Cut 10-inch schedule 40 pipe in just over a minute with this purpose-built pipe saw from RIDGID RIDGID® Pipe Saw delivers quick, efficient cuts from the fab shop to the field. Fully transportable, this tool cuts 1-inch to 12-inch pipe up to a ½-inch wall thickness. Designed for versatility, the Pipe Saw is configured to Read more

Toolbox

Cut 10-inch schedule 40 pipe in just over a minute with this purpose-built pipe saw from RIDGID

RIDGID® Pipe Saw delivers quick, efficient cuts from the fab shop to the field. Fully transportable, this tool cuts 1-inch to 12-inch pipe up to a ½-inch wall thickness.

Designed for versatility, the Pipe Saw is configured to cut steel and stainless steel and with a quick switch to one of the optional blades it can cut plastic and cast steel. Eliminating the need to struggle with gas tanks, open flames, or handle loose tools, the Pipe Saw secures to the pipe with a rugged 3-point roller system that sets up and cuts up to 12-inch pipe in minutes.

Conveniently placed handlebars and feed rate speed monitoring with LED interface enable easily controlled rotation from a comfortable, ergonomic position. Built-in handles and dedicated cord wrap provide easy

portability.

“Since introducing the RIDGID B-500 Transportable Pipe Beveller a few years ago, RIDGID saw a need for a portable cutting solution…Pipe Saw is the answer and ideal complement,” said Larry Feskanich, senior global marketing manager, pipe fabrication, RIDGID for Emerson. “The speed and efficiency in making quality cuts, paired with its ergonomic and easily transportable design, make the RIDGID Pipe Saw an ideal cutting solution.”

The Pipe Saw comes backed by the RIDGID full lifetime warranty.

To purchase or learn more about the Pipe Saw, contact your local distributor, visit RIDGID.com, or call toll-free: 1-800-4RIDGID.

By Mike Fowler, Application Specialist and Jeffrey Stewart, Technical Sales Engineer, with Kano Laboratories Anyone who works with exposed ferrous metal (iron or steel) knows it’s going to rust. It’s a fact of life and science. Even rock star Neil Young knows rust never sleeps. All it takes is metal exposure to oxygen, water, or Read more

By Mike Fowler, Application Specialist and Jeffrey Stewart, Technical Sales Engineer, with Kano Laboratories

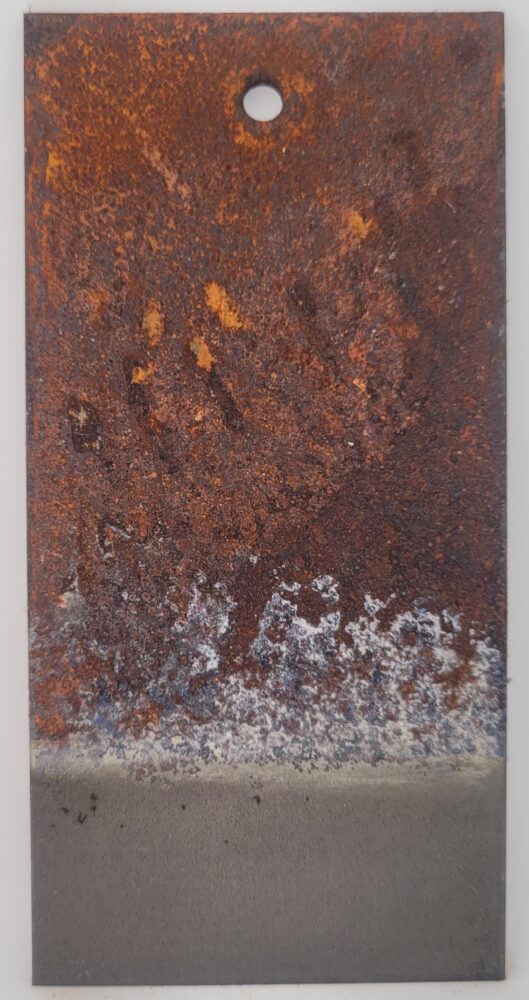

Anyone who works with exposed ferrous metal (iron or steel) knows it’s going to rust. It’s a fact of life and science. Even rock star Neil Young knows rust never sleeps. All it takes is metal exposure to oxygen, water, or humidity. It’s the enemy of steel and iron, causing damage and deterioration.

In the industrial workplace, there are several factors to consider and questions to ask when choosing to remove rust versus replacing metal parts and machinery.

- has the part been structurally weakened?

- is the surface so pitted that it is impractical to apply coatings?

- what is the availability and/or cost of the replacement part?

- how practical is removing the rust?

- what methods are available for rust removal?

- how much time is available for rust removal?

Most rust removers are used in automotive where old vehicle restoration is taking place. Rust remover around fender wells and lower body panels where road salt and other materials have corroded are most common. Rust must be stopped and removed before paint process begins.

Outside equipment needs rust remover before any repaint begins. Inside equipment that is exposed to moisture can develop rust on surfaces. For example, a shaft that needs a bearing removed and the exposed metal has rusted, causing a problem in bearing removal.

Any outside or inside Heating, Ventilation and Air Conditioning that is rusty and can hinder the operation or outside surface rust might need rust remover where sanding or steel brushes will not remove the rust.

Which method to use

Phosphoric acid is an effective and efficient rust removal agent. It cleans the iron or steel parts by chemically reacting with the rust and converting it to water soluble components. These components remain in the liquid solution which is easily washed away leaving the iron/steel surface clean and ready for use or for application of any type of coating to prevent further rust formation.

For heavy rust, soaking parts in a liquid rust remover is the most effective. Kano Laboratories developed a product called Exrust, whose active ingredient is phosphoric acid, to penetrate and chemically react with iron oxide, quickly removing it. It’s versatile in that it’s effective on all ferrous metals without damaging the base metal. Exrust may be used to remove other metal oxides but must be used with extreme caution as it will react with and dissolve base metals such as aluminum and copper.

There are also mechanical methods to remove rust that involve sandblasting or grinding it off. Depending on the work area, the dust and debris from sandblasting may not be possible. Grinding can create sparks and isn’t an option in a flammable area. Some of the equipment may be too delicate to use a grinder or sandblast. Mechanical means remove base metal which could weaken or damage parts, even putting holes in them.

For lightly rusted equipment, consider brushing on a rust remover. Following all safety protocols, the product will remove light surface rust. The now rust-free surface needs to be thoroughly rinsed with water and dried with a cloth. After treatment, consider applying a protective coating.

What maintenance pros look for in an industrial rust remover

- Performance – how well does it work? If you are looking for a clean surface for a part’s or tool’s performance, to meet a cleanliness requirement for a coating or lining, or purely for aesthetics, be sure that you are getting a rust remover that dissolves the rust away rather than a rust converter which just changes the rust to a more stable layer of iron oxide. These layers may inhibit further corrosion and may be suitable for some coatings and linings, but the buildup may interfere with moving mechanisms, be incompatible with some coatings and linings, and leave a visually unpleasant roughness.

- Ease of use and convenience – How difficult is it to use and how long does it take to get results? In choosing the right rust remover some products work best as a soak and some are designed with a jelly-like consistency to be applied to surfaces that are not capable of immersion. The soaks are most efficient and fastest when the entire surface to be cleaned can be immersed in the solution. Sometimes doing large parts takes some creativity to get the whole part immersed at one time. When using gels or soaks on surfaces that can’t be immersed, the cleaning process may be much slower because the amount of rust dissolved is proportional to the amount of active ingredient in contact with the surface. Soaks or low viscosity products can be used on areas by spraying the product on, letting it sit to have time to react with the rust and then scrubbing off. Smaller areas can be cleaned by covering with a thoroughly wetted cloth. Allow it to sit while the product reacts with the rust, then remove the rag, and scrub it off.

- Safe to use – The product label and safety data sheet (SDS) should give clear directions for proper use including personal protection equipment.The manufacturer should provide easy access to the SDS. Research the product to guarantee that it is compatible with material that is being cleaned. Know whether it will damage the base metal, paint or mar the finish of the component that is being cleaned, prior to use. Testing a small spot to see the effect of the rust remover prior to wetting the entire part may be a good idea. In rust removers, there is a certain performance tradeoff between acid-based products that have more inherent safety risks than chelating agents that are safer for the user.

- Speed / Efficiency – Before choosing a rust remover it is beneficial to identify the process by which the rust is removed. Acid based product’s speed of performance will be a function of the type of acid in the rust remover. Chelating agents tend to be a little slower than strong acids and may be faster than weaker acids like vinegar.

- Won’t damage the base metal – those who want to get rid of rust in a hurry may use strong acids like Muriatic Acid (dilute Hydrochloric Acid) or Sulfuric Acid, but these will dissolve the base metal as readily as the rust and great care is required lest the part you are trying to clean is damaged beyond use. Chelating agents will not harm the base metal but may not be as fast or thorough enough. A good middle ground is a Phosphoric Acid based product that properly designed will provide quick dissolving of the rust with no risk of base metal damage.

- Cost Effectiveness – An advantage of products designed as a soak is their ability to be reused. Kept in a reusable container, the soak may be used several times before the active ingredient is used up. For products designed as gels, they are a single use and when wiped or washed away are gone even if only a small portion of the active ingredient was used.

- Availability – Products that are American-sourced and made, like Exrust, increase the chance that the product will be there when you need it. Look for multiple distributors or outlets to increase product accessibility.

Mike Fowler is the Application Specialist at Kano Laboratories based in Nashville, Tennessee. He conducts distributor training on all Kano products. Fowler has more than 32 years in territory sales management with 16 of those years in industrial chemicals and lubricants.

