Greenlee Textron Inc., a Textron Inc. company, introduces a new line of Next Generation tool bags. The innovative Next Generation bags are engineered to reduce strain on the user and withstand wear and tear. In addition, the two back packs allow for customization with a personalized name patch. “Greenlee is committed to producing ergonomic tools Read more

Toolbox

Greenlee Textron Inc., a Textron Inc. company, introduces a new line of Next Generation tool bags. The innovative Next Generation bags are engineered to reduce strain on the user and withstand wear and tear. In addition, the two back packs allow for customization with a personalized name patch.

Greenlee Textron Inc., a Textron Inc. company, introduces a new line of Next Generation tool bags. The innovative Next Generation bags are engineered to reduce strain on the user and withstand wear and tear. In addition, the two back packs allow for customization with a personalized name patch.

“Greenlee is committed to producing ergonomic tools and products that reduce injury and increase productivity to support the professionals who use them daily,” said Dale Speggen, product manager at Greenlee. “Our network of professional contractors helped to test the Next Generation tool bags and provided valuable feedback. We are confident these durable, long-lasting and lightweight bags will help get the job done.”

Engineered to be rugged, the Next Generation tool bags can manage heavy loads and harsh work environments. Next Generation bags are constructed from a poly and nylon Ripstop fabric. This construction contains any tear that should ensue, maintaining the durability and utilization of the bag. Critical seams that receive stress from weight are reinforced with double and triple stitching to prevent separation. Next Generation bags are lined with a light green interior to increase visibility of bag contents. A durable, hard plastic bottom keeps dirt and water out and allows the bag to stand in an upright position for easy access.

The new Next Generation tool bag line features four unique designs to fulfill the exact needs of the professional. Additional features include:

Professional Tool Backpack (0158-26)

- Personalized embroidered name patch

- Designed for the work environment

- Separate compartment for safety glasses

- Nickel chromium zippers for added durability

- Padded lumbar support reduces back strain when carrying a loaded backpack

- S-strap shoulder strap designed for ergonomic form-fit to evenly distribute weight

- 30 double-stitched pockets for tool storage and organization

Professional Tool & Tech Backpack (0158-27)

- Personalized embroidered name patch

- Designed for the office and the work environment

- Features a laptop compartment

- Same ergonomic benefits as the tool backpack

- 27 double-stitched pockets for tool storage and organization

- Zippered compartment allows for tablet or laptop storage

20″ Heavy-Duty Multi-Pocket Tool Bag (0158-21)

- Reinforced slip-proof padded shoulder straps with clips to hold the bag closed

- ABS waterproof plastic bottom keeps tools and bag protected from the elements

- 28 double-stitched pockets provide tool storage and organization

11″ Electrician’s Open Tool Carrier (0158-24)

- Open top and light green interior makes it easy to locate and access tools

- Reinforced, padded shoulder straps

- 27 double-stitched pockets provide tool storage and organization

Greenlee will launch four additional bags this spring. For more information, visit www.greenlee.com or call 1-800-435-0786.

This is the Domino Automatic stairclimber by Zonzini. The first tracked stairclimber the Hub’s Eric Aune has personally seen. The platform measures approximately 37”x22” with the load sitting only 5-1/4” off the ground. Three different models (160, 300 & 400kg) can lift loads of 350lb, 660lb and 881lbs with runtimes of up to 1000 steps Read more

This is the Domino Automatic stairclimber by Zonzini. The first tracked stairclimber the Hub’s Eric Aune has personally seen.

The platform measures approximately 37”x22” with the load sitting only 5-1/4” off the ground. Three different models (160, 300 & 400kg) can lift loads of 350lb, 660lb and 881lbs with runtimes of up to 1000 steps on a single charge.

The track rotation allows for 360 degree rotation so spiral staircases are simple to navigate. Tracks are made of silicone and non-marking on fine surfaces like wood floors. Fork attachments are available in place of the flat platform shown.

Sales are handled direct and shipping is available worldwide. Info available at zonzini.us, pricing was not immediately available.

Milwaukee Tool continues to revolutionize the tool industry with the introduction of the TICK™ – a professional-grade Bluetooth™ tool and equipment tracker. Designed to withstand the harshest jobsite environments, the TICK™ can be easily attached and hidden from sight on any product, regardless of brand, providing users an invaluable way to track anything in their Read more

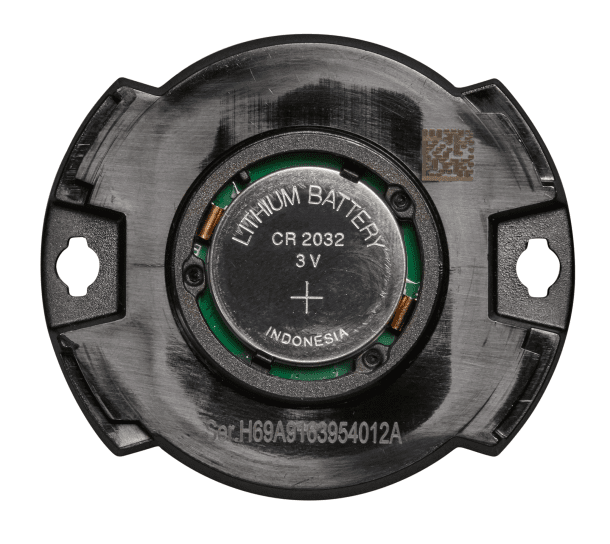

Milwaukee Tool continues to revolutionize the tool industry with the introduction of the TICK™ – a professional-grade Bluetooth™ tool and equipment tracker. Designed to withstand the harshest jobsite environments, the TICK™ can be easily attached and hidden from sight on any product, regardless of brand, providing users an invaluable way to track anything in their inventory through the ONE-KEY™ app.

Milwaukee Tool continues to revolutionize the tool industry with the introduction of the TICK™ – a professional-grade Bluetooth™ tool and equipment tracker. Designed to withstand the harshest jobsite environments, the TICK™ can be easily attached and hidden from sight on any product, regardless of brand, providing users an invaluable way to track anything in their inventory through the ONE-KEY™ app.

“Tool loss, and the time spent looking for missing tools, contributes significantly to a company’s bottom line. A single lost or damaged tool on a jobsite can increase the time spent completing a task by over 30%. This, multiplied across the length of a large project, can add up to tens of thousands of dollars in wasted labor, and cause significant overruns on project schedule. The goal of ONE-KEY™’ is to simplify the process of managing tools, removing costly or cumbersome methods used today. The ability to quickly identify a tool’s location can save time and money if a tool goes down or is needed on short notice,” said Steve Matson, Senior Product Manager. “By harnessing the same Integrated Tool Tracking technology found within ONE-KEY™* enabled tools, we’re giving users a way to track any tool, simply by attaching the TICK™. For professionals everywhere, their tools and equipment are key to their livelihood – the TICK™ ensures they have eyes on everything to better manage their investment.”

With its low profile design, the TICK™ can securely attach to anything through glue, screw, rivet, or strap. Its flat back enables a snug fit to a variety of surface types and its circular shape fits into a range of places hidden from view; for instance, the underside of a ladder or miter saw stand. Each TICK™ is also laser engraved with a serial number so users can easily identify and assign multiple TICK™s. Once attached and hidden from view, the TICK™ makes tracking tools and equipment as simple as pulling out your phone.

Products with a TICK™ attached are paired via the ONE-KEY™ app. Tool records and locations are updated when any device with the ONE-KEY™ app comes within 100 feet of the TICK™. These location updates are transmitted through any ONE-KEY™ app that’s in-range, regardless of whether the app is open or not, allowing users to pinpoint missing tools more quickly. In addition, users can easily manage all of their tools through the app’s Simplified Tool and Equipment Management features. These features allow users to assign and store detailed information for all of their tools and equipment – whether it’s a tool equipped with a TICK™, a ONE-KEY™ enabled tool or any other tools and equipment.

Fully embodying the Milwaukee promise of “Nothing but HEAVY DUTY,” the TICK™ is ruggedly protected from the harshest environments – giving professionals peace of mind that they’ll receive updated locations of their tools and equipment, no matter what. Its water and dust-tight closure protect the internal components from weather elements, and UV rated plastics keep the TICK™ from getting brittle when exposed to extended periods of direct sunlight. In addition, its rugged electronics housing can stand up to high vibration and impact, as well as heavy duty tracking applications, like underneath a generator.

Available in February 2017, the TICK™ is a true testament to Milwaukee’s focus on the user and investment in game changing technology. For more information on ONE-KEY™ please visit http://www.milwaukeetool.com/one-key.

