Southland Industries was founded in Long Beach, California, in 1949 as a Southern California-based supplier of residential heating solutions. After years of growing organically and expanding their services and capabilities, they are now one of the nation’s largest MEP (mechanical/electrical/plumbing) building systems experts.

Today, Southland has 3,200 employees who serve most of the East and West Coast regions, as well as a Mountain West Division with offices in Tempe, Arizona and Las Vegas. The company’s capabilities encompass everything within each stage of the building lifecycle, including customized engineering, construction, building automation, service, and energy solutions.

“When Southland expanded to the East Coast in the mid-1990s, we were the first true design-build contractor in the area,” explained J. Gilbert, Mid-Atlantic Division plumbing supervisor. Gilbert has been with the company for 12 years and has presided over substantial growth during his tenure.

“At that time, other installers had no choice but to hire outside professional firms for design and engineering work,” continued Gilbert. “We had that capability in-house, which really set us apart from the competition. We’re now one of the largest MEP firms in the country.”

J. Gilbert, Mid-Atlantic Division plumbing supervisor.

According to Mike Dye, senior purchasing agent, much of Southland’s work in the Mid-Atlantic region includes government contracts, data centers, and pharmaceutical and educational customers. The company’s ability to bring every element of a project into consideration, including building automation and energy solutions, is a big advantage for large corporations and government agencies.

Professional plumbing

In 2017, Southland outgrew its existing offices and fabrication shop in Lorton, VA, and moved to a new facility in Laurel, MD.

The new facility, like all others owned by Southland, is a one-stop-shop for mechanical customers. The building’s 240,000 square feet is occupied by administrative offices, an engineering department, a sheet metal shop, mechanical piping (hydronic) fabrication space, plumbing, and a process piping area. It houses 100 union workers, including 30 plumbers.

“Southland Industries pre-fabricates components for every single project we’re on, and plumbing pre-fabrication is no exception,” said Gilbert. “The ability to work in a controlled environment, minimize jobsite waste, and reduce onsite labor is a huge advantage.”

One of the company’s most frequently used plumbing products are commercial water closet carriers. As one would expect, they’re used on every job. Dye purchases hundreds each year through local manufacturer’s representative, The Joyce Agency, based in Chantilly, VA.

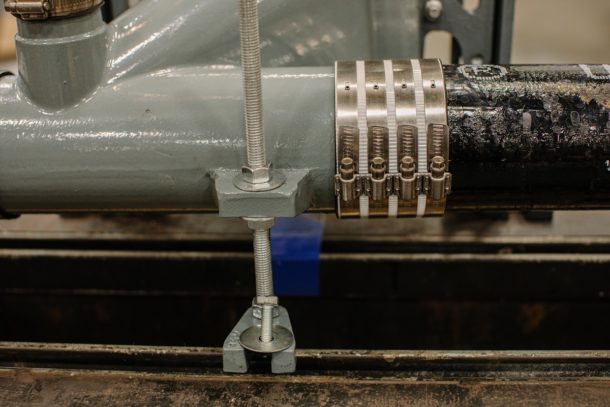

“The QT QuickTurn™ closet carrier is one of dozens of Watts products we source through Kevin Cerretani at The Joyce Agency,” said Gilbert. “Its design expedites both the prefabrication process here at the shop and the final installation in the field.”

Plumber Joe Gencavage assembles many of the carrier systems in the fab shop. There, water supply, vent, and waste water piping is cut to length, attached to the carriers, and disassembled for later use in the field.

“The enamel finish on the QT QuickTurn carrier is great, as are the no-hub vent and wastewater connections and the dual threaded boss for supply water pipe support,” said Gencavage. “For install crews, the ability to adjust the face plate left and right makes the job easier. Same goes for the side-facing carrier support legs. It’s a nicely streamlined design.”

The new carrier system was one of several new products brought to Southland by The Joyce Agency in 2019.

Partnered for growth

“We’ve had a strong relationship with Southland for 15 years,” said Cerretani, who’s been with The Joyce Agency for 29 years. “I think that has been one source of success for both companies.”

The Joyce Agency’s plumbing division provides pipe, water closet and lavatory carriers, drainage products, flush valves, plumbing fixtures, sinks, water coolers, electric tankless water heaters, safety equipment, steam components, acid waste piping and laboratory fixtures to Southland. The agency’s main facility in Chantilly has three divisions: plumbing, architectural products, and HVAC.

“We’re very happy with the Watts products and the breadth of their line, but one of the biggest advantages of buying Watts products for us comes through our relationship with The Joyce Agency,” said Gilbert. “We can count on them to get products to us in a timely manner and provide exceptional service.”

The Joyce Agency represented a different carrier line for 23 years, switching to Watts six years ago. Cerretani has found that many of the costly options offered by other manufacturers are standard features in the Watts line.

“The epoxy coating on the carriers is one example of a Watts standard feature,” said Cerretani. “Another feature we like on the QT QuickTurn is the O-ring seal and ABS nipple. Pushing the nipple into place is much faster than threading the nipple into place.”

“The true superstars in the supply chain are the folks in our quotations group, the commercial inside sales group, and our warehouse personnel,” continued Cerretani. We have an open line of communications with the folks at Southland to streamline the process of product selection, submittals, and providing the right material on time. I’m blessed to work with the professionals at Southland, as well as my Joyce Agency associates.”

“Watts and The Joyce Agency both really set themselves apart when it comes to customer service,” said Dye. “They’re the experts, and we lean on them both during the design phase and beyond.”

Join the conversation: