The Plastics Pipe Institute, Inc. (PPI) announced the winners of its Projects and Members of the Year program during its annual meeting held on May 5, 2020. A Project of the Year and a Member of the Year were selected for each of the five PPI divisions: Building and Construction, Drainage, Energy Piping Systems, Municipal Read more

Featured Articles

The Plastics Pipe Institute, Inc. (PPI) announced the winners of its Projects and Members of the Year program during its annual meeting held on May 5, 2020. A Project of the Year and a Member of the Year were selected for each of the five PPI divisions: Building and Construction, Drainage, Energy Piping Systems, Municipal and Industrial plus Power and Communications. The meeting was conducted on-line due to the coronavirus pandemic. PPI is the major North American trade association representing all segments of the plastic pipe industry.

“This year was a little different for us because it was the first time we could not physically congratulate each winner,” stated PPI President David Fink. ”But just as in years past, the nominated projects in each of our five divisions were remarkable and the winners exceptional. It was a healthy competition, and that must be very satisfying to the winners.”

The association’s annual awards program recognizes projects and members for exceptional contributions to the industry. Submissions in the association’s divisions are reviewed, evaluated and voted upon by the PPI members.

The PPI winning projects and members are:

PPI Building & Construction Division Project of the Year

- Vancouver International Airport Geoexchange System, Vancouver, Canada

- PPI Member Company: Versaprofiles, Saint-Lazare-de Bellechasse, Canada

The Vancouver International Airport’s new Central Utilities Building (CUB) will improve efficiency by centralizing all of the equipment needed to meet the airport’s heating, cooling and electrical demand. To achieve this goal, the project will rely on one of the largest Geoexchange systems in Canada. Geoexchange technology uses the earth’s renewable energy, just below the surface, to heat or cool buildings. This system will provide sustainable heating and cooling for the terminal.

The borefield for the CUB Geoexchange system is substantial in size— 841 boreholes at 500 feet each in depth that equals 79.64 miles (420,500 feet) of drilled borehole and 159.28 miles (841,000 feet) of 1.25-inch HDPE 4710 piping. The Geoexchange system is expected to substantially reduce CO2 emissions from heating and cooling demands by 30 to 35 percent.

PPI Drainage Division Project of the Year

- Hugh K. Leatherman Sr. Terminal, North Charleston, South Carolina

- PPI Member Company: Advanced Drainage Systems, Inc., Hilliard, Ohio

The original storm drainage design for the new terminal incorporated reinforced concrete pipe and concrete box culverts. During the design phase of the project, the engineer became concerned about joint separation and the potential for infiltration due to predicted sub-surface soil settlement along the Cooper River. In order to mitigate joint separation and possible infiltration, Advanced Drainage Systems’ HP Storm Polypropylene Pipe was selected as the storm drain conveyance pipe for the entire project due to its ease of handling, extended joint, double gaskets, and flexible design. As a result of the redesign, some 27,000 feet of ADS HP STORM was used to convey all storm water on the 280+ acre site.

PPI Energy Piping Systems Division Project of the Year

- Henderson Municipal Gas (HMG) PA 12 Gas Pipe Installation, Henderson, Kentucky

- PPI Member Company: Teel Plastics, Inc., Baraboo, Wisconsin

In a multi-stage project, the City of Henderson, Kentucky installed 2,720 feet of polyamide 12 (PA 12) gas pipe extruded by Teel Plastics. This marked the first PA 12 installation under the PHMSA Mega Rule effective January 2019, which allows PA 12 to be installed without a special permit.

HMG installed the pipe through an industrialized area of the city. To minimize disruption to businesses, Henderson installed it underneath driveways and existing utilities. HMG buried sections using horizontal directional drilling (HDD), pulling the pipe through bored holes and fusing the sections together. More ductile and much lighter than steel, PA 12 made the HDD installation much easier than it would have been with steel pipe.

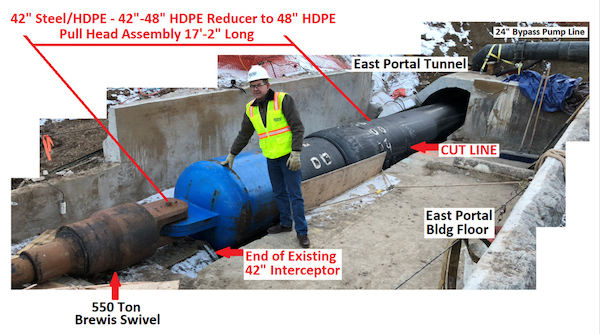

PPI Municipal & Industrial Division Project of the Year

- Colsman Tunnel Sewer Sliplining, Centennial, Colorado

- PPI Member Company: WL Plastics, Ft. Worth, Texas

To rehabilitate a deteriorating brick sewer, 48-diameter HDPE pipe was sliplined into the old sewer. Flow was not allowed to stop during the pull, so a custom completely sealed pull head had to be designed and built so that sewage would not fill the drill string during the pull in. Another restriction was that the staging area only allowed for no more than 200 feet of pipe to be out of the tunnel at once. So, the pipe string was pulled as each stick of pipe was fused and added to the string of pipe. Total pull length was more than 8,000 feet. Custom winch system was brought in for the heavy pull that included two spools of wire cable to get the length required.

PPI Power & Communications Division Project of the Year

- Alliant Energy Private Fiber Optic Network, Madison, Wisconsin

- PPI Member Company: Teel Plastics, Baraboo, Wisconsin

Teel conduit is being installed across Alliant’s service area in Iowa and Wisconsin to improve its telecom network’s security, speed, and reliability. For a utility with a large service area including more than 970,000 electric and 420,000 natural gas customers, reliability and capacity are is crucial during critical events. The conduit will protect the existing infrastructure and allow for later expansion of network capabilities while providing cost savings to Alliant Energy.

The cost savings associated with installation of the conduit and fiber benefits Alliant Energy in multiple ways. Replacing their telecommunication carriers with their own network will protect them from future price increases. Alliant Energy will also decrease their reliance on over-the-air communication, such as microwave radios. In addition, the fiber optic network serves as a gateway for Alliant Energy to work on advances in energy efficiency and technology, which would not be possible without a private fiber network.

A Navy veteran, John Hudek served in the Naval Construction Battalion, better known as the Seabees, and part of their slogan is “Can do” and “The difficult we do now, the impossible takes a little longer.” Throughout her life growing up, watching her father work so hard and the mountains he climbed for his family Read more

A Navy veteran, John Hudek served in the Naval Construction Battalion, better known as the Seabees, and part of their slogan is “Can do” and “The difficult we do now, the impossible takes a little longer.” Throughout her life growing up, watching her father work so hard and the mountains he climbed for his family, Linda Hudek learned from his example. “He taught me that hard work, persistence and determination is key. Those character traits are even more important than natural talent, and I have taken that mantra into adulthood. I love to take on difficult projects and jobs that demand unique solutions where others have said ‘no thanks’ or ‘it can’t be done.’ I am the queen of ‘Can Do,’” says Hudek.

Linda Hudek and her dad, John.

Celebrating nearly 10 years of self-employment, Hudek, LH Plumbing Services, Fairfield, Ohio, has an already extensive decorated resumé. In 2005, working for her dad—a self-employed Master Plumber who, at one time, employed 20 plumbers—she started out in all new construction plumbing. “I began working for him the summer before my senior year of high school just to have a job and I decided that I really loved it. Although much to his displeasure at the time, he didn’t want me in such a rough environment,” jokes Hudek. “I enjoyed the new challenges on a daily basis and the feeling of accomplishment that comes with physical, tangible work. I also loved the constantly varied workplaces and meeting new people on each and every project. I went to college at night and also obtained an Associates in Business Management degree while working for him, as well,” says Hudek.

