Starting over 60 years ago in a small province in northern Italy, Caleffi has increased its footprint, expanded its international presence, survived the current pandemic, all the while manufacturing some of the most innovative PHVAC, heat metering and renewable products in the world.

Chairman Marco Caleffi talking with Bob ‘Hot Rod’ Rohr and MH’s Eric Aune, while on an overseas video call with MH’s John Mesenbrink.

This past fall, Mechanical Hub was honored to tour the Caleffi S.p.A. global headquarters in Fontaneto d’Agogna, Italy. We were joined by Bob “Hot Rod” Rohr, Training and Education Manager, Caleffi North America. Afterward, we sat down to chat with Chairman Marco Caleffi. To break the ice, we asked Marco what type of sports he enjoys watching, whether it be American football or European soccer. Marco promptly reached to the shelf behind him and put a vibrant yellow cheese wedge on his head, signifying his admiration for the Green Bay Packers and solidarity with Caleffi’s North American headquarters, located in Milwaukee, Wisconsin. In disbelief and shock—as I am a Chicago Bears fan—I appreciated the gesture, but I needed to change the subject, and quickly!

A Taste of Caleffi

Upon arrival we were greeted with an impactful historical display of how Caleffi S.p.A.’s site was first constructed and the many expansions it has experienced in the decades since. During our walking tour, we were led through the entire manufacturing process—from the brass bar stock to final packaging of literally thousands of catalog offerings. “I’ve been on a fair number of factory tours, but I can say none showcase new technology and innovative manufacturing methods quite like Caleffi did,” said Eric Aune, co-owner, Mechanical Hub.

Standing at the entrance to the plastics manufacturing plant, from left: Ellen Rohr, Fabio Rossi, Hot Rod Rohr, Eric Aune & Heather Aune.

With all the technology, synchronization and automated machinery, there still exists a proud workforce that is instrumental in the final product sold to plumbers, HVAC techs and other contractors around the world. “It was so cool to meet the people responsible for the products we buy every day. Equally as impressive, we were able to watch the process as literally every product Caleffi manufactures is tested before final packaging ships. I was blown away—the tour and people are first class all the way,” said Aune.

60 Years of Leadership

In 1961, beginning with two small lathes in his basement used for parts he crafted for OEMs, Francesco Caleffi founded the company. Fast forward to today and the Caleffi Group has grown to employ 1,400 people worldwide with subsidiaries and commercial offices in 18 countries. It produces and moves products via four Italian manufacturing and logistics facilities. Unlike other companies that are in the third or fourth generation, Francesco started from the beginning. “My father was like a hurricane. To be honest, he was able to build Caleffi in only one generation,” said Marco Caleffi.

Fabio Rossi about to give the Caleffi tour with Hot Rod, Mark Olson and Eric Aune.

Marco boasts that his father was a good mechanic, personally machining items and producing spare parts for other companies. “After two years, my father decided to make new, finished products such as air vents and safety valves,” said Marco. As technology advanced, automation became a big factor in the company’s success, a key contribution Marco’s father pushed for. “With forward-thinking automation, we have far greater control over quality. The standard of consistency is much, much better than manned assembly.”

From the beginning, what set Caleffi apart from competitors was “while they were only making ball valves, fittings and manifolds we were much more focused on the needs of the systems while making valves, fittings and manifolds,” continued Marco.

Fabio showing the details of how every catalog item is tested before leaving the plant

Early in Caleffi’s development, an instrumental partnership was formed. Marco’s uncle, Dante Bonini, joined Francesco Caleffi and was responsible for building a new commercial division. According to Marco, the two created a nice collaboration and they were a good balance for each other. “My father was difficult to manage because he wanted new buildings, new facilities and new investments before we needed them,” chuckled Marco.

Bonini offered a calming temperament that assisted Caleffi in making strategic moves when the time was right. “When we moved from the Gozzano regional plant in the Italian province of Novara, we bought this piece of land with room to grow in Fontaneto. It is still our headquarters today. Since the day we arrived, it has been our intention to expand,” said Marco.

In front of the CUBOROSSO (from l to r): Mark Olson, Fabio Rossi, Hot Rod Rohr and Eric Aune.

In 2008, Caleffi opened its new research center, named CUBOROSSO, a bright red building where products are researched, developed and tested. It is a building that stands in stark contrast with the others on the Caleffi campus. “It represents the color of the Italian mechanical ‘soul,’” said Marco. “Like Ferrari, Ducati and Alessi, red represents the mechanical side of Italian innovation.

In 2009, Caleffi continued its investment in innovation with its completely unmanned Automatic Vertical Warehouse (MAV), which improves customer service by optimizing logistical processes. When the storage and handling of goods are entirely automated, the result is shorter processing times and minimized operator error—the standard quality aforementioned by Marco. “It is critical to have finished products for delivery and spare parts for what is needed in assembly,” said Marco.

Checking out the “wall” of mixing valves.

“Everyone said it was so clean and modern, but it’s not until you’re on the floor and walking around that you realize you don’t see piles of materials and parts,” observed Aune. “Everything is very organized to the point where in the assembly stations, they move only the materials they need for a certain amount of time and a certain amount of product and then move them out quickly to be replaced with the next product. Everything was very orderly. It seemed that everything had a place. You could tell that that’s how they operate every day, not just because we were touring.”

If You Build It, They Will Come

In the 1980s, Caleffi was ready to expand into Europe and opened its first subsidiary in Germany. By the 90’s, another followed in England. “When we decided to expand, the initial branch was targeted for Germany because it’s a country that is associated with the ‘mechanic’s reference for innovative, precisely manufactured technology.’ There are a lot of German car makers, valve producers and boiler companies. We experienced nice success in Germany and then expanded into England. Now, 25 years later, we continued making our way into the U.S. and Canadian markets,” said Marco.

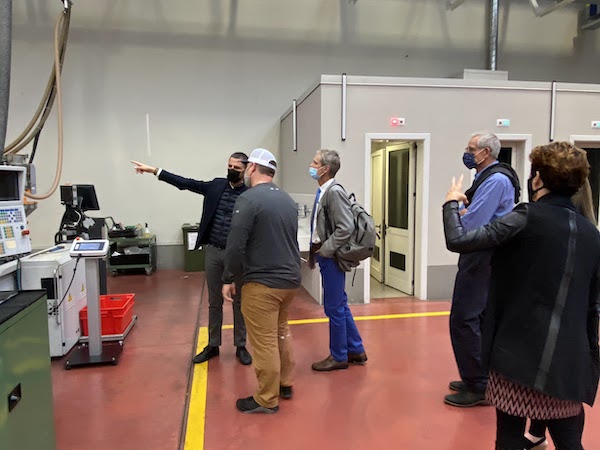

Fabio conducting the tour.

That introduction into North America came in 2001 when Roger Michaud and Rex Gillespie joined with Caleffi S.p.A. to begin pioneering the market. Mike Schreiner, now Chief Technology Officer, signed on in 2003 to develop a new zone valve line which ultimately became a key factor in Caleffi’s early growth.

From Caleffi S.p.A., Sergio Casarino was appointed Area Export Manager responsible for North America. He became an expatriate and for two years lived in Milwaukee to help get the fledgling business off the ground. Giovanni Monti, now General Manager, strategically positioned the growing world-wide company, providing a balanced configuration of management expertise and direction.

To further accelerate growth and organize North America for expansion, veteran Mark Olson was hired as CEO in 2005 where he continues to serve. Caleffi then began bringing on seasoned hydronic and plumbing experts such as Bob “Hot Rod” Rohr to head training and Roger Corrente to head sales.

Working piping systems are on display in the CUBOROSSO training center

Marco explains, “Once the decision to expand into North America was made, we were committed to deeply understanding the unique design elements in their hydronic and plumbing systems. We rejected the idea that we had to introduce this Italian valve or that Italian valve. If you understand the system needs, you can then devise better products for that market. With the balance of the right product configurations and management expertise, we are finding success in the North American market. It’s not easy when an Italian company goes elsewhere—such as to the U.S.—to find success.”

Hot Rod closely inspecting a radiator.

Bob Rohr further explains, “We’ve seen companies come into the U.S. and say ‘you’re going to do it the way we do it in our home country’ and most often it doesn’t work. Mark was smart to emphasize listening and observing: what do the American products need to be? A big part of our success is listening to the market instead of taking our way of doing business in some other place of the world and trying to force it into the market.”

To that point, training plays an integral role. Commented Marco, “We must learn and teach the system needs of our markets. In North America, applying the experience and reputation of experts like Hot Rod makes it much easier to extend our success. I think Bob and other veterans we hired have been key factors to our success.”

To that point, training plays an integral role. Commented Marco, “We must learn and teach the system needs of our markets. In North America, applying the experience and reputation of experts like Hot Rod makes it much easier to extend our success. I think Bob and other veterans we hired have been key factors to our success.”

“Before Mark Olson came on board, our focus didn’t extend much beyond simply selling. Mark brought a technical and market-based mindset. With his influence, we became more organized and stable. Today we have a premium market reputation with a deep technical staff and strong after sales support. With around 50 employees in the States, it’s almost like another company,” said Marco.

A COVID Epicenter

Early in 2020, Italy was one of the first countries ravaged by COVID-19. Caleffi was proactive even before the government shutdown. “Two days before the Italian government shut down all production, I personally decided to halt production because it was too difficult. The hospitals were full of patients. There were people working in the office and in production without knowing what could happen. It was a tough time, to be honest,” said Marco.

But then something powerful happened. “After staying home for two or three weeks, people wanted to come back to the company, which I never expected. Plenty of people were dedicated to the company, and it’s these employees that make up the soul and the environment of the company,” said Marco. Subsequently, Caleffi increased production in May, June and July of that year, running two shifts per day throughout the rest of the year.

“Especially now,” Marco said, “I feel proud of the choices we’ve made in the last decades in terms of business organization. Giovanni Monti is no doubt our key leader as he steadily positions and implements improvements year after year with his business resolution and experience as Managing Director for Caleffi. Giovanni is able to keep every process under control while mindfully planning actions with accuracy. It is an essential approach as we move beyond COVID.”

“Especially now,” Marco said, “I feel proud of the choices we’ve made in the last decades in terms of business organization. Giovanni Monti is no doubt our key leader as he steadily positions and implements improvements year after year with his business resolution and experience as Managing Director for Caleffi. Giovanni is able to keep every process under control while mindfully planning actions with accuracy. It is an essential approach as we move beyond COVID.”

“The rumor I picked up during my visit,” said Aune, “was that people hired at Caleffi feel that they’ve been ‘welcomed to the last company they will ever want to work for’. Now that’s impressive.”

Rohr adds, “My wife, Ellen, accompanied us on the tour. She observed that when Marco walked into the factory, everyone stood a bit taller,” said Rohr. “The employees are proud of the company and they are proud of the work they do. I am proud of the company I work for and it’s nice to see the people here are too.”

Eric admiring some components not yet available in North America used to filter incoming water on a Combi-boiler

Marco believes that success lies well beyond the company, “I think if you are involved in a company, you don’t only need to make money, you also need to create value in the company by making things better for the people and community. That was what my father believed in,” said Marco.

Currently, Caleffi has subsidiary locations in England, North America, Germany, France, Poland, Turkey, Netherlands, Portugal, Slovenia, Brazil and Australia. With these hubs, Caleffi S.p.A. sells its products in more than 90 countries. Caleffi is planning for more international growth and geographical expansion.

Says Marco, “We are currently planning an 80,000-square-meter warehouse expansion. My vision for the future is to see Caleffi in more countries with a much larger group of products to broaden the range of products we currently offer. Right now, our export business is expanding nicely and our branches are well staffed and managed. I see Caleffi continuing to extend its reach.”

I’m sure Francesco Caleffi would have been proud of the direction and leadership of his son, especially over these difficult past two years. Throughout the journey, the future looks bright for Caleffi.

Behind the scenes, Mark Olson sits in on the “virtual” interview with Marco Caleffi by John Mesenbrink.