https://youtu.be/VD8thVlIZP8 Our latest Hub On The Road series video brings us to RIDGE Tool company to see the making of their iconic pipe wrench. The world famous cast iron pipe wrench is started at the Urick Foundry in Erie, PA. We get the very first public look into this decades old manufacturing facility were the Read more

Featured Articles

Our latest Hub On The Road series video brings us to RIDGE Tool company to see the making of their iconic pipe wrench.

The world famous cast iron pipe wrench is started at the Urick Foundry in Erie, PA. We get the very first public look into this decades old manufacturing facility were the molten metals are poured into molds, sand is cast and robots work alongside dedicated employees with years of service.

From Urick the guys take their fresh wrench to Elyria, OH to RIDGID’s world headquarters and factory floor to finish the process of grinding, painting, assembling the plumbing and piping industries most iconic tool.

This video is a first ever look behind the scenes of this American made legend. We at MH thank whole hearteldy our partners and friends for welcoming us into their house and allowing us to make this video.

We sincerely hope you find this entertaining,

Team MH

This is the first in a multi-part series on the history of geothermal heating and cooling in the United States and beyond. It focuses on the efforts of two men: Dan Ellis and David Hatherton, the latter having trademarked the WaterFurnace name back in 1981 in Ontario, Canada. David Hatherton is the son of a Read more

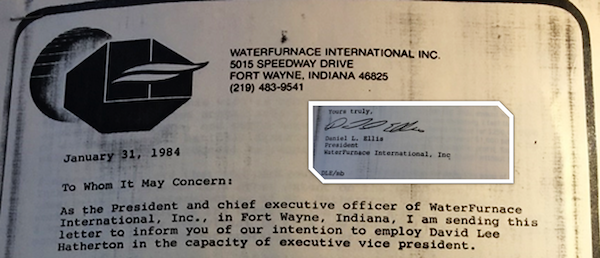

This is the first in a multi-part series on the history of geothermal heating and cooling in the United States and beyond. It focuses on the efforts of two men: Dan Ellis and David Hatherton, the latter having trademarked the WaterFurnace name back in 1981 in Ontario, Canada.

David Hatherton and Dan Ellis

David Hatherton is the son of a water well driller with business operations located in Ontario, Canada. David first noted the energy available in the ground during one particularly cold winter day in Ontario. He still remembers inadvertently placing his hand into the water flowing from a newly drilled water well. He recalls how startled he was that it felt so warm. That’s when he realized that there was truly thermal energy available in the ground. He realized that this is an unlimited resource; if only he could just figure out how to tap it and turn it into heating for home buildings.

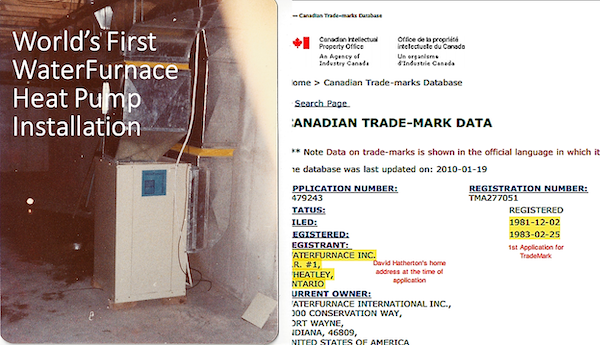

In 1980, David’s father passed away, and David did not want to continue in the drilling business. Instead, he put together a water source heat pump that he tied into one of the water wells on his property. Shortly after that, he came up with the name “WaterFurnace,” and trademarked it in Ontario, Canada.

The First WaterFurnace Installation & Trademark Paperwork

Interestingly, many folks did not like the name WaterFurnace. But as Dave shared, the name told the story of the water source heat pump. Instead of a furnace that combusted some type of fuel, the WaterFurnace heat pump used the energy from water in the earth to provide heat.

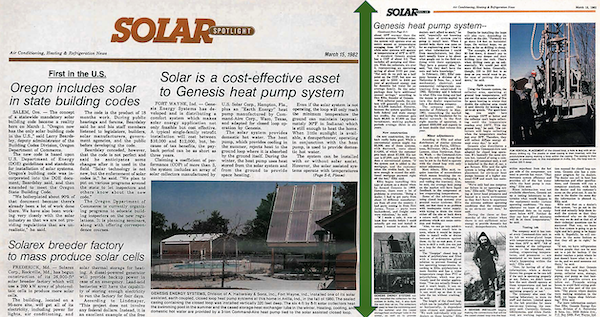

Meanwhile, Dan Ellis was in the business of saving oil and energy. Starting in 1978, a year of double-digit inflation, Dan was working out of an old van and had started a company called “Genesis Energy Systems.” His idea involved a water source heat pump with a solar thermal boost. You can see the first article that ran in 1982 about that system in the Air Conditioning, Heating & Refrigeration News.

The News Article from March 15, 1982

This article piqued David’s interest, and he traveled to Fort Wayne, Ind., to meet Dan Ellis at the office of a successful HVAC contractor, Command Air, at which Dan was a division manager. They had dinner with Harmon Hensley https://www.ahattersley.com/our-story , President of Hattersley and Sons in Fort Wayne, a man of means that caught this vision of what they wanted to do.

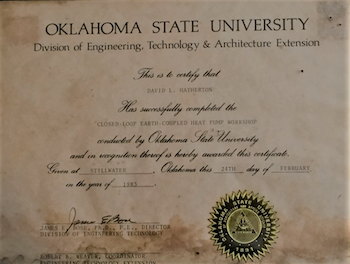

About the same time, the late Dr Jim Bose of Oklahoma State University (OSU) started working with Gerald Parker on geothermal closed loop science, coming up with the first equations for piped heat transfer in a horizontal closed loop exchanger. That effort eventually spawned the International Ground Source Heat Pump Association (IGSHPA) in 1987 https://igshpa.org/about-us/.

When you consider the date on Dave’s certificate for successful completion of the Closed-Loop Earth-Coupled Heat Pump Workshop, which was signed by Dr Jim Bose, it gives an idea of how far ahead they were. The date of Dave’s attendance is February 24, 1983, and IGSHPA was organized at Oklahoma State University 4 years later in 1987, with Dr. Jim Bose as the Executive Director.

David’s 1983 OSU Closed-Loop Certificate

The pair was set to be a prime distributor for Command Air, on which they planned to affix the new ‘WaterFurnace” label, but the deal did not materialize. They went on to work with investors to create WaterFurnace International in April 1983 in what they affectionately call the “carpeted warehouse.” You can see the harvest-gold carpet in the image in which they are standing proudly in front of the first WaterFurnace booth.

The First WaterFurnace Trade Show Booth

Dan wrote a letter to get Dave a visa to come to U.S. to work as the Executive VP of WaterFurnace. By January of 1984, according to the letter, Dave’s distribution company in Ontario had sold $500,000 worth of WaterFurnace equipment and was the largest single distributor in North America. As a result of their alliance, during 1984, WaterFurnace set up about 20 distributors, enlisted the support of electrical coops to monetize geothermal heat pump rebates in their areas, and had completed some significant commercial projects involving as many as 324 vertical boreholes.

Employment Letter from Dan to David

At this time, the Carter Administration still had federal tax credits on the rolls for heat pumps, but those were eliminated by the new administration in 1984. Even with that, WaterFurnace sold $2.2 million in geothermal heat pumps by the end of 1984, showing a $300,000 profit.

When the Command Air part of the deal failed, Dan Ellis arranged for the purchase the water-source division of McQuay with the help of investors, which bootstrapped WaterFurnace fully into the manufacturing business in 1985.

In the next segment, we’ll share information on Dave moving back to Ontario where he worked with the utility to get 7,300 systems installed in three years, Dan moved over to ClimateMaster, and guided them from the red to a $200M company in 10 years.

Jay Egg is a geothermal consultant, writer, and the President of Egg Geo, LLC. He has co-authored two textbooks on geothermal HVAC systems published by McGraw-Hill Professional. He can be reached at jegg@egggeo.com

Jay Egg is a geothermal consultant, writer, and the President of Egg Geo, LLC. He has co-authored two textbooks on geothermal HVAC systems published by McGraw-Hill Professional. He can be reached at jegg@egggeo.com

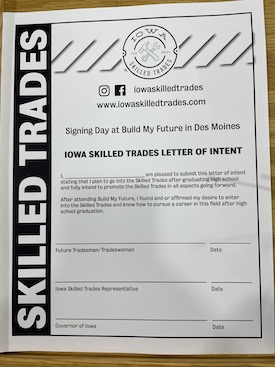

It was the most impressive gathering of young people interested in joining the trades that I have seen in quite some time. Iowa Skilled Trades (www.iowaskilledtrades.com), in conjunction with Home Builders Association of Des Moines (www.dsmhba.com) and the Skilled Trades Academy at Central Campus Des Moines Public Schools (https://centralcampus.dmschools.org/skilled-trades/), organized the very successful Iowa Build Read more

It was the most impressive gathering of young people interested in joining the trades that I have seen in quite some time. Iowa Skilled Trades (www.iowaskilledtrades.com), in conjunction with Home Builders Association of Des Moines (www.dsmhba.com) and the Skilled Trades Academy at Central Campus Des Moines Public Schools (https://centralcampus.dmschools.org/skilled-trades/), organized the very successful Iowa Build My Future event.

More than 5,000 students attended the Build My Future event held at the Iowa State Fairgrounds in Des Moines, Iowa.

