Around the time you start thinking about the rest of your life, Seth Michael was seriously considering becoming a police officer. “In high school, I took two years of criminal justice classes and thought I wanted to become a police officer. Toward the end of my senior year, I realized I didn’t have a passion Read more

Featured Articles

Around the time you start thinking about the rest of your life, Seth Michael was seriously considering becoming a police officer. “In high school, I took two years of criminal justice classes and thought I wanted to become a police officer. Toward the end of my senior year, I realized I didn’t have a passion for police work, nor was that what I wanted to do the rest of my life. By then I realized I wanted to work with my hands, and heard about Vincennes University and their welding degree. I took a leap of faith and entered their program,” says Michael, who graduated with a degree in welding technology in 2018.

Seth Michael

Michael’s first welding job out of college was with a company that was low paying and non-union. “I realized it was not a good career choice for me in the long run. That is when I started researching various trades in Northwest Indiana,” says Michaels, who is currently paving his career path as an apprentice welder at Vidimos Inc., a union sheet metal shop established in 1945 in East Chicago, Ind., a contractor member of the Sheet Metal and Air Conditioning Contractors’ National Association (SMACNA), and a member of Sheet Metal Workers Local 20.

A SMACNA-member contractor works on a welding job.

There are many benefits to joining the trade, says Michael. “Good starting wages with about a $2-an-hour increase every six months while in the apprentice program, finishing with a minimum hourly wage of $43 after five-year apprenticeship program.” Michael also highlights a good pension, 401A, and health insurance. “One of the most important benefits is that my union is there to represent and train me as a member of the Local 20, Sheet Metal Workers,” says Michael.

In addition to the invaluable training through the Local 20, Michael draws knowledge from SMACNA, of which his employer is a member. “Knowledge is powerful. Sheet metal work is creative and fast-paced with cutting-edge technologies such as material removal automation that are helping shape the future of the industry. It is important to stay at the forefront in order to grow in your career, but to also learn and practice in-demand skills that set sheet metal workers apart from other tradespersons,” says Jeff Henriksen, executive director of communications at SMACNA.

A sheet metal shop in Pittsburgh.

Making sure a job is professionally completed is critical and there are no better trained or skilled workers than the signatory sheet trade. “Every single worker on a SMACNA contractor’s jobsite is highly qualified, and they all received the same four years of training. That provides many general contractors, builders and developers with greater peace of mind,” continues Henriksen.

Michael loves that he is constantly learning while on the job and through the apprentice class. “I love the journeymen that I get to work with on a day-to-day basis, and the knowledge I gain from them. I get to see and do new things every day, and I can see myself in this trade until retirement.”

Refreshing to hear, for sure, especially with the aging workforce top of mind within the industry. “Workforce development initiatives like Ignite Your Career are a great opportunity to build awareness of rewarding career opportunities. It is important to attract and retain the best candidates, showing the valuable benefits of establishing a career in sheet metal—which is one of the highest salaried trades,” says Henriksen.

Refreshing to hear, for sure, especially with the aging workforce top of mind within the industry. “Workforce development initiatives like Ignite Your Career are a great opportunity to build awareness of rewarding career opportunities. It is important to attract and retain the best candidates, showing the valuable benefits of establishing a career in sheet metal—which is one of the highest salaried trades,” says Henriksen.

Ignite Your Career is one piece of SMACNA’s larger workforce development initiative designed to promote the advantages of working in the sheet metal industry and supporting our members in recruitment efforts. It stemmed from recognizing a need to address the aging workforce and it has been a continued priority for SMACNA. The site itself, IgniteYourCareer.com, launched earlier this year and is a valuable resource for supporting recruitment needs of our members and helping those interested in the trade learn more about career opportunities.

Related, SMACNA and SMART (the International Association of Sheet Metal, Air, Rail and Transportation Workers) jointly own and run more than 130 training centers across the country as part of a Registered Apprenticeship Program (RAP) that enables people to receive cost-free training while working in the industry. “The equipment in each training center may vary slightly by location, but to be a RAP, you have to register and have your national training program approved by the Department of Labor. This provides our members who graduate with the ability to take their skills anywhere in the country and be qualified to work for SMACNA Contractors,” says Henriksen.

A SMACNA contractor asks questions regarding the robotic equipment.

All the apprenticeship programs allow people to enter the sheet metal trade, earn while they learn and leave debt-free with opportunities to grow their career and earn a great living. Typically, apprenticeship programs see 15,000 people in the apprenticeship program at any one time. “Upon graduation, they become a journeyperson, earning around $90,000 per year, after serving as an apprentice for four to five years during which time they earn more than $250,000—a substantial difference from those that choose the college route and end up in debt with no guarantee of a well-paying job,” says Henriksen.

For Michael, he continues to work on his apprenticeship, even through COVID. “Thankfully, I have been working throughout COVID, and although work has been slow here and there, I’ve been maintaining a regular work schedule of 40 hours a week. With little social opportunities outside of work, I’ve been able to be more focused on my apprentice class and my tasks at work,” says Michael.

SMACNA is an association of Signatory sheet metal contractors, so if a sheet metal contractor wants to become a union shop, they are welcome to contact the association to begin that process. Those interested in the apprenticeship program can contact the International Training Institute (ITI) jointly run by SMACNA and SMART. Call SMACNA at 703-803-2980 or email memberservices@smacna.org. Call ITI at 703-739-7200 or visit https://www.sheetmetal-iti.org/.

The Drain, Waste and Vent (DWV) piping system in a building is a crucial component of the overall plumbing infrastructure. In a building, the Drain, Waste and Vent (DWV) system is an often overlooked, yet it is an essential component of the plumbing infrastructure. The majority of DWV piping systems are hidden below floors, behind Read more

The Drain, Waste and Vent (DWV) piping system in a building is a crucial component of the overall plumbing infrastructure.

In a building, the Drain, Waste and Vent (DWV) system is an often overlooked, yet it is an essential component of the plumbing infrastructure. The majority of DWV piping systems are hidden below floors, behind walls, and in ceilings. Out of sight, out of mind. That is until your previously fully functional plumbing system has a problem.

Plumbing may be out of sight, but just like any other mechanical system, your DWV piping should be properly and regularly maintained, regardless of the material. Developing a DWV maintenance plan will keep your plumbing system top of mind. This will help facility management to budget effectively for your system maintenance and diminish the likelihood of plumbing emergencies that could send your building occupants reeling.

DWV System Evaluation

There is no one-size-fits-all maintenance program for DWV systems. Building occupancy type and usage, piping material, and other special conditions that are unique to your building requires evaluating your DWV systems as a first step.

Facility management can start by performing a regularly scheduled visual examination of the DWV system. You are looking for proper slope, appropriate support of the piping system and components, suitable venting and clear vents, and of course, any visible leaks in the piping system, among other things. Regular visual inspection is just one step in a larger effort to maintain your DWV system.

If your visual inspection reveals no obvious signs of wear and tear, do not assume that you are in the clear. Many factors outside of the DWV system can have negative effects on it and its long-term functionality. These factors are what are at the heart of the maintenance program. As conditions change, the frequency and the way you maintain your system should change with it.

Once you have completed your visual inspection, consider the risk factors that make your building unique. What are some of the considerations when determining the factors and frequency of your maintenance program?

- Cleaning chemicals Harsh cleaning chemicals having a pH range outside the normal range of expected sanitary effluents could be harmful to the DWV system, unless properly flushed.

- Grease Interceptors These should be serviced in accordance with manufacturer’s recommendations so as not to allow its contents to go septic. Proper disposal of food particles is key to the health of an interceptor.

- Gases from the municipal sewer Some municipalities depend on the building’s vent system to vent gases from the sewer, which can be harmful to the building vent piping because this is not the intended application. When these gases are in the system, regular flushing should be performed to minimize the impacts.

- Building usage Is the buildings occupancy year-round or seasonal? If usage is low, more frequent maintenance of the DWV system may be required.

- Low flow or no flow fixtures The proliferation of low flow and waterless fixtures for conservation have unintended consequences. Not enough water in the lines to self-scour or to float the proverbial boat leaves behind microbes that are potentially harmful to your piping system.

- Soda fountains Sodas are typically low pH fluids. In high concentrations, they can be detrimental to pipe and fittings, especially if they are not properly flushed through the system.

- Commercial kitchens High temperature fluids from pasta stations or commercial dishwashers can exceed the working temperatures of certain piping systems and lead to system failures.

- Special waste Any waste outside the scope of normal sanitary effluents should be treated as such, with piping approved for the materials that they are conveying. Any special chemicals must be properly diluted before being allowed in the city sewer.

- De-icing Agents De-Icing agents (road salts, sand and the like) used on roadways can accumulate in the DWV system in parking garages. This accumulation needs to be assessed and a maintenance schedule developed to flush and clean the system to the municipal sewer.

How To Maintain Your DWV System

There are countless tools available for you to incorporate into a facility maintenance program. Here are just a few:

- Camera inspection allows you to see inside your piping system and identify issues that would otherwise remain hidden until it is too late.

- Jetting, drain cleaning, cabling, or rodding to the municipal sewer are also effective methods for cleaning and clearing your DWV system.

- Solenoid may be installed to introduce water to dilute, wash or clean the DWV system where needed.

- Installing vented running traps to isolate the building’s DWV system from the city sewer will prevent your municipality from relying on your building to vent gases into the city sewer system.

- Follow the manufacturer maintenance recommendations of any dilution tanks the building may have.

- Identify and replace any aggressive cleaners that the building cleaning or maintenance personnel may be using with a neutral pH cleaning alternative.

- Consider installing upstream flush valves on soda fountain lines for proper dilution.

Many factors outside of the DWV system itself can have long-term effects on the system’s performance and functionality. Slope, system design, fixtures, frequency of use, chemicals and cleaners, maintenance, materials, and water levels and quality are just some of the factors that can affect a DWV system. All of these influences and more need to be examined and properly assessed by facility management when creating an effective plastic or cast iron DWV system maintenance program.

The information above is not meant to be a complete list of all factors that need to be considered and are merely suggestions for formulating a maintenance program. Proper flushing of your DWV system on a regular time schedule is crucial to a long service life. It may be necessary to consult a plumbing professional when designing an effective DWV preventative maintenance program to keep your plumbing system from being top-of-mind for all the wrong reasons.

How It Be with DannyG—I was curious. Could this third-person reference have anything to do with his burgeoning rap career? Or was it something else. I needed to find out. Referring to himself—tongue in cheek—as an old rapping plumber, turns out, “How it Be With DannyG” actually originated from a series of “how-to” videos—created for Read more

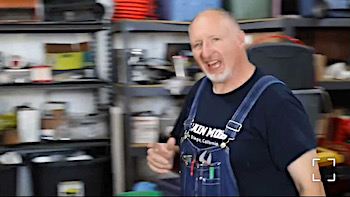

How It Be with DannyG—I was curious. Could this third-person reference have anything to do with his burgeoning rap career? Or was it something else. I needed to find out. Referring to himself—tongue in cheek—as an old rapping plumber, turns out, “How it Be With DannyG” actually originated from a series of “how-to” videos—created for a social media group and hosted on Youtube—aimed at helping other plumbers. Okay, got that solved, but why the rapping? At first glance, the rapping image is fun and refreshing, but as I dug a little deeper, Danny G the rapper is no joke, and something Danny Gronendyke takes very seriously. “I do take great pride in my rapping. It started in my freshman year of high school in the mid-80s. Someone at school started playing Run-DMC and I was hooked, and I have been listening and rapping ever since. I think it’s the rhyming that hooked me, and doing it to a beat was fascinating to me, and still is,” says Danny Gronendyke, owner, Gronendyke Plumbing Inc., Merrillville, Ind.

How It Be with DannyG—I was curious. Could this third-person reference have anything to do with his burgeoning rap career? Or was it something else. I needed to find out. Referring to himself—tongue in cheek—as an old rapping plumber, turns out, “How it Be With DannyG” actually originated from a series of “how-to” videos—created for a social media group and hosted on Youtube—aimed at helping other plumbers. Okay, got that solved, but why the rapping? At first glance, the rapping image is fun and refreshing, but as I dug a little deeper, Danny G the rapper is no joke, and something Danny Gronendyke takes very seriously. “I do take great pride in my rapping. It started in my freshman year of high school in the mid-80s. Someone at school started playing Run-DMC and I was hooked, and I have been listening and rapping ever since. I think it’s the rhyming that hooked me, and doing it to a beat was fascinating to me, and still is,” says Danny Gronendyke, owner, Gronendyke Plumbing Inc., Merrillville, Ind.

But don’t look for Danny to take his rapping tour to a town near you anytime soon. “I don’t do well with performing live; I get distracted by the audience and forget lyrics. I am more of a recording artist. Less pressure to get it right when you are in a recording booth than when you are live,” says Gronendyke.

However, you may notice Danny’s rapping skills now more than ever. This past year, Danny has honed his rhymes for a number of different companies. In fact, a very proud moment indeed, he just finished shooting for NIBCO. “2020 has been a wacky year for so many reasons. One of which is that after 37 years of rapping for fun and hobby, my rather unexpected rap career has taken off. Who would have saw that coming? At 51 years old, I sure would have not predicted that,” says Gronendyke.

Plumbing Roots

I guess you could say that Danny G has always had that entrepreneurial, creative spirit. After high school, Gronendyke spent five years in the U.S. Air Force as a firefighter. When he left the service, Gronendyke worked 12 years in a steel mill where his father worked. “The last four of those years, I was bit by the entrepreneurial bug. While working full time at the mill, I also came up with a concept for a video game super store called “Games By The Day,” which focused on renting video games for one day at a time instead of others in the industry who only had five day game rentals at a higher rate. We also bought sold and traded new and used games. I was open every day for four years!” says Gronendyke enthusiastically.

Yet, after opening a second location, that store didn’t do as well, and Gronendyke decided to get out of the video game business and give plumbing a try. Gronendyke had a lifelong friend who was in a good position to help him get into the plumbing apprenticeship program and also hired him at the company for which he worked. “When a great friend said he was hiring plumbers, and he could help get me into the school, I gave it great consideration. I thought of other trades, but in my opinion, the plumbing trade would be the one trade that I felt would ALWAYS have people in need and therefore became my choice of trades to learn,” says Gronendyke.

Yet, after opening a second location, that store didn’t do as well, and Gronendyke decided to get out of the video game business and give plumbing a try. Gronendyke had a lifelong friend who was in a good position to help him get into the plumbing apprenticeship program and also hired him at the company for which he worked. “When a great friend said he was hiring plumbers, and he could help get me into the school, I gave it great consideration. I thought of other trades, but in my opinion, the plumbing trade would be the one trade that I felt would ALWAYS have people in need and therefore became my choice of trades to learn,” says Gronendyke.

“I worked for three companies during my first six years. Then, I was laid off most of 2011 when construction plummeted. So, in the spring of 2012, I decided to open Gronendyke Plumbing, Inc., and work for myself. I have not had a day off that I didn’t want in the last 8 1/2 years. So, by that measure, I call myself successful in what I set out to do.”

Specializing in residential service work, Gronendyke also peppers in some remodeling jobs with two trusted contractors. “I enjoy residential service because it’s something new every day—new problems to solve, new people to help, a new universe to save! Well, that may have gone too far, but I do love to save the day for people when they are in such need.”

What Gronendyke loves most about the plumbing trades is that he loves the changing landscape all the time. “Different places, new faces, new problems, never the same thing. It keeps my mind turning to solve problems and come up with solutions and install systems that work long after I am done with them. Overall, it gives me that feel good feeling. And the money is good, too.”

But after COVID hit, you could say it left Gronendyke in a brief state of high anxiety. “The first two days after restaurants were shut down for dining in, my phone did not ring. I was a little nervous about that.” Then day three hit, says Gronendyke, and everything went back to normal. “Plumbing problems are pandemic-proof. I have been doing the same amount of plumbing, and adding rapping to the mix has kept me much busier this year,” says a grateful Gronendyke.

Gronendyke throws props to a particular mentor, Bob Coleman, a now-retired plumber who took Danny under his wing and taught him how to do things right. Showing great patience with Gronendyke early on, “He was old school and always emphasized quality over quantity. He is the one who really instilled in me the set of values that would have me taking great pride in my craft and in my workmanship. And yes, he wore bib overalls,” says Gronendyke.

Gronendyke throws props to a particular mentor, Bob Coleman, a now-retired plumber who took Danny under his wing and taught him how to do things right. Showing great patience with Gronendyke early on, “He was old school and always emphasized quality over quantity. He is the one who really instilled in me the set of values that would have me taking great pride in my craft and in my workmanship. And yes, he wore bib overalls,” says Gronendyke.

As an industry veteran, Gronendyke does see needed improvements within the plumbing trade. “I wish that someday the industry will come together and agree on a plumbing code that would work everywhere. I know there would be climate considerations that would still be in place, but it seems that the industry could come together a bit more when it comes to standards and practices and code requirements.”

Another area of concern for Danny G, and one that has plagued the industry for years and will continue to do so, is the recruitment and training of the next generation of plumbers. “If the industry doesn’t act on this, our future is going to be rough with a shortage of plumbers in our country.”

Another area of concern for Danny G, and one that has plagued the industry for years and will continue to do so, is the recruitment and training of the next generation of plumbers. “If the industry doesn’t act on this, our future is going to be rough with a shortage of plumbers in our country.”

What are some words of wisdom that Gronendyke would share with those contemplating or entering the trades? “Learn everything you can about your trade, and give your absolute best in all you do. Always keep your head on a swivel and keep your ears alert to pick up stuff that others may or may not be willing to share. Ask lots of questions and absorb the answers. Never give up. It can be a tall mountain to climb, but you do it one step at a time,” says Gronendyke.

Personal Touch

Working in the trades can be difficult when trying to balance work and family time. Being self-employed, Gronendyke likes that he can schedule my time as he sees fit. Admittedly, Gronendyke works a lot, and he doesn’t turn down much work. However, there are times that he will purposely not schedule work so that he can spend time with his family. “I am happily married to a wonderful woman and I enjoy her company, traveling and experiencing new things in life with her. She is a school teacher and is as passionate about her career, as I am mine. I also have four children—two sons and two daughters. They are all grown and out on their own, but I enjoy the changing role that I play in their lives. Finally, I get to be less of a teacher to them, and more of a friend. It’s refreshing.”

In addition, as mentioned earlier, Gronendyke loves to write and record rap songs, and he enjoys watching movies. “I don’t always manage my balance well, though. About five years ago I was accomplishing goals in fitness, including running three full marathons in a five-week period. I then moved on to triathlons. I worked myself up to competing in a 70.3 half Ironman Triathlon. After that, I got so busy with work that I let it go and have been contemplating getting back into it and train for a full Ironman Triathlon. That is big on my bucket list.”

In addition, as mentioned earlier, Gronendyke loves to write and record rap songs, and he enjoys watching movies. “I don’t always manage my balance well, though. About five years ago I was accomplishing goals in fitness, including running three full marathons in a five-week period. I then moved on to triathlons. I worked myself up to competing in a 70.3 half Ironman Triathlon. After that, I got so busy with work that I let it go and have been contemplating getting back into it and train for a full Ironman Triathlon. That is big on my bucket list.”

Working on his aspiring rap career, social media had played a big part. “Social media is responsible for my rap career kicking off. It’s been a great outlet to get my music out there, and it’s how my clients have heard of me and contacted me to do rapping work for them,” says Gronendyke.

Moreover, social media had benefited Gronendyke (@howitbewithdannyg on Instagram) in other ways, mainly in his professional life. “Meeting so many other plumbing professionals and talking shop with them, and learning so many different tips/tricks and new methods of performing various tasks has really upped my game. Social media has been there for me too, when I need information or help, I can reach out and get good answers and assistance. I like to be there for others as well as a way to give back.”

Finally, I would be remiss if I didn’t tackle one last thing. What’s the deal with all of the Milwaukee tools? Evidently, it goes way back. As an apprentice, Gronendyke decided to tool up for side jobs. He really liked the look and feel of Milwaukee tools, he bought a 5-piece kit, and before long he was married to a battery platform and it made sense to stay Team Red.

Finally, I would be remiss if I didn’t tackle one last thing. What’s the deal with all of the Milwaukee tools? Evidently, it goes way back. As an apprentice, Gronendyke decided to tool up for side jobs. He really liked the look and feel of Milwaukee tools, he bought a 5-piece kit, and before long he was married to a battery platform and it made sense to stay Team Red.

You might call this an obsession. But for Gronendyke, there really are no perfect tool platforms, but he finds that Milwaukee has done a great job with developing a large variety of general tools and plumbing-specific tools, which captivated him early, having used almost all of the Milwaukee tools that he has amassed. “It’s possible that I have the largest Milwaukee Tool collection of any one-man shop. Some say that I have a problem, an addiction. They may be correct,” says Gronendyke.

You might call this an obsession. But for Gronendyke, there really are no perfect tool platforms, but he finds that Milwaukee has done a great job with developing a large variety of general tools and plumbing-specific tools, which captivated him early, having used almost all of the Milwaukee tools that he has amassed. “It’s possible that I have the largest Milwaukee Tool collection of any one-man shop. Some say that I have a problem, an addiction. They may be correct,” says Gronendyke.

Mechanical Hub recently talked with Tod Hebert, manager, customer relations, and Chuck O’Donnell – director of marketing, LAARS Heating Systems, Co. regarding the benefits—and differences—in condensing and non-condensing boilers in residential installations. The following is information garnered from that Q&A. MH: It would seem that condensing boilers would be the right choice for an install in Read more

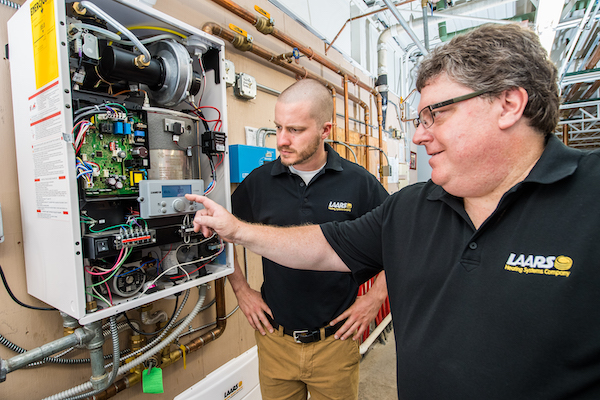

Mechanical Hub recently talked with Tod Hebert, manager, customer relations, and Chuck O’Donnell – director of marketing, LAARS Heating Systems, Co. regarding the benefits—and differences—in condensing and non-condensing boilers in residential installations. The following is information garnered from that Q&A.

MH: It would seem that condensing boilers would be the right choice for an install in terms of energy efficiency and energy savings. Perhaps there is more than meets the eye here. What are the pros and cons of each?

LAARS: Both condensing boilers, with Annual Fuel Utilization Efficiencies (AFUE) in the 95% range, and mid-efficiency boilers, with AFUEs in the mid-80% range, have their place depending on the home and homeowner’s goals when purchasing a new boiler.

Condensing boilers do offer higher efficiencies and can greatly reduce heating bills. However, they must be installed correctly and controls set up so that the boiler will condense as often as possible throughout the year. Condensing boilers work best when low return water temperatures of roughly 130F or lower are seen, otherwise the boiler’s installed efficiency will drop considerably. Low temperature heat emitters such as in-floor radiant, air handlers, or low temperature baseboards are ideal as they are designed for low boiler water temperatures.

A tech conducts a service check on a LAARS NeoTherm condensing boiler.

However, even standard high temperature baseboard can return cold enough water for condensing to happen if, for example, outdoor reset is used. During the course of a heating season a modulation condensing boiler with outdoor reset can maximize efficiency by matching its heat output with the heating needs of a home. Outdoor reset changes a boiler’s outlet temperature based on the outdoor temperature. Milder outdoor temperatures experienced in the fall and spring results in cooler boiler water temperature that will still keep a house warm. Cooler boiler water temperatures promote condensing and that results in higher efficiency.

However, non-condensing boilers may be the better choice when home heat loss calculations in conjunction with the use of high temperature heat emitters indicate that low return water temperatures will not occur often. In many cases a modern mid-efficient boiler can offer considerable savings when replacing an older mid 70% or low 80% efficient boiler. There are also venting installation requirements that should be considered. A condensing boiler cannot be vented into a standard chimney unless it is lined with stainless steel or high temperature rated plastic such as polypropylene or CPVC vent materials. This can be costly to the homeowner, especially if placed inside a long chimney run.

MH: What is typical lifespan on each? Does one outlive the other?

LAARS: If maintained properly both condensing and non-condensing boilers can provide many years of efficient, reliable home heating. However, as a general statement, non-condensing boilers tend to have slightly longer life spans in the 20 year or longer range where condensing products typically have lifespans of 15 years or longer. This, of course, is often dependent on site-specific run time and installation practices.

Checking the the high ffficiency Mascot FT (Fire Tube) combi condensing boiler.

MH: How often does each unit need to be serviced?

LAARS: It is recommended that all residential boilers undergo yearly inspection and servicing. However, condensing boilers can be compared to a high-performance vehicle that may need more attention at service time vs. a non-condensing boiler that may not need as much work come service time. Again, these are general statements, and much depends on how boilers are installed and run time based on a homeowner’s thermostat settings per zone in their homes.

MH: You may have touched upon this in question 1, but is there a big difference in energy efficiency, savings and a reduction in carbon footprint?

As with any boiler, the key to longevity is proper maintenance. Here a service tech performs a combustion analysis.

LAARS: The less fuel consumed results in a lower carbon footprint and therefore a condensing boiler in general will result in a lower carbon footprint as compared to standard efficient boilers. In addition to lower carbon footprint, NOX emissions (pollutants) are normally lower on modern condensing boilers, due to advanced burner technologies that optimize the combustion process.

MH: In terms of initial and long-term costs, what is the investment in both units?

LAARS: A typical condensing boiler installation will cost between $10,000 to $15,000. However, the number may be higher or lower depending on the size of the home and thus boiler size, number of zones, and if major corrections need to be made to the piping in a replacement job. We see non-condensing installations come in around $8,000 to $12,000, again lots depend on job site specifics to land on a final number.

Condensing units typically have lower fuel costs than mid-efficiency boilers over the life of each unit. However, non-condensing units tend to last a few years longer and have lower maintenance costs. These should be looked at when doing any ROI calculation.

MH: What is the warranty on heat exchanger, parts and labor?

LAARS: Condensing boilers typically have a 10 to 12-year heat exchanger warranty and 2 -5-year parts coverage. Noncondensing boilers typically have a 20-year heat exchanger warranty and 1-year part coverage.

MH: What are the differences in installation? (venting, for example)

LAARS: Non-condensing units can be vented directly into standard chimneys without much additional cost (sometimes older chimneys need upgrade or liners). Condensing units must be vented with materials that can withstand the corrosive nature of condensing flue products. These materials include PVC (residential appliances), CPVC, or polypropylene venting materials. Federal, state, and local venting codes must always be followed as allowable materials change depending on the authority having jurisdiction in any given area. Condensing products also must have a condensate neutralizer kit installed and a drain line installed to dispose of the condensate generated during combustion. In some homes, there is not a drain near the boiler installation, and this can complicate a high-efficiency boiler installation.

LAARS: Non-condensing units can be vented directly into standard chimneys without much additional cost (sometimes older chimneys need upgrade or liners). Condensing units must be vented with materials that can withstand the corrosive nature of condensing flue products. These materials include PVC (residential appliances), CPVC, or polypropylene venting materials. Federal, state, and local venting codes must always be followed as allowable materials change depending on the authority having jurisdiction in any given area. Condensing products also must have a condensate neutralizer kit installed and a drain line installed to dispose of the condensate generated during combustion. In some homes, there is not a drain near the boiler installation, and this can complicate a high-efficiency boiler installation.

MH: Is there an advantage with condensing in terms of corrosion control?

LAARS: Non-condensing boilers use various heat exchanger materials such as copper, steel, or cast iron. Condensation can attack these metals, so effort needs to be made to protect them from sustained low temperature return water, which causes condensation. Most condensing boilers will have stainless steel heat exchangers to handle the corrosive condensate that is produced via high efficiency combustion. Low return water temperature is not a concern, and in fact optimizes the efficiency of these units.

MH: Approximately when were condensing boilers introduced into the market?

LAARS: Condensing boilers found their start in the late 1990s; however, their popularity did not gain traction until the early to mid-2000s.

MH: Finally, is one more popular than the other currently? Is condensing gaining traction?

LAARS: Condensing boilers have grown in popularity, and their rate of use has grown quickly over the past ten years. However, there are still more non-condensing boilers installed each year vs. condensing, but the gap is closing.

Growing the PHCC and creating a more active membership is the goal; Hunter Botto is excited to handle the new normal with the great leadership already in place. As he answered the phone sitting on his sailboat docked in Florida, I got a sense early in our conversation that Hunter Botto was going to be Read more

Growing the PHCC and creating a more active membership is the goal; Hunter Botto is excited to handle the new normal with the great leadership already in place.

As he answered the phone sitting on his sailboat docked in Florida, I got a sense early in our conversation that Hunter Botto was going to be okay as the new Plumbing Heating Cooling Contractors—National Association (PHCC) president, even in light of the COVID-19 pandemic. Able to navigate adversity, this relaxed, chill semi-retired, former Navy vet and licensed boat captain—when not handling PHCC issues—enjoys his spare time sailing.

Nobody could have foreseen what 2020 would bring, and it just so happened that it was Hunter’s time to lead throughout this mess as the new PHCC president. “We as contractors face many challenges every day. The list is as long as a city mile but we have thick skin and can handle the task at hand,” says Botto. “This was not the plan—to be a leader during a pandemic but we have a job to do. The great staff at PHCC has adapted and has kept the ball moving. It’s like we move ahead or get out of the way—we are moving ahead! Our members are ready; they are being trained to the new normal and they are thinking outside the box to adhere to the new normal.”

Botto’s family business has been around since the early 1930s as his grandfather and his grandfather’s brother— Irwin and Robert Botto—ran a hardware business, which morphed into Botto Hardware and Plumbing & Heating, a combination of plumbing, heating, hardware and appliance business. In 1950, Botto’s father, Richard, and his cousin, Irv, started Botto Brothers Plumbing & Heating, Hicksville, N.Y., and ran that successful business until the early 1960s, when the two partners decided to split. Richard continued the legacy of Botto Brothers Plumbing & Heating while Irv formed Botto Mechanical in 1963.

