Danfoss, a leading global supplier of technologies for HVAC/R, will exhibit their broad portfolio of solutions to help their customers reach decarbonization goals at the annual AHR Expo, January 21-23, the premier annual event for the HVAC/R industry. With an expected 50,000 attendees and 1,600 exhibitors, the event provides an invaluable opportunity to showcase the company’s technologies Read more

Product News

Danfoss, a leading global supplier of technologies for HVAC/R, will exhibit their broad portfolio of solutions to help their customers reach decarbonization goals at the annual AHR Expo, January 21-23, the premier annual event for the HVAC/R industry. With an expected 50,000 attendees and 1,600 exhibitors, the event provides an invaluable opportunity to showcase the company’s technologies that enable customers to build energy-efficient heat pumps, data centers, rooftop units, Dedicated Outdoor Air Systems (DOAS), chillers and food retail refrigeration systems. Reflecting the growing push toward decarbonization, Danfoss HVAC/R solutions offer robust and energy-efficient performance to end users looking to reduce carbon emissions along with their energy and maintenance expenses.

On display will be the newest technologies, including the BOCK 6-cylinder CO2 compressor, its accompanying CO2 condensing unit, Turbocor compressors, the iC2 Micro family of drives and the EC+ technology for HVAC drives. Booth visitors will be able to see demonstrations of Alsmart and Alsense, Danfoss’ automation solutions for building HVAC systems and food retail, respectively. A feature this year will be a Lego-sized model of a Smart Store, utilizing the latest energy-efficient and low-carbon food retail solutions. Visitors to the booth will have the opportunity to enter to win a set of Legos by snapping a selfie next to the Smart Store display, posting the photo on LinkedIn and tagging the Danfoss North America page.

On display will be the newest technologies, including the BOCK 6-cylinder CO2 compressor, its accompanying CO2 condensing unit, Turbocor compressors, the iC2 Micro family of drives and the EC+ technology for HVAC drives. Booth visitors will be able to see demonstrations of Alsmart and Alsense, Danfoss’ automation solutions for building HVAC systems and food retail, respectively. A feature this year will be a Lego-sized model of a Smart Store, utilizing the latest energy-efficient and low-carbon food retail solutions. Visitors to the booth will have the opportunity to enter to win a set of Legos by snapping a selfie next to the Smart Store display, posting the photo on LinkedIn and tagging the Danfoss North America page.

Also on display will be the new DSG compressor, winner of the Expo’s Innovation Award in the Cooling category. The DSG is specifically designed for low pressure, low GWP (global warming potential) refrigerants and provides chiller systems with a wide range of compressor capacities to support unit design requirements. It showcases Danfoss expertise in helping its customers make the transition to environmentally friendly refrigerants as HFC phasedown continues. As an award category winner, the DSG compressor is a finalist for Product of the Year, which will be announced at the Expo.

“Danfoss innovation in decarbonization and energy efficiency will be on full display at the Expo,” said Rick Sporrer, president of Danfoss North America. “With our broad portfolio of solutions, we have the expertise needed to become our customers’ preferred decarbonization partner. We are looking forward to highlighting our latest solutions and sharing our insights with the industry.”

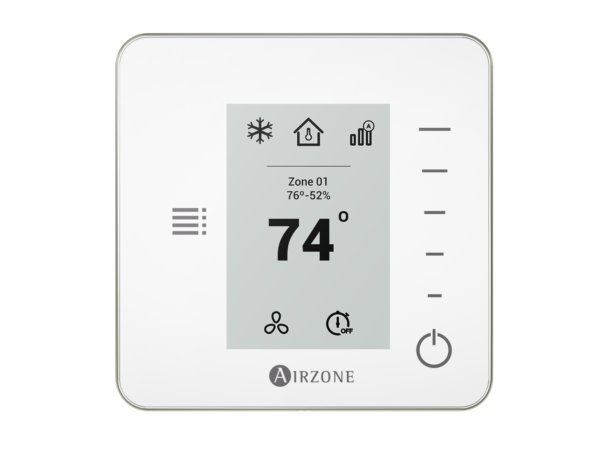

Aidoo Pro integration with Nest thermostats ushers in a new era of Inverter/VRF HVAC control and interoperability. Airzone Control, provider of HVAC solutions for zoning, automation and smart control, announces a revolutionary new integration with the full portfolio of Nest™ thermostats. The integration between the Airzone Aidoo Pro and Nest smart thermostats (Nest Thermostat™ and Nest Read more

Aidoo Pro integration with Nest thermostats ushers in a new era of Inverter/VRF HVAC control and interoperability.

Airzone Control, provider of HVAC solutions for zoning, automation and smart control, announces a revolutionary new integration with the full portfolio of Nest™ thermostats. The integration between the Airzone Aidoo Pro and Nest smart thermostats (Nest Thermostat™ and Nest Learning Thermostat™) enables seamless bi-directional communication between the Inverter/VRF and mini split HVAC units that are soaring in popularity.

Two Expanding Categories, One Growing Problem

The Inverter/VRF solutions market is expected to reach $31.9 billion by 2025, with a CAGR of 12.7 % between 2021 and 2025. The global smart thermostat market is expanding in parallel and expected to triple by 2028 as more users gravitate towards innovative solutions that provide control over a critical component of indoor spaces: heating and cooling. While these are two of the fastest-growing categories in the HVAC industry, there is a costly roadblock.

The core problem stems from these two technologies developing and evolving in insolated environments. These systems fail to communicate complex instructions effectively due to inadequate two-way communication. Without a solution in between, Inverter/VRF and mini split solutions deployed with a smart thermostat are incompatible. The resulting communication breakdown between the two forces the HVAC system to revert back to single-speed operations, undermining the full potential and sophisticated features of the system.

Simplified, smart thermostats and HVAC unit speak different languages. Since Inverter/VRF and mini split HVAC systems are traditionally adjusted by means of their own communication protocol, and the output for the smart thermostat is a dry contact closure, the full picture is never effectively communicated back to the heating/cooling system and critical information is missing. Within this scenario, the smart thermostat is unable to provide information about how hard the system should be working or the deviation from the desired set point temperature. As a result, the system cannot modulate output to precisely match the temperature needs of an environment, and the air handling unit (AHU) becomes forced to operate at maximum capacity, creating inefficiency and discomfort.

The Solution Backed By Expertise

The Airzone Aidoo Pro is a simple-to-install system add-on that sits between the HVAC system and the Nest smart thermostat and serves as a conduit between the world of HVAC and IoT to preserve Inverter/VRF features, benefits, and functionality while meeting user demand for smart control.

Airzone’s exclusive library of manufacturer-certified HVAC protocols enables full bi-directional communication between the Aidoo Pro, the HVAC solution, and the Nest Thermostat or Nest Learning Thermostat. The Aidoo Pro receives smart thermostat data, interprets it, and then sends the appropriate commands to the Inverter/VRF or mini split unit via system specific, manufacturer-certified protocols. The Inverter/VRF solution continues to function at a variable rate, preserving the superior comfort and efficiency of the system.

Airzone has spent decades cultivating privileged working relationships with the industry’s leading HVAC Inverter/VRF and mini-split manufacturers. The Aidoo Pro has manufacturer-certified HVAC protocols from all leading brands, including Daikin, Fujitsu, Hitachi, LG, Mitsubishi Electric, and Panasonic. Now, with a dedicated integration with Nest, the industry’s most popular smart thermostat solutions can be connected to and properly control Inverter/VRF and mini split HVAC systems using the Aidoo Pro.

“Our integration with the Nest smart thermostats through Aidoo Pro represents an unprecedented leap forward for our industry,” said Antonio Mediato, founder, and CEO of Airzone. “This brings together two of the industry’s fastest growing sectors in a way that was previously thought impossible. With Nest as our valued partner, together we are setting a new standard for the industry and redefining what is possible in the world of HVAC and IoT.”

Both Airzone and Google Nest will be at the upcoming AHR Expo taking place in Chicago January 22-24, 2024. For the opportunity to learn more about the Aidoo Pro/Nest integration in person, be sure to visit Airzone at AHR Expo 2024 at booth S8659 and the Google Nest Pro team at booth N1549.

To learn more about Airzone, visit https://www.airzonecontrol.com/na/en/.

Google, Nest, Nest Thermostat, Nest Learning Thermostat, and related marks and logos are trademarks of Google LLC.

Airzone’s Inverter/VRF zoning solution reduces AHU demands, supporting ASHRAE 15 Compliance. Airzone Control, provider of HVAC solutions for zoning, automation, and smart control, will showcase their expanded Easyzone product line at AHR Expo, the essential event for HVACR industry professionals. This all-in-one zoning solution for concealed Inverter/VRF HVAC units is now compatible with the top Read more

Airzone’s Inverter/VRF zoning solution reduces AHU demands, supporting ASHRAE 15 Compliance.

Airzone Control, provider of HVAC solutions for zoning, automation, and smart control, will showcase their expanded Easyzone product line at AHR Expo, the essential event for HVACR industry professionals. This all-in-one zoning solution for concealed Inverter/VRF HVAC units is now compatible with the top seven leading manufacturers in the North American market, including Samsung, Daikin, Mitsubishi, LG, Toshiba, Fujitsu, and Hitachi.