Hudek owes much of her success and drive to her parents. With John and Herma as the driving force, “They raised me to love and serve God, and to work hard. And, they love me—they even tolerate my wild adventures. My dad also gave me my trade. I can never repay them for what they have given me.”

A one-woman shop, she started her company in late 2010, “oh how young and dumb, I was,” jokes Hudek. But she obtained her master and backflow licenses shortly thereafter. For the past two years, Hudek has been in the shop location of her dreams, and has since migrated to a majority of service work in both commercial and residential sectors with some plumbing remodeling. In addition to residential and commercial service plumbing and drain cleaning, her talents include natural gas, sewer and water line replacements, backflow testing, and plumbing projects that require scuba diving. She joined her local PHCC chapter as a board member, and is currently the Vice President of the Ohio PHCC.

Being a woman in a mostly male industry, Hudek doesn’t even think about it, really. “I am a plumber first and foremost, and the quality of my work is a testament to that,” says Hudek. “I believe that high quality, professional work speaks volumes to potential tradespeople, customers and the layman alike. I want people to remember me for being able to get shit done, and for working hard. I want to encourage anyone and everyone to join the trades; there is so much satisfaction and joy to be found as a plumber. I am thrilled that women—and men alike—are not only considering joining the trades, but doing so after seeing me and other women successfully working in the field. It helps to see someone they can relate to, whereas it might be more intimidating to consider the trades without seeing successful tradeswomen,” says Hudek.

According to Hudek, she has encountered very few stereotypes concerning her gender. There have been a few people who have said that she wouldn’t be able to accomplish what a man could accomplish, but she simply proves them wrong daily. “Everyone has an opinion; some are simply incorrect and ignorant.”

To be honest, says Hudek, the most aggravating stereotypes would be from the individuals who say that the trades are for the less intelligent or troubled individuals who couldn’t do anything else or couldn’t go to college. As in any career, the best tradespeople are hard working, determined, intelligent, strive for excellence, continue their education and are motivated. “I went to college and my master license is far more valuable to me than my college degree ever could be. You can take that to the bank. I did,” says Hudek.

The advice she’s give other women thinking of entering the trades is this: find a company offering an apprenticeship program. Ask questions constantly. Anticipate your journeyman. Work hard and leave the attitude at home. Stay off drugs and stay physically fit. Learn as much as you can—spend some time each week furthering your education by gathering as much info as you can and join in the many free classes offered by suppliers and manufacturers. When you have the opportunity to earn certifications—jump on it. “Don’t be intimidated. If you want it, the sky’s the limit in the trades.”

Yet, the trade industry faces a skilled labor shortage and it needs help in recruiting talented people. Hudek suggests having more apprenticeship offerings in the non-union companies. “Plenty of people could come into the trades, but have no experience and need a structured and planned learning environment,” says Hudek.

Yet, the trade industry faces a skilled labor shortage and it needs help in recruiting talented people. Hudek suggests having more apprenticeship offerings in the non-union companies. “Plenty of people could come into the trades, but have no experience and need a structured and planned learning environment,” says Hudek.

Because some companies only want to hire experienced plumbers, “We need to get back to legitimate apprenticeships. We need more training and flexible childcare options to attract single and working parents. Many companies think they can’t afford to attract the best help, but that’s generally because they aren’t charging enough for their services.”

Also, Hudek wants to see more youth outreach in elementary, middle and high schools. “Take a day or an afternoon and talk to a class about the trades. It’s so much fun and the best time to reach out is when they’re young!”

Also, Hudek wants to see more youth outreach in elementary, middle and high schools. “Take a day or an afternoon and talk to a class about the trades. It’s so much fun and the best time to reach out is when they’re young!”

Speaking of youth, Hudek cherishes spending time with kids. “I love spending time with kids. So many children don’t have good role models or loving families. One of the best things you can do for a child is to simply live by example. Teach them to work hard, how to love, and show them where that hard work and love can take them. Your example is far more telling than your words.”

As for personal time, Hudek says she works, a lot, and admits it can take its toll on relationships and her sanity. “But I feel like I’m maintaining a good balance now,” says Hudek. “I make time to spend with my significant other, my family and friends—sometimes it may only be for an hour or two—other times I might get the chance to randomly take a day off and spend it with loved ones. It’s one of the perks of being independent and self-employed. Oh, and I try to never work on Sundays unless it’s an absolute emergency for a good customer.”

When she can escape, Hudek is an avid scuba diver, kayaker, hiker and lover of the outdoors. She enjoys traveling all over the world when she finds the time. In fact, Hudek swam from Alcatraz Island back to San Francisco Bay for the Sharkfest Swim. “That was wild!”

Lately, Hudek has been active on social media (@thebrunetteplumber on Instagram). According to Hudek, it has opened up a whole new world and it has allowed her to bring customers into her world—helping them understand the importance of hiring licensed professional tradespeople in ways they could have never understood before. It has also helped her network with so many plumbers and business owners alike.

“These people are my rock. They have become the best friends I could ever ask for. So many have encouraged me, taught me new tricks, been referred to me, and I’m able to listen and share about things that only plumbers are going to understand and relate to. It has been a huge blessing. It has also helped me encourage others to join the trades. I’m glad to inspire them and encourage them.”

Proud of being featured in such media outlets such as Mechanical Hub, Plumber and Cleaner magazines, in the end, Hudek loves her career—she enjoys providing services that protect the health of the nation. For her, it is supremely satisfying to routinely complete projects that affect peoples’ lives in such an extreme manner, and she loves seeing the results of her work. It is tangible and visible. “And, we will be needed to sustain the quality of life that people enjoy in modern society. Unless we go back to the stone ages, we will always be needed.”

Proud of being featured in such media outlets such as Mechanical Hub, Plumber and Cleaner magazines, in the end, Hudek loves her career—she enjoys providing services that protect the health of the nation. For her, it is supremely satisfying to routinely complete projects that affect peoples’ lives in such an extreme manner, and she loves seeing the results of her work. It is tangible and visible. “And, we will be needed to sustain the quality of life that people enjoy in modern society. Unless we go back to the stone ages, we will always be needed.”

The last time she had a great day? “I was running a new gas service outside in the sunshine on a job with no one on site to bother me—just me, the trackhoe and some Nine Inch Nails.”

When millions of gallons of water are traveling through your piping system every month, it’s bound to put wear and tear on the system. The folks at Model Linen Service in Ogden, Utah, realized that huge volumes of water were doing a number on their copper; so in a new laundry facility building, they incorporated Read more

When millions of gallons of water are traveling through your piping system every month, it’s bound to put wear and tear on the system. The folks at Model Linen Service in Ogden, Utah, realized that huge volumes of water were doing a number on their copper; so in a new laundry facility building, they incorporated stainless pipe instead.

Then, in looking at options for connecting the 3” and 4” pipe, they discovered Viega’s ProPress Stainless fittings and thought it could be a better option than threading.

“ProPress made the day!” said Ryan Thon, Chief Engineer at Model Linen. “I’ve been using copper over the years and just found that I wasn’t getting the life out of it. We get so much water volume through the pipes that it wears out the copper. So we decided to go with the Schedule 40 stainless.”

Model Linen services about 700,000 pounds of linen a week. Their main business in the facility where the ProPress fittings are located is restaurant service items like bar towels and floor mats. Running at capacity, Model Linen needed to expand, so they built a 19,000-square-foot facility bordering the original main plant.

When Thon and his crew started on the building in April 2018, circumstances beyond his control meant they had to start threading instead. He said the first quarter of the building was threaded.

“There’s so much time and effort involved with threading Schedule 40 pipe,” he said. “Then [when circumstances changed], I was able to get the press tool and jaws. And I’d say it probably took me the same amount of time to press the other three-quarters of the building with Viega as it did to thread the first quarter!

“It’s a big facility and it took months of time—but pressing made it so much easier. I’d probably still be threading right now!” Thon said with a laugh.

In the building, there is a 4” water main that brings in the cold water. It’s softened and goes into an exchanger. Thon explained that old, dirty water coming from the washers is recycled and feeds through the exchanger to work as a heater. It raises the city water up to about 95 degrees without any heating elements.

“It’s hot water. Why let it go straight into the sewer?” Thon said. “All we’re using is the radiator and pumps to pump it, but we re-water to get our tempered water.”

From there, half of the tempered water goes into the washers and the other half goes through a heater to make hotter, 165-degree-water.

Model Linen does a good job in saving as much water and energy as possible. In addition to using the reclaimed hot water to heat the incoming water supply, the washer’s final-rinse hot water is also reused.

“At that point with the last rinse, the soap is out and it’s clean, so that water drops into its own trench and recirculates to be used in the first part of the wash cycle with the detergent,” he explained. “It’s a pretty cool process instead of using more clean city water.”

In total, nearly 100 Viega fittings were used in Model Linen’s new building, ranging in size from 1¼ ” adapters to 4” fittings in various configurations.

Thon said he’s confident the ProPress Stainless fittings will hold up well to the demands of Model Linen’s system. He said there are not many chemicals that run through the pipes, just a mild softener.

One of the concerns in piping a laundry facility are issues with water hammer, Thon said.

“If the washer has a 3” valve open, that’s a lot of water going in quickly; and if it shuts off too quickly, then it shakes the whole system,” he said. “Luckily we have good equipment dialed in well so that they close slowly. There has been no movement with the pipes at all—I was impressed.”

Thon was so pleased with Viega fittings that they’ll be appearing in Model Linen’s other building a few miles down the road, where all of their hotel linens are serviced. He said he purchased a “whole stack of 3” ProPress Stainless” and was getting ready to tear out all the old copper and put in stainless piping at that facility, too.

“Pressing these fittings down saved the day,” he said simply. “I’ve been pretty impressed with the whole thing.”

Rusty and Randy Tigges, co-owners of R&R Septic Services of Carroll, Iowa built a profitable business niche—fast. R&R uses the JM-1000 Mini-Jet, a compact, powerful water jet from General Pipe Cleaners, to service and clean modular wastewater treatment installations. Decentralized modular septic systems like AdvanTex are becoming more common in rural areas not served by Read more

Rusty and Randy Tigges, co-owners of R&R Septic Services of Carroll, Iowa built a profitable business niche—fast.

R&R uses the JM-1000 Mini-Jet, a compact, powerful water jet from General Pipe Cleaners, to service and clean modular wastewater treatment installations.

Decentralized modular septic systems like AdvanTex are becoming more common in rural areas not served by municipal-style treatment plants—including housing subdivisions, apartments, golf courses, RV parks, campgrounds and more.

Rusty Tigges says that the Mini-Jet’s hose and nozzle are the perfect size to clean pipes and orifices of a modular septic system filter pod. And since R&R offers fixed-price septic maintenance contracts, work productivity remains key to profitability.

Rusty Tigges says that the Mini-Jet’s hose and nozzle are the perfect size to clean pipes and orifices of a modular septic system filter pod. And since R&R offers fixed-price septic maintenance contracts, work productivity remains key to profitability.

“Most septic maintenance guys use a bottle brush at the end of fish tape—too slow and slipshod for us,” he adds. “But our JM-1000 Mini-Jet does a faster, more reliable job!”

More Installations In Less Time

The compact, lightweight, electric-powered JM-1000 Mini-Jet—smallest in General’s popular gas and electric powered Jet-Set water jets—is excellent for clearing sludge, sediment, grease, and ice from small, 1-1/2 to 3 inch lines, up to 50 feet long.

