By Paul Carmody Small business owners face constant challenges in their quest for growth. In the home service industries, numerous obstacles threaten to block the path, from staffing shortages to increasing overhead expenses and competition. Add to that a few trade-specific challenges, such as fluctuations in seasonal demand and ever-changing regulations and advances in technology Read more

ShopTalk

By Paul Carmody

Small business owners face constant challenges in their quest for growth. In the home service industries, numerous obstacles threaten to block the path, from staffing shortages to increasing overhead expenses and competition. Add to that a few trade-specific challenges, such as fluctuations in seasonal demand and ever-changing regulations and advances in technology, and it becomes clear these businesses need a reliable way to streamline operations, improve efficiency and keep everyone on the same page.

While there’s no one-size-fits-all solution for growing a service business, there are several common pain points we hear over and over again in the field that must be addressed in order to get to that next level:

Pain Point #1: Issues Empowering Technicians in the Field

We often hear that it can be hard to track a technician’s time when they are in the field, or to outfit techs with all of the tools they need on their phone or device. When the software you’re using is lacking in features or functionality for the field or the back office, it can mean missed job notifications, slowly processed invoices and lack of customer history – all causing day-to-day headaches for the technician team.

Pain Point #2: Navigating a Mobile App vs. Back-End

Does your business have a user-friendly mobile interface for field technicians but grapple with back-end infrastructure that’s inefficient and disjointed? You are not alone. There is often a disconnect between a strong mobile app and an outdated back-end system, and a lack of integration between the two can cause communication delays between field and office staff. The unhappy result is missed appointments and disappointed customers, which leads to a tarnished company reputation.

Pain Point #3: Juggling Software Systems

Using multiple software systems that rely on an API or data sync to move data from one platform to another doesn’t always work as planned. Maintaining multiple software packages can create compatibility issues and numerous software updates that cause downtime and disruptions to critical business operations. It also adds on costs for licensing, training, and support. For technicians, switching between multiple apps to access customer details, job updates and invoicing is frustrating. Their productivity takes a hit, and the risk of error increases with manual data entry.

Prescription for Pain Relief

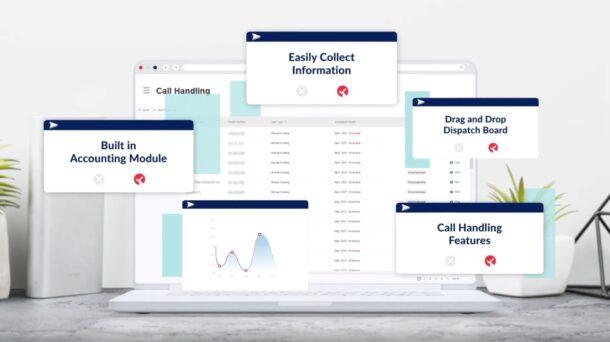

Fortunately, it’s possible to have a unified business management platform that streamlines day-to-day operations. Look for one that is tailored to meet the unique demands of your industry and allows for customized workflows, reports, and processes to align with your specific business requirements. Today’s best software has features designed to streamline processes, enhance business operations, help your employees make informed decisions and provide excellent customer service to your clients.

To specifically address empowering technicians in the field, provide them with a mobile app that allows them to collect payment, input customer opportunities or equipment, and invoice right from their phone or device at the jobsite.

It’s definitely time to say goodbye to paper and embrace custom digital forms that techs can access right from their mobile app. Another way to make techs (and back-office staff) happy is by eliminating the paper timecard. Time tracking in a mobile app is a must, as are digital invoices. No more waiting for the back office to email or mail an invoice; your customer can get it right away from the tech. Customers have a better experience too because they won’t have to call into the office with their payment information or wait days for an invoice to be mailed.

Once you have all that convenience in a mobile app, you want to make sure it’s connected with a powerful back-end system that answers all of your software needs in one package. A few key features to look for include:

- Accounting: integrated accounting features should be robust enough to eliminate the need for third-party accounting software or hiring an accountant to create your general ledger. The functionality should also eliminate the need for double information entry and reduce admin time by including tools like one-click digital invoicing. More accurate financial data can be at your fingertips. For instance, Successware’s accounting functionality lets users defer revenue from agreements to the period the visit occurred, leading to increased accuracy.

- Agreements: Agreement management built directly into the software will save time for call takers and dispatchers. For instance, when call takers are on the phone with a current customer, you want them to be able to see if they have an active agreement for which they need to schedule service. Dispatchers can more easily fill in jobs on the dispatch board when they can see agreement visits that need to be scheduled.

- Reporting: When operational and job data reside in the same platform as your financial data, it can do wonders for reporting. You won’t have to export data from multiple platforms to create robust reports, and if you have multiple businesses on one platform, you can consolidate financial reporting to see all data in one report. Reports in the new Successware Platform are run using Microsoft® Power BI, an industry leading platform.

There will always be pain points in business, but your business management software doesn’t have to be one of them. Do your research and find the right all-in-one solution that will reduce expenses, simplify processes and increase your revenue and profits so you can grow and scale your home service business.

Paul Carmody has over 20 years of experience as a senior executive in Software-as-a-Service, technology-enabled services, internet infrastructure, and supply chain/manufacturing industries. He has served as a key executive in five successful exits and one IPO. He is currently President of Successware, an Authority Brands company.

Paul Carmody has over 20 years of experience as a senior executive in Software-as-a-Service, technology-enabled services, internet infrastructure, and supply chain/manufacturing industries. He has served as a key executive in five successful exits and one IPO. He is currently President of Successware, an Authority Brands company.

Managing a construction fleet involves a unique set of challenges that can significantly impact efficiency, cost and project timelines. From dealing with equipment downtime to navigating complex compliance requirements, fleet managers in the construction industry face numerous hurdles. Understanding these pain points can help professional tradesmen optimize their fleet operations and improve overall job site Read more

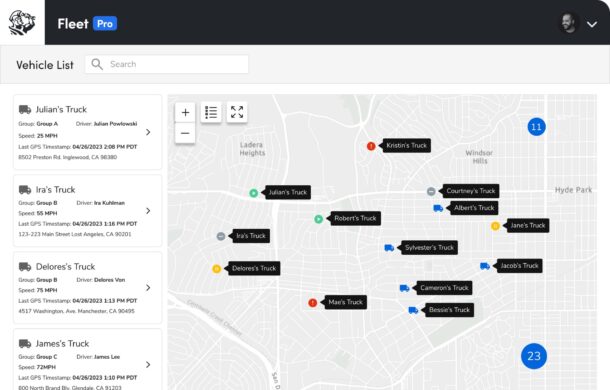

Managing a construction fleet involves a unique set of challenges that can significantly impact efficiency, cost and project timelines. From dealing with equipment downtime to navigating complex compliance requirements, fleet managers in the construction industry face numerous hurdles. Understanding these pain points can help professional tradesmen optimize their fleet operations and improve overall job site productivity. Here, we explore the top pain points for construction fleets and offer insights into addressing these issues.

Equipment Downtime

One of the most critical challenges for construction fleets is equipment downtime. When machinery breaks down or is unavailable, it can halt projects, leading to delays and increased costs. Several factors contribute to equipment downtime:

- Maintenance Issues: Regular maintenance is essential, but unexpected breakdowns still occur. Without a proactive maintenance schedule, minor issues can escalate into significant problems, leading to prolonged downtime.

- Lack of Spare Parts: Delays in obtaining necessary spare parts can extend the time equipment is out of service.

- Operator Error: Inadequate training or operator mistakes can lead to equipment damage and downtime.

To mitigate these issues, fleet managers should implement a robust preventive maintenance program, ensure a steady supply of spare parts, and invest in comprehensive training for equipment operators. Using asset maintenance software can also streamline these processes and reduce downtime.

Rising Maintenance Costs

Maintenance costs for construction fleets are on the rise due to several factors, including:

- Aging Equipment: Older machinery often requires more frequent and costly repairs.

- Complex Technology: Modern construction equipment comes with advanced technology, which, while improving efficiency, also increases the complexity and cost of maintenance.

- Labor Costs: Skilled technicians are needed to perform maintenance, and their labor costs are rising.

Fleet managers can address rising maintenance costs by strategically planning equipment replacement, negotiating better rates with suppliers, and using data analytics to predict costly repairs.

Fuel Management

Fuel is a significant expense for construction fleets. Inefficient fuel use can lead to increased costs and environmental impact. Key fuel management challenges include fuel theft, inefficient fuel use, and lack of monitoring. Implementing fuel monitoring systems, educating drivers on efficient driving practices, and securing fuel storage can help manage fuel costs effectively.

Driver Management

Managing drivers in a construction fleet comes with its own set of challenges:

- Driver Shortage: The industry faces a shortage of qualified drivers, making it difficult to find and retain skilled personnel.

- Training and Compliance: Ensuring that drivers are properly trained and comply with regulations is critical for safety and efficiency.

- Performance Monitoring: Tracking driver performance to ensure adherence to safety and operational standards can be challenging.

Fleet managers can overcome these challenges by investing in driver training programs, implementing driver incentive schemes and using telematics to monitor driver performance.

Compliance With Regulations

Compliance with regulations is a major concern for construction fleet managers. Regulations cover a wide range of areas, including:

- Safety Standards: Ensuring that all equipment and operations meet safety standards is essential to avoid penalties and accidents.

- Environmental Regulations: Compliance with emissions standards and other environmental regulations is increasingly important.

- Record Keeping: Maintaining accurate records for inspections, maintenance and driver hours is mandatory and can be time consuming.

Staying updated with regulatory changes, using fleet management software to streamline compliance tasks and conducting regular audits can help manage regulatory compliance effectively.

Data Management

In the modern construction fleet environment, data plays a crucial role. However, managing and utilizing data effectively can be challenging:

- Data Overload: The sheer volume of data generated by modern fleet management systems can be overwhelming.

- Integration Issues: Integrating data from various sources into a cohesive system can be difficult.

- Actionable Insights: Turning raw data into actionable insights requires specialized skills and tools.

Fleet managers can address data management challenges by investing in advanced fleet management software that offers data integration and analytics capabilities, and by training staff to interpret and act on data insights.

Construction fleet managers face numerous challenges, from managing equipment downtime and rising maintenance costs to ensuring compliance with regulations and effectively managing drivers. By understanding these pain points and implementing strategic solutions, tradesmen can optimize their fleet operations, reduce costs, and improve efficiency on the job site.

Sam Kraft is Content and Communication Manager at Whip Around. Kraft brings 13-plus years of copywriting experience to Whip Around, where he’s immersed in “all things fleet” on a daily basis. He’s the go-to guy for fleet technology insights, breaking down industry trends and making sure fleet managers get the information they need to keep their equipment safe, compliant and productive.

Sam Kraft is Content and Communication Manager at Whip Around. Kraft brings 13-plus years of copywriting experience to Whip Around, where he’s immersed in “all things fleet” on a daily basis. He’s the go-to guy for fleet technology insights, breaking down industry trends and making sure fleet managers get the information they need to keep their equipment safe, compliant and productive.

By Heath Betts, Nexstar Network Leadership & Culture Coach The hardest expectations to manage are the ones we don’t know about As a Nexstar coach, I have the enormous privilege of traveling across the United States to visit our members’ shops. Most companies, I’ve noticed, have a lot in common – especially when it comes Read more

By Heath Betts, Nexstar Network Leadership & Culture Coach

The hardest expectations to manage are the ones we don’t know about

As a Nexstar coach, I have the enormous privilege of traveling across the United States to visit our members’ shops. Most companies, I’ve noticed, have a lot in common – especially when it comes to success and struggles! The largest challenges I see most often are those surrounding clear communication.

If you lead a team, you might feel that you’ve done a great job of communicating your expectations to everyone. But now, your people aren’t performing, or they aren’t accomplishing the things that you think they should. However, I’d be willing to bet your team thinks they’ve accomplished a lot. In fact, right now, they’re saying, “I went above and beyond; I did more than what I was supposed to do.”

So, now what we have is this enormous expectation gap. An expectation gap is the space that lies between what we expect to happen and what actually happens. And in the middle of that gap, there’s anger, disappointment, and a lack of trust from both sides. We need to do everything we can to get rid of that gap! And the only way to do it is to attempt to reset expectations in a clearer way.

Everyone on your team should know exactly what’s expected of them in the role that they perform. They need to know what their goals are, and the clearer we can be about those goals, the more effective your team is going to be. That way, when things start getting crazy and ideas start flying in and people want to go in all different directions, you can bring them back to what’s expected, what the defined goals are, and what things need to be accomplished for those goals to be met. Then your team gets to focus on the work that they know they need to be focused on, instead of going all over the place and getting into other people’s lanes.

Sounds easy, right? It can be, if we’re intentional about how we go about this. A great exercise to help you clear up your expectation gap is to sit down with your team members and conduct an Expectations Exchange. Ask them, “What do you believe is expected of you?” Then, you can share what you expect of them. Compare notes and get clarity – this will go a long way towards eliminating that gap.

Another thing that you can do is have your team write down answers to the question, “What do you expect from me as a leader?” You, as the leader, can write down what you believe they expect from you. Now, compare notes. Read all the answers out loud. I guarantee it will be an eye-opening experience; you’re going to discover a lot of things. And the things you’ll discover will help you get rid of that expectation gap. Imagine that: Getting rid of that anger, frustration, disappointment, and lack of trust. Moving forward with your team to work more effectively. With that expectation gap removed, you’re going to have lots more fun coming to work and accomplishing great things together, too!

Heath Betts has owned and operated successful businesses in five different states. During his career, he has taught HVAC technical classes for a local community college and for manufacturing companies. Heath has coached more than 300 HVAC companies and provided mainstage presentations to thousands. He loves to see organizations succeed, and helps Nexstar members understand how culture and leadership affects the health of their companies.

Heath Betts has owned and operated successful businesses in five different states. During his career, he has taught HVAC technical classes for a local community college and for manufacturing companies. Heath has coached more than 300 HVAC companies and provided mainstage presentations to thousands. He loves to see organizations succeed, and helps Nexstar members understand how culture and leadership affects the health of their companies.

How Efficient Freight Forwarding Can Save Time and Money Efficiency and reliability are crucial in the fast-paced HVAC world (Heating, Ventilation, and Air Conditioning). From small-scale residential projects to large commercial installations, HVAC businesses must navigate a complex web of supply chains, manage tight schedules, and ensure the timely delivery of equipment and materials. One Read more

How Efficient Freight Forwarding Can Save Time and Money

Efficiency and reliability are crucial in the fast-paced HVAC world (Heating, Ventilation, and Air Conditioning). From small-scale residential projects to large commercial installations, HVAC businesses must navigate a complex web of supply chains, manage tight schedules, and ensure the timely delivery of equipment and materials. One critical aspect that can significantly impact these operations is logistics. Efficient freight forwarding, mainly through global freight forwarding solutions by Foresmart, can play a pivotal role in saving time and money for HVAC businesses.

The Role of Freight Forwarding in HVAC Logistics

Freight is the commercial transport of cargo from one region to another utilizing various modes, including water, air, road, and rail. This method involves a lot of planning, coordination, and control to facilitate product delivery in the required location and quality. To HVAC businesses—where large, massive, and at times delicate equipment is transported—the role of freight forwarding cannot be overstated.

HVAC projects usually contain several items produced by different manufacturers. Builders also purchase materials in bulk to save on costs. These components may include air conditioners, heaters, vents, and many other parts that can be tiny in size. Moreover, it is imperative to have a proper plan for obtaining all these items from various suppliers at the project site. That is where efficient freight forwarding comes in handy. Therefore, HVAC companies can coordinate with a credible freight forwarding firm to ensure that all needed parts are shipped simultaneously so that delays due to late or missing shipment parts can be avoided.

Cost Savings through Consolidation and Optimization

Another notable method through which efficient freight forwarding lowers costs for HVAC companies is combination and improvement. Ad hoc logisticians have less experience coordinating various small shipments into a single large shipment than freight forwarders do. This process, called consolidation, makes economic sense to the shipping company because it is cheaper to handle consolidated shipments than handle many small shipments that are likely to come in. Besides, freight forwarders can choose the correct route and carriers, which would help reduce transportation costs.

Typically, these cost savings are considerable for HVAC businesses. When purchasing HVAC equipment or parts, transporting them separately can easily add up, especially if you are importing from another country. Freight forwarders can also significantly reduce the extreme cost of shipping by combining shipments and reviewing all the possible routes that HVAC companies can use, thus increasing company revenue.

Last, effective freight forwarding brings the added benefit of dealing with customs procedures and paperwork complexities. HVAC businesses require importing parts from international manufacturers, meaning the companies must deal with many formalities and documentation. These regulations are also known to freight forwarders, and they can also check that all paperwork is done correctly and on time. Such expertise also reduces the possibility of costly and time-consuming customs holdups, which can prove expensive to any company.

Enhancing Project Management and Scheduling

The most valuable commodity in the HVAC industry is time; hence, the companies in this industry must ensure that they manage their projects accordingly. For instance, the absence of some critical parts for the project can result in time extension and additional charges that will be anathema to clients. Effective freight management prevents HVAC companies from suffering from such problems due to the ability to maintain consistent and reliable delivery schedules.

Freight forwarders have satellite tracking and communication with the shipment to track it in real time. This transparency means that HVAC companies can keep their clients informed about the progress of their orders and adjust project timelines accordingly. Freight forwarders are in a position to come up with workarounds should any sudden occurrences happen; for instance, they can easily change the route or search for another mode of transportation to ensure that the cargo gets to the intended destination.

In addition, increased use of freight forwarders can also help HVAC businesses manage their inventory more efficiently. By procuring sub-components within a few days or weeks before they are needed, firms minimize the need for large inventories and the likelihood of having excess or inadequate inventory. This just-in-time inventory approach impacts cash flows positively and decreases the costs that are incurred when holding stocks.

Leveraging Expertise for Improved Supply Chain Efficiency

Freight forwarders encompass more than just shipping companies whose primary function is transporting goods from one location to another; they also provide additional services that could benefit HVAC companies regarding supply chain management. These services may involve packaging and labeling services, warehousing and distribution, and supply chain consulting services. By utilizing these services, HVAC companies can eliminate every stage in the procurement and delivery process.

Freight forwarders can also offer other important information about market trends and shipping activities. They ensure that they have updates on the existing trends in trade relations, the cost of shipping, and the performance of the carrier companies. This knowledge ensures that HVAC businesses have the proper understanding of their logistics strategies for their operations, as they are able to change with market situations.

For instance, if the specific shipping lane is congested, the particular carrier is slow, or the carrier is out of a freight forwarder’s preferred list, the forwarder can suggest a better lane or carrier for delivery purposes. This helps to manage HVAC projects effectively and achieve the desired outcomes within the set timeline and cost constraints.

Conclusion

This is especially true because the HVAC industry is one of the most competitive, and it is crucial to meet the market’s demands to provide efficient logistics services. Outsourcing to an experienced and capable freight forwarding company can help HVAC businesses gain the knowledge, tools, and strategies to optimize procurement and transportation functions for better efficiency, costs, and schedules.

Another aspect of the supply chain management process in HVAC companies is that freight forwarders assist them in downsizing redundancies in the supply chain, increasing efficiency, and implementing superior supply chain solutions to meet their clients’ needs. By opting for the global freight forwarding solutions by Foresmart, HVAC businesses can attain improved operational efficiency, cost control, and enhanced customer satisfaction that sets them up for sustainable business growth in the long run.

Fashions and fads come and go, but buildings and architecture leave a legacy. Architecture both reflects and shapes the society it serves. As a discipline, it provides a functional framework for fashionable structures that convey contemporary building trends and materials. As an art, architecture speaks to the prevailing preferences, problems and cultural norms and values Read more

Fashions and fads come and go, but buildings and architecture leave a legacy. Architecture both reflects and shapes the society it serves.

As a discipline, it provides a functional framework for fashionable structures that convey contemporary building trends and materials. As an art, architecture speaks to the prevailing preferences, problems and cultural norms and values of society at the time.

Nowadays, the most pressing problem of today’s society – the need to address climate change and protect the natural environment – has become the dominant factor driving decisions in the art and science of modern architecture and building.

This mega-trend is dictating choices in structural design, material manufacturing and building performance through 2024 and beyond. Eva-Last, leaders in advanced composite building materials, unpacks how this legacy will impact current building trends and architecture:

Green Building & Sustainability as a Mega-Trend

Without a doubt, green building and sustainability is the dominant force influencing international urban development.

Green building is now the most prevalent movement happening in the built environment. The entire construction industry is looking to service an increasingly urbanized population, while reducing its enormous environmental impact. And never has the call for sustainable development been more urgent!

Statistics show that the construction sector contributes a whopping 7-8% towards global carbon emissions. And as government policies and building regulations force compliance to achieve ambitious carbon reduction targets, every segment of the construction sector – from materials manufacturers, design professionals to developers, property owners and project managers – are seeking ways to enhance their built environment without harming the natural one.

Progressive architects, designers and builders are favoring more sustainable green building designs over previously popular styles or traditional building materials.

Savvy building materials manufacturers, such as Eva-Last, are engineering new resource-efficient, eco-friendly and enhanced building components that can contribute towards a net zero carbon site, while energy-efficiency ratings and certifications such as LEED (Leadership in Energy and Environmental Design) are set to become the norm.

Energy-efficiency

The need to reduce our reliance on fossil fuels to power our everyday activities (and reduce pollution that causes climate change) has seen an emphasis on energy-efficiency and passive design principles across structures, and our appliances.

This encompasses everything that affects the energy required for lighting, heating and cooling, ventilation and indoor air quality.

Careful consideration of the aspect or orientation of the building on site and its natural environment improves its performance parameters around energy-efficiency, facilitating heating and cooling using natural light and airflow. This in turn, reduces the need for insulation, ventilation, shading or added lighting.

In addition, the use of materials with natural thermal regulation properties such as bamboo which outperforms concrete, or steel, further improves the energy-efficiency of the build. Materials like Eva-Last’s VistaClad cladding profiles provide both an insulation barrier but also allow for building ventilation through design, simply by cladding the building’s façade, while decorative shading or protection from glaring sunlight can be achieved using Lifespan’s lightweight architectural beams for pergolas or screening to further enhance energy-efficiency.

Eco-friendly materials

Responsibly sourced renewable and eco-friendly building materials are being specified with their carbon footprint in mind.

Everything from solar systems to rainwater harvesting, low-flow taps and drought-resistant landscaping, energy-efficient lighting to technically advanced products that conserve scarce natural resources are finding their way into modern buildings.

Resource-efficient, easily replenishable raw material inputs are replacing limited natural resources like wood with advanced composite products.

Eva-Last’s beautiful bamboo composites combine fast-growing bamboo with recycled plastic. Their range of composite decking, cladding, balusters and beams look like timber without contributing to deforestation. In addition, their recycled plastic content introduces superior wear characteristics and durability while simultaneously eliminating the mountains of plastic waste polluting our oceans and landfills.

Biophilic Design

This integrates nature into architecture to enhance wellbeing and sustainability. By incorporating natural elements such as greenery and natural light, biophilic design fosters a sense of calm and connection to the environment that improves productivity and health. It’s evident in our preference for natural tones, textures and organic materials such as wood or stone, as well as our penchant for patterns of plantscapes and flora and the inclusion of landscaping and water features in our surroundings.

Eva-Last’s latest composite decking range Pioneer connects people to plants by recreating the natural tones and textures of endangered wood species using photorealistic digital print technology. The embossed, patterned surface texture provides the most natural-looking finish in composite products yet.

Lightweight materials

Buildings are going up and getting taller due to limited space. This has spurred demand for new strong, durable but lightweight materials other than steel or concrete.

Eva-Last consistently introduces enhanced performance properties into their building products – the hollow aluminum core of Lifespan’s lightweight architectural beams, or the glass-fiber reinforced (GFR) core of Pioneer and Apex Plus decking, allowing for increased spans, are examples of ingenious innovations specifically developed for these types of applications.

Remodel or Renew

High interest rates, labor costs and excessive material requirements, coupled with limited space and urban decay is driving the need to remodel or renew rather than build from scratch. Existing buildings such as abandoned factories, vacant offices or old outdoor structures are being given a facelift with attractive cladding, outdoor decks and patios and shady pergolas or rooftop lounges. These existing spaces are being repurposed into stylish accessory-dwelling units (ADU’s) suitable for guesthouses, multi-generational living (such as garden flats) or extended living areas.

Conclusion

Since architecture and building leave a legacy for future generations, be sure to select a product that is built to last.

Eva-Last’s extensive range of bamboo composite products are specifically designed to enhance the environment while minimizing any negative impacts. Engineered to outperform traditional building materials, the collection boasts attractive low maintenance benefits combined with sterling sustainability credentials.

To delve deeper into the latest trends in building and architecture and explore the intricacies of the Architecture, Engineering and Construction (AEC) industry, join Eva-Last at the AIA24 Conference of Architecture and Design taking place in Washington D.C. from June 5-8.