Technology has revolutionized most aspects of modern human life, including the engineering field. Innovative minds are required to design buildings and constructions that solve the community’s basic challenge. This means engineers are in high demand more than ever. Engineers typically combine the principles of math, physics, sciences, and critical thinking to design new structures and Read more

Whats New

Technology has revolutionized most aspects of modern human life, including the engineering field. Innovative minds are required to design buildings and constructions that solve the community’s basic challenge. This means engineers are in high demand more than ever.

Engineers typically combine the principles of math, physics, sciences, and critical thinking to design new structures and constructions. Thankfully, the current digital world has enabled engineers to easily complete engineering tasks. Engineers can also complete their engineering degrees online. If you’ve considered a career in engineering, earning an engineering degree is the first step.

Can You Complete an Engineering Degree Online?

Unknown to most people, you can complete an engineering degree online. Despite the technical nature of engineering programs, current technologies have made it possible for engineering students to get quality education online compared to traditional college settings.

The only big difference is online engineering degree students enjoy greater flexibility. You can complete various engineering degree studies, including a masters of engineering management online. Most practical sessions for these programs are completed at home, as they don’t require hands-on supervision.

What to Expect from Online Engineering Courses

Online courses slightly differ from physical in-campus courses. Online engineering degree courses vary based on program type and level. For instance, bachelor’s degree programs take four years, while associate programs take two years to complete. Master’s and doctoral programs take between three and five years. Below are a few things to expect from online engineering courses:

1. Be ready for math and physics courses

Engineering degrees are primarily based on math and physics. As such, engineering engineers should be ready to tackle linear algebra, differential equations, and calculus courses. Physics training varies by program. Most disciplines have thermodynamics, mechanics, fluid dynamics, and electrodynamics courses.

2. You will be required to take core classes and a few engineering electives

Undergraduate engineering students begin their training by learning the basics of engineering. Core courses include programming, dynamics, mechanics, and circuits. They also take general classes and can add specializations and electives as they progress. The courses on offer include:

- Artificial Intelligence and cyber-physical Systems for computer engineering students

- Structural and transportation engineering for civil engineers

- Water resources and sustainability engineering for those taking environmental engineering

3. Internships give you hands-on experience with what you’ve learned

Like medical programs, internships for engineering programs are designed to give learners hands-on experience. Students should complete more than one internship session to complete their studies. Internships also expose students to different engineering sectors in the field. This makes it easier for them to identify specific areas of interest.

Is an Online Engineering Degree Worth It?

Because of the technical and highly specialized nature of engineering, an online degree in engineering is a perfect gateway to a high-paying career. There’s also a high demand for engineers across the globe. According to BLS, the median yearly wage for engineers was $91,010 in 2016. There will also be an estimated 140,000 new engineering jobs by 2026. These figures make an online engineering degree certainly worth it.

Endnote

Advancing technology has made it easy for students to complete their courses remotely. Gone are the days students had to attend in-physical classes to get a degree. All you should do is get a reliable internet, choose your preferred engineering program, and enroll in the course.

If your business runs a warehouse, then you already know that they can be quite costly affairs. They require teams to run them, training to keep those teams up to date with the needs of the job, not to mention machinery and digital technology costs. As such, you can’t afford to let waste, errors, and Read more

If your business runs a warehouse, then you already know that they can be quite costly affairs. They require teams to run them, training to keep those teams up to date with the needs of the job, not to mention machinery and digital technology costs. As such, you can’t afford to let waste, errors, and inefficiency run rampant. Here, we’re going to look at some of the most common causes of warehouse error, and what you can do to fix it.

Poor layouts

The bigger your warehouse, the more that you have to pay close attention to how you lay it out. Even well-organized warehouses with plenty of storage and shelving units can get pretty labyrinthine, so you want to keep the rows of shelves as uniform as possible and have larger thoroughfares that can be used to navigate big stretches of space. One way to optimize your warehouse layout is by considering the vertical space often underutilized in traditional settings. Incorporating mezzanines can drastically enhance storage capacity and efficiency by adding additional levels of usable floor space without expanding the building’s footprint. Effective warehouse signage can be vital for preventing people from getting turned around and lost, as well. If you make it so that they’re always able to see which way to go, they can learn the layout of the warehouse much more quickly.

Make sure that they can see

Of course, signage isn’t going to be great if they’re having trouble seeing where they’re going. Similarly. If the visibility of your shelving spaces is poor, it’s all too easy for things to get put in the wrong place. Accidents, including vehicle accidents, slips, trips and falls, and the like are all a lot more likely in places that are not well-lit. As such, investing in high-quality lighting, such as a led retrofit kit can be vital for your warehouse. Make sure that you have both large-scale lighting as well as more proximal lighting for places that require precision work.

Take care of your assets

Whether it’s PPE, the machinery you use to move stock, or even the shelves themselves, you should make sure that you invest in proper maintenance of your warehouse to keep it efficient. This means creating a list of tasks that you do, not just every month or every year, but the things that you have to keep up with every single day. When it comes to issues like messes and spills, your team should be trained to deal with them on the spot rather than let them remain a hazard.

Items disappearing

We’ve already highlighted how issues like poor visibility and layout can lead to items easily getting lost among the rows of your warehouse. However, there is also the threat of items being stolen which you have to be mindful of. Regardless of how it happens, you can prevent item loss by investing in inventory management systems. Equipping your team with scanners can allow you to log the last reported location of any given piece of stock, making it much less likely that things can simply slip through the cracks.

You can’t expect to reduce the costs of your warehouse to next to nothing, but you can make sure that you’re not simply throwing money away. Keep an eye out for your sources of errors and loss.

Living in Bethesda, MD, means enjoying the beauty of all four seasons, but it also means experiencing hot and humid summers. During this time, having a properly functioning air conditioning system is crucial to maintain a comfortable indoor environment. However, like any other mechanical system, AC units can encounter issues requiring professional repair services. In Read more

Living in Bethesda, MD, means enjoying the beauty of all four seasons, but it also means experiencing hot and humid summers. During this time, having a properly functioning air conditioning system is crucial to maintain a comfortable indoor environment. However, like any other mechanical system, AC units can encounter issues requiring professional repair services. In this blog post, we will explore the importance of AC repair in Bethesda, MD, and highlight the benefits of promptly addressing AC problems.

Signs of AC Problems

Recognizing the signs of AC problems is the first step toward timely repairs. Some common indicators include:

- Insufficient Cooling: If you notice that your AC is not cooling your home adequately, even after setting the temperature lower, it may be a sign of a malfunctioning unit.

- Poor Airflow: Insufficient airflow from the vents can indicate a clogged air filter, blocked ductwork, or a problem with the blower motor.

- Strange Noises: Unusual sounds, such as grinding, squealing, or rattling, coming from your AC unit may indicate loose or worn-out components that require immediate attention.

- Frequent Cycling: If your AC frequently turns on and off without reaching the desired temperature, it may indicate an underlying issue that needs professional diagnosis and repair.

Importance of Timely AC Repair

Addressing AC problems promptly offers several benefits, including:

- Energy Efficiency: A malfunctioning AC system often consumes more energy to maintain the desired temperature, resulting in higher utility bills. Timely repairs can restore the unit’s efficiency, helping you save money on energy costs.

- Extended Lifespan: Regular maintenance and timely repairs help extend the lifespan of your AC unit. Ignoring minor issues can lead to more significant problems over time, potentially shortening the overall lifespan of the system.

- Improved Indoor Air Quality: A malfunctioning AC unit can impact the air quality in your home, leading to poor ventilation and an accumulation of dust, allergens, and pollutants. By promptly addressing AC issues, you can ensure better indoor air quality and a healthier living environment.

- Consistent Comfort: A properly functioning AC unit maintains consistent and comfortable temperatures throughout your home. Timely repairs prevent unexpected breakdowns and ensure that your living spaces remain cool and comfortable during the hot summer months.

Choosing the Right AC Repair Service

When it comes to AC repair in Bethesda, MD, selecting the right service provider is crucial. Consider the following factors before making your decision:

- Experience and Expertise: Look for a company with a proven track record of providing quality AC repair services. Experience and expertise ensure that the technicians have the knowledge and skills to diagnose and fix a wide range of AC issues.

- Licensing and Certification: Ensure that the AC repair company you choose is licensed and certified. This indicates their compliance with industry standards and regulations.

- Prompt Response Time: AC problems can escalate quickly, especially during the summer months. Look for a service provider that offers prompt response times and emergency services to address urgent repair needs.

- Customer Reviews and Recommendations: Check online reviews and seek recommendations from friends, neighbors, or family members who have previously used AC repair services. Their feedback can provide valuable insights into the company’s reliability and customer satisfaction levels.

Conclusion

AC repair is essential to maintain optimal cooling and comfort in Bethesda, MD, especially during the hot summer season. By recognizing the signs of AC problems, promptly addressing issues, and choosing a reliable AC repair service, you can ensure that your AC unit operates efficiently, prolong its lifespan, and create a comfortable indoor environment for you and your family. Remember, timely AC repairs not only save you from discomfort but also prevent more extensive and expensive repairs in the long run. Don’t hesitate to contact a professional AC repair service in Bethesda, MD, at the first sign of trouble.

A Comprehensive Overview of Features, Applications, and Benefits Automatic access doors play a vital part in various industries. As access doors, they provide quick access to critical areas such as mechanical rooms, hazardous zones, and machinery and equipment rooms. They help authorized personnel and service teams to safely reach these areas to perform routine checks Read more

A Comprehensive Overview of Features, Applications, and Benefits

Automatic access doors play a vital part in various industries. As access doors, they provide quick access to critical areas such as mechanical rooms, hazardous zones, and machinery and equipment rooms. They help authorized personnel and service teams to safely reach these areas to perform routine checks and repairs to maintain their functionality.

Read on and learn more about the full potential of automatic access doors and their comprehensive overview of features, applications, and benefits they offer.

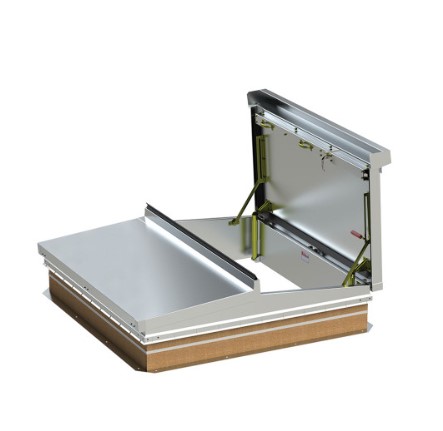

Mechanical Access Doors Quick Overview

Automatic access doors are the ideal solution for infrastructures with restricted areas that you need to protect from unauthorized personnel, rodents, and damaging weather situations. These access doors have excellent durable designs that serve as physical barriers to protect the sensitive area and important building components from potential risks.

However, you must at least know the different mechanical access doors to enjoy and maximize their benefits. Construction professionals usually use four of the most common access doors.

- Hinged Doors

Hinged Doors are versatile mechanical access doors with advanced locking mechanisms and hinges that allow their panel to swing open when someone uses them smoothly.

- Sliding Doors

If you are looking for space-saving automatic access doors, the sliding door type is the ideal access door. You can operate it by sliding the door horizontally, saving more space than other access panels, such as the hinged and security doors.

- Security Doors

Security access doors have a structural design intended explicitly as an extra layer of protection to the building while protecting vital units and systems such as HVAC systems and control rooms.

These doors are also ideal for institutional and correctional facility installations due to their reinforced structural design, durability, and enhanced lock mechanisms that can highly secure the area.

Top 9 Features of Mechanical Access Doors

Automatic access doors have a wide range of features that helps them control and enhance the infrastructure’s security and safety.

- Robust Construction

Automatic access doors such as Bilco access doors and panels models, use steel and aluminum, durable enough to protect the building’s basic units and systems from corrosion, adverse weather conditions, and forced entry.

- Enhanced Locking Mechanisms

Most automatic access doors have enhanced locking mechanisms that you can integrate with today’s technology giving you better security control. The advanced lock features can also prevent unauthorized access more efficiently than traditional key locks.

- Integrating Security Hardware

Another feature of automatic access doors that you must consider is easily integrating them with other security hardware to reinforce their structural integrity and design and make them tamper-proof and impact resistant.

- Fire-rated Options

Due to different building needs, manufacturers guarantee that property owners have fire-rated options to help protect their belongings from fire, as this feature can prevent fire spread for a specific period.

- LEED-Certified

LEED-certified automatic access doors are ideal for property owners who want their infrastructure to be LEED certified. Installing a mechanical access door that meets its requirements can help increase the building’s LEED points which is essential, especially if the company has goals to have platinum LEED certification.

- Access Control Systems

Every building needs a control system that can prevent and track unauthorized access. The mechanical access door best fits these buildings as they can handle advanced access control systems that you might connect to it.

- Vision Panels

Some automatic access doors have vision panels that allow security personnel and the maintenance team to quickly look at components without opening the door. Choosing this type of access door will reduce the risk of security breaches.

- Ease of Installation

The automatic access door’s structural design allows the installation and repair teams to install the door quickly. It does not require heavy-duty tools to install it.

- Customizable

Automatic access doors are also customizable, one of the important features your access door must have. Allowing you to choose a size, design, and lock mechanism will guarantee that the access door meets specific building and local codes.

The above features are essential to check when shopping for automatic access doors.

However, before purchasing a mechanical access door, you must also know its purpose and application to determine which access panel best fits your project.

Mechanical Access Door Applications

You can install automatic access doors in different industries, such as the government and defense, transportation infrastructure, research centers, and residential buildings. However, construction professionals install them mostly in industrial facilities, commercial buildings, and healthcare institutions.

- Industrial Facilities

Industrial facilities must have automatic access doors with advanced locking mechanisms to secure vital equipment, materials, and resources from unauthorized staff and thieves.

- Commercial Buildings

Visitor management in commercial buildings is essential. It must strictly prevent unauthorized personnel from accessing specific rooms, areas, or floors to maintain the safety of the people inside the building.

Automatic access doors can help control the people who can only access these areas, especially if you integrate them with advanced control systems.

In addition, commercial buildings need to be energy efficient, which means all equipment, tools, and other devices must help reduce energy consumption. Insulated mechanical access doors are perfect for these commercial buildings.

- Healthcare Institutions

Automatic access doors adhere to several building safety and security standards, making them ideal for healthcare institutions with specific guidelines to meet to stay highly compliant with regulatory standards, which is essential to control the spread of infectious diseases.

Benefits of Mechanical Access Doors

Automatic access doors have various benefits you will enjoy when you install one for your property.

- Enhanced Security

The access door’s robust materials add an extra layer to the building’s security, preventing burglary, thief, and other security breaches.

- Improved Safety

The automatic access doors have structural integrity you can rely on to maintain a safe place for employees while reducing the number of work-related injuries.

- Increased Efficiency

These access doors can enhance the company’s workflow by streamlining the operations to improve the process and employee productivity.

Protection Against Environmental Factors

Manufacturers designed the automatic access doors to withstand different weather situations such as extreme heat, cold, wind, flood, and even fire emergencies protecting the essential building components such as cables, wires, and HVAC systems without compromising the structural integrity and longevity of the access panel.

Conclusion

Automatic access doors are a vital component of every infrastructure. They can help prevent unauthorized access, enhance energy consumption, promote safety and security, and sometimes optimize traffic flow.

Thus, it is essential that you must consider installing an access door to ensure that the critical components are well-protected from unauthorized access and severe weather conditions to reduce unwanted downtimes, which will affect your business operations, causing you to lose sales.

If you’re an aspiring entrepreneur or a business owner aiming to broaden your horizons, gaining a deep understanding of the complexities surrounding governmental contracts can truly transform your prospects. As a small-scale enterprise, taking advantage of the expansive range of opportunities presented by governmental entities can generate a reliable revenue stream and unveil untapped markets Read more

If you’re an aspiring entrepreneur or a business owner aiming to broaden your horizons, gaining a deep understanding of the complexities surrounding governmental contracts can truly transform your prospects. As a small-scale enterprise, taking advantage of the expansive range of opportunities presented by governmental entities can generate a reliable revenue stream and unveil untapped markets. In this post, we aim to unveil the landscape of government contracting, explaining the procedures, prerequisites, and potential advantages for small businesses.

1. Market Research

Before diving into the world of government procurement, it becomes important to carry out exhaustive market research. Such a venture necessitates the accumulation of key information concerning governmental entities, their procurement requisites, forthcoming undertakings, and the competitive environment.

Small businesses may align their offerings and customize their strategies by scrutinizing market preferences, demand fluctuations, and the distinct demands involved in governmental contracts. As a trusted business, market exploration offers invaluable knowledge, empowering you to execute well-informed judgments, identify target agencies discreetly, and establish a competitive force.

2. Proposal Submission

When navigating the world of governmental agreements, the process of presenting proposals may appear as an intricate and overwhelming ordeal for small enterprises. This is precisely where government procurement services come as invaluable partners and resources. Government procurement services operate as intermediaries, connecting small-scale businesses with governmental agencies, and offering aid in the careful preparation and submission of proposals.

Possessing a good understanding of the procurement procedure, including the prerequisites, documentation, and appraisal criteria prescribed by governmental entities, these services offer guidance to small enterprises in navigating the complexities of proposal formulation. Their presence ensures compliance with regulations while heightening the probability of winning a contract.

3. Evaluation and Award

Following the submission of a proposal by a small-scale enterprise for a government contract, the phase of evaluation and award comes into play. This stage assumes utmost significance, as it determines whether the effort and dedication invested in the proposal shall yield desired outcomes. The evaluation process encompasses an exhaustive analysis of the proposals, skillfully scrutinizing predetermined criteria such as technical prowess, pricing subtleties, historical accomplishments, and adherence to regulations.

Government agencies may employ measures such as interviews, presentations, or site visits as part of this assessment. The evaluation is conducted by an expert team that analyzes and impartially scores each proposal. Once the evaluation is complete, the agency will deliberate and clandestinely designate the small business deemed worthy of being awarded the contract.

4. Contract Compliance

Adhering to contractual obligations constitutes an essential facet within the world of governmental contracts tailored for small-scale enterprises. After the allocation of a contract, it becomes vital for small businesses to understand and comply with the extensive requisites dictated by the government agency. Contract compliance, which unfolds throughout the contract’s duration, demands the fulfillment of specific obligations, adherence to regulations, and adherence to reporting standards.

These prerequisites encompass punctual submission of progress reports, alignment with labor standards, compliance with safety regulations, documentation and record-keeping, and financial reporting, among other obligations. Failing to meet these obligations may result in penalties, termination of contracts, or even legal ramifications.

Endnote

Governmental contracts provide small-scale enterprises with avenues to secure consistent revenue streams and expand their market presence. By executing comprehensive market exploration, small businesses can identify lucrative opportunities and establish a competitive foothold.