I don’t like to admit it, but I’m becoming an “old-timer” in the geothermal HVAC industry. Regardless, I have made a commitment to continue to look for better ways to do things. If you need a quick review of geothermal heating and cooling, this article is a quick and fun read from Mechanical Hub; it should get you right up to speed.

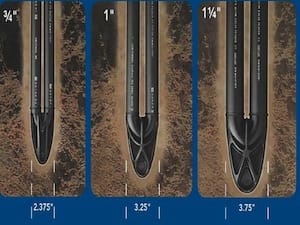

Most geothermal systems start with a vertical closed loop-field. The biggest expense relative to geothermal systems is often the unseen, underground heat exchanger, made of High Density Poly Ethylene (HDPE). Drilling, HDPE pipe and labor combine to cause these loop-fields run up the cost of a geothermal HVAC system to roughly 3 times what a standard air sourced system might cost.

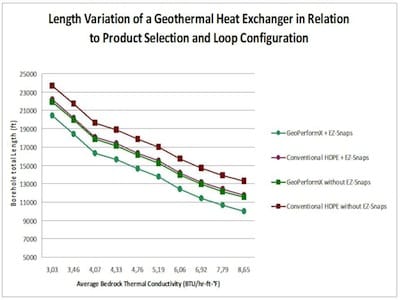

When pipe manufacturer, “Versaprofiles” sent me some information on their “thermally enhanced HDPE pipe”, I didn’t have especially high hopes. The pipe costs about twice what standard HDPE costs. It is however 75% more conductive that standard HDPE pipe. That translates to about 11% less drilling. That doesn’t sound like much, but I went ahead a looked a little further.

I called an engineer that had specified the thermally enhanced pipe on the College of Lake County, Grayslake, IL Campus. Norbert Repka, PhD was hard to pin down, and when I did get him on the phone, his first comment was, “I don’t know what I’ve got to tell you about the pipe; we’ve only just finished the drilling.” What I wanted to know was what made Norbert choose the pipe, and did he see an advantage. Norbert spent about 10 minutes on the phone with me.

Norbert’s calculations showed that for their purposes, the pipe provides a 25% improvement in performance, and that they could save about 5% on borehole length. He said that with nearly 100 boreholes drilled they saved (eliminated) 5 boreholes due to the higher thermal conductivity of the thermally enhanced HDPE.

I looked into multiple projects, many of which showed even better results. St. Laurent Sports Complex completed in 2013 is another example of a project that saved considerable resources on loop-field costs.

New York City Transit Authority is planning a test with the thermally enhanced HDPE pipe on their facilities. It’s no secret that New York is a hot bed of activity for geothermal efforts, thanks in part to the efforts of NY-Geo. Anything that can save space and first cost is getting noticed.

Even with Norbert’s conservative calculations, he said the net savings were about $64,000. That means that if they followed the manufacturer’s estimated 11% reduction in borehole length (rather than the 5% they conservatively used), the savings might have been closer to $130,000. Either way, it was a win; both in time and money. In my opinion the pipe is a winner.

This not-so-new pipe (it’s been around since 2009) will be featured in a product showcase on Wednesday at 3:30 at the IGSHPA Expo in Kansas City.

Industry Stakeholders have created a website with vast resources to educate the public on geothermal heat pumps. The “Geothermal Day” Website http://www.geothermalday.com/ aims to raise awareness about environmental and economic benefits of geothermal energy and its vital role in building a clean and secure energy future. We are inviting industry partners, communities, businesses and educators to join efforts to advance further understanding and acceptance of geothermal technology as an unlimited, renewable form of energy. Join us by co-creating and sharing educational resources and participating in interactive activities in local communities and online.

Jay Egg is a geothermal consultant, writer, and the owner of EggGeothermal. He has co-authored two textbooks on geothermal HVAC systems published by McGraw-Hill Professional. He can be reached at jayegg.geo@gmail.com.

Jay Egg is a geothermal consultant, writer, and the owner of EggGeothermal. He has co-authored two textbooks on geothermal HVAC systems published by McGraw-Hill Professional. He can be reached at jayegg.geo@gmail.com.

Join the conversation: