Prototyping is an essential step in the product development process. Ideally, when you have a great idea for a product, you can go straight to manufacturing. However, in reality, it’s often best to find the right rapid prototyping companies to prototype your ideas before spending the money on mass production.

Prototyping allows you to test your design and make sure that it is feasible and meets customer needs or are ready for manufacturing. It also helps to identify any potential problems with the design before too much money has been invested. By prototyping your product, you can ensure that it is ready for market and avoid costly mistakes.

Here’s a look at how to create prototypes and what to consider before moving to production.

How to create prototypes

A prototype is a three-dimensional representation of a design idea. It can be either a small-scale model or a larger one that is used for testing, depending on what you’re trying to test. For example, if you’re testing a new feature for a mobile app, you might create a basic prototype that includes the essential elements of the design. If you’re testing a new piece of hardware, you might need to create a more complex prototype that includes all the features and components. No matter what you’re testing, prototypes are an essential part of the development process.

When you’re starting a new project, it’s important to create prototypes to test your ideas, as it allows designers to test their ideas before investing in costly production processes. There are several methods for creating prototypes, including 3D printing, CNC machining, and injection molding. Each method has its own advantages and disadvantages, so it is important to choose the right one for the specific project.

1. 3D printing

Designers and engineers have long used prototypes to test the feasibility of new ideas. In the past, creating a prototype usually involved expensive and time-consuming machining operations. However, advances in 3D printing technology have made it possible to create prototypes quickly and inexpensively. The first step in using 3D printing for prototyping is to create a 3D model of the desired object. This can be done using specialized CAD software or by scanning an existing object. Once the model is complete, it can be exported to a file format that is compatible with 3D printers. The next step is to choose the appropriate printer and material. For complex prototypes, it may be necessary to use multiple print runs with different materials. Finally, the prototype can be post-processed as needed, such as by painting or sanding. With its ability to produce high-quality prototypes quickly and economically, 3D printing has become an essential tool for product development.

2. CNC machining

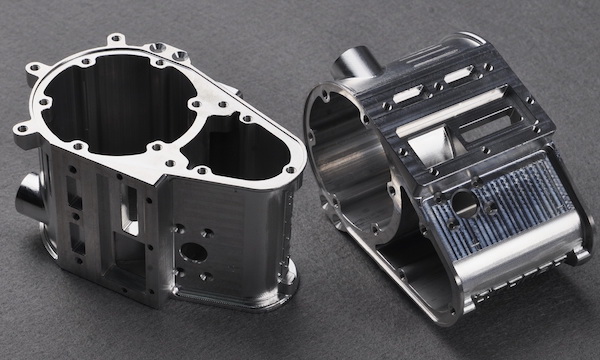

CNC machining is a great way to create prototypes quickly and easily. By using computer-controlled machinery, CNC machining can create complex shapes and patterns with a high degree of accuracy. This makes it ideal for creating prototypes, as well as for mass production. CNC machining is more expensive but can be used to create prototypes from a variety of materials, including metals, plastics, and composites. As a result, CNC machining is a versatile manufacturing technology that can be used to create high-quality prototypes quickly and easily.

3. Injection molding

Injection molding is one of the most popular methods for creating prototypes. It works by injecting molten plastic into a mold, where it cools and hardens to take on the shape of the mold. Injection molding is fast and efficient, and it produces prototypes that are extremely accurate and have a high level of detail. The biggest downside of injection molding is that it is relatively expensive, so it is best suited for projects that require a large number of prototypes.

If you are considering using injection molding to create prototypes, there are a few things you will need to keep in mind. First, you will need to choose the right type of plastic for your project. There are many different types of plastic, and each has its own set of properties that can impact the final result. Second, you will need to create a detailed design for your prototype. The more complex the design, the more difficult it will be to inject the plastic into the mold. Finally, you will need to find a reputable injection molding company that can produce high-quality prototypes at a reasonable price. With careful planning and execution, injection molding can be an excellent way to create prototypes for your next project.

Conclusion

When it comes to manufacturing your product, you will want to take the time to prototype your ideas first. This way, you can perfect the design and function of your product before mass-producing it. Prototyping also allows you to test out different materials and methods to find the most efficient and cost-effective way to manufacture your product.

Join the conversation: