Imagine a tool that can tell you how it is “feeling,” — how it is performing its capabilities, how it can maximize its potential, and to whom it is assigned at the jobsite? Sounds like tool therapy, but for Milwaukee Tool it’s their latest offering that will help redefine the future of the tool industry. They call it ONE-KEY™.

Christian Coulis addresses the media regarding the ONE-KEY platform during the opening ceremony at this year’s tool symposium.

Continuing its philosophy of putting the tradesperson first, the new Milwaukee ONE-KEY platform will give users the ability to access their tools and manage their information at a level that has never before been possible. Provided to their tools and other assets by custom cloud-based connectivity, ONE-KEY is available for free and is IOS and Droid compatible through an App, and/or a web interface.

ONE-KEY will provide a new level of control and access to information that will revolutionize the way work gets done. This will fundamentally change the way users interact with their tools, and help solve user problems and frustrations the industry has never before been able to address.

“The first phase of ONE-KEY will deliver three core benefits that will have an immediate impact on productivity: tool control, inventory management and tool reporting,” says Christian Coulis, Vice President of Product Management for Milwaukee Tool.

The three ONE-KEY aspects:

• Inventory Management (Sept. 2015) — This mobile App and web interface will allow users to input any product (via serial #, receipts, etc.) and keep detailed records of each tool. Whether tracking purchase information, or assigning each tool to locations or users to improve accountability, the user will be able to manage these details for all of their tools and equipment, even non-Milwaukee brands). The first component available, Inventory Management will be available through the web and mobile app, creating a central place for users to manage all of their tools and equipment across their network of jobs and operators.

Managers are also able to assign locations or specific owners to each asset, providing accountability, and enabling easy information sharing between the field and back-office. As a cloud based solution, updates and edits will be synchronized real-time throughout all levels of an organization.

I had asked about the possibility of an auto shut-off feature for the tool for guys who take the tool home from the jobsite, or the possibility of embedding some type of GPS component; Milwaukee representatives didn’t rule it out for the future. “This is really just the beginning,” I was told.

• Tool Reporting (October 2015) — This will first be available with the launch of the M18™ FORCE LOGIC™ 6T Utility Crimper in October. It will give the user the ability download critical information and use this information to generate reports that can confirm the success/accuracy of an installation, and will be able to upload data and history to create custom reports that track the success and timing of electrical terminations. By syncing tool data, users can conduct preventive maintenance through data analysis and collection. (Image: M18™ FORCE LOGIC™ 6T Utility Crimper)

Furthermore, the ONE-KEY™ program will assist in tracking the utilization and service intervals of the tool to maximize uptime and keep inventory lean.

• Tool Control (January 2016) — Launching Q1, this aspect of ONE-KEY will give users infinite customization capabilities for various applications. Users can use pre-determined set-ups for specific fasteners and materials, or completely customize their own profile with torque and speed settings for the application at hand. With a touch of the button on the tool, they can easily go back and forth between these saved profiles so that each application is done with the most accurate and productive settings. The new products will include M18™ FUEL Drill and Driving products.

80 New Products

Although ONE-KEY was a huge announcement in its own right, that was just part of this year’s Tool Symposium, an annual event held by Milwaukee to showcase its new tools and technology. Over the course of the year, Milwaukee announced that it would release 80 new tools when it is all said and done.

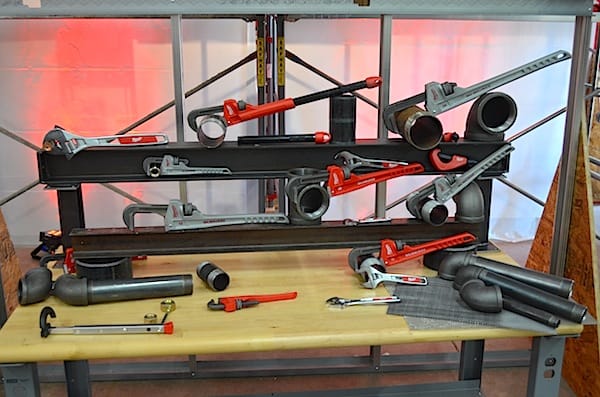

Catching the eye of attendees in the Plumbing & Electrical Breakout sessions:

• The SUPER HAWG® cordless right angle drill will not only power through 6” holes, but can drill over (75) 2-9/16” holes per charge for a completely cordless rough in. Optimized for plumbing and HVAC applications, the M18 FUEL™ SUPER HAWG is the first cordless tool of its kind, delivering game-changing productivity for professionals drilling with up to 4-5/8” self-feed bits and up to 6” hole saws. “This was designed with the plumber in mind,” said Tyson Apfelbeck, associate product manager, Milwaukee Tool.

New additions to the hand tool line include adjustable wrenches like Milwaukee’s Cheater pipe wrench with interchangeable threaded handle (top).

• Milwaukee Tool and Uponor introduced the industry’s first expandable 3” PEX and the only tool on the market that can expand it, the M18™ FORCELOGIC™ 2” – 3” ProPEX® Expansion Tool. “Until now, its use in commercial has been limited due to tubing size and installation tooling. We are proud to partner with Uponor to deliver a solution that will make larger diameter ProPEX® a compelling solution for commercial system installations,” said Corey Dickert, Director of Product Marketing.

• The TRUE VIEW family of LED lighting Milwaukee is rolling out is top of the line. Milwaukee boasted its rugged M18 Stand Light; this LED, expandable tripod work light extends up to 7 feet in height and can emit 2000 lumens. “This is just the start of what we are doing in lighting,” said Mike Monteleone, senior product manager.

• M12 Next Gen M-Spector™ AV, a jobsite video inspection system hits the market in October. With its wireless LED display, flexible, swiveling camera head tip, and a light output that increases viewing distance makes M-Spector™ AV one of the most versatile inspection systems to hit the market.

• M18 FUEL™ 1-1/2” Magnetic Drill & M18 FUEL™ 1-1/2” Lineman Magnetic Drill are faster than their corded counterparts, maximize user safety and productivity by delivering the strongest magnetic hold on ¼” steel, and can drill up to (40) 13/16” holes per charge.

Join the conversation: