OSHA’s Crystalline Silica Standard will be in effect September 23, 2017. OSHA is issuing the standard to protect workers from exposure to respirable crystalline silica in the construction industry in order to allow employers to tailor solutions to the specific conditions in their workplaces. The new standard has had tool manufacturers working overtime to engineer Read more

ProStaff Reviews

OSHA’s Crystalline Silica Standard will be in effect September 23, 2017. OSHA is issuing the standard to protect workers from exposure to respirable crystalline silica in the construction industry in order to allow employers to tailor solutions to the specific conditions in their workplaces.

The new standard has had tool manufacturers working overtime to engineer tools and too attachments that will keep us productive while meeting the dust collection requirements. Here at The Hub we will be sharing reviews and information in the coming days and weeks leading up to September 23 date showing the various tools and attachments you might consider for your own compliance. Here is our first review:

https://youtu.be/mWLfwgkPLCc

Bosch HDC100 Dust Collection Attachment

Bosch knows concrete and the tools needed to work efficiently and effectively on the plumbing & hvac job site. Whether you’re working with a Bosch Bulldog rotary hammer or nearly any other modern rotary hammer of another brand this attachment is simple to install and use and is priced right in our opinion.

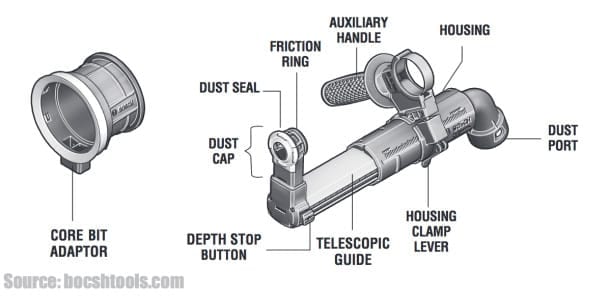

We’re referring to the HDC100 as a “universal” attachment, though it’s not listed as such on Bosch’s website it will fit any modern rotary hammer with a barrel mounting neck for a standard auxiliary handle (see pic above).

We’re referring to the HDC100 as a “universal” attachment, though it’s not listed as such on Bosch’s website it will fit any modern rotary hammer with a barrel mounting neck for a standard auxiliary handle (see pic above).

The 1.5lb composite plastic dust collection attachment has a built-in depth stop with a maximum drilling depth of 4-3/4” and can handle SDS drill bits up to ¾” diameter, dry core drilling up to 3-1/8” diameter [when using the core bit adapter, included].

As seen in the video the HDC100 is very effective at collecting nearly 100% of the dust from the ½” holes drilled for the drop-in anchors, an extremely common task on any mechanical job site. The dust port can be hooked up to a 1-3/8-In. vacuum hose nozzle, or it can accommodate 1-1/4-In. or 2-In. nozzles when combined with an appropriate optional adapter.

It is important to note that the HDC100 alone is not all that is needed for compliance with the OSHA standard. The HDC100 must be connected to a HEPA rated dust collector vacuum that meets the minimum requirements of the Crystalline Silica Standard to be compliant. In the video we are using the Bosch GBH18V-26 18V EC Brushless 1 In. SDS-plus® Bulldog Rotary Hammer and Bosch VAC090A 9 Gallon Dust Extractor with Automatic Filter Clean.

We have done some online price searches and found that nearly all Bosch tool retailers are listing the HDC100 at $69-70 US, its available for purchase currently.

This is only one of many tools Bosch has engineered to meet the OSHA standard, please watch for reviews of additional tools soon here on mechanical-hub.com.

It’s been two months since I took delivery of the Dewalt DCE200 press tool and I’ve had the opportunity to put it to work on a handful of jobs now. This is a feature-packed tool unlike many on the market today. With capabilities of handling any and all press systems common in North America and Read more

It’s been two months since I took delivery of the Dewalt DCE200 press tool and I’ve had the opportunity to put it to work on a handful of jobs now. This is a feature-packed tool unlike many on the market today. With capabilities of handling any and all press systems common in North America and Europe team Black & Yellow pulled out all the stops in engineering their first at what I’m guessing will be a team of press tools to come.