With 1500 psi of raw cleaning power, General’s powerful little water jet hits soft stoppages with wall-to-wall high-pressure water—and flushes them away.

“General’s nozzle head design really helps negotiate the twists and turns of septic system pipes, Randy says. “And it’s far more thorough than hand-cleaning with a bottle brush.”

JM-1000 Mini-Jet performance also offers R&R the speed and reliability to service multiple septic installations in a shorter period of time.

“It’s definitely improved our productivity and profitability,” Rusty smiles. “When doing several systems a day, just one technician can knock a half-hour off each job with the JM-1000. And that really helps.”

Portability & Pulse Technology Aid Productivity

Pulse technology helps slide the hose around tight bends and farther down lines. It breaks the initial tension between the hose surface and pipe walls, increasing cleaning power. And it separates General’s Jet-Set from ordinary pressure washers.

Rusty Tigges likes the Mini-Jet’s compact size, too.

As large as a typical toolbox, the JM-1000 Mini-Jet’s rugged, diamond plate metal case containing pump and motor assemblies measures just 24” L x 10-1/2” D x 11” H. At just 23 lb, it’s easy-to- carry—making it perfect for one-person operation.

Including servicing septic system installations. “With the right knack, one technician can go seamlessly from pipe to pipe on an AdvanTex filter pod,” he says. “It works pretty slick!”

Equipment Arsenal Built From Trust

Performance like that also lets R&R use the JM-1000 Mini-Jet on a range of inside drain cleaning jobs.

Rubber feet on the carrying case help protect delicate counter tops in kitchens and baths. It also sports key safety features—like a sensor to shut-off the motor if water stops flowing, and a 3-wire Ground Fault Circuit Interrupter.

“Trust in our tools is very important for daily operations,” says Rusty Tigges. “And General has a great reputation for making highest quality tools.”

Designed with an effortless sense of style and definitive beach-house chic vibe, Lido House by Marriott has quickly become one of Newport Beach’s favorite upscale destinations. The hotel’s design and iconic architecture celebrates the town’s Cape Cod aesthetic with elegant twists on a variety of nautical themes, making this a sought-out locale for out-of-town visitors Read more

Designed with an effortless sense of style and definitive beach-house chic vibe,

Lido House by Marriott has quickly become one of Newport Beach’s favorite

upscale destinations. The hotel’s design and iconic architecture celebrates the

town’s Cape Cod aesthetic with elegant twists on a variety of nautical themes,

making this a sought-out locale for out-of-town visitors and area residents

alike. Residing on the site of former City Hall, the Lido House features 130

stylish guest rooms, along with five unique cottages—each curated by a local

designer, paying homage to the unique ambiance and coastal lifestyle of the

affluent community. The resort also includes a full-service restaurant, rooftop

deck and full day spa for guests.

The Lido House is shown on Tuesday, July 23, 2019 in Newport Beach, Calif. (Carlos Delgado/AP Images for LG Air Conditioning Technologies)

With a location just minutes to the beach, the property often faces fluctuations

in weather and temperature, necessitating an HVAC solution that provides

year-round heating and cooling with superior energy efficiency.

After analyzing the design and overall HVAC requirements for the property, the project team and property management were quick to realize that they needed to maximize open space for leisure amenities for hotel guests. The team also required an ultra-efficient system that could unobtrusively fit within the interior design aspects of the upscale property while maintaining a sense of quiet serenity and guest comfort throughout the hotel’s various communal and guest rooms. With these necessities identified, the team set out to find an HVAC solution to satisfy the unique criteria of the property.

Construction partner R.D. Olson tapped into leading local HVAC expert ACH

Mechanical Contractors, Inc.’s expertise to design an efficient solution that would allow for simultaneous heating and cooling throughout the property and individual guest rooms, while at the same time, seamlessly integrating into the overall aesthetic of this upscale hotel.