Jeffrey Stewart is Technical Sales Engineer at Kano Laboratories based in Nashville, Tennessee. He has over 40 years of experience in chemical production and sales. Stewart graduated from the University of Pittsburgh with a BS in Chemical Engineering and obtained a PE license in the state of Ohio.

RIDGID, part of Emerson’s professional tools portfolio, introduces the smallest and lightest press tool on the market, the RP 115 Mini Press Tool. Designed for residential and lightweight commercial plumbing use, it completes the majority of press connections installed in the market with ease, while getting professionals to their next job faster. Engineered with the Read more

RIDGID, part of Emerson’s professional tools portfolio, introduces the smallest and lightest press tool on the market, the RP 115 Mini Press Tool. Designed for residential and lightweight commercial plumbing use, it completes the majority of press connections installed in the market with ease, while getting professionals to their next job faster.

RIDGID, part of Emerson’s professional tools portfolio, introduces the smallest and lightest press tool on the market, the RP 115 Mini Press Tool. Designed for residential and lightweight commercial plumbing use, it completes the majority of press connections installed in the market with ease, while getting professionals to their next job faster.

Engineered with the quality and technology that have kept RIDGID first in pressing for decades, the RP 115 can press 1/2-inch to 3/4-inch copper and stainless steel fittings. It is 14.6 inches long, 2.5 inches wide and weighs only 5.5 pounds with battery and jaws. The RP 115 has a SlimGrip handle and optimized trigger for balance and control; one-handed jaw opening and operation for reach and ease of use; and 210-degree head swivel for access to tight spaces.

Visit RIDGID.com for more info.

MILWAUKEE, WI – Milwaukee Tool has officially introduced the M18 PACKOUT Six Bay Rapid Charger. With the ability to rapid charge two batteries simultaneously, this new solution can charge six M18 REDLITHIUM XC5.0 battery packs in just three hours, so users can get back to work quicker. “As our M18 system continues to expand, there is Read more

MILWAUKEE, WI – Milwaukee Tool has officially introduced the M18 PACKOUT Six Bay Rapid Charger. With the ability to rapid charge two batteries simultaneously, this new solution can charge six M18 REDLITHIUM XC5.0 battery packs in just three hours, so users can get back to work quicker.

“As our M18 system continues to expand, there is a growing need for a portable, multi-bay, fast charging solution,” said Kelli Semon, Product Manager for Milwaukee Tool. “We are excited to pair our charging technology with PACKOUT™ Modular Storage, delivering faster charging and increased portability, leading to our most versatile M18 charger yet.”

The new M18 PACKOUT Six Bay Rapid Charger can charge two batteries simultaneously at a rapid charge rate. Users can charge one battery at a time on each side of the charger, with charging then automatically moving sequentially to the next available battery as charging progresses. The increased charge speed reduces downtime spent waiting for batteries to charge, delivering more productivity with every charge. Full compatibility with the PACKOUT Modular Storage System provides an optimized solution for transporting and storing batteries on the jobsite. The USB-A port provides charging of personal devices such as phones, headlamps, and flashlights.

Milwaukee Tool is committed to driving toward a cordless jobsite by delivering innovative solutions that maximize productivity for users. The new M18 PACKOUT Six Bay Rapid Charger represents this commitment, providing reduced downtime and unmatched portability, allowing users to get more work done throughout the day.

Specifications

M18™ PACKOUT Six Bay Rapid Charger (48-59-1809)

- Charge Rate: Rapid

- Charge Type: Two-Battery Simultaneous

- Fully compatible with PACKOUT Modular Storage System

- M18 Ports: 6

- Power Source: AC

- DC Output: (1) USB-A Port: 5V/2.1A (10W)

*Batteries sold separately

For HVAC contractors, is an industrial-grade corrosion inhibitor, lubricant, and cleaner that prevents and removes rust, helping contractors to be significantly more productive, while improving equipment reliability and extending its lifespan. The corrosion inhibitor penetrates into metal parts to prevent rust and corrosion while forming a bond that repels water and other contaminants. The protectant Read more

For HVAC contractors, is an industrial-grade corrosion inhibitor, lubricant, and cleaner that prevents and removes rust, helping contractors to be significantly more productive, while improving equipment reliability and extending its lifespan.

The corrosion inhibitor penetrates into metal parts to prevent rust and corrosion while forming a bond that repels water and other contaminants. The protectant goes on wet and dries in place. A shield-like film coating protects equipment against the effects of moisture and corrosion, including coastal salt air. This helps to ensure HVAC equipment reliability and prolongs its usable life.

As a lubricant, the fast-acting, penetrating compound cuts through corrosion, rust and dirt, quickly getting into metal parts that have become frozen or encrusted to get them working again. It contains synthetic-based additives that act like microscopic ball-bearings to reduce friction, facilitate maintenance and improve operation.

Dealers wanted: For more info, call 678-883-3578; visit www.force5products.com; or write to Force5 Products at 3434 Howell St. NW, Suite B, Duluth, GA 30096.