Mechanical Hub recently talked with Tod Hebert, manager, customer relations, and Chuck O’Donnell – director of marketing, LAARS Heating Systems, Co. regarding the benefits—and differences—in condensing and non-condensing boilers in residential installations. The following is information garnered from that Q&A.

MH: It would seem that condensing boilers would be the right choice for an install in terms of energy efficiency and energy savings. Perhaps there is more than meets the eye here. What are the pros and cons of each?

LAARS: Both condensing boilers, with Annual Fuel Utilization Efficiencies (AFUE) in the 95% range, and mid-efficiency boilers, with AFUEs in the mid-80% range, have their place depending on the home and homeowner’s goals when purchasing a new boiler.

Condensing boilers do offer higher efficiencies and can greatly reduce heating bills. However, they must be installed correctly and controls set up so that the boiler will condense as often as possible throughout the year. Condensing boilers work best when low return water temperatures of roughly 130F or lower are seen, otherwise the boiler’s installed efficiency will drop considerably. Low temperature heat emitters such as in-floor radiant, air handlers, or low temperature baseboards are ideal as they are designed for low boiler water temperatures.

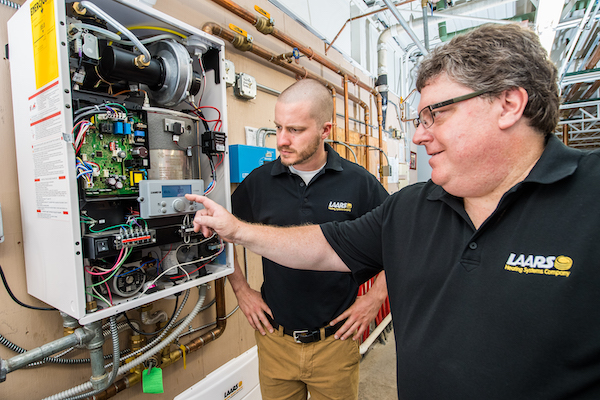

A tech conducts a service check on a LAARS NeoTherm condensing boiler.

However, even standard high temperature baseboard can return cold enough water for condensing to happen if, for example, outdoor reset is used. During the course of a heating season a modulation condensing boiler with outdoor reset can maximize efficiency by matching its heat output with the heating needs of a home. Outdoor reset changes a boiler’s outlet temperature based on the outdoor temperature. Milder outdoor temperatures experienced in the fall and spring results in cooler boiler water temperature that will still keep a house warm. Cooler boiler water temperatures promote condensing and that results in higher efficiency.

However, non-condensing boilers may be the better choice when home heat loss calculations in conjunction with the use of high temperature heat emitters indicate that low return water temperatures will not occur often. In many cases a modern mid-efficient boiler can offer considerable savings when replacing an older mid 70% or low 80% efficient boiler. There are also venting installation requirements that should be considered. A condensing boiler cannot be vented into a standard chimney unless it is lined with stainless steel or high temperature rated plastic such as polypropylene or CPVC vent materials. This can be costly to the homeowner, especially if placed inside a long chimney run.

MH: What is typical lifespan on each? Does one outlive the other?

LAARS: If maintained properly both condensing and non-condensing boilers can provide many years of efficient, reliable home heating. However, as a general statement, non-condensing boilers tend to have slightly longer life spans in the 20 year or longer range where condensing products typically have lifespans of 15 years or longer. This, of course, is often dependent on site-specific run time and installation practices.

Checking the the high ffficiency Mascot FT (Fire Tube) combi condensing boiler.

MH: How often does each unit need to be serviced?

LAARS: It is recommended that all residential boilers undergo yearly inspection and servicing. However, condensing boilers can be compared to a high-performance vehicle that may need more attention at service time vs. a non-condensing boiler that may not need as much work come service time. Again, these are general statements, and much depends on how boilers are installed and run time based on a homeowner’s thermostat settings per zone in their homes.

MH: You may have touched upon this in question 1, but is there a big difference in energy efficiency, savings and a reduction in carbon footprint?

As with any boiler, the key to longevity is proper maintenance. Here a service tech performs a combustion analysis.

LAARS: The less fuel consumed results in a lower carbon footprint and therefore a condensing boiler in general will result in a lower carbon footprint as compared to standard efficient boilers. In addition to lower carbon footprint, NOX emissions (pollutants) are normally lower on modern condensing boilers, due to advanced burner technologies that optimize the combustion process.

MH: In terms of initial and long-term costs, what is the investment in both units?

LAARS: A typical condensing boiler installation will cost between $10,000 to $15,000. However, the number may be higher or lower depending on the size of the home and thus boiler size, number of zones, and if major corrections need to be made to the piping in a replacement job. We see non-condensing installations come in around $8,000 to $12,000, again lots depend on job site specifics to land on a final number.

Condensing units typically have lower fuel costs than mid-efficiency boilers over the life of each unit. However, non-condensing units tend to last a few years longer and have lower maintenance costs. These should be looked at when doing any ROI calculation.

MH: What is the warranty on heat exchanger, parts and labor?

LAARS: Condensing boilers typically have a 10 to 12-year heat exchanger warranty and 2 -5-year parts coverage. Noncondensing boilers typically have a 20-year heat exchanger warranty and 1-year part coverage.

MH: What are the differences in installation? (venting, for example)

LAARS: Non-condensing units can be vented directly into standard chimneys without much additional cost (sometimes older chimneys need upgrade or liners). Condensing units must be vented with materials that can withstand the corrosive nature of condensing flue products. These materials include PVC (residential appliances), CPVC, or polypropylene venting materials. Federal, state, and local venting codes must always be followed as allowable materials change depending on the authority having jurisdiction in any given area. Condensing products also must have a condensate neutralizer kit installed and a drain line installed to dispose of the condensate generated during combustion. In some homes, there is not a drain near the boiler installation, and this can complicate a high-efficiency boiler installation.

LAARS: Non-condensing units can be vented directly into standard chimneys without much additional cost (sometimes older chimneys need upgrade or liners). Condensing units must be vented with materials that can withstand the corrosive nature of condensing flue products. These materials include PVC (residential appliances), CPVC, or polypropylene venting materials. Federal, state, and local venting codes must always be followed as allowable materials change depending on the authority having jurisdiction in any given area. Condensing products also must have a condensate neutralizer kit installed and a drain line installed to dispose of the condensate generated during combustion. In some homes, there is not a drain near the boiler installation, and this can complicate a high-efficiency boiler installation.

MH: Is there an advantage with condensing in terms of corrosion control?

LAARS: Non-condensing boilers use various heat exchanger materials such as copper, steel, or cast iron. Condensation can attack these metals, so effort needs to be made to protect them from sustained low temperature return water, which causes condensation. Most condensing boilers will have stainless steel heat exchangers to handle the corrosive condensate that is produced via high efficiency combustion. Low return water temperature is not a concern, and in fact optimizes the efficiency of these units.

MH: Approximately when were condensing boilers introduced into the market?

LAARS: Condensing boilers found their start in the late 1990s; however, their popularity did not gain traction until the early to mid-2000s.

MH: Finally, is one more popular than the other currently? Is condensing gaining traction?

LAARS: Condensing boilers have grown in popularity, and their rate of use has grown quickly over the past ten years. However, there are still more non-condensing boilers installed each year vs. condensing, but the gap is closing.