It’s been two months since I took delivery of the Dewalt DCE200 press tool and I’ve had the opportunity to put it to work on a handful of jobs now. This is a feature-packed tool unlike many on the market today. With capabilities of handling any and all press systems common in North America and Europe team Black & Yellow pulled out all the stops in engineering their first at what I’m guessing will be a team of press tools to come.

First off I’d like to cover the important specs.

- Capable of pressing ½”-2” copper & stainless steel V-groove fittings

- Compatible with competitor jaw sets for Iron Pipe [Mega-Press]

- Compatible with competitor jaw sets for PEX press [Viega/Nibco]

- 4-ton pressing force

- Current online pricing searches average $1999.00

I first learned of this tool back in July/August of 2016 at the annual new tool event hosted by Dewalt. When I first put my hands on it I admit I was a little surprised of the physical size overall but after using it for both boiler and tankless water heater installations now I can honestly say the size of the tool has not proved to be an issue at all. Weighing in at 7.16lbs without a jaw it is lighter than other comparable tools common on the job today. Ergonomics may be a slightly different story and I do carry a bias toward in-line design press tools. This tool is front-end heavy, loaded with anything over 1″ jaws and it will not stand on it’s own. That may be partially due to the small footprint of the 20V battery or the handle angle and placement. Either way its a strain on the wrist and requires two hands to steady the tool most of the time.

Features

This pistol-grip press tool is packed with some new innovation to the market that should prove useful to many contractors working on commercial & residential projects alike. Notably, Dewalt’s proprietary software system Crimp Connect. This free software download allows the owner/user to connect the press tool via the onboard mini USB port providing ability to print detailed reports of the date, time, force, and successfully completed cycles of the presses completed by the tool as well as the tools calibration and service history.

Located on the top rear of the tool you’ll find a somewhat familiar interactive panel where the tool’s power is controlled along with LED light indicators showing the successful completion of a single press, battery indicator, low & high temperature warnings. There’s even a “service required” indicator light telling the user that the tool has reached the cycle limitations.

Located on the top rear of the tool you’ll find a somewhat familiar interactive panel where the tool’s power is controlled along with LED light indicators showing the successful completion of a single press, battery indicator, low & high temperature warnings. There’s even a “service required” indicator light telling the user that the tool has reached the cycle limitations.

While the power panel is not unique to press tools of this caliber, the Crimp connect feature is. An added feature I found interesting is the double trigger.

The bottom trigger controls the start and completion of the press cycle. Dewalt went with a “manual” cycle operation here. You’ll need to depress the trigger completely for the duration to complete the press cycle. Cycle time is anywhere between 4-6 seconds depending on the diameter and type of material being pressed. The unique second trigger, the top trigger can be used to release the press cycle at any point. This is useful when a cycle has started but the operator decides [far various reasons] to stop the press. When pressed fully, the top trigger will release the pressure in the hydraulic cylinder and allow the ram to retract quickly. This would allow for repositioning of the tool or fitting when needed, potentially saving a fitting from incorrect attachment to the piping.

The bottom trigger controls the start and completion of the press cycle. Dewalt went with a “manual” cycle operation here. You’ll need to depress the trigger completely for the duration to complete the press cycle. Cycle time is anywhere between 4-6 seconds depending on the diameter and type of material being pressed. The unique second trigger, the top trigger can be used to release the press cycle at any point. This is useful when a cycle has started but the operator decides [far various reasons] to stop the press. When pressed fully, the top trigger will release the pressure in the hydraulic cylinder and allow the ram to retract quickly. This would allow for repositioning of the tool or fitting when needed, potentially saving a fitting from incorrect attachment to the piping.

A shoulder strap and ring attachment point are included with the tool. Dewalt states in the manual that it should be used for transporting the tool on the jobsite. Some feedback I have received from other plumbers is the strap may be useful when working on a ladder, a situation that often lends to the possibility of dropping a tool like this….I’ve done that and it wasn’t pretty.

The tool is made in France but the jaw set is delivered to Dewalt from Germany. Dewalt is offering a 3 year limited warranty, 1 year service and 90 day money back guarantee. You’ll most likely have to order this tool from specialty tool suppliers offering the whole Dewalt lineup. You can also look to plumbing and mechanical supply houses for stock as well.

https://www.youtube.com/watch?v=WVIlalA-Abs

https://www.youtube.com/watch?v=_b-m69_obcM I have to be honest. I don’t normally stand around in 4”-5” of water on the job. I do however walk through unplowed driveways, parking lots and through the rain while moving tools and equipment in and out of the truck so having dry feet is paramount to capping off a good day at Read more

https://www.youtube.com/watch?v=_b-m69_obcM

I have to be honest. I don’t normally stand around in 4”-5” of water on the job. I do however walk through unplowed driveways, parking lots and through the rain while moving tools and equipment in and out of the truck so having dry feet is paramount to capping off a good day at work.

I’ve been wearing the KEEN Utility Pittsburgh boots for work [and play] for a couple months now and I’m impressed not only with the KEEN.DRY system but the comfort and support has surpassed my expectations. For those not familiar, the KEEN.DRY system is a proprietary waterproof membrane that lets vapor out without letting water in. I’d put it up against the major brand of waterproofing we’re all familiar with.

The support and protection built-in include full-length TPU stability plate providing forefoot flexibility and underfoot stability; when mated with the metatomical footbed design where an engineered arch support cradles your foot for all day comfort.

The support and protection built-in include full-length TPU stability plate providing forefoot flexibility and underfoot stability; when mated with the metatomical footbed design where an engineered arch support cradles your foot for all day comfort.

I’ve been a longtime wearer of natural leather upper boots so moving into a composite build boot of natural leather and cloth took a little getting used to. Boots like the Pittsburgh are slightly bulkier than the typical all-leather boot but that has more to do with the engineering in design for flexibility and durability. Rubber, cloth, nubuck leather all play a role in the upper build of the boot.

The soles are non-slip oil resistant rubber and provide aggressive traction on this model. I’m more accustomed to a less “off-road” tread but I haven’t found anything negative to say about the tread pattern; if I have any comments on the tread I’d say climbing my step ladder is where I most notice the aggressive pattern. Once in a while my foot will catch on the edge of a ladder rung where it may not have with a smoother, more typical work boot tread pattern.

Overall I’m impressed with the KEEN Utility Pittsburgh boots. Material quality is very high, build quality as well. Comfort concerns went straight out the window after day one of wear and have not changed in the short time I’ve been putting them to work. I’ve got my eye on a few other models that may be a little closer to what I’m used to for style and features but, these being the most popular model in the US [in Canada they’re known as the Hamiltons] I’m not surprised based on the overall quality and design.

Overall I’m impressed with the KEEN Utility Pittsburgh boots. Material quality is very high, build quality as well. Comfort concerns went straight out the window after day one of wear and have not changed in the short time I’ve been putting them to work. I’ve got my eye on a few other models that may be a little closer to what I’m used to for style and features but, these being the most popular model in the US [in Canada they’re known as the Hamiltons] I’m not surprised based on the overall quality and design.

Click this link to visit KEEN’s site and see more about the Pittsburgh boots.

Innovation takes on many forms, but in the world of plumbing and HVAC piping systems, change and or progress has been somewhat slow to take place. Copper press fitting systems have been on the scene for nearly 20 years in the U.S., even longer in Europe, but industry-wide adoption is a work in progress. If Read more

Innovation takes on many forms, but in the world of plumbing and HVAC piping systems, change and or progress has been somewhat slow to take place. Copper press fitting systems have been on the scene for nearly 20 years in the U.S., even longer in Europe, but industry-wide adoption is a work in progress. If you’ve been following us here on The Hub you already know my opinion that pressing copper or iron pipe for nearly every application is not only efficient but also profitable for any size contracting firm. But I’m not here to debate the merits of press versus soldering or threading; instead, I’d like to talk about a couple new tools we’ve had in the shop for review.

The new Gorilla™ pressing tool line features two unique tools: the inline battery pressing tool (INLNPRESS-KIT19kN) and the pistol grip battery powered pressing tool (PSTLPRESS-KIT32KN). I’ve personally put both tools to work on a handful of plumbing and heating projects over the last month, and I’m impressed.

Not unlike other press tools in the market the Gorilla press tools will complete a watertight connection, whether pressing copper, steel or PEX, with a 3-5 second cycle time. Here are the features of each tool kit broken down separately:

The larger of the two Gorilla press tools is capable of pressing up to 2″ copper or steel fittings with the included tongs/jaws. When equipped with compatible jaws such as the RIDGID XL-C or Milwaukee M18 ring sets the pistol tool is capable of joining 2-1/2″ thru 4″ copper and steel. Greenlee offers additional factory supplied jaw sets for PEX Press systems (NIBCO) as well.

The key here is jaw compatibility. For contractors who already own other press tools or for those looking at a new press tool as a first purchase knowing what tool is right for you based on its capabilities should be the focus. The PSTL tool is compatible with all of the Viega PROPRESS copper, stainless and iron pipe (MEGAPRESS) fitting systems when either using the Greenlee jaw sets for 2″ and smaller copper or the RIDGID or Milwaukee M18 jaws for XC copper fittings or MEGAPRESS. A list of compatible jaw sets is included at the bottom of this review.

The PSTL-KIT32kN kit includes six V-profile copper/steel press jaws in sizes from 1/2″ to 2″, two 3.0Ah 18V Makita battery packs, rapid battery charger and heavy duty case with foam tool organizer insert. The 7,200 lb (32kN) force is delivered to the jaw set at the end of the swivel shaft. The unique pistol-grip offers an ergonomic design, placing the majority of the weight directly over the users hand and wrist for more balanced control when using the large diameter jaws. A single trigger deploys the hydraulic piston for a 3-5 second press cycle but is not automatic, requiring the user to fully depress the trigger for the entire cycle. However, once the press is complete, the tool retracts automatically, which does not require the operator to hold the trigger. In addition, the tools have the ability to retract the jaws at any point in time. An indicator light illuminates if the tool senses insufficient force during a press cycle and AUTOSTOPP technology stops the piston once optimal force is reached to complete the press of a fitting. The tool carries a 5-year warranty from the manufacturer and boasts the ability to go 40K press cycles before factory authorized service is required.

Inline Press (INLNPRESS-KIT19kN)

This is the more compact tool of the Gorilla lineup. Measuring in at just over 17″ when geared up with the 3/4″ copper jaws this swivel shaft tool is sleek and capable of sitting in tight spaces where only one hand may be appropriate for tool operation. The 4,275 lb (19kN) force tool features a single trigger, swivel head and 18V Makita 2.0Ah 18V battery.

The inline tool is capable of pressing both PEX press [up to 1-1/2″, see video] and v-profile copper/steel fittings (Viega type) up to 1-1/4″ diameter making it prime for all residential applications. As with the pistol tool the inline tool carries a 5-year manufacturer warranty and is capable of pressing 40K times in between service intervals. Press cycle time is 3-5 seconds depending on fitting type and diameter. The user is required to depress the trigger for the entire press cycle until the AOTOSTOP technology feature senses sufficient force, the piston retracts automatically the same as the pistol tool. The kit includes two Makita 18V batteries, rapid charger and heavy duty case with rigid foam organizer insert.

Recap

Overall the build quality of the Greenlee Gorilla press tools is high. Having been manufactured in Germany by the Greenlee owned Klauke tool company they’re developed from years of pressing experience and thousands of tools having been in use for many years. The 5-year warranty is impressive and compatibility with other manufacturer jaw sets makes both models very attractive in my opinion. Current jaw offerings open these tools up to the popular Sporlan Zoomlock refrigeration press fitting system as well even further expanding the capabilities and usefulness of these tools to HVAC contractors as well as plumbers. The Inline tool kit should be expected to price out between $2,100-$2,300, the more capable pistol tool will cost a contractor $3,300-$3,500 for the kit making both tools competitive in the press tool market.

https://www.youtube.com/watch?v=z9SXJYzzIGw

https://www.youtube.com/watch?v=Cys2STrvtRc

Are you ready to ditch the gas can and forever say goodbye to pesky 2-stroke engines that, for no matter how hard you try, never seem to run right come springtime? The big three tool manufacturers have hit the summer of 2017 running with cordless string trimmers, blowers, hedge trimmers and even chainsaws that operate Read more

Are you ready to ditch the gas can and forever say goodbye to pesky 2-stroke engines that, for no matter how hard you try, never seem to run right come springtime?

The big three tool manufacturers have hit the summer of 2017 running with cordless string trimmers, blowers, hedge trimmers and even chainsaws that operate on the same batteries you have in the shop or on the job.

Banking on the more power is better philosophy; these cordless yard machines are delivered with large capacity battery packs. The same batteries running high demand tools like right angle drills, rotary hammers and saws.

Whether you’re tired of finicky small engines or have better things to do with your time than make that last minute run to the gas station just so you can mix up a gallon or two to trim out the yard, these tools are definitely worth looking twice at.

Here is a quick rundown of my own experience with the Dewalt 60V, Milwaukee 18V and Makita 36V OPE. Watch for additional reviews as more tools are arriving weekly here at The Hub.

Milwaukee M18 FUEL String Trimmer

New product/tool design engineers are always tasked with designing the next best thing, the fastest or most powerful tool that will turn heads and ring in sales. One guiding principle in design is the “KISS” method. Standing for “keep it simple stupid” but it’s not necessarily a negative connotation in the final production model of the M18 string trimmer.

With a simple safety locking throttle trigger, high/low speed selection and a single 9.0Ah battery pack this trimmer is as simple as it gets. Oh yeah, and its extremely powerful. The 14”-16” cutting swath and straight shaft are perfect for clearing thick overgrowth or manicuring your 9th hole-like lawn.

With a simple safety locking throttle trigger, high/low speed selection and a single 9.0Ah battery pack this trimmer is as simple as it gets. Oh yeah, and its extremely powerful. The 14”-16” cutting swath and straight shaft are perfect for clearing thick overgrowth or manicuring your 9th hole-like lawn.

I only wish my video turned out a little better but you’ll have to take my word for it, this 18V tool is a beast when considering power and runtime. You’ll want to have a 9.0Ah battery but you’ll only need one to finish your yard. I trim about an acre and can complete the job on about 2 bars.

Dewalt 60V MAX String Trimmer If you’re familiar with the new FLEXVOLT tool lineup from Dewalt then take a look at this trimmer. Running on a single 60V 3Ah FLEXVOLT battery, this cordless trimmer has a ton of power upfront and decent battery runtime. Motor placement is different than all the others in this category in that it’s placed directly at the head/end above the line spool. Like the other two here the 60V MAX uses full-sized trimmer line, which absolutely rocks when comparing these trimmers to early models of electric/cordless trimmers. I have run this trimmer thru some pretty tough paces and have been thoroughly impressed with its power. I’m a little concerned with the amount of debris buildup on the motor housing but I believe most of that is from using it to clear heavy overgrowth in the field out back. Typical yard usage would likely not cause such buildup and therefor not pose a problem to the motor itself.

Makita 36V String Trimmer

If you’ve got a couple Makita 5Ah batteries and enjoy a tool truly designed with the user in mind then look no further.

The Makita XRU09 string trimmer has an outer rotor brushless motor direct drive system which provides for high power and high torque. The engineers included nearly all the bells with this one giving it two speeds and even reverse. You might be wondering “why reverse” and the answer is simple really. When clearing tall grass or weeds in heavy overgrowth areas the head of any trimmer will likely be wrapped up over time; the reverse rotation setting allows for quick clearing of the trimmer head and in my opinion that simple genius in design. They added a switch and circuitry to run the motor backwards for a short duration, why didn’t the others do that? I personally like the ergonomics of this trimmer best. Its also smoother and powerful enough to handle all my trimming needs over nearly and acre of yard and landscaping. Videos are still in the making.