You may have heard about plasma spray, but when it comes to knowing what it is, you might need help understanding what it does and how it works. If you are new to plasma spraying and want to use it, then there is a lot that you need to understand, as it is a complex job that should be done only after acquiring enough information.

Before starting, you must ensure you’re in a safe working environment that follows all the regulations. Follow regulations to avoid hazardous working conditions, which are dangerous for beginners and experts alike.

So, let’s get to business.

Plasma Spraying: Explained

Plasma Spraying: Explained

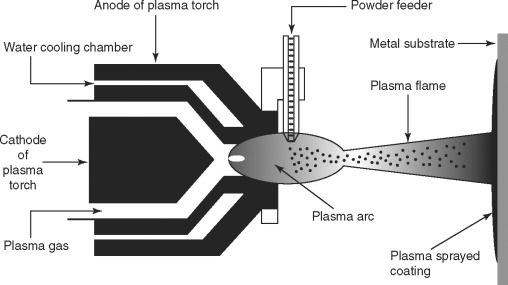

Plasma spraying is a thermal process where a coating is applied by spraying heat-induced particles onto a substrate. These particles are usually in the form of powder. The powder is injected into the plasma flame. It gets heated, softens the particles, and is later sprayed onto the object or materials and left to cool off. Once the sprayed particles cool off, it forms a coating.

Plasma spraying is used to coat a wide range of products. It is a time-efficient method to coat any material without worrying about damaging it. Plasma spraying may not be suited for all kinds of products, such as objects with Teflon layers, but there is always a variety of thermal coating available for each kind.

How does it work?

The way in which a plasma spray works is quite easy to understand, as it is a simple process. But it does require quite a bit of expertise to handle. It is an engineering marvel that has made the coating process easier. But, working with a plasma spray requires some getting used to. Here is how the entire process of a plasma spray takes place.

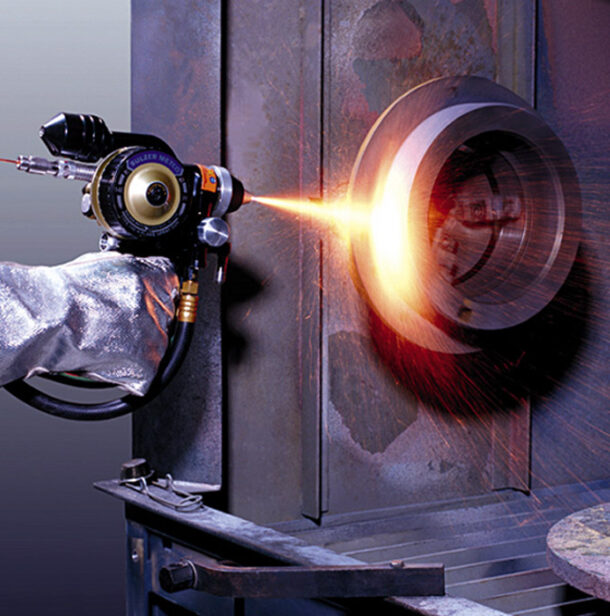

In plasma spraying, a plasma gun is used as a flame source. To start the heating process, the plasma gun receives a source of plasma gas. A highly powered electric charge is used to create the plasma. An external supply powder is for powder coating. The plasma flame melts the powder in a special nozzle, after which the plasma spray gun creates an ultra-hot flame that creates the coating.

For a plasma spray to work, one needs the right environment and a lot of planning to ensure the coating is suitable for industrial applications. It requires expertise and experience to handle the work of a plasma spray.

Benefits of plasma spray coating

Plasma spray is the most popular method for producing coatings on an object. The coating is specially designed for industrial applications. It is a huge time saver and provides results in a more time-efficient manner. The coating itself has many benefits, and the plasma spray makes it more reliable.

One major reason to go for plasma spray coating is that each part that goes through it becomes more and more durable. The part’s reliability and lifespan increase does save an extra cost for replacement. It makes them resistant to oxidation, thus, preventing wear and tear. It also provides thermal insulation, along with protecting them from corrosion.

Plasma spray is capable of covering a wide variety of components of different sizes, both large and small. It also provides better temperature management, along with better electrical resistivity and conductivity.

Conclusion

Plasma spray coating is a magnificent method that can improve the quality of a product by a huge margin. It is one of the most popular and widely used methods for coating. It provides a lot of benefits. Although, it does require expertise and an understanding of the right environment. Only if it is done right can it successfully apply a thermal coating.

Join the conversation: