NIBCO Inc. introduces its PVC Termination Vent Screens (#4818-SCRN) for high efficiency appliance lines in residential construction. The new vent screens prevent wildlife, leaves and debris from blocking PVC exhaust vent pipes. Available in 2″, 3″ and 4″ diameter sizes, the vent screens are easy to install by push or interference fit with PVC or Read more

Products

NIBCO Inc. introduces its PVC Termination Vent Screens (#4818-SCRN) for high efficiency appliance lines in residential construction. The new vent screens prevent wildlife, leaves and debris from blocking PVC exhaust vent pipes.

NIBCO Inc. introduces its PVC Termination Vent Screens (#4818-SCRN) for high efficiency appliance lines in residential construction. The new vent screens prevent wildlife, leaves and debris from blocking PVC exhaust vent pipes.

Available in 2″, 3″ and 4″ diameter sizes, the vent screens are easy to install by push or interference fit with PVC or ABS sockets. No solvent cement or glue is required for installation.

“These new termination vent screens are ideal for preventing unwanted matter from entering pipes,” said Marilyn Morgan, senior product manager-metal fittings, of NIBCO. “A simple investment in vent screens can prevent unnecessary problems and damage due to pipe obstruction or infestations from pests.”

The vent features a stainless-steel screen with1/4″ mesh opening that is corrosion resistant and allows for maximum air flow. The interference fit makes it easy to install and easy to remove during freezing temperatures when condensation could freeze the opening shut.

Jones Stephens introduces Tankless Water Heater Service Kits, a collection of six SKUs with ¾” and 1” sizing and IPS and SWT connections. These convenient kits include high-quality forged brass valves and select models include a pressure relief valve and gas connector – all in one box. Jones Stephens’ tankless water heater kits provide quick Read more

Jones Stephens introduces Tankless Water Heater Service Kits, a collection of six SKUs with ¾” and 1” sizing and IPS and SWT connections. These convenient kits include high-quality forged brass valves and select models include a pressure relief valve and gas connector – all in one box.

Jones Stephens introduces Tankless Water Heater Service Kits, a collection of six SKUs with ¾” and 1” sizing and IPS and SWT connections. These convenient kits include high-quality forged brass valves and select models include a pressure relief valve and gas connector – all in one box.

Jones Stephens’ tankless water heater kits provide quick and simple installation and a leak-free connection. Identifying hot and cold water systems is made simple with their color-coded red and blue handles. Their strong, forged brass construction reduces the risk of pinhole leaks, and their stems are blowout-proof—ensuring system durability and safety.

Made to the highest quality standards, Jones Stephens’ tankless water heater kits are cUPC and IAPMO approved. They are lead law compliant and meet NSF/ANSI standards.

Made to the highest quality standards, Jones Stephens’ tankless water heater kits are cUPC and IAPMO approved. They are lead law compliant and meet NSF/ANSI standards.

For more information: Jones Stephens | WE GOT IT.

SunTouch, a Watts brand, is pleased to announce the new SunStat® ConnectPlus™ thermostat. Through this new connected thermostat, customers can remotely access and control their floor warming system, using voice control with Alexa and Hey Google. They can connect this thermostat to their home’s Wi-Fi system and enjoy features such as automatic clock setting, current Read more

SunTouch, a Watts brand, is pleased to announce the new SunStat® ConnectPlus™ thermostat. Through this new connected thermostat, customers can remotely access and control their floor warming system, using voice control with Alexa and Hey Google.

SunTouch, a Watts brand, is pleased to announce the new SunStat® ConnectPlus™ thermostat. Through this new connected thermostat, customers can remotely access and control their floor warming system, using voice control with Alexa and Hey Google.

They can connect this thermostat to their home’s Wi-Fi system and enjoy features such as automatic clock setting, current outdoor temperature reading, warm weather compensation, and warm weather shut down.

Other features include a stylish new design with glass front and capacitive touch screen, and remote access through the Watts Home mobile app. In addition, features include a voltage level detector and ammeter with diagnostic screen and wireless technology of 915MHz for connecting accessories (SunStat® Relay R4 and ConnectPlus™ Smart Sensor).

The new SunStat® ConnectPlus™ thermostat is included in SunTouch WarmWire® and TapeMat® Kits.

To learn more, go to https://www.suntouch.com/ConnectPlus.

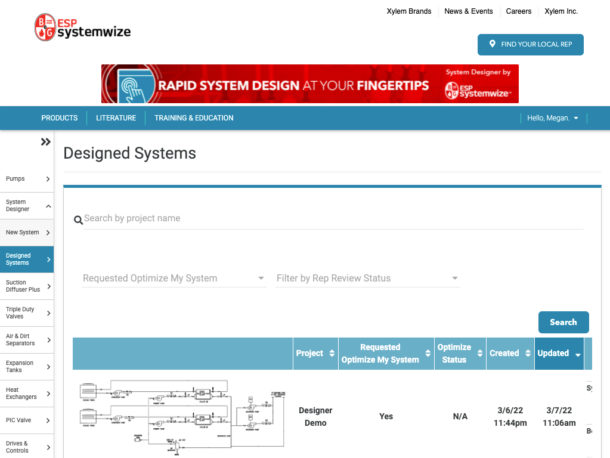

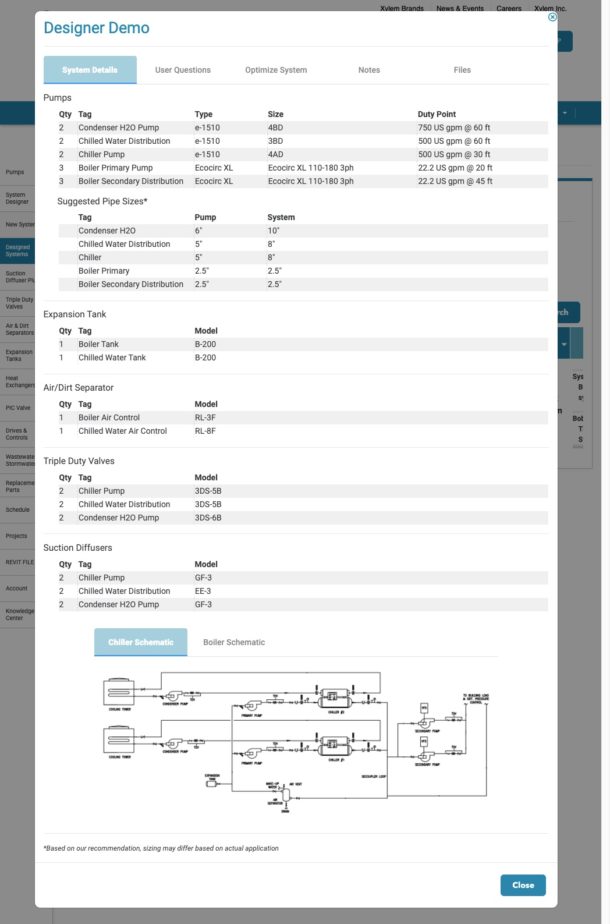

New intelligent functionality enables users to design complete hydronic systems faster, easier and better ESP-Systemwize, the industry’s most complete hydronic product selection software by Bell & Gossett, now offers a powerfully intelligent functionality called System Designer. Users simply answer four questions online in the Systemwize interface and, within minutes, System Designer generates a complete hydronic system Read more

New intelligent functionality enables users to design complete hydronic systems faster, easier and better

ESP-Systemwize, the industry’s most complete hