“I grab two things when I leave my truck: my flashlight and my VersaPlunge”. That’s Michael Williams, Field Manager for Just Drains LLC – the “the Number 1 drain cleaning company in Philadelphia” – on the revolutionary new plunger from General Pipe Cleaners. “It’s what pros use,” he quickly adds. “And it’s what we recommend!” Read more

Featured Articles

“I grab two things when I leave my truck: my flashlight and my VersaPlunge”.

“I grab two things when I leave my truck: my flashlight and my VersaPlunge”.

That’s Michael Williams, Field Manager for Just Drains LLC – the “the Number 1 drain cleaning company in Philadelphia” – on the revolutionary new plunger from General Pipe Cleaners.

“It’s what pros use,” he quickly adds. “And it’s what we recommend!”

Williams knows what he’s talking about. With six expert crews, Just Drains LLC serves Southeastern Pennsylvania from the Delaware River to Harrisburg. And their seasoned professionals demand maximum performance from all the tools they have.

Innovative New Plunger Design

With its patented, extremely pliable VersaFlange™ cone, the VersaPlunge® plunger easily conforms to nearly any shaped toilet bowl opening, creating a tight seal in virtually any toilet design.

Williams pulls no punches: “It works better than any other plunger on the market. Period.”

Traditional plungers, by contrast, have hard rubber round cones – incompletely and loosely sealing the bowl drain, risking messy, germ-laden splash-back.

“VersaPlunge gives both the suction and tight seal you need,” Williams notes. “Where you put it, VersaPlunge stays.”

Extra Performance When It Counts

“Its remarkable,” he continues. “You don’t get any back-pressure – and no blow-back. If you push down on a conventional plunger, it can actually collapse on you – and you gotta fight to bring it back up.”

Not with VersaPlunge, he declares.

General’s innovative tool sports a convenient relief valve in the handle to minimize overflow. And its super-compressible, accordion-style bellows lets users apply extra force on stubborn stoppages.

“VersaPlunge comes back up – and actually ‘breathes’,” Williams contends. “As you push down, it stays in place – gives what you need to get the full plunge each time.”

For More Than Just Toilets

VersaPlunge is extremely versatile, too.

Roll up the VersaFlange end – and make a flat bottom to clear sinks, tubs, and other drain openings.

“You can use in floor drain traps to make sure the trap doesn’t have debris in it,” said Williams. “If it still holding water you can plunge it to get it open without using the big machine.”

That’s why many professionals carry extra VersaPlunge plungers to handle a range of problems.

“The flexibility of the handle and bellows lets you precisely position VersaPlunge for maximum performance,” he explains. “It’s good in sinks with a fixed faucet. If you can’t move the spout, the accordion style bellows let you flex the handle to the side and plunge effectively from an angle. You can’t do that with conventional plungers.”

The Bottom Line

Michael Williams thinks “every drain cleaning and plumbing professional” should carry a few VersaPlunge plungers for a range of stoppages.

He says that VersaPlunge helps clear clogs faster than old-fashioned plungers do – and keeps surroundings cleaner.

“With VersaPlunge, you’re not just getting a plunger – you’re getting the plunger!” he smiles. “VersaPlunge is like a plunger on steroids!”

Xcel Energy is headquartered in Minneapolis, Minn., and is the largest electrical energy provider in Colorado. The company also provides electricity and natural gas to eight states in the Upper Midwest and Southeast. Its thermal energy business began in 1998, but its history as an electrical power supplier began more than 100 years ago in Read more

Xcel Energy is headquartered in Minneapolis, Minn., and is the largest electrical energy provider in Colorado. The company also provides electricity and natural gas to eight states in the Upper Midwest and Southeast. Its thermal energy business began in 1998, but its history as an electrical power supplier began more than 100 years ago in many of the states it serves. Xcel Energy serves more than 3.6 million electricity customers and two million natural gas customers. It is a forward-thinking energy company when it comes to providing clean power. It has set a carbon reduction goal of 80% from 2005 levels by 2030 and has an aspirational goal of offering 100 percent carbon-free electricity to customers by 2050. Xcel Energy currently employs about 12,000 people.

Denver District Cooling Building – Denver, CO

Refrigerant monitoring updates were needed at Xcel Energy’s Chilled Water building in downtown Denver. The different types of refrigerant monitoring systems that were in use offered no communications ability among plant locations in the city. The Thermal Energy team was spending time conducting constant walkthroughs of five separate buildings to check the health and functionality of 16 chillers and related mechanical equipment, including the refrigerant.

There was also inconsistent monitoring and the absence of data that could identify leaking refrigerants. This, plus the lack of consistency and reliability in the refrigerant equipment used throughout the plants, made troubleshooting difficult and finding correct spare parts from manufacturers arduous.

The result was sub-optimal refrigerant use, monitoring and communications plus inefficiencies in maintenance and repairs and potential safety issues. Today, Xcel Energy uses refrigerant monitors in its five locations to monitor the chillers. Each plant has its own Multi-Zone (MZ), Halogen Gas Monitor and they all communicate with the building automation system, which records levels of refrigerant readings while each plant is continually monitoring for potential refrigerant leaks. The MZs use an NDIR (Non-Dispersive Infrared) sensor that enables early refrigerant leak detection to 1 ppm and a pump that allows for fast sequential sampling up to 16 points.

Michael O’Malley, Operations Manager at Xcel Energy’s Thermal Energy Department in Denver, Colorado, has been with the company for 10 years and has double that experience in operations management. He and his team are responsible for a system that includes five different locations, 16 chillers and four miles of underground pipes that distribute chilled water to some of the city’s most important downtown buildings, including the art museum, main branch of the city’s public library, convention center, hotels, data centers, courthouses and Denver city and county buildings. In each building heat exchangers have been installed, eliminating the need for owners to provide their own equipment.

Clear Requirements

After evaluating refrigerant monitoring products and understanding the operation of the legacy system, Mr. O’Malley thought it important to find active sampling refrigerant monitoring equipment. A system that used a pump for sequentially monitoring different locations would get air through to the sensor and the possibility of increasing sampling frequency could help to prevent any serious consequences. To be proactive and quickly counteract any refrigerant leaks, Mr. O’Malley wanted to set up alarm sensitivities at levels lower than what a passive refrigerant monitor is able to detect. “The cost of a large refrigerant leak to our organization could range from $10,000 to $100,000 or more, depending on the size of the leak,” said Mr. O’Malley.

Using different refrigerant gases such as R22, R123, and R134a at multiple locations, it was also important that the same monitoring system within the different buildings look for all these refrigerant types and that all monitors could communicate with the main plant.

Rocky Mountain High Implementation

The implementation and installation of the first new refrigerant monitor involved a collaborative effort between Xcel Energy, Bacharach and the local representative. A number of refrigerant monitors were installed at different Xcel Energy facilities, so there were some concerns about product reliability. Michael O’Malley wanted to make sure the products would last a long time, be reliable and not require a lot of maintenance. Once Xcel Energy selected the unit it wanted, the initial installation went great, recalled the local representative. Shortly after, however, they were experiencing issues with filters and false alarms. Due to Denver’s mile high altitude, the diaphragms in the pump were working much harder. The issue was quickly remedied by replacing the sealed unit with a more robust rubber diaphragm that would not crack or break. The MZ was installed at a remote plant and as budgets allowed a total of 5 MZs were installed.

Reliable refrigerant monitor Bacharach’s HGM-MZ ensures Xcel Energy chillers remain in good operating condition.