Botto’s family business has been around since the early 1930s as his grandfather and his grandfather’s brother— Irwin and Robert Botto—ran a hardware business, which morphed into Botto Hardware and Plumbing & Heating, a combination of plumbing, heating, hardware and appliance business. In 1950, Botto’s father, Richard, and his cousin, Irv, started Botto Brothers Plumbing & Heating, Hicksville, N.Y., and ran that successful business until the early 1960s, when the two partners decided to split. Richard continued the legacy of Botto Brothers Plumbing & Heating while Irv formed Botto Mechanical in 1963.

In 1980, Hunter joined his father at Botto Brothers. Prior to joining, Hunter was a boiler technician in the United States Navy. “My brother Roger and I purchased the business together in 1993 and we operated the business well into the 2000s. I am happily semi-retired, and in 2015, Roger introduced his oldest son, Christopher, into the business, where it is still owned and operated today.”

The introduction into the trades started at an early age for Hunter. His great uncle was one of the first master plumbers in our township and he learned a great deal from his work ethic and technical savvy. Hunter always looked up to him as he was not only a master plumber but a skilled craftsman. “Going to work with my dad at the early age of 11 was expected and I got into doing what helpers were expected to do every day—digging trenches, being a ‘gofer,’ cutting pipe, installing boilers, bathroom renovation, and doing clean-up after the jobs were done. My time in the Navy was a vacation from the family business,” says Botto.

While working for the family business, Hunter’s dad retired and Hunter took over but he had no idea how to run the business side of things. “Believe me when I say this, PHCC saved my life. I was tired of competing with unlicensed contractors, utility issues, code issues, antiquated licensing issues, and poor business-minded contractors. PHCC helped me with these issues, and I have been associated with PHCC for the past 23 years, and they have treated me well and helped me run the business,” says Botto.

While working for the family business, Hunter’s dad retired and Hunter took over but he had no idea how to run the business side of things. “Believe me when I say this, PHCC saved my life. I was tired of competing with unlicensed contractors, utility issues, code issues, antiquated licensing issues, and poor business-minded contractors. PHCC helped me with these issues, and I have been associated with PHCC for the past 23 years, and they have treated me well and helped me run the business,” says Botto.

“Over the years, the local PHCC president, Richard English, asked me to attend a local meeting to help him create a new, younger vision for the industry. With a father and grandfather in the industry, Richard came from the same mold as I did, and he had a vision to get younger professionals involved. Our goal was to ‘raise the bar’ on Long Island,” says Botto.

After years of struggling, Hunter finally joined PHCC and got quickly involved in focusing on licensing issues with in our county. He climbed up the leadership chairs of our local PHCC, while finding new talent with the same vision in promoting professionalism. Hunter got involved as local president, attending state conventions, national conventions and meeting the leaders of this great organization. Hunter was asked by PHCC Past President Kevin Tindall to become a zone director, “which was one of the most exciting assignments he ever had in PHCC, well, until now, of course,” says Botto.

Through the years, Hunter has served on many committees, attending legislative conferences, and meeting people in the know, all while running a 60-year-old family business. “So here I am on the precipice of becoming the president of the oldest, most prestigious and most professional trade organization in the United States. I truly have been blessed and I look forward to the challenges at hand—just like any other day at the office like so many PHCC contractors do every day,” says Botto.

Through the years, Hunter has served on many committees, attending legislative conferences, and meeting people in the know, all while running a 60-year-old family business. “So here I am on the precipice of becoming the president of the oldest, most prestigious and most professional trade organization in the United States. I truly have been blessed and I look forward to the challenges at hand—just like any other day at the office like so many PHCC contractors do every day,” says Botto.

But today is an unprecedented time. Teamwork will get it done, believes Botto. “Working with a greatly trained team gets the job done, bottom line. All of our state and local associations are the backbone of our association,” says Botto.

As Botto sets his sights on the future, he says membership is key. “Strength in numbers makes us the most respected trade association, but making the industry aware and seeking new leaders is a major goal,” says Botto.

“We need to bring in younger industry voices and show them the benefits of PHCC. With the new technology available to all of us, it is PHCC’s responsibility to get the word out and get professionals involved. Workforce development is also at the top of our list, and as the pandemic has created barriers, our online apprenticeship program is in full swing and growing every day,” says Botto.

Botto’s message is clear. “I have always been committed to this industry as it has allowed me to raise a family, give back to the community and grow younger professionals. My message to all PHCC members is to give back to the industry that has given so much to us.”