“I’m paying attention to the specifications of the planet,” said Bryan Uhler, second-generation builder, YouTuber and Instagram influencer. Long-term quality and conservation within the building trade are calling cards for Pioneer Builders Inc., which Bryan’s father, Tim Sr., founded in Port Orchard, Wash., nearly 50 years ago. Today, Bryan serves as vice president of the Read more

Featured Articles

“I’m paying attention to the specifications of the planet,” said Bryan Uhler, second-generation builder, YouTuber and Instagram influencer.

Long-term quality and conservation within the building trade are calling cards for Pioneer Builders Inc., which Bryan’s father, Tim Sr., founded in Port Orchard, Wash., nearly 50 years ago. Today, Bryan serves as vice president of the company. His brother, Tim Jr., is lead carpenter.

Their father remains involved as an advisor, and the third generation is beginning to take shape. Bryan’s son, Ethan, helps with digital content production.

From l to r: Bryan, Ethan, Tim Sr. and Tim Jr.

In addition to handling land acquisitions, project development, permitting, sales, job costing, and payroll, Bryan emphasizes constructing homes with a strong emphasis on conservation.

While the company constructs spec homes almost exclusively, it has also built all variety of custom and pre-sale homes. Over the years, Pioneer’s emphasis on efficiency and green building technologies has outpaced Washington state’s stringent energy code, which is one of the strictest in the nation.

Taking the Next Step

“In 2024, we made a commitment to construct Zero Energy Ready homes,” said Uhler. “This is a certification through the Department of Energy (DOE) for homes built to a rigorous set of requirements, providing high levels of energy conservation, comfort, health and durability. Through the Inflation Reduction Act, homes built to this standard can qualify for the 45L tax credit worth $5,000.”

The goal behind Zero Energy Ready homes is to provide residences that are so efficient, a renewable energy source could offset the home’s power consumption. All of Pioneer’s spec homes are also ENERGY STAR certified.

As important as energy conservation is, the recent fires in southern California are the latest reminder that water conservation may soon be the nation’s greatest challenges.

Concentrating on Water Conservation

“Conserving water is as big an environmental concern as reducing energy consumption,” said Bryan. “If you curb domestic hot water use, you achieve both.”

For years, Pioneer Builders has specified water-conserving fixtures. They use Gerber’s line of faucets, toilets and shower heads.

“With properly designed equipment, the homeowner can reduce household water consumption without sacrificing comfort or even being aware of the fact that they’ve reduced water use,” said Bryan.

Bryan Uhler displays how Pioneer Builders pairs a heat pump water heater with Taco’s SmartPlus-e recirculation system.

This principle is carried into the mechanical room, where Pioneer Builders partners with Herdman Plumbing. Heat pump water heaters are used in all Pioneer’s homes. While this provides energy savings and eliminates on-site fossil fuel consumption, it does present one challenge.

“Our homes feature domestic hot water circulation, which saves a great deal of potable water, not to mention increasing the comfort level,” said Bryan. “The issue is that heat pump water heaters and conventional DHW recirculation systems don’t play well together. I’m willing to admit that we’ve done everything wrong at least once, and this is no exception.”

By using the Taco SmartPlus-e, Pioneer Builders avoids the pitfalls caused by pairing a heat pump water heater with a DHW recirculation pump.

The number one issue when pairing these two technologies is that a DHW recirculation system that runs continuously tends to disrupt stratification within the water heater. Recirculation lines, even when properly insulated, also shed heat while circulating, causing the heater to recover when the cooler water returns to the tank.

This often causes the heater to operate when there isn’t a call for DHW or switch the unit from heat pump mode to electric resistance backup. Not all recirculation pumps are created equally. Some pumps – specifically those that don’t feature ECM motors – are inefficient, and this raises the HERS rating. That’s a bad thing for an energy conscious contractor.

“I didn’t know there was a solution until Eric Aune from Mechanical-Hub suggested I look at Taco’s SmartPlus-e recirculation system,” said Bryan. “He explained that the system paired a small ECM circulator with a smart control, eliminating the problems caused by constant circulation. That’s a winning combination.”

The recirculation system’s temperature sensor is installed under pipe insulation on the hot water supply line.

The SmartPlus-e includes two components, a 006e3 circulator and a SmartPlug control, which can be paired with any recirculation pump. The SmartPlug can operate in Pulse mode, which continuously cycles the pump on and off, or Smart mode. In Smart mode, the control records hot water use patterns in the home and only operates the pump according to those patterns.

“We’ve found that the SmartPlus-e system helps us hit some of the benchmarks needed to achieve ENERGY STAR certification,” Bryan shared. “Our projects range from around 2,500-4,000 square feet with about the bathrooms. With the water heater in the garage, the potential to save water and energy with a recirculation system is considerable.”

A Holistic Approach

Bryan makes it evident that creating a durable, healthy, energy efficient home can’t be achieved by selecting one or two energy-efficient products and adding a bit more insulation. It’s a holistic approach that begins in the design phase and continues through to educating the homeowner during the final walk-through.

One of the biggest changes Pioneer has made over the past decade, especially with the use of air-to-air heat pumps, is to bring the ductwork into the conditioned space. This saves a great deal of energy being lost to the attic.

Another improvement is the careful selection of building materials in the interest of indoor air quality. Natural materials like hardwood flooring and rockwool insulation reduce the VOCs in newly constructed homes.

“We insist that each of our homes provides comfort while actively contributing to the health of its occupants and the preservation of our environment,” said Bryan. “That typically means making a lot of little improvements to the built environment, rather than one big change.”

Check out Pioneer Builders at pioneerbuildersonline.com.

Welcome to Tech Transformation, a new feature showcasing the evolution of a technology or product over time. We start with Milwaukee Tool’s SAWZALL. Over the past 20 years, Milwaukee Tool has significantly advanced the SAWZALL®, a product that has set industry standards since its invention nearly 75 years ago. At the turn of the millennium Read more

Milwaukee SAWZALL in 2008

Welcome to Tech Transformation, a new feature showcasing the evolution of a technology or product over time. We start with Milwaukee Tool’s SAWZALL. Over the past 20 years, Milwaukee Tool has significantly advanced the SAWZALL®, a product that has set industry standards since its invention nearly 75 years ago. At the turn of the millennium, Milwaukee® introduced the world’s first cordless SAWZALL® that could compete with its legendary corded counterpart, allowing professionals to cut the cord for the first time. Powering the 0719 model was the 28 Volt LITHIUM-ION battery pack, exclusively from Milwaukee, which marked a revolutionary leap in cordless tool technology at the time.

Today’s M18 FUEL™ SAWZALL® Recip Saw, Gen 2, w/One-Key

Milwaukee set out to change the lives of users introducing the M18™ cordless system and made a commitment that they continue to deliver on to this day: Milwaukee would continue to invest in new technology without the need for users to change platforms. This innovation paved the way for the game-changing M18 FUEL™ SAWZALL®.

Since then, Milwaukee has continued to push the boundaries of performance and reliability. The current M18 FUEL™ SAWZALL® Recip Saw w/ ONE-KEY™ (2822-22) now boasts fastest cutting in class, improved durability, and lightweight designs for reduced fatigue. Leveraging a POWERSTATE™ Brushless Motor, this newest generation provides 3,000 SPM and a 1-¼” stroke length for faster material.

The gear-protecting clutch further enhances durability by safeguarding against impact, upholding the legendary SAWZALL® reputation. Additionally, the introduction of ONE KEY™ tracking technology and slider crank mechanism upgrades ensure that the SAWZALL® remains a leader in the industry, continually meeting the evolving needs of professionals.

For more information, www.milwaukeetool.com

https://vimeo.com/1067501692 On this week’s Mechanical Hub update: As I watched the recovery efforts—for the astronauts stuck in space for nine months—live off the coast of Tallahassee, Fla., all I kept thinking about was, “Where have these two astronauts been going to the bathroom for that extended period of time?” I guess I’m not alone in Read more

On this week’s Mechanical Hub update: As I watched the recovery efforts—for the astronauts stuck in space for nine months—live off the coast of Tallahassee, Fla., all I kept thinking about was, “Where have these two astronauts been going to the bathroom for that extended period of time?” I guess I’m not alone in that thought because it is one the most commonly-asked questions for astronauts visiting the space station.

Subscribe to the Mechanical Hub newsletter:

Podcasts:

Thermal Energy Networks:

Part 2 of 2: Thermal Energy Networks: Why TENs Are the Future

AHR with Caleffi

This Is Part 2/2 of Building a Sustainable Future with Thermal Energy Networks by Marc Miller, Egg Geo, LLC Modern energy demands are growing, and the need for sustainable, efficient solutions to heat and cool our homes and businesses has never been greater. Enter Thermal Energy Networks (TENs)—innovative systems that distribute and reuse energy to Read more

This Is Part 2/2 of Building a Sustainable Future with Thermal Energy Networks by Marc Miller, Egg Geo, LLC

Modern energy demands are growing, and the need for sustainable, efficient solutions to heat and cool our homes and businesses has never been greater. Enter Thermal Energy Networks (TENs)—innovative systems that distribute and reuse energy to reduce costs, cut emissions, and optimize performance.

This article continues to explores the implementation of TENs, their benefits, and how one would connect their home or building to a TEN, helping you understand their potential to transform energy systems for the better.

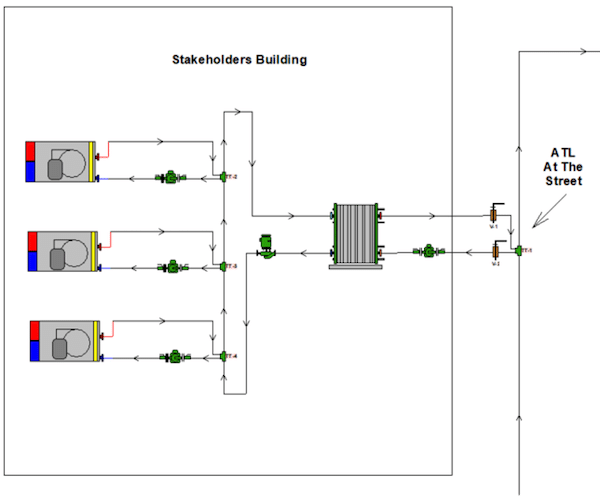

TENs Connected to Buildings

Regardless of whether the stakeholder is a home, a light commercial building, or an industrial building, the fundamental connection to the ATL remains the same: the decoupled secondary loop. This loop features a circulator pump sized to handle the maximum load of the system. As a result, there’s no need for a balancing valve, as the flow rate (GPM) delivered to the intermediary heat exchanger is regulated by maintaining a delta T (temperature difference) across the heat exchanger.

The pump automatically adjusts to sustain this delta T, with its rated capacity based on the maximum flow required to meet the stakeholder’s demands. For instance, in heating mode, if the ATL circulating heat transfer medium is of a low temperature, compared to normal operating conditions, the secondary pump increases speed to deliver a higher rate of flow with a lower temperature fluid. Conversely if the temperature of the fluid increases, then the flow rate can be reduced.

This is because of the following formulas:

BTU/hour = Flow Rate (GPM) × ΔT (°F) × 500

Flow Rate (GPM) = BTU/hour ÷ (ΔT (°F) × 500)

ΔT = The temperature difference between the inlet and outlet water temperature of the heat exchanger

500 = a constant that accounts for the weight of water (in pounds per gallon), the specific heat of water, and a time conversion factor.

For instance, if a stakeholder requires 120,000 BTUs to be delivered to their building while maintaining a 10°F delta T across the heat exchanger inlet and outlet water temperatures, we can determine the required GPM (gallons per minute) using the following formula:

GPM = BTU / (ΔT × 500)

Now, plug in the values:

GPM = 120,000 / (10 × 500)

GPM = 120,000 / 5,000

GPM = 24

So, the GPM required is 24 gallons per minute.

Now, if the temperature in ATL drops because of thermal diversity and temperature cascade effect, the water in the ATL will contain less thermal energy. To compensate, we would need to either increase the size of the heat exchanger to provide more surface area for thermal energy transfer or increase the volume of water that has fewer BTUs to continue to deliver 120,000. Because there are fewer BTUs the delta t will decrease to 5℉-6℉. To determine the required flow rate (GPM), we use the same formula:

GPM = BTU / (ΔT x 500)

Now, plug in the values:

GPM = 120,000 / (6 x 500)

GPM = 120,000 / 3,000

GPM = 40

So, the GPM becomes 40.

In most two-pipe systems, heat exchangers are designed to operate at a specific flow rate (gpm) and a fixed temperature differential (delta T), typically around 10°F. However, one-pipe systems are can be engineered for a varying delta T’s, which necessitates the use of a larger heat exchanger for worst case scenario.

The steady-state heat transfer equation: Q = U x A x ∆T is used applied to heat exchangers to determine its thermal energy transfer capabilities.

- Q: The total heat transfer rate (measured in BTU/hr or similar units).

- U: The overall heat transfer coefficient, which measures how effectively heat is transferred through a material or system (units: BTU/hr·ft²·°F).

- A: The surface area through which heat is being transferred (measured in square feet).

- ∆T: The temperature difference between the two sides of the material or system (measured in degrees Fahrenheit).

To calculate the heat transfer rate (Q) for a plate and frame heat exchanger made of copper/nickel using the formula Q = U x A x ∆T, we can substitute the known values directly.

Here’s the example:

Given:

- A (surface area) = 24 ft²

- ∆T (temperature difference) = 10°F Between the house water loop and the ATL

- U (overall heat transfer coefficient for copper/nickel) ≈ 500 BTU/hr·ft²·°F

Q = U x A x ∆T

120,000BTU/hr = 500 x 24 x 10°F

Result:

The heat transfer rate (Q) for this copper/nickel plate and frame heat exchanger is 120,000 BTU/hr.

This equation calculates the heat transfer rate across a surface by incorporating the area, the thermal properties of the material, and the temperature difference driving the heat flow. Widely applied in engineering disciplines such as thermodynamics and HVAC system design, it serves as a foundational tool for optimizing energy systems.

In an Ambient Temperature Loop (ATL) system, as the ATL temperature drops and the delta T narrows to just 5°F or 6°F between the inlet and outlet water temperatures to meet the required BTU transfer, the pump operates efficiently without significantly increasing its speed. This approach minimizes head pressure and reduces energy consumption for pumping. The pump’s maximum speed is calibrated to manage worst-case scenarios with a 5°F–6°F delta T, ensuring consistent and energy-efficient performance under demanding conditions.

Conversely, as the ambient loop temperature rises, the delta T proportionally increases due to the higher thermal energy present in the water. In response, the pump slows down—potentially to 50% of its capacity—to adhere to the industry-standard 50/90 design principle. This ensures both energy efficiency and system reliability across varying load conditions.

The ATL system is specifically designed to align with the 50/90 guideline, a cornerstone in HVAC system efficiency. This principle prioritizes sustainable energy use by setting pumps to operate at 50% capacity under normal conditions, reducing energy consumption while maintaining peak performance. During maximum load conditions, the system scales up to 90% capacity, leveraging pump affinity laws to ensure reliable operation without over-sizing equipment. The integration of variable speed drives further enhances this strategy, enabling precise flow control and optimizing thermal energy transfer for maximum efficiency.

Additionally, the heat exchanger acts as a hydraulic separator, ensuring no physical mixing of water between different stakeholders while facilitating efficient energy exchange. This design isolates the hydraulics of each stakeholder connected to the loop, maintaining system efficiency and providing seamless, independent energy sharing.

Why TENs Are the Future

Thermal Energy Networks represent the next evolution in energy systems—offering a path to decarbonization while improving efficiency and reducing costs. Whether adopted by urban centers, industrial complexes, or residential neighborhoods, TENs can dramatically reduce energy dependencies and support long-term climate goals.

It’s not just about scaling renewable energy; it’s about harnessing it smarter. By integrating geothermal technology, heat pumps, and innovative distribution systems, TENs set a precedent for sustainable energy solutions we can all count on.

Interested in how this technology can benefit your community or business? Start exploring implementation options today to join the growing movement toward a sustainable energy future.

Part I of this story can be found here: https://mechanical-hub.com/building-a-sustainable-future-with-thermal-energy-networks/

Marc Miller is a Mechanical Systems SME – Educator – Technical Writer – Author – Construction Management Consultant with Home – Egg Geo. He is presently the Lead Author on two textbook projects with Egg Geo. He may be reached at marcm@egggeo.com.

Marc Miller is a Mechanical Systems SME – Educator – Technical Writer – Author – Construction Management Consultant with Home – Egg Geo. He is presently the Lead Author on two textbook projects with Egg Geo. He may be reached at marcm@egggeo.com.

https://vimeo.com/1065326549 Did you know that it has been a tradition to dye the Chicago River green? In fact, the Chicago Journeymen Plumbers Local 130, or the Chicago Plumbers Union, have been dyeing the river since 1962. The process includes an orange, vegetable-based powder that is dumped into the river. The powder is spread by two Read more

Did you know that it has been a tradition to dye the Chicago River green? In fact, the Chicago Journeymen Plumbers Local 130, or the Chicago Plumbers Union, have been dyeing the river since 1962. The process includes an orange, vegetable-based powder that is dumped into the river. The powder is spread by two motorboats (one for dumping, one for stirring the water). The dye is designed to be environmentally safe and does not pose a threat to the river’s ecosystem. We talk about that, AHR videos, thermal energy networks and much more.