Latest Technology

The role of technology is inseparably linked to the Xcel Energy Chilled Water Plant. It remains an important safety factor to the team to have highly sensitive leak detection technology incorporated into the refrigerant monitors. Using a technologically advanced sensor that recognizes a variety of refrigerants and a system that provides faster cycle times for all monitoring zones would provide continual sampling to detect any refrigerants that might leak into the mechanical room. Mr. O’Malley said, “It’s important that the operations team have confidence that it’s safe to go into the room–that no refrigerant leak happened in the mechanical space and that nothing is leaking into the environment. We need to keep refrigerant inside the chiller. That’s important, so I’m not constantly buying refrigerant.”

The local representative noted that Xcel Energy was not using the same gases in all the chillers and not all those gases were supported in the product they were using. This situation could be addressed by the HGM-MZ’s extensive library of gases built into the monitor plus the accuracy of the refrigerant readings provided.

The HGM-MZ has a library of over 60 refrigerant gases, solving the refrigerant variety issues within the plant for detecting R22, R123 and R134a. Product standardization keeps maintenance easy by using the same product for spare parts and for quick replacement. The Xcel Energy Operations Team has had a significant reduction in the frequency of the walkthroughs they need to conduct. The MultiZone system also keeps refrigerant emissions at bay by having 1ppm performance. It also solved the issue of needing to monitor for different refrigerants at different locations.

Charcoal filter and detection point shown beside the HGM MZ refrigerant monitor.

Clear Financial Advantage

Reducing lost refrigerant, cutting technician travel time for repair work and having the right system to do the job were important from a cost and environmental perspective. According to Mr. O’Malley, “It’s critical we find refrigerant leaks early. Most importantly, we are concerned with the negative effects on the environment. I don’t want refrigerants getting into the atmosphere. The second concern is the financial impact. The machines’ performance will suffer if they don’t have the refrigerant. It’s like gas leaking out of your car.”

Because of the time it took to check the legacy product, it was critical to have a product that would constantly be drawing sequential samples at the chillers and recording refrigerant levels to ensure the product was in operation, no matter the location. “Having reliable, continuous monitoring that we could see from a central location would allow us to dispatch a technician only when having to make an assessment or deal with a minor issue,” Mr. O’Malley said. The technician’s time alone would save costs. Additional benefits include system performance, lower energy costs and reduced refrigerant cost.

Reliability

Being able to rely on the equipment in continual operation was another important consideration. The manufacturer’s representative remembers visiting the Xcel Energy chiller plant in downtown Denver and noted that it was the largest underground chiller plant he had ever visited. He recalls that Xcel Energy wanted a “set-it and forget-it”’ type unit and that they had some concerns surrounding code compliance. Wanting to focus on refrigerant sensitivity, the representative demonstrated that the refrigerant monitor could detect leaks down to 1pm.

“The monitors have been reliable. I don’t recall having to change out the pumps in quite some time,” said Mr. O’Malley, “You basically hang them on the wall and will get years and years and years of service out of them.”

Building Automation System and Communications

The facilities supplied with water by Xcel Energy are either directly owned by the building’s owners or are leased. At any time customers can request records from Xcel Energy on the management of the system. “If a customer wanted to see records on how we’re managing the system, all we would have to do is pull the data to show them the preventive maintenance we are doing and the historical data,” said Mr. O’Malley. “The monitor can talk back to the building management system if the pump goes bad or if the unit sees refrigerant. It will tell you and you don’t have to walk by it to find out.

Functionally, it “talks” the building system language,” he said. Based on the equipment performance, impression and usability, Mr. O’Malley and his Operations team are making good use of the MZs reliability, ensuring the 16 chillers remain in good operating condition and helping keep Xcel Energy’s environmental commitment and reliable service to customers.

When designing a building, architects and contractors alike face the challenge of merging aesthetics with function. Mechanical systems—HVAC in particular —are essential to the comfort and safety of occupants, but can take up valuable space, disturb occupants with operational noise and drive up utility bills by wasting energy. In collaboration with engineers, architects must determine Read more

When designing a building, architects and contractors alike face the challenge of merging aesthetics with function. Mechanical systems—HVAC in particular —are essential to the comfort and safety of occupants, but can take up valuable space, disturb occupants with operational noise and drive up utility bills by wasting energy. In collaboration with engineers, architects must determine how to prevent mechanical systems from disrupting designs and livable space without compromising performance. Modern heat pumps offer new possibilities for maintaining the integrity of architectural designs while meeting requirements for smart comfort, control, efficiency and sustainability.

