Taco Comfort Solutions® has expanded their family of easy to use, high-efficiency ECM circulators with the addition of the 0034e™ and 0034ePlus™ models. With a maximum of 34 feet of head and 50 gpm, the new circulators offer up to 85% energy savings over a conventional circulator. These circulators are available with cast iron or Read more

Uncategorized

Taco Comfort Solutions® has expanded their family of easy to use, high-efficiency ECM circulators with the addition of the 0034e™ and 0034ePlus™ models. With a maximum of 34 feet of head and 50 gpm, the new circulators offer up to 85% energy savings over a conventional circulator.

Taco Comfort Solutions® has expanded their family of easy to use, high-efficiency ECM circulators with the addition of the 0034e™ and 0034ePlus™ models. With a maximum of 34 feet of head and 50 gpm, the new circulators offer up to 85% energy savings over a conventional circulator.

These circulators are available with cast iron or NSF/ANSI 61 & 372 certified stainless steel volutes, so they are ideal for closed-loop heating systems as well as domestic hot water recirculation systems. Both circulators also offer a convenient, rotatable control box cover for a professional look, no matter the orientation of the installed circulator.

The 0034e features an easy-to-use dial with five operating modes, including constant pressure, fixed speed, Taco’s exclusive activeADAPT™ self-adjusting proportional pressure, and 0-10V capability. The 0034ePlus adds proportional pressure and more constant pressure settings as well as a digital display with real-time feedback, including watts, GPM, feet of head, and RPM. Both circulators are dual-voltage 115V/230V.

Both new circulators come with exclusive features that make Taco’s ECM high-efficiency circulators so easy to use, including SureStart® automatic unblocking and air purging, BIO Barrier® black iron oxide protection, dual electrical knockouts, six-inch stranded leads, recessed flange nut-grabbers and double insulation so no ground wire is needed.

For more information, visit www.TacoComfort.com

This customizable solution helps users organize and store bits with ease Towson, Md. — DEWALT debuts ToughCase®+ Accessory Storage Sets that are the latest addition to the brand’s accessory storage, with premium features to help keep drilling and fastening bits organized. The system includes four container sizes; the Small Bulk Storage Container, Small ToughCase®+ Container, Medium Read more

This customizable solution helps users organize and store bits with ease

Towson, Md. — DEWALT debuts ToughCase®+ Accessory Storage Sets that are the latest addition to the brand’s accessory storage, with premium features to help keep drilling and fastening bits organized. The system includes four container sizes; the Small Bulk Storage Container, Small ToughCase®+ Container, Medium ToughCase®+ Container, and Large ToughCase®+ Container for unlimited configurations.

Towson, Md. — DEWALT debuts ToughCase®+ Accessory Storage Sets that are the latest addition to the brand’s accessory storage, with premium features to help keep drilling and fastening bits organized. The system includes four container sizes; the Small Bulk Storage Container, Small ToughCase®+ Container, Medium ToughCase®+ Container, and Large ToughCase®+ Container for unlimited configurations.

The ToughCase®+ Containers feature newly-designed bit storage, with a unique bit bar position that allows for easy removal of bits. Clear lids let users see what’s in the case at a glance. In addition, the Small, Medium and Large ToughCase®+ Containers include a proprietary latch system to connect to each other for optimized storage space. The Small Bulk Storage Container fits into each of the units as well, and helps loose materials stay organized.

The ToughCase®+ Containers feature newly-designed bit storage, with a unique bit bar position that allows for easy removal of bits. Clear lids let users see what’s in the case at a glance. In addition, the Small, Medium and Large ToughCase®+ Containers include a proprietary latch system to connect to each other for optimized storage space. The Small Bulk Storage Container fits into each of the units as well, and helps loose materials stay organized.

The user-friendly features included in the ToughCase®+ Accessory Storage Sets help users stay organized and ready-for-action. The sets are available with the most popular lines of bits from DEWALT, including Max Fit® Bits, FlexTorq® Bits, Tough Grip™ Bits and more. Available this summer, the Small Bulk Storage Container and Small ToughCase®+ Container range from $5.99 to $16.99 MSRP. Available in fall 2019, the Medium ToughCase®+ Container and Large ToughCase®+ Container range from $19.99 to $39.99 MSRP.

Joliet, Ill.-based contractor and Johnson Controls join forces to support Building Homes for Heroes Milwaukee, Wis. – On September 17th, Johansen & Anderson partnered with other local contractors and Building Homes for Heroes during a Welcome Home ceremony in Joliet, IL for United States Marine Corps Sergeant Nicholas Wallace. Wallace, who joined the military out of Springfield Read more

Joliet, Ill.-based contractor and Johnson Controls join forces to support Building Homes for Heroes

From l to r – Craig Palmer, territory manager, BASE Solutions ; Chris Cozzi, regional general manager, BASE Solutions; Sergeant Nicholas Wallace; Wallace’s daughter; Andy Weis, vice president, Johansen & Anderson; Sara Dapson, community engagement manager, Building Homes for Heroes.

Milwaukee, Wis. – On September 17th, Johansen & Anderson partnered with other local contractors and Building Homes for Heroes during a Welcome Home ceremony in Joliet, IL for United States Marine Corps Sergeant Nicholas Wallace. Wallace, who joined the military out of Springfield, Ill. in 2003, was injured during his deployment in Iraq, causing him to suffer multiple injuries, including a traumatic brain injury. His injuries require specific modifications to his home in order to live safely and focus on his recovery.

To support Wallace, Johnson Controls donated a YORK heating and cooling system with a Wi-Fi capable YORK touch-screen thermostat to better assist him with adjusting his home’s temperature without the need to get up. Johansen & Anderson donated the HVAC installation services for the veteran’s new home.

“Teaming up with Building Homes for Heroes gives us an opportunity to give back to real heroes within our local community who have made tremendous sacrifices for our country,” said Rick Cronholm, president and owner, Johansen & Anderson. “We’re honored to contribute our services to help Sergeant Nick Wallace and his daughter live comfortably in their new home for years to come.”

Building Homes for Heroes is a national organization that recognizes those who serve in the United States Armed Forces by supporting the needs of severely wounded or disabled soldiers and their families. The organization strives to build or renovate quality homes and donate them, mortgage-free, to injured veterans nationwide.

“Having the support of companies like Johnson Controls and Johansen & Anderson gives us the opportunity to honor injured veterans with a mortgage-free home,” said Chad Gottlieb, director of construction development, Building Homes for Heroes. “The customized amenities companies like Johnson Controls are able to bring to these homes allows veterans to live their lives in greater comfort and dignity.”

The YORK brand of Johnson Controls has been a proud sponsor of Building Homes for Heroes since 2014. The company has been recognized by US Veterans Magazine as a top veteran-friendly company. Johnson Controls is also committed to hiring veterans and military spouses. Veteran employees are honored to design, engineer and assemble systems that help improve the lives of fellow veterans.

Building Homes for Heroes invites anyone wishing to volunteer or donate to the organization to contact Building Homes for Heroes at info@buildinghomesforheroes.org. To learn more about Building Homes for Heroes www.buildinghomesforheroes.org.

To learn more about Johansen & Anderson, please visit jnaonline.com or follow them on Facebook.

Back in late spring, I had the chance to attend the annual Plumbing Industry Leadership Coalition (PILC) meeting to discuss current issues facing the plumbing industry. PILC is mainly comprised of the largest and most influential associations, professional societies, nonprofits and third-party certification bodies representing manufacturers, laborers, contractors, engineers and water efficiency experts. The efforts Read more

The PILC meeting in DC.

Back in late spring, I had the chance to attend the annual Plumbing Industry Leadership Coalition (PILC) meeting to discuss current issues facing the plumbing industry. PILC is mainly comprised of the largest and most influential associations, professional societies, nonprofits and third-party certification bodies representing manufacturers, laborers, contractors, engineers and water efficiency experts.

The efforts of this group have been very successful, and its message and action items are heavily advocated on Capitol Hill. Successful past campaigns have seen the extension of the WaterSense program, and a Drainline Transport study to exemplify the unintended consequences of water efficiency. In terms of low-flow fixtures combined with plumbing design (slope, water flow, stagnation) in commercial buildings, the question is, how low can you go? The in-depth study revealed that at the current flow rates, no change is imminently needed, but if we continue to go lower, perhaps a new investigation would be in order.

Guest speaker, Dr. Greg Allgood, World Vision, talked about the global water crisis and said that 1,000 kids die every day around the world due to unsanitary water conditions, yet people aren’t outraged anymore because it happens so often. We’ve become desensitized, or perhaps we take a Not in My Backyard (NIMBY) view. Interestingly, according to Allgood, “844 million people don’t have access to a clean water source near their homes.”

World Vision provides safe drinking water to an average of one person every 10 seconds. For example, the organization is currently working on a project that seeks to ensure that 100% of the inhabitants of Rwanda have access to improved water resources. Dr. Allgood expressed a desire to work closer to the plumbing industry.

Action Items

The PILC meeting had its share of action items. The Alliance for Water Efficiency’s Mary Ann Dickinson is working to create a tax exemption status for consumer incentive rebates on water efficient products.

PILC is also seeking input for the development of the National Water Reuse Action Plan. According to PILC, “Federal leadership is sorely needed to help ensure that, as we go forward with utilizing this critically important resource, we make sound, scientifically based decisions that work to prepare our country for the successful utilization of all alternate water sources.”

In order to protect public health and safety as we embark on this collective effort, says PILC, it will be critically important to develop and build on a strong foundation, beginning with the establishment of common terms and definitions for the various alternate water sources.

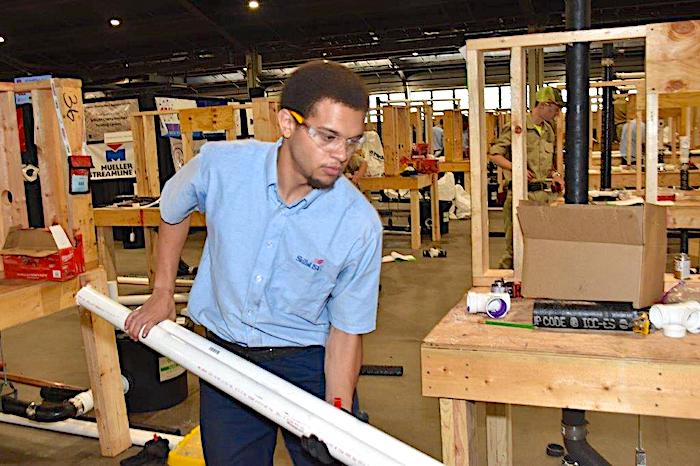

Workplace development is critical.

Currently, alternate water source terms and definitions are being developed in technical silos. Some terms have been generally well defined and are adequately descriptive of the water source. However, other terms, especially those utilizing various colors, such as graywater (greywater) and blackwater, fail to communicate an adequate level of technical accuracy or a reasonable description of the resource that would allow for a clear public understanding.

Concern arises in that terms that were once considered appropriate now convey inappropriate connotations. The term “wastewater,” for example, was appropriate for a time when the goal was to simply separate water used for any purpose in a building from the building occupants as quickly as possible through the building’s sanitary system. In an age where we now seek to convey to the American public that this water is a valuable resource that needs to be carefully treated and reused efficiency in order to help secure our Nation’s water future, this term is clearly outdated and counter-intuitive.

In addition to the terms “blackwater,” “brown-water” and “yellow-water” being inadequately descriptive of the resource, they have potential to reinforce negative stereotypes about people of color. The use of color descriptors for water that is considered a public health risk could be seen as reinforcing a culture where the colors are associated with “bad” versus “good,” which runs counter to the fact that all alternate water supplies can be put to beneficial end uses.

To begin the process of developing a consensus-built terminology for water reuse, PILC suggests the use of an in-person expert workshop to develop terminology and definitions.

Workplace Development

Finally, and perhaps most important, in my opinion, was the topic of workplace development. A task group will be established to focus on how best to reach out to “Generation T” with messaging and career opportunities in the plumbing industry. “Marketing and messaging need to be more poignant.”

Interestingly, I was a surprised to see that not everyone in the room that day thought that workplace development was of major concern. When I arrived back to my office, Michael Copp, executive vice president, Plumbing-Heating-Cooling Contractors-National Association (PHCC), and I discussed this issue with a bit more urgency. When asked, Copp said, “Workforce challenges are not the same across the country and across industry sectors. In general, though, according to the Bureau of Labor Statistics (BLS), the economy will resume a growth rate of 2.5% and construction starts will remain virtually unchanged ($808 billion) in 2019. The number of plumbing and HVAC companies will grow by 1.8% and 2.6% respectively. For every four jobs that are vacated, the industry is only filling one. According to the Bureau of Labor Statistics (BLS), there were 480,600 plumbing jobs back in 2016, with positive growth expected for the next 10 years.”

According to Copp, by the end of 2020, more than 50% of businesses entering the construction industry will be minority- or female-owned. He says that we need to reestablish vocational education that was dismantled in much of the country. We need to achieve greater diversity within the skilled-trades industries to include more women, minorities and at-risk youths: all seeking that same level of importance and respect applied to their contribution to society.

According to BLS, “Employment of plumbers, pipefitters, and steamfitters is projected to grow 16% from 2016 to 2026, much faster than the average for all occupations.”

According to Copp, while the narrative is slowly changing from “College Readiness” to “Career Readiness,” we have to overcome what has been a cultural norm in which “For two or three generations, the focus has been to go to college, get a degree and in doing so you will ensure a brighter future with more access to employment,” (Joshua Wright, America’s Skilled Trades Dilemma: Shortages Loom As Most-In-Demand Group Of Workers Ages, 2013).

“We need a movement,” says Copp, “a cultural shift in which parents, guidance counselors and others do not view vocational skilled-trades education/ apprenticeships as a second option to going to college. With the right policy reforms and resetting national priorities, skilled- trade education can lead to additional education and career advancement. The Department of Labor reported on September 21, 2016 that, “Today, 91% of apprentices remain employed after completing their programs, with average annual starting wages above $50,000. The return on investment for employers is substantial, as studies indicate that for every dollar spent on apprenticeship, employers receive average of $1.47 return in increased productivity.”

Copp says that we need to reestablish vocational education that was dismantled in much of the country. “We need to achieve greater diversity within the skilled trades industries to include more women, minorities and at-risk youths—all seeking that same level of importance and respect applied to their contribution to society. We must overcome stereotypes, and starts with better messaging.”

The all-expenses-paid 3-day trip involved a variety of VIP professional and networking experiences, including the opportunity to build their own iconic RIDGID custom pipe wrench, a featured spot in a RIDGID photoshoot, a premium fishing excursion on Lake Erie and more. Winners also received a behind-the-scenes tour of the RIDGID plant, getting a sneak peek Read more

The all-expenses-paid 3-day trip involved a variety of VIP professional and networking experiences, including the opportunity to build their own iconic RIDGID custom pipe wrench, a featured spot in a RIDGID photoshoot, a premium fishing excursion on Lake Erie and more.

Winners also received a behind-the-scenes tour of the RIDGID plant, getting a sneak peek at the latest RIDGID innovations that have yet to hit the market and providing insight for future product developments. “You think plumbing, you think RIDGID,” said John Thompson, contest winner and owner of Thompson Family Plumbing in Hesperia, California. “It’s iconic. We’re proud and honored to be here and see how this company operates and develops tools for tradesmen and women.”

“Having these hardworking professionals come into our facilities and hearing them talk with the men and women who make the products they use is inspiring for all of us,” said Becky Brotherton, manager, marketing communications, RIDGID. “Getting to spend a few days celebrating the passion of the RIDGID Experience winners is something we look forward to every year.”

“Having these hardworking professionals come into our facilities and hearing them talk with the men and women who make the products they use is inspiring for all of us,” said Becky Brotherton, manager, marketing communications, RIDGID. “Getting to spend a few days celebrating the passion of the RIDGID Experience winners is something we look forward to every year.”

Details on the next RIDGID Experience Contest will be announced in early 2020. Visit the RIDGID Facebook page for details. Emerson’s professional tools business, which includes RIDGID as well as the Greenlee and Klauke brands, provides the industry’s broadest portfolio of advanced, reliable tools and technologies for the mechanical, electrical and plumbing trades globally. Visit emerson.com/professionaltools for more information.