The Lido House is shown on Tuesday, July 23, 2019 in Newport Beach, Calif. (Carlos Delgado/AP Images for LG Air Conditioning Technologies)

Once plans for the design were complete and LG was identified as the ideal solution due to their expansive offering, design flexibility and energy-efficient units, local HVAC equipment company DMG Corporation specified LG’s Multi VTM 5 and Multi VTM S VRF systems, both of which have garnered critical acclaim for their incredible energy efficiency, flexibility in design and installation options, to satisfy this project’s needs.

In order to properly condition a large property that regularly sees wide

temperature swings, thanks to the cool ocean breeze, LG’s Multi V 5 was the ideal solution for the main hotel, as it features an expanded operating range that will allow for individualized comfort throughout the entire shared spaces, guest rooms and cottages. Multi V 5 also comes with exclusive LG features such as Smart Load Control which measures ambient air humidity and temperature to monitor changing weather conditions in real-time, adjusting operation before the change has an opportunity to impact indoor comfort. This was a key benefit given the weather and temperature fluctuations in the coastal

California climate. Two LG Multi V S systems were incorporated into the Lido House’s kitchen and IT/Data Server room. They provide dedicated temperature control while taking into account the increased need for cooling within those spaces, no matter the ambient temperature throughout the year.

Additionally, LG Multi V 5 systems were selected to condition the five rental cottages on the Lido House property. In an effort to create maximum comfort for guests, the Multi V 5 allows for personalized comfort control within each zoned area of the cottages. The system allows for a wider operating range

with cooling capabilities in ambient temperatures up to 122° F as well as a

continuous heating in colder temperatures. Ideal for residential settings, it is an effectively efficient, quiet and seamless solution for the Lido House’s goal of tranquility and relaxation throughout its property.

The Lido House is shown on Tuesday, July 23, 2019 in Newport Beach, Calif. (Carlos Delgado/AP Images for LG Air Conditioning Technologies)

LG’s outdoor units were placed on the hotel’s roof, thanks to their innovative space-saving and light-weight design, rather than other locations that could take up precious real estate that could be used for other purposes. Additionally, two LG AC Smart central controllers were installed to help building managers effectively control the HVAC system throughout the main building space.

“The Lido House is an Autograph Hotel – among the most luxurious of Marriott’s offerings – and is meant to be an intimate residential-style boutique hotel,” said Matt Ewing, development manager, R.D. Olson Construction. “One of the big benefits of partnering with LG is not only its quietness, but that they manufacture slim-profile ducted units that we were able to install above the ceilings of all the bathrooms, allowing for maximum comfort and tranquility

for each guest. The last thing we want is for our guests to see and hear the HVAC unit.”

Jason Freeman, sales engineer for DMG Corporation added, “We used almost the entire LG equipment offering on this project, throughout the hotel and the custom-designed cottages. We believe that LG’s VRF systems are the highest quality on the market and that’s why we use them consistently throughout our projects.”

The advanced HVAC systems help Lido House guests have a premium vacation experience. To ensure guest comfort and experience at the property, the team installed 24-total LG VRF systems, allowing for more efficiency, control

and space-saving positives for the property. Additionally, two LG AC Smart controllers were installed in the building engineer’s office, making managing the overall system a seamless process for the management staff.

“With the location of the property being so close to the beach and cool Pacific Ocean breeze, we needed an HVAC solution that can simultaneously heat and cool our spaces, providing maximum comfort for the most discerning clientele,” said Ted O’Brien, Ventura operations manager, ACH Mechanical. “LG’s efficient and effective solutions checked off all the boxes, as we’re able to get way more with less equipment thanks to LG VRF condensing units, which fit perfectly on the roof of the hotel space.”

Alex Ramos, chief engineer for Lido House noted, “I love the feedback that we receive from the guests. This system is so quiet, they can barely tell that it is on, which is music to my ears when it comes to their ultimate satisfaction. The LG VRF system requires low maintenance, guests love it and it’s so simple to manage and operate, thanks to LG’s AC Smart central controllers being easy

to navigate.”