Heat Pumps 101

Heat pumps are designed to transfer thermal energy to and from interior spaces. At the most basic level, a heat-pump system consists of an outdoor unit connected to one or more indoor units via a pair of refrigerant piping. During heating, the outdoor unit extracts ambient heat, and using refrigerant as the medium, transfers heat to interior spaces. During cooling, the indoor unit transfers heat from interior spaces to the outdoor unit where the heat is rejected.

Residential and light-commercial architects like the split-ductless and variable-capacity ducted heat-pump systems. These heat-pump systems reduce or eliminate bulky ductwork and are more compact than traditional systems.

Architects who design larger facilities will incorporate Variable Refrigerant Flow (VRF) heat-pump systems. VRF systems offer more connections to indoor units per outdoor unit and greater capacities (tonnage) for heating and cooling compared to residential and light commercial systems. VRF systems can be ductless, ducted or a hybrid. Heat pump systems are typically applied in moderate climates and in buildings with a single zone. In buildings with diverse requirements — such as a hotel, office or multifamily building — architects select heat-recovery VRF systems for simultaneous heating and cooling.

Zoned Comfort and Indoor Unit Styles

VRF systems and residential heat pump systems enable architects to design comfort zones of various sizes and with consideration for how occupants will use a given zone. Each zone is served by at least one indoor unit, which can be controlled individually to customize comfort. The variety of indoor units include ductless options such as ceiling cassettes, wall-mounted units and floor-mounted units as well as ducted options such as low-profile air handlers, multi-position air handlers and horizontal-ducted units.

Heat Pumps and Design Freedom

Minimal duct requirements along with the small footprint and modularity of VRF and residential heat-pump equipment give architects the freedom to fully realize their designs. These systems take up less space than conventional systems and can be applied with greater flexibility. Split-ductless systems are ideal for projects involving prefabrication with mounting and parts of the installation performed on the factory floor in some instances. With VRF systems, architects can raise ceiling heights and reduce the size of plenums. Architectural designs can also account for the impact of sound on comfort with outdoor units that can operate very quietly. If a building owner decided to provide a rooftop amenity like a restaurant or garden, operational noise will not disturb occupants.

Energy Efficiency and Control

Split-ductless systems, ducted heat pumps and VRF systems accomplish simultaneous heating and cooling through the transfer of conditioned refrigerant between each zone’s indoor unit(s) and an outdoor unit. Sensors continuously feed information about environmental conditions to the system, where the INVERTER-driven compressor then varies its speed and refrigerant capacity to match the heating or cooling load of a zone. The data also is used by the integrated controllers to vary the system’s performance. Variable-capacity systems save money and promote sustainability by modulating refrigerant flow and using only the precise amount of electricity required to maintain the set point.

The continuous communication between components provides users with precise control and insight into their environments whether they’re facility managers who control a set of buildings on a campus or homeowners that use wall-mounted thermostats or smartphone apps.

Sensors are becoming increasingly sophisticated and may be used with algorithms that make zones more energy efficient and responsive to the needs of occupants. For example, there are units that can recognize the presence and location of people in a room by detecting their heat signatures and enables systems to automatically adjust conditioning and airflow as needed.

Heat Pumps for Every Climate

Heat pumps continue to grow in popularity as architects, engineers, facility managers, commercial building owners and contractors recognize how these systems can be applied in buildings of all different sizes and in a variety of climates. This includes colder climates in the Northeast and Midwest. Technology can allow systems to deliver 100% capacity in temperatures as low as 5 degrees Fahrenheit.

With advancing technologies, increased variety in equipment styles, and nationwide trends toward sustainability, high-performance heat pumps have arrived as the go-to HVAC option to support both residential and commercial architectural designs in every region.

Mike Smith, senior manager of marketing communications, Mitsubishi Electric Trane HVAC US

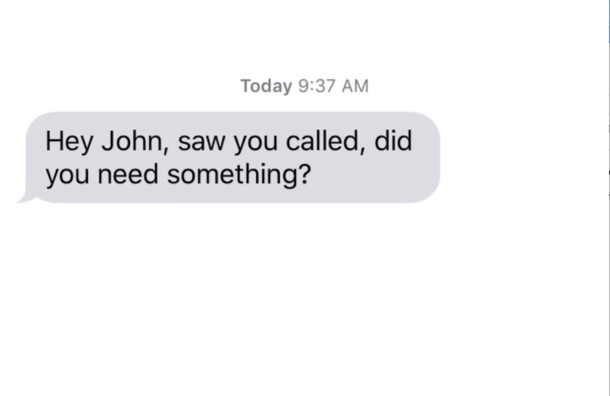

This. This is one of my top 21st-century pet peeves. Yes, I needed something that is why I called. Otherwise I would have texted. Too much back and forth and in-depth information needs to be shared instead of fleeting texts. I understand that people are insanely busy these days and the amount of actual face-to-face Read more

This. This is one of my top 21st-century pet peeves. Yes, I needed something that is why I called. Otherwise I would have texted. Too much back and forth and in-depth information needs to be shared instead of fleeting texts. I understand that people are insanely busy these days and the amount of actual face-to-face and telephone correspondence has diminished, but there is something to be said about a personal encounter or a phone call—eye contact, reactions, expressions, tone of voice and subtle nuances not picked up in texts or DMs.

Perhaps we are entrenched in this the new generation of communication, as I watch my own children interact with their acquaintances more through Snapchat, their gaming systems, and texting, for example. So much so that when I witness the bus stop interactions or holiday gatherings, I see heads down buried deep into their phones and eye contact eliminated.

Stop lights are now being positioned in the streets and sidewalks for pedestrian safety; they don’t actually have to lift their head from their phones to the see the street light. Photo credit Interesting Engineering

As of a few years ago, Gallup did some research on how Americans communicate and texting, emailing and phone calls via a cell phone were the popular choices among the ages of 18-50. Americans 65 and older preferred cell phones, landlines (what’s that?) and email. “The younger the American, the more likely he or she is to communicate using these newer technologies, meaning millennials today are a generation that is highly “in touch” with their friends and relatives … It is also possible that younger Americans have simply been the quickest to embrace the communication capabilities that new technology represents, and that use of such technology will increase in older age cohorts as the millennials age in the years ahead,” said the report. I would have to think that if this same research was done today, social media and texting would be the overwhelmingly favorite choice to communicate.

Running A Business

When it comes to the contractor in the field, we asked some on our Trade Talk group (https://www.facebook.com/groups/1545670948828435/) about their preferred form of communication and most overwhelmingly replied that they prefer email or text so that the correspondence can be recorded or documented. One user commented, “Knowing what channels and methods your customers live in is so important. Giving them multiple ways to communicate with is key. Giving them the option to use what channel/method they prefer is the key.”

This somehow brings me to industry trade shows. As I recall, there were some media outlets that tried virtual trade shows throughout the years, and from what I gathered, they didn’t fare too well. I give credit for the creativity for sure, but you just can’t mimic one-on-one interaction and the ability to “touch” and test out certain products on the floor during the show. And, there is that ever so important connectivity you get with company reps and fellow tradesman while traversing a selected industry trade show. Yes, there are still a lot of trade shows, but there is still value there if the particular trade show is a specific target for you and your business.