Held at the Iowa State Fairgrounds, the third such event held live since its inception, Iowa Build My Future far surpassed any past events with more than 5,000 middle school, high school and other students—from more than 120 schools from across the state of Iowa—bussed in to take part of this career day, industry showcase and hands-on trades expo held April 13.

Students from across the state of Iowa participated in the hands-on Build My Future event, which included testing tools, working with ropes, roof building, excavating demos, and much more.

Brandon Patterson, architect of the Build My Future event in Iowa, is all smiles as the event went off without a hitch.

“The goal is to have the students get their hands on things they’ve never done before. Maybe they don’t have shop class, maybe they’ve never understood of any careers in manufacturing. We are letting them have a hands-on experience with these different careers,” says Brandon Patterson, workforce development, HBA of Greater Des Moines, the driving force behind the event.

Those different careers include plumbing, HVAC, electrical, carpentry, masonry, welding, and more. Housed inside and out, hands-on activities included soldering, roofing, welding and jobsite excavator demos, rope climbing with harnesses, and much, much more.

Students getting ready for the letter of intent signing.

During the show, there was a Letter of Intent signing, indicating that students intended to enter the trades after high school. “We are actually going to do a signing day for kids that are going into the skilled trades industry, most likely construction. We want to showcase these kids and show them what it’s all about,” says Patterson.

The letter also was co-signed by Iowa Governor, Kim Reynolds, who was in attendance for the Build My Future event. “I want to congratulate the students here today for taking the initiative to jump start your careers in apprenticeships that gives you an advantage; it gives you hands-on experience, a chance to earn while you learn, and it’s exciting,” said Reynolds.

The letter also was co-signed by Iowa Governor, Kim Reynolds, who was in attendance for the Build My Future event. “I want to congratulate the students here today for taking the initiative to jump start your careers in apprenticeships that gives you an advantage; it gives you hands-on experience, a chance to earn while you learn, and it’s exciting,” said Reynolds.

Reynolds continued, “I’m excited about the growth in Iowa’s registered apprenticeship programs. In 2021, we received 181 new programs in our state, the most ever in a single year and it puts Iowa as the national leader … we are going to continue to work with the kids, business, construction and the trades and we are going to transform the state of Iowa.”

Students were given plenty of swag from the event.

The letter signing was supported by RIDGID, Pfister, Iowa Skilled Trades and American Plumber Stories, and some key swag was given away at that time.

The Build My Future event left quite an impression on those attending, especially Mechanical Hub’s Eric Aune. “I wish I had something like this when I was in high school,” says Aune.

Prior to the Build My Future event, Mechanical hub was treated to a tour of the Skilled Trades Academy at the Central Campus in downtown Des Moines, Iowa. Tour guides Dan Knoup, executive officer, HBA of Greater Des Moines and Gary Scrutchfield, Lumberman’s Drywall & Roofing Supply, who are both active with the Skilled Trades Academy.

The Academy is open to 42 school districts and offers 89 various program courses from agriculture to electrical to plumbing to automotive to carpentry to marine biology. Yes, marine biology. High school students are transported there for a minimum of 90 minutes per visit to get them educationally on the right trade track.

The Hub’s Eric Aune interviews Mike Murphy, a former U.S. military serviceman, heads up the plumbing and mechanical department for the Skilled Trades Academy.

Central Campus complements and extends the programs of Central Iowa Schools, offering unique academic and career opportunities that direct, inspire, and motivate a diverse group of students.

Located at the heart of the model district for urban education, Central Campus offers hands on, real world work-based educational programs to a highly diverse community and surrounding areas. One of our greatest strengths is the friendships and networking of students from diverse backgrounds and communities. Des Moines Public Schools dedicates itself to excelling at unique and technologically advanced opportunities for all learners. Central Campus commits itself to providing equal access and prospects through rigorous academic and career training experiences for all.

Fun fact: the building was an assembly plant for Ford’s Model T.

Foley Mechanical worked with the owner of a 1920 home in the Cleveland Park section of Washington, D.C. on a heating system upgrade. The project included a 95% AFUE condensing gas boiler that replaces an existing conventional cast iron gas boiler. https://youtu.be/O_rQ1JOw6f0 Resideo hydronic products that are highlighted included the following: Hydro-Separator ECM Pumps Zone Read more

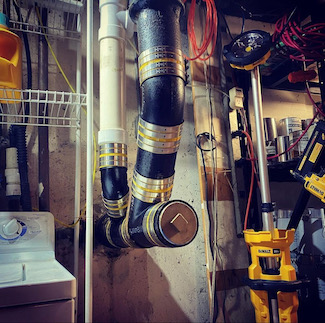

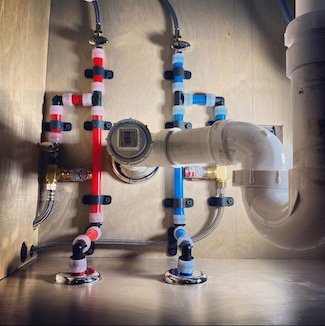

Foley Mechanical worked with the owner of a 1920 home in the Cleveland Park section of Washington, D.C. on a heating system upgrade. The project included a 95% AFUE condensing gas boiler that replaces an existing conventional cast iron gas boiler.