Zoning is a powerful tool for engineers, contractors and owners in delivering decarbonization benefits to building designers, contractors and owners, while offering practical solutions that can help mitigate ASHRAE 15. Easyzone is Airzone’s uniquely effective plug-and-play zoning solution. There are compatible Easyzone prewired kits for all of the industry’s top providers, covering 90 percent of the North American market.

Easyzone by Airzone eliminates the need for bypass dampers, resulting in optimal energy savings. At AHR, the Airzone team will be showcasing projects from across the US and Europe that will demonstrate the efficiency results and ease of application and installation.

Leveraging Easyzone for ASHRAE 15 Compliance

The HVAC industry will navigate a complex minefield of efficiency incentives and regulatory changes over the next three years; zoning solutions will be essential to the industry’s future. The EPA has mandated a transition away from R-410A refrigerants to R-32. These newer, more climate-friendly refrigerants are far more volatile: To ensure system safety, ASHRAE Standard 15 will limit the amount of R-32 refrigerant each system may use. This leaves HVACR professionals with a paradox: how can they provide the same level of comfort from less powerful systems?

Easyzone is this answer. This solution allows HVAC engineers to use fewer and/or less powerful air handling units (AHUs) than an un-zoned solution. In addition, Airzone’s unique control board precisely adjusts the airflow and unit capacity, resulting in energy consumption savings of up to 30%.

Airzone leaders Borja Ferndandez and Victoria Garcia Massimo will offer additional guidance on navigating forthcoming regulations at the AHR session The No By-Pass Zoning Solution That Can Help Mitigate ASHRAE 15, scheduled for January 22, 2024 at 4:15 PM CT in Theater D. The presentation is free and open to all AHR attendees. This session will educate the design and construction community on simple, cost-effective zoning strategies for their next commercial or large residential project.

“The growth of Easyzone solutions comes at a pivotal moment,” says Antonio Mediato, CEO of Airzone. “As a global leader in innovative HVAC control systems with a headquarters in Spain, Airzone has already weathered the transition to R-32 refrigerant. Easyzone already enables engineers across Europe to deliver both superior comfort and compliant system designs. This is a proven solution North American engineers can rely on to effectively reduce the number of AHUs per project, supporting AHRAE Standard 15 compliance.”

Flexibility for Any Application

Easyzone offers the efficiency HVAC engineers will require for future designs – as well as the flexibility to integrate with practically any system. Easyzone is compatible with a broad range of fully programmable wired and wireless thermostats, and integrates with BMS such as BACnet and Modbus and home automation systems including Control4, Crestron, Lutron, ELAN, and Savant.

The full power of Airzone’s portfolio will be on display at AHR Expo 2024. Stop by booth S8659 for additional information, product demonstrations, or to connect directly with Airzone to learn more about how Easyzone can help you deliver efficiency and comfort with ease.

To learn more about Airzone, visit https://www.airzonecontrol.com/na/en/.

Inverter Ducted Split (IDS) Ultra Cold Climate Heat Pump and GreenTronic 7000T Hybrid Electric Water Heater among Bosch’s latest product offerings in 2024 Bosch Home Comfort (formerly Bosch Thermotechnology) is introducing two products for 2024 – the Inverter Ducted Split (IDS) Ultra Cold Climate Heat Pump and GreenTronic 7000 T Hybrid Electric Water Heater – Read more

Inverter Ducted Split (IDS) Ultra Cold Climate Heat Pump and GreenTronic 7000T Hybrid Electric Water Heater among Bosch’s latest product offerings in 2024

Bosch Home Comfort (formerly Bosch Thermotechnology) is introducing two products for 2024 – the Inverter Ducted Split (IDS) Ultra Cold Climate Heat Pump and GreenTronic 7000 T Hybrid Electric Water Heater – at the 2024 AHR Expo for HVACR industry professionals. Both systems support the industry shift toward electric solutions for home heating, cooling, and hot water.

“Decarbonization is a crucial step toward a healthier planet, and many homeowners are looking for ways to minimize their reliance on finite resources. With the introduction of these new products that we are excited to showcase at AHR 2024, Bosch Home Comfort is continuing to pave the path towards a cleaner energy future. We are driven as a company to continue innovating our technologies and offering solutions for consumers who want to reduce their carbon footprint without sacrificing comfort,” says Alexander Wuthnow, president and CEO of the Bosch Home Comfort Group in North America.

Warm Up Efficiently in Frigid Temperatures with Inverter Ducted Split (IDS) Ultra

Bosch’s latest heat pump makes energy-efficient home comfort accessible across almost all climate zones in North America. The IDS Ultra is the first Bosch air-to-air heat pump designed specifically for cold climates—even areas that experience sub-zero temperatures. Powered by Bosch inverter technology, the system can heat at 100 percent heating capacity down to an outdoor temperature of 5° Fahrenheit and will continue to initiate heating even down to -13° Fahrenheit.

Bosch’s latest heat pump makes energy-efficient home comfort accessible across almost all climate zones in North America. The IDS Ultra is the first Bosch air-to-air heat pump designed specifically for cold climates—even areas that experience sub-zero temperatures. Powered by Bosch inverter technology, the system can heat at 100 percent heating capacity down to an outdoor temperature of 5° Fahrenheit and will continue to initiate heating even down to -13° Fahrenheit.

The U.S. Department of Energy (DOE) confirmed that Bosch’s cold climate heat pump meets the requirements to progress from lab to field testing as part of the Residential Cold Climate Heat Pump Technology Challenge. The goal of the challenge is to advance the technology to allow consumers to make the switch to a cleaner energy future with less carbon emissions.

Anticipated to arrive on the market in late 2024, the IDS Ultra will be available in up to 5-ton capacities and eligible for a variety of state rebates and federal tax credits to support homeowners in their transition to electrified systems.

Additional features include:

- Highly efficient: up to 19 SEER2 and up to 10 HSPF2 (Region IV), 8.5 HSPF2 (Region V)

- 24,000 and 55,000 BTU/hr

- System can be set to communicating or non-communicating depending on site and application needs

- Accepts utility demand response events directly

- 10-years Residential Limited Warranty

Blend Efficiency and Comfort with GreenTronic 7000 T Hybrid Electric Water Heater

Bosch’s most efficient water heater to date integrates heat pump technology into an electric storage water heater to meet all hot water needs for the home. The result is the GreenTronic 7000 T–a water heater that boasts 3 to 4 times the efficiency of traditional electric storage water heaters, thereby

lowering running costs. Homeowners could also save up to $2,000 on the cost of their installation thanks to the 25C federal tax credit, with the potential to save more money through local rebates. The unit has four operational modes, is designed to meet Energy Star and NEEA Tier4, and will be offered in 50 and 80 gallon capacities.

Slated to launch in summer 2024, the GreenTronic 7000 T Hybrid Electric Water Heater is an ideal replacement for electric storage units and a great option for new construction as well.

Additional features include:

- Sleek design

- Demand response port: Allows more control for utilities (CTA-2045 port).

- Cools and dehumidifies installation Space

- Side connections for easier installation

- 10-years Residential Limited Warranty

Both the IDS Ultra and GreenTronic 7000 T will be on display at AHR 2024 at Bosch Home Comfort’s booth #S8188. For more information about Bosch Home Comfort’s full suite of product offerings, please visit www.bosch-homecomfort.us.

Trusted manufacturer empowers heating professionals with new robust, high-performing solutions designed to fit a wide range of applications Bradford White Water Heaters, an industry-leading manufacturer of water heaters, boilers and storage tanks, announces the release of its new Brute® XTR commercial boilers and volume water heaters. Brute XTR boilers and volume water heaters are available in Read more

Trusted manufacturer empowers heating professionals with new robust, high-performing solutions designed to fit a wide range of applications

Bradford White Water Heaters, an industry-leading manufacturer of water heaters, boilers and storage tanks, announces the release of its new Brute® XTR commercial boilers and volume water heaters.

Brute XTR boilers and volume water heaters are available in six sizes, ranging from 399 MBH to 1500 MBH, and deliver AHRI-certified thermal efficiency of 96-plus percent.

“With the Brute XTR, we’re offering an advanced solution that meets the high standards of heating professionals in the field and empowers them to deliver the high-performing, long-lasting products their customers need,” said Louise Prader, senior director of product management for Bradford White. “The Brute XTR was developed to ensure our professional customers have a robust, easily installed solution that fits a wide range of applications.”

The Brute XTR line-up features:

- A reliable stainless steel, low-pressure drop water tube heat exchanger

- Dual venturi combustion system for 10:1 turndown

- PVC, CPVC or PP venting materials

- Variable speed boiler pump

- Top gas and water connections and easy access service panels for flexibility in installation

- Convenient touchscreen control platform

For more information about Bradford White Water Heaters and the Brute XTR series of boilers and volume water heaters, visit www.bradfordwhite.com.