Getting Social

According to statista (www.statista.com), market leader Facebook was the first social network to surpass 1 billion registered accounts and currently sits at almost 2.41 billion monthly active users, followed by YouTube at 2 billion, with Instagram coming at 1 billion. According to the site, due to a constant presence in the lives of their users, social networks have a decidedly strong social impact. The blurring between offline and virtual life, as well as the concept of digital identity and online social interactions, are some of the aspects that have emerged in recent

Nevertheless, the wonderful community created on Instagram, for example, encourages support and communication, but better yet, when these people behind the user names and avatars get together for an Instagram meet up, this is where life-long friendships are made and solidified.

Getting back to the original text screen grab above. Is it possible that my number comes up and somebody just doesn’t want to talk at that given time? Nah, c’mon, I can’t believe that for a second. But we do live in a world with a shortened attention span, so the quick text and social media message are the preferred choice here in most instances.

The subtle irony here is that I am posting this to our site and through social media. At Mechanical Hub, we value our followers and interactions each and every day. We hope that we can meet you at a meet up, trade show or some industry event. Stay tuned for more on that …

Integrated Facility Services completes fast-track renovation of heating and cooling systems as a part of Hannibal School District’s Energy Savings Project Integrated Facility Services (IFS) recently completed work on a $4.9 million HVAC renovation project for the Hannibal School District. IFS was a key part of a team of professionals assembled by the prime energy Read more

Integrated Facility Services completes fast-track renovation of heating and cooling systems as a part of Hannibal School District’s Energy Savings Project

Integrated Facility Services (IFS) recently completed work on a $4.9 million HVAC renovation project for the Hannibal School District. IFS was a key part of a team of professionals assembled by the prime energy services contractor, Performance Services, Inc. (PSI), to complete the HVAC renovation. IFS performed the mechanical portion of the project. In addition to the work by IFS, PSI implemented a complete replacement of the existing building’s plumbing system, new ceilings and lighting in all classrooms and corridors, a new addressable fire alarm system, and new U/G electric service feeds and upgraded electrical service.

Under PSI’s direction, IFS designed and installed a completely new HVAC and controls system to improve comfort for Hannibal High School’s more than 1,000 students. Since the high school did not previously have air conditioning in most of the building, the school closed an average of eight days each year due to high temperatures. IFS also installed HVAC equipment and controls to serve portions of the Hannibal Career and Technical Center (HCTC).

Despite the large scope of the project and a condensed schedule, IFS successfully installed 52 heat pumps, 10 rooftop units (RTUs), two chillers, one fluid cooler, seven boilers, 27 fan terminal units, 30 dual duct boxes, and all pumps, peripherals and controls in less than 12 weeks. IFS was able to complete their scope within schedule through diligent project management and constant communication between trades. The IFS-Mid Missouri office led the IFS portion of the project with support from engineers at IFS’ corporate headquarters in St. Louis.

One of the primary project challenges was installing extensive ductwork and equipment within the 90-year-old high school building without changes in structural work. Under the direction of PSI, IFS was able to establish duct paths from each HVAC unit to provide fresh air for 43 classrooms while minimizing the number of chase walls that were required to conceal the ductwork.

In addition, IFS reduced the install time of the piping fittings that serve all 52 water-source heat pumps by using Victaulic and NIBCO fittings. Victaulic’s virtual design team created a 3D scan of the boiler room and provided cut sheets for more than 150 custom fittings.

As part of PSI’s energy savings contract, IFS selected equipment with integrated BACnet interfaces so that PSI and IFS controls engineers can monitor and control equipment remotely and effectively without the added cost of additional controls. PSI and IFS’ standard control sequences include energy-saving measures such as optimum start and stop, demand limits and resets, as well as night setup and setback.

Manufacturer installed products and materials included:

- Lochivar Boilers

- Taco Pumps

- Daikin Heat Pumps

- Marley Fluid Cooler

- Daikin Dedicated Outdoor Air Systems

- Carrier Roof Top Units

- Carrier Chillers

- Victaulic Press Fittings

- NIBCO Fittings