Written by Chris Carrier, RWC Senior Marketing Director The shortage of plumbers our industry is dealing with has become so serious, it’s making headlines in the business world. An article in Bloomberg Businessweek’s March 2024 issue puts the problem in a national context: “America’s Plumber Deficit Isn’t Good for the Economy.” The article elaborates with a slew of Read more

ShopTalk

Written by Chris Carrier, RWC Senior Marketing Director

The shortage of plumbers our industry is dealing with has become so serious, it’s making headlines in the business world. An article in Bloomberg Businessweek’s March 2024 issue puts the problem in a national context: “America’s Plumber Deficit Isn’t Good for the Economy.” The article elaborates with a slew of stats that back up this subheading: “Young people are shunning an occupation that’s physically demanding and sometimes dirty, though well paid.

While the labor shortage isn’t new to those who have been in the industry long, it’s worth exploring the main cause of it and ways to get more people into the trade right now.

Understanding the plumbing recruitment crisis: The age factor

Age plays two roles in the plumber shortage. A large portion of the current plumbing workforce is nearing retirement age, and recruiting young people into plumbing is proving difficult. Although the recruitment pipeline is leaking at both ends, the jobs are there for the taking, with plenty of new opportunities opening. The latest data from the U.S. Bureau of Labor Statistics (BLS) projects there will be nearly 43,000 job openings for plumbers, pipefitters and steamfitters each year through 2032. These jobs mostly result from the need to replace workers who retire, change occupations or leave the workforce.

Knowing plumbing is one of the steadiest industries, how can plumbing business owners stay staffed with good plumbers? The truth is that it’s going to take some convincing.

Images courtesy of SharkBite Plumbing Solutions.

Repairing the leaky recruitment pipeline through education

If you run a plumbing company, the most concerning consequence of the labor shortage is the challenge of keeping enough good plumbers on your team. In the skilled trades, recruiting hinges on educating recruits. Raising awareness of opportunities is foundational. Many young Americans are simply unaware of the specialty options, job security and earning potential in plumbing. As an industry, we must invest more resources in promoting the plumbing profession. Just ask Mark Brown, a Philadelphia high school plumbing program instructor.

“There are so many people in our country who struggle with finding a suitable career path for them, and I believe it’s due to lack of exposure to career choices such as plumbing,” Brown said. After telling young people an opportunity exists, we need to convince them to explore it. To be persuasive, explain why plumbing is an excellent career option. Then dispel the myths and be open and truthful about the hard parts. Any recruiting efforts—whether joint or solo, online, printed or spoken—should start by selling the benefits, including:

Clint McCannon owns Cannon Plumbing in Braselton, Georgia.

Job security and stability

When you need a plumber, it’s rarely optional. Plumbing is an essential service with consistent demand, providing long-term job security and protection against economic downturns. For example, when the COVID pandemic put millions out of work, plumbers stayed on the job with a steady income.

“I was really nervous when COVID hit,” said Clint McCannon, owner of Cannon Plumbing in Braselton, Georgia. “I didn’t know what was going to happen. Our numbers were up over 35%, and it didn’t slow down. It sped up. Even when the economy is going down, if it’s something they can’t handle on their own, they’re going to call you.”

Given the plumber shortage, it’s highly unlikely that this career benefit will change anytime soon. Even as technological advances disrupt other trades, in plumbing, new technology tends to make the work easier rather than displacing the workers.

High earning potential

Plumbers enjoy competitive wages, and many have opportunities for overtime and bonuses. Their extent varies depending on the employer and specific job role. Even without pursuing overtime or bonuses, plumbers can enjoy a financially rewarding career free from the burden of student debt.

A high school diploma or equivalent is the standard education requirement for starting paid training or trade school. The BLS lists the 2023 median pay at $61,550 per year ($29.59 per hour), up from $60,090 in 2022 ($28.89 per hour), with plumbers at the high end of the spectrum earning a six-figure salary.

Geography greatly influences earnings, with average wages varying by state, based partly on the cost of living. According to Consumer Affairs, Illinois ranks highest with an annual average wage of $88,000, while Arkansas is at the bottom with plumbers earning $47,000 on average. Nationally, the top 10% of wage earners made more than $101,000 annually, and industry wages have been climbing steadily since at least 2012.

Paid training as an apprentice plumber

You don’t need any prior experience to start training to become a plumber, and once you apply for and secure an apprenticeship, it’s paid training on the job. Vocational-technical schools and unpaid pre-apprenticeships are the most common routes people take before getting on-the-job experience.

Choosing a paid plumbing apprenticeship over attending college with an unpaid internship can be a game-changer. With an apprenticeship, you’re earning money from day one while learning a valuable trade, rather than racking up student debt. You earn hands-on experience, real-world problem-solving skills and a direct path to a rewarding career in a high-demand field.

Apprenticeships also provide a structured learning environment where mentors are invested in your success, ensuring you gain both practical knowledge and industry credentials. For anyone looking to build a stable and prosperous future without the financial burden of college, a paid apprenticeship offers a practical and lucrative track.

Leslie McGlenen owns Pipe Wench Plumbing & Heating.

Career advancement opportunities

The plumbing profession also offers clear pathways for advancement, including opportunities to become a well-paid master plumber, start your own business or move into management roles. After finishing a plumbing apprenticeship, career advancement in the U.S. plumbing industry typically follows a structured path.

First, you become a journeyman plumber, gaining more responsibilities and independence. With experience and further certification, you can advance to a master plumber, which opens doors to higher-paying jobs and leadership roles. Any apprentice can become a master in this trade if they’re dedicated, and it pays to work your way up. An HR technology company called PayScale reports that in 2023, the median pay of a master plumber went up to $82,700—a jump of 21% from 2022.

Some plumbers eventually become contractors or specialize in areas like pipefitting, leading to even more career opportunities. Some of the most profitable plumbing businesses are owned or managed by plumbers who started as apprentices. Lesley McGlenen owns and operates Pipe Wench Plumbing & Heating in British Columbia, Canada.

“I got a lot of experience as a young apprentice,” she said. “Most of the time, I was the only apprentice at this company, so I got to work under three skilled journeymen who did different parts of the job. Depending on who I was working under, I learned different techniques.”

Successful franchise owners like Lesley can expand their businesses, creating a comfortable income and good jobs.

Kim Yeagley owns Gold Canyon Plumbing in Gold Canyon, Arizona.

Job satisfaction and community impact

Plumbers play a vital role in maintaining public health and safety. Being an essential part of your community’s workforce provides a sense of pride and fulfillment for those who appreciate making a tangible difference in people’s lives, homes and workplaces.

“When you leave, you’ve fixed their problem, you’ve made their day. That’s a good feeling inside,” said Kim Yeagley, owner of Gold Canyon Plumbing in Gold Canyon, Arizona. Despite the occasional dirty conditions, the satisfaction of solving problems and providing essential services to your community is genuinely rewarding. And like other skilled trades, plumbers take pride in their craftsmanship and enjoy building something from scratch. As a plumber, you can also choose to prioritize family and personal time.

“I don’t live to work. I work to live,” said Russel Sweeney, owner of Sweeney Remodeling and Plumbing in Jacksonville, Florida. “Through the years, I’ve learned that there is a necessity for work-life balance.”

Flushing fears and reconfiguring perceptions of plumbing

While there are many benefits in plumbing, there are still a lot of misconceptions and valid concerns that must be addressed in recruitment, including:

Physical demands

Don’t sugarcoat it. Plumbing is physically strenuous, often involving heavy lifting, strong tool work, awkward positions and repetitive movements. But desk jobs aren’t for everyone either. Plumbing can be a great career fit for people who love working with their hands. Former plumbing apprentice Anna Pearson said an office job just wouldn’t suit her.

“Forty hours out of my life every single week, being stuck in a cubicle, it’s just my actual nightmare,” she said.

Modern equipment helps with the physically challenging aspects. Advancements in technology and tools have made most tasks easier and more efficient than in decades past. For example, push fittings like SharkBite Max make it easy for new plumbers to start repairing and reconfiguring pipes with minimal instruction, performing smaller jobs in just minutes. They also help plumbers get in and out of tight or uncomfortable spaces more quickly so they can put minimal strain on their bodies.

Russel Sweeney owns Sweeney Remodeling and Plumbing in Jacksonville, Florida.

Safety and working conditions

The job sometimes involves working in dirty and confined environments, which can be unappealing or seen as hazardous. Fortunately, plumbers of all types get paid to earn comprehensive safety training through their certifications that prepare them to handle potentially dangerous job site situations safely. Plus, safe working conditions are required by law. The Occupational Safety and Health Administration (OSHA) enforces federally mandated safety standards that plumbing employers must comply with, which apply to both service and commercial plumbers. Employers provide all the necessary protective gear and equipment to ensure safety and comfort on tough jobs, including water-proof gloves, knee pads, safety glasses, hard hats and respirators.

Serious injuries are very rare for plumbers, pipefitters and steamfitters. Nonfatal injuries are also exceptionally rare for both residential plumbers and commercial plumbers who work on new builds, even though working in people’s homes is generally considered safer than plumbing on a construction site. In 2022, BLS data shows that out of 865 reported fall injuries, including slips and trips, only 27 involved plumbers (3%). The BLS lumped plumbers in with HVAC contractors. This group had no reported injuries that year from exposures to harmful substances or environments, and no injuries caused by contact with objects or equipment.

Social stigma and perception

The reality is that many college graduates have student debt and still earn less than the plumber they call to fix their toilet, but there’s a strong societal push toward college degrees in high school, leading many young people to overlook the trades as they’re considering a career path. In the absence of hard facts, students often view trades like plumbing as a less prestigious career compared to white-collar jobs.

However, plumbers earn competitive salaries with excellent job security because they’re essential to our homes, businesses and critical infrastructure. Remind recruits that this trade offers opportunities for entrepreneurship and a stable, upward career path, with the added satisfaction of helping people every day. Another perk is that you can live almost anywhere and still have excellent job prospects.

Job security concerns

Some mistakenly perceive plumbing as less stable compared to careers in rapidly growing tech and service sectors where layoffs are actually far more common. Layoffs are very rare in plumbing, even during recessions, and the labor shortage shows that’s unlikely to shift.

“It’s a very recession-proof job,” Sweeney said. Research firm IBISWorld reports that “constant demand keeps direct competition low.” Industry analysts expect a steady demand for plumbing services in new construction, and IBISWorld states that “refurbishment and maintenance of aging plumbing systems have remained steady streams of income for independent plumbers and companies alike. This will not change in the near future.”

If you encounter stability concerns as you do outreach, set the record straight and back it up with facts. The U.S. Department of Labor provides a helpful resource with its Occupational Outlook Handbook for Plumbers, Pipefitters and Steamfitters. This periodically updated handbook answers every question a plumbing recruit is likely to ask.

Training requirements

Extensive apprenticeships and on-the-job training can deter those looking to enter the workforce quickly. Plumbing apprenticeships can indeed last up to 5 years, but they allow you to earn a living while gaining hands-on experience in the field, providing valuable training without the high costs of a traditional degree.

Another option is vocational-technical programs that fast-track your plumbing career, offering practical skills, recognized certifications and employment immediately after graduating.

Mark Brown, a Philadelphia high school plumbing program instructor.

Take advantage of the facts

Whether it’s educational social media videos, partnering with trade schools or hosting open- house demonstrations in your community—whichever format, strategy or platform you choose for your recruiting efforts—take a fact-based approach. Reality is your ally in persuasion. With excellent job prospects and rising pay, it’s a great time to join the plumbing profession, and having the facts on your side can make recruiting a little easier. Take it from Pearson.

“I researched it for a few days, I saw nothing but good things,” the former plumbing apprentice said. “And so, I decided to go ahead and take the plunge.”

In a hydronic system, every installation is an opportunity to improve efficiency. The products you select for the job not only impact the installation of today but the performance of tomorrow. This is especially true when installing a boiler; the components you pair with the unit can mean the difference between a simple installation and Read more

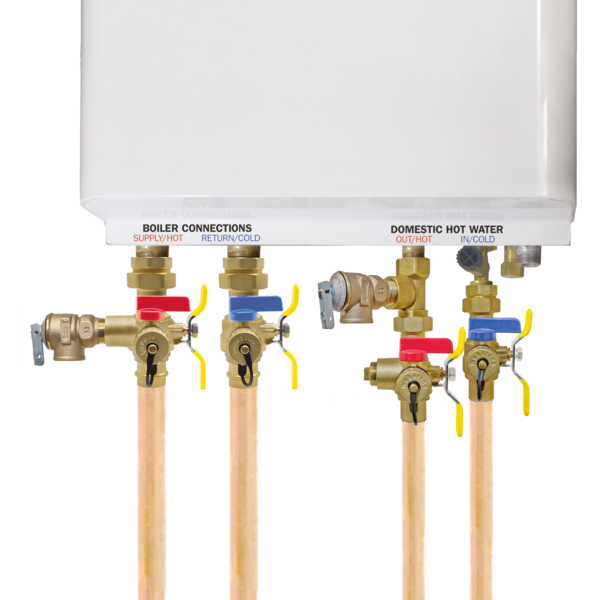

In a hydronic system, every installation is an opportunity to improve efficiency. The products you select for the job not only impact the installation of today but the performance of tomorrow. This is especially true when installing a boiler; the components you pair with the unit can mean the difference between a simple installation and a smarter installation.

Auxiliary boiler accessories range in both form and function. The best products for the job should be designed to save time, space, and labor during installation. They should also provide controls to ease future maintenance and should protect the boiler and system components over time.

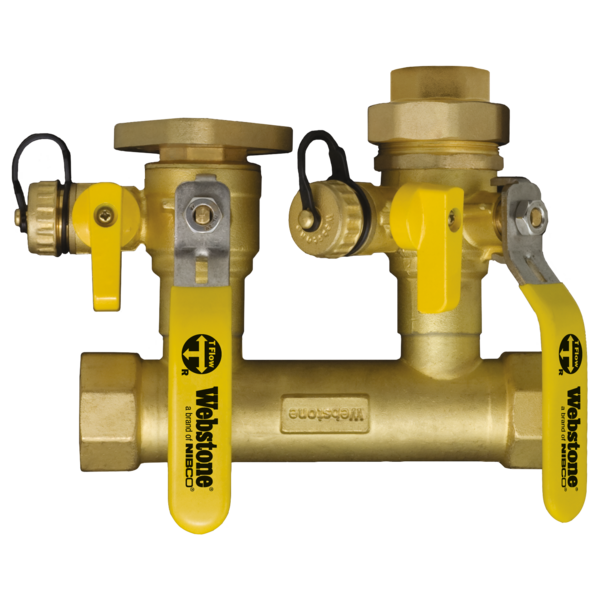

With these goals in mind, Webstone has developed the most complete selection of under boiler solutions available today. Its under boiler program is a single source for better installations, with products that also simplify and reduce the number of maintenance callbacks.

The Hydro-Core™ manifold simplifies the installation and service of the primary heating loop. This solution combines closely-spaced tees with isolation valves to achieve hydraulic separation for the heating loops, isolates the components within the loop, and purges the system. A T-Flow ball directs the flow into either the boiler or the drain, which can be configured in a number of ways to assist with purging, filling, and descaling/cleaning. Its compact, forged-brass body replaces up to 17 individual components, eliminates 16 leak paths, and saves over two hours of labor.

To improve overall system performance, the Air Separator uses a unique stainless-steel coalescing medium that captures both microbubbles and static air. The separated air collects in the top of the unit, where it forces a pin-guided float to drop down and open a vent. Once the air is released, the float rises once again and closes the vent. This reduces noise as well as wear on system components caused by trapped air in the pipes. The vertically mounted model is ideal for installing on the boiler outlet, where the air can be separated and vented before it reaches the rest of the system.

To protect the boiler from iron sludge that can accumulate in a hydronic system, consider the Magnetic Boiler Filter. Installed on the system return line, it captures ferrous and non-ferrous debris before it can reach the boiler using a high-powered 12,000 Gauss magnet and plastic filter. The drain makes it simple to remove accumulation, with a strapped cap that can be used to actuate the drain valve. A universal diverter allows the Magnetic Boiler Filter to be used in both horizontal and vertical piping orientations. The service tool is also included to help install and maintain the filter with ease.

Both the vertical mount Air Separator and Magnetic Boiler Filter are outfitted with removable G1 threaded end connections (available in sizes ¾” and 1”, with MIP, FIP, SWT, or Press ends), offering added versatility to any installation. These threads allow the installer to easily add isolation valves for future service, or a temperature gauge to verify boiler output right at the source.

A full-featured under the boiler installation from Webstone requires no more than 22” of space and delivers cleaner, more professional-looking results. Solutions are also available for boilers with external pumps and combi domestic hot water connections from the E-X-P™ Series of Tankless Water Heater Service Valves. To find all of these products and more, visit www.webstonevalves.com.

As a significant portion of energy consumption in both residential and commercial settings, HVAC systems offer plenty of opportunities for efficient improvements. HVAC and plumbing provide crucial comfort and sanitary systems for each building, but the systems are not always installed, implemented, or used efficiently. Ineffective use of these systems can lead to lost energy Read more

As a significant portion of energy consumption in both residential and commercial settings, HVAC systems offer plenty of opportunities for efficient improvements. HVAC and plumbing provide crucial comfort and sanitary systems for each building, but the systems are not always installed, implemented, or used efficiently. Ineffective use of these systems can lead to lost energy, an excessively high comfort threshold, or greater stress on the equipment. By considering these factors, HVAC professionals can target their efforts to greater efficiency and optimal system performance.

Ensure Optimal Installation

Optimal installation can improve output, decrease the likelihood of overuse or system failure, and maintain a higher level of efficiency. Proper sizing is key. HVAC specialists should perform thorough load calculations and estimate the needs for temperature and humidity control in the space to determine the correct output range for the equipment. Installing temperature sensors in places without sun exposure or drafts can help to ensure accurate temperature control. Comprehensive testing of the equipment post-installation can confirm that the system works properly with correct output and high efficiency.

Optimize Damper Position

Damper position controls the volume of air that can enter a space at any given time. Variable air volume (VAV) boxes adjust the temperature and rate of airflow based on the load. In many cases, a VAV box’s damper position sits open to a higher degree than necessary, leading to wasted energy and improper temperature control. Setting the damper position to the minimum according to ASHRAE standards can minimize energy consumption without compromising performance.

Utilize Smart Data Systems

Smart systems can predict usage needs based on existing data about operation in similar spaces and can also adjust schedules and other controls for the needs of a particular space. Systems collect data about routine usage and use that information to create efficient settings for HVAC and plumbing. Sensors track temperature in individual rooms, providing real-time data about system efficacy and allowing owners to tailor usage for maximum comfort and efficiency. Use of these systems can decrease the number of manual overrides, as well as maintaining a precise level of temperature and humidity control.

Implement Temperature Controls

Dynamic temperature controls can minimize the use of energy to heat supply air or water, reducing energy consumption without compromising the ability to meet demand. Supply air controls can dictate the temperature of the supply air, adjusting upward or downward depending on the load. Similarly, boiler and water heater temperature controls can adjust the minimum or maximum temperature of the operating limit based on demand. Systems that change these limits dynamically can provide better heating for high demand, while minimizing use during lower load times.

Decrease Unnecessary Operations

A system that works automatically can provide heating, cooling, and ventilation when none is needed, calling for attention to unnecessary operation. Inaccurate scheduling, excessive manual overrides, and a lack of zoning systems can contribute to wasted energy. Specifically, owners should create commercial HVAC settings that maintain the proper temperature and humidity for the right times, minimizing use outside of peak hours. Adjusting ventilation based on occupancy can help to maintain a comfortable indoor temperature for areas with fewer numbers, while maintaining ideal ventilation in crowded spaces. Implementing smart automated systems can make the transition effortless, allowing building owners to manage dynamic heating, cooling, and plumbing needs.

Designing an HVAC or plumbing system to meet the needs of a space requires some analysis of overall efficiency. Overuse or ineffective use of a system can make a space feel uncomfortable or unsanitary, while contributing to high energy usage or increased repair needs. Evaluating the installation, setup, and use of each system can highlight ways for HVAC professionals to improve efficiency and performance. By adding smart technology and following best practices in mechanical systems, HVAC technicians and plumbers can eliminate wasted energy and accurately reach the comfort goals for the space.

Author Bio: Michael Carlson is the President of Gene May Heating & Cooling. He has been in the heating and cooling industry for more than 32 years and is the sole owner of the business.

Smart plumbing technology provides great improvements in a variety of aspects of plumbing management. In decades past, property owners relied on their personal observations and their water bills to get a sense for their water usage and efficiency. Smart systems can automate many of the monitoring tasks, allowing plumbers to assess a system and quickly Read more

Smart plumbing technology provides great improvements in a variety of aspects of plumbing management. In decades past, property owners relied on their personal observations and their water bills to get a sense for their water usage and efficiency. Smart systems can automate many of the monitoring tasks, allowing plumbers to assess a system and quickly form an effective plan for maintenance or repair. With these tools, property owners can improve their efficiency, reduce water consumption and minimize the effects of water damage.

Leak Detection

Smart plumbing systems offer the latest in leak detection technology. Sensors can track multiple factors, including water pressure, volume, temperature, humidity, the presence of intrusions and more. When integrated with a smart plumbing system, the sensors can alert property owners to the existence of a leak as soon as it arises. Because the sensors are spread throughout the system, property owners can get detailed information about the location of the leak, helping plumbers to find and address the leak more quickly.

Efficient Water Heaters

Along with other devices in the Internet of Things, smart water heaters help property owners to control their hot water usage and efficiency. A smart water heater often uses less energy by allowing users to set limits on their water consumption. The smart system can adapt demand by tracking household usage data to help minimize energy consumption when residents use it the least. Additionally, a smart water heater offers remote operation, leak detection and system alerts, so that owners can turn off the system or discover problems before they lead to serious water damage.