Resideo hydronic products that are highlighted included the following:

- Hydro-Separator

- ECM Pumps

- Zone Valves

- Relay Controls

- Expansion Tank

- Fill Valve and Backflow Preventer

Radiant floor heat was added to a new basement concrete slab. The existing cast trim radiators on the three upper floors were RE-piped and RE-valved. Foley Mechanical used this opportunity to zone by floor using Resideo zone valves. Nearly six months in and in February the owner shared that he had never been more comfortable in his home.

For more information about the Resideo products in this sponsored installation, please visit HERE.

“If pipes are involved, it’s my specialty,” says Matt Benevides, owner of Benevides Plumbing & Mechanical Inc., New Bedford, Mass. A self-proclaimed workhorse, Matt’s journey didn’t quite start off working with pipes. Benevides went to a vocational school for welding and sheet metal, got a job hanging duct work in schools for about three years Read more

“If pipes are involved, it’s my specialty,” says Matt Benevides, owner of Benevides Plumbing & Mechanical Inc., New Bedford, Mass. A self-proclaimed workhorse, Matt’s journey didn’t quite start off working with pipes. Benevides went to a vocational school for welding and sheet metal, got a job hanging duct work in schools for about three years until he eventually got laid off. “My grandmother kept telling me to be a plumber like her father; that way I’d never get laid off. I took her word and jumped,” says Benevides.

“If pipes are involved, it’s my specialty,” says Matt Benevides, owner of Benevides Plumbing & Mechanical Inc., New Bedford, Mass. A self-proclaimed workhorse, Matt’s journey didn’t quite start off working with pipes. Benevides went to a vocational school for welding and sheet metal, got a job hanging duct work in schools for about three years until he eventually got laid off. “My grandmother kept telling me to be a plumber like her father; that way I’d never get laid off. I took her word and jumped,” says Benevides.

Benevides started his apprenticeship for a large outfit just outside of Boston in 2006. “They hired me with no experience, no apprenticeship card—probably hired me because I broke out my funeral suit for the interview,” says Benevides.

When Benevides thinks back, he realizes that the opportunity doesn’t happen very often where a company takes a chance on someone and provides them with in-house schooling for three years—as long as you passed. “Once I received the ticket, my next goal was to work my way to foreman,” says Benevides.

Benevides worked his way to become the lead guy on projects until the company had the confidence in him to run small projects. They then gave him a van and he ran small commercial projects and commercial service. “Once I grew out of that spot, I knew I wanted to run larger projects so I switched companies to run larger projects like schools and a marine biology center, for example.”

Benevides worked his way to become the lead guy on projects until the company had the confidence in him to run small projects. They then gave him a van and he ran small commercial projects and commercial service. “Once I grew out of that spot, I knew I wanted to run larger projects so I switched companies to run larger projects like schools and a marine biology center, for example.”

Once Benevides figured out he could do the work, he was looking for something else and started doing residential side work at night and weekends. “After a year, I was able to take off on my own, and now I’m on year two.”

Leading the Way

Leading the Way

Benevides owes a lot of his work ethic and drive from watching his dad his entire life. “My dad owned and operated his own landscaping business, and seeing that made me want more.” As far as the trades are concerned, Benevides had a foreman named Steve Lima who started with him as a 2nd year apprentice and followed him around. “He showed me the ins and outs of plumbing and running commercial jobs. I called him my ‘plumbing father,’” says Benevides.

Benevides says that he wants to pay it forward through his Instagram page (@boston_plumbing_monstahs_). “I would hope that I’m making the trade more enjoyable so visitors to my page can see the ins and outs of plumbing rather than a plumber equals a plunger,” says Benevides. “Social media is the way to kids these days so I’d say we are on the right road.”

Moreover, the Instagram page has recently led to some local jobs and the opportunities are endless, says Benevides. “You never know who will see something you post.”

Moreover, the Instagram page has recently led to some local jobs and the opportunities are endless, says Benevides. “You never know who will see something you post.”

Balancing work with leisure time is not always that easy. Beneivdes’ spare time is dedicated to his family, if I’m not working, I’m trying to be there for my wife and four kids. “I do my best to be there when my family needs me, and I take at least one day off a week. When the weather gets warm again, I make sure to bring the kids outside as much as possible. Other than that, I plumb.”