*ONE-KEY™ is the first digital platform for tools and equipment. By integrating industry-leading tool electronics with a custom-built cloud based program, ONE-KEY™ provides a new level of control and access to information that revolutionizes the way work gets done. The ability to customize, track, and manage through ONE-KEY™ fundamentally changes the way users interact with their tools.

TICK™ Product Offering

- 1-Pack (48-21-2000) – $29

- 4-Pack (48-21-2004) – $99

- 10-Pack (48-21-2010) – $219

- 50-Pack (48-10-2050) – $999

As tool manufacturers continue to develop more powerful tools, the bits that work in tandem must also improve to keep up with the pace of the jobsite. That’s why Bosch developed Impact Tough™ Impact Driver Bits – upgraded with design functionality and toughness to deliver 10X more life than standard impact bits. “Impact drivers today Read more

As tool manufacturers continue to develop more powerful tools, the bits that work in tandem must also improve to keep up with the pace of the jobsite. That’s why Bosch developed Impact Tough™ Impact Driver Bits – upgraded with design functionality and toughness to deliver 10X more life than standard impact bits.

The new Bosch Impact Tough™ Impact Driver Bits, upgraded to deliver 10X more life than standard impact bits.

“Impact drivers today are offering more torque than ever before, so professionals need a series of bits that can keep up with these more powerful tools,” said Desmond Smith, product manager, accessories, Robert Bosch Tool Corporation. “As a power tool accessory leaders, Bosch took the time to perfect the manufacturing process for Impact Tough bits in order to meet the most rugged applications on the jobsite.”

The upgraded Impact Tough bits include an impact-rated line of screw driving bits, double-ended bits, nut setters, sockets and bit holders, each enhanced to handle next-generation high torque impact drivers.

Bosch started by developing its Xtended Torsion Zone™, a feature that absorbs torque peaks to reduce breakage. Impact Tough series transfers torque stress at the tip of the bit to the enhanced Torsion Zone for tension dissipation, making them stronger and more reliable.

In addition, the tips themselves are precision designed and machined for a better integrated fit. This delivers more torque to the screw, lessens slippage and reduces cam-out damage for a longer-lasting bit. And Bosch designed an exclusive manufacturing process, incorporating heat-treated materials to improve each bit’s strength and overall life.

Impact Tough Double-Ended Bits (6″ bits) now provide a Dual Torsion Zone, protecting each end of the bit. This feature means these bits last twice as long, doubling their life while delivering higher ultimate torque in tough applications.

All the bits in the upgraded Impact Tough series come with a silver, high-visibility sleeve so pros on the jobsite can easily find them in a toolbox or on the ground. The easily recognizable coating also has laser markings to clearly identify each bit. The laser inscriptions are easier to read than traditional stamped scripts.

To learn more about the Bosch Impact Tough™ Impact Driver Bits or to find a local dealer, visit www.boschtools.com or call 877-BOSCH-99. Check out www.bethepro.com for additional tips and videos.

Lead Free Compliant & Molded from RADEL® Resin For use in hot and cold potable water distribution systems, Matco-Norca has introduced Cold Expansion ASTM F1960 Pex Fittings molded from RADEL® Resin. Lead free compliant, these fittings are available in a range of configurations: couplings, elbows, male adapters, tees and rings with stops, all in various Read more

Lead Free Compliant & Molded from RADEL® Resin

For use in hot and cold potable water distribution systems, Matco-Norca has introduced Cold Expansion ASTM F1960 Pex Fittings molded from RADEL® Resin. Lead free compliant, these fittings are available in a range of configurations: couplings, elbows, male adapters, tees and rings with stops, all in various sizes.

RADEL Resin is a general purpose extrusion grade of modified PPSU (polyphenylsulfone) that provides exceptional hydrolytic stability and toughness.

Matco-Norca’s Cold Expansion Pex Fittings comply with the ASTM F1960 specification for cold expansion fittings and pex reinforcing rings as well as other standards including NSF 14/NSF/ANSI 372/NSF/ANSI 61 and CS B137.5.

These fittings have a maximum temperature rating of 320ºF and a maximum working temperature/pressure of 210ºF at 150 PSI.

For more information on F1960 Cold Expansion Fittings from Matco-Norca, visit www.matco-norca.com and click on Fittings in the navigation bar.