Irrigation Systems

The advancement of smart irrigation systems allows property owners to minimize their water consumption based on weather patterns, without compromising the quality and health of the landscaping. Smart sprinkler controllers make it easy for property owners to control the property’s watering schedule by a smartphone or tablet. Capability of individual controllers depends on the equipment. Owners who buy sensors may be able to have the system automatically adjust watering based on moisture levels. Without these tools, smart controllers use data about local temperatures and precipitation to estimate the best watering schedule.

Smart Sewer Cameras

In recent years, plumbers have used closed-circuit television cameras to identify the location of leaks or damaged pipes as part of plumbing repair. The cameras provide an opportunity for plumbers to inspect or assess the condition of the interior pipes without having to dig up the landscaping first. Smart technology can make this task more effective. Smart cameras provide intelligent metering, so that plumbers know how approximately where the problem sits in the plumbing, without having to use a manual cabling system. Smart systems can also provide other data to assist in the diagnostic process.

AI Defect Prediction

Finding defects in existing pipes is not new technology, but the software to predict it is on the cutting edge. Pattern recognition is a significant advantage of artificial intelligence technology, and plumbers can use it to determine the most likely spots for a leak or burst pipe. New software options take existing camera footage of sewer inspections and use that data to create detailed maps of a plumbing system. This technology can help plumbers decide where to look first or target their maintenance work to the areas with the greatest need.

Due to its location, plumbing presents a number of obstacles for repairs and upkeep. Smart technology is revolutionizing the plumbing industry with tools and systems that can improve efficiency and simplify the process of finding defects or problems. Smart tools provide useful data to plumbers, so that they can find a leak faster. Smart systems also alert owners to the presence of problems, such as low water pressure or high water usage. By using these tools, owners can reduce the likelihood of unexpected water bills or property damage.

Author bio: Kareem Haddad is the owner of Absolute Rooter & Plumbing, a family-owned and operated company that has been improving the plumbing systems of Orange County and surrounding areas since 2010.

Author bio: Kareem Haddad is the owner of Absolute Rooter & Plumbing, a family-owned and operated company that has been improving the plumbing systems of Orange County and surrounding areas since 2010.

Enginuity (now part of Ainsworth), a mechanical contractor based in Mechanicsburg, Pennsylvania, was preparing for a refrigerated warehouse expansion that included nearly 50,000 square feet of cooler and freezer space. Based on the large scale of the project, Almir Kapetancic, who led the Enginuity team, decided to use RLS press fittings instead of brazing the Read more

Enginuity (now part of Ainsworth), a mechanical contractor based in Mechanicsburg, Pennsylvania, was preparing for a refrigerated warehouse expansion that included nearly 50,000 square feet of cooler and freezer space.

Based on the large scale of the project, Almir Kapetancic, who led the Enginuity team, decided to use RLS press fittings instead of brazing the massive number of joints that would be required. The plan was to reduce labor hours and accelerate the timeline with RLS fittings – including the company’s “XL” 1-5/8” and 2-1/8” sizes.

By using hundreds of press fittings across the project, Kapetancic was able to reduce on-site labor hours by two-thirds, better manage and schedule his staff, deliver the completed project faster for the customer – and do it all more profitably.

“This was the first time that I’ve utilized press fittings on a job site, but it was an absolute game changer for both our workflow and bottom line,” says Kapetancic. “The benefits of added flexibility and efficiency of labor on-site more than made up for the investment we made in the press fittings and tools themselves.”

“I had full faith that I could explain the technique for press fittings to even the greenest contractor and they could confidently reapply it across the worksite after a quick hands-on instruction” he said. “The alternative is a brazing certification, which is an in-depth process that can’t be taught on a whim or in passing. Brazing certified contractors are also becoming harder to find these days, so RLS has allowed us to adapt to an evolving workforce without compromising the quality of our installations.”

In addition to the major efficiency and ease-of-use advantages of RLS, Kapetancic and his team also found the fittings to be completely reliability. “We haven’t needed to revisit any of the connections that used press fittings” he said. “The proven reliability and resilience of XL press fittings from RLS have me very excited about the positive impact they can have on our business going forward.”

For more information about RLS fittings – the only HVAC/R press fittings with a 9+ year track record and sizes up to 2-1/8” – visit the RLS website.