With more and more commercial buildings creeping past the 50-year mark, concerns about aging infrastructure are growing. And as those buildings age, the old copper and metal piping systems behind the walls are corroding away.

In fact, experts are saying that with the amount of buildings aging across the landscape, the plumbing repipe market will soon surpass the new construction market. Translation: There’s lots of money to be made in this area.

So, what’s the best solution for plumbing repipes?

With its flexibility, durability and long coil lengths, PEX is proving to be the best solution for commercial plumbing repipes. The long, flexible coils can snake into tight openings and maneuver around the existing structure with ease, making repipes faster and easier with less impact on the building. Plus, with a life expectancy of more than 100 years, PEX will outlast any metal piping system on the market.

With its flexibility, durability and long coil lengths, PEX is proving to be the best solution for commercial plumbing repipes. The long, flexible coils can snake into tight openings and maneuver around the existing structure with ease, making repipes faster and easier with less impact on the building. Plus, with a life expectancy of more than 100 years, PEX will outlast any metal piping system on the market.

Unfamiliar with PEX? Here’s a quick overview.

PEX is an acronym for crosslinked polyethylene. There are currently three different methods for manufacturing PEX (known in the industry as PEX-a, PEX-b and PEX-c) which generate pipe that is crosslinked to varying degrees.

PEX pipe is manufactured to be a copper tube size (CTS) pipe with a wall thickness conforming to a standard dimension ratio of 9 (SDR9). And PEX is approved by all model plumbing codes for domestic-water piping applications according to ASTM F876 and F877 standards.

Due to the shape memory of the pipe, it can expand and retract back to its original size, making it highly resistant to damage from frozen water in a piping system. Plus, PEX is also resistant to corrosion, pitting and scaling which can plague metal piping systems.

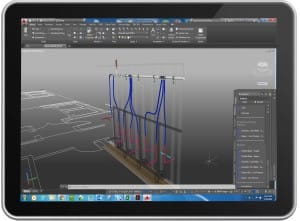

With pipe and fittings sizes available up to 3″, PEX is a great solution for both risers and distribution piping, and it is also approved for direct burial in soil or concrete.

For suspended piping applications, PEX can be supported by the same CTS pipe hangers or supports used for metallic pipe. The horizontal support spacing for 1 inch and smaller PEX is 32 inches; for 1¼ inch and larger PEX, 48 inches. (Note that some codes only allow for 32-inch horizontal support spacing regardless of pipe size, so be sure to check local codes for verification.)

For suspended piping applications, PEX can be supported by the same CTS pipe hangers or supports used for metallic pipe. The horizontal support spacing for 1 inch and smaller PEX is 32 inches; for 1¼ inch and larger PEX, 48 inches. (Note that some codes only allow for 32-inch horizontal support spacing regardless of pipe size, so be sure to check local codes for verification.)

For suspended applications requiring less or more restrictive support spacing, a PEX-a Pipe Support product is available that offers support spacing of 8 ft. as well as the ability to field-insulate around the piping and support channel.

Additionally, as hybrid piping systems begin to increase in the commercial landscape, more and more transition fittings are entering the market, making it viable to transition from PEX to other piping materials, such as copper and CPVC.

Want to see how professionals are saving time and money repiping with PEX? Check out the story about this century-old iconic hotel or this 50-year-old senior complex or this 16-story high-rise.

To learn more about PEX system solutions, visit uponorpro.com.

Kim Bliss is the technical communications manager at Uponor. She holds more than 25 years of writing experience with an emphasis in technical and manufacturing. She can be reached at kim.bliss@uponor.com.

Kim Bliss is the technical communications manager at Uponor. She holds more than 25 years of writing experience with an emphasis in technical and manufacturing. She can be reached at kim.bliss@uponor.com.

Join the conversation: