers. Available at select retailers, Bosch Air Purifiers are helping homeowners breathe easy by removing over 99% of air impurities commonly found inside homes.

Fotograf: André Wagenzik

“Most of us spend the majority of our time indoors and unfortunately, studies from the U.S. Environmental Protection Agency show that the concentration of some pollutants are two to five times higher inside than they are outside,” said Divya Darshini Piskala, product manager at Bosch Home Comfort. “This is a scary statistic, but it does demonstrate how important clean air is for our health and well-being. At Bosch, we believe that improving our indoor air quality can help improve our quality of life as well. Bosch Air Series Purifiers are designed to significantly reduce the amount of pollen, pet dander, dust, viruses, and odors we inhale on a daily basis.”

Leveraging innovative filtration technology to help remove dust, smog and other respiratory triggers from the air, Bosch Air Purifiers come in three sizes to fit your space, and are capable of improving air quality in rooms up to 2,745 square feet in size (about the area of a tennis court). Whether looking for an air purifier for a small space or large room, each model in the Bosch Air series features easy-to-use controls such as an LED light ring to indicate air quality, a built-in timer and three levels of ventilation regulations; quiet mode operation; and smart sensors to detect dust and automatically adapt to the air quality and room size.

Bosch Air 6000

Bosch Air 2000 Specifications

Bosch Air 2000 was designed to purify spaces 810 square feet or less, and can be placed on a table tops due to its compact size. Bosch Air 2000 features include:

• Removes over 99% of all impurities such as Pollen, Bacteria, Viruses, Smoke, Dust, Dander, Outdoor Pollution, and Odors

• Filters the air in rooms up to a size of 810 ft² and can be placed anywhere due to its compact size (table version)

• Purifies the air with an output (Smoke CADR) of 106 Cubic Feet per Minute (CFM)

• Features smart sensors, an automatic mode, and an LED light ring to indicate the air quality

Bosch Air 4000 Specifications

For those seeking a mid-size air purifier, Bosch Air 4000 specifications include:

• Removes over 99% of all contaminants such as pollen, pet dander, dust, viruses, and odors

• Filters the air in rooms up to a size of 1,345 ft²

• Purifies the air with an output (Smoke CADR) of 177 Cubic Feet per Minute (CFM)

• Features smart sensors, an automatic mode, and an LED light ring to indicate the air quality

Bosch Air 6000 Specifications

The largest and most robust air purifier in the series, Bosch Air 6000 can filter out harmful elements in large homes or rooms. Bosch Air 6000 features include:

• Removes over 99% of all particles such as pollen, pet dander, dust, viruses, and odors

• Filters the air in rooms up to a size of 2,745 ft²

• Purifies the air with an output (Smoke SCADR) of 353 Cubic Feet per Minute (CFM)

• Smart sensors and an automatic mode to measure air quality, temperature, and humidity

For more information, please visit bosch-homecomfort.com/us/en/ocs/residential/bosch-air-series-purifiers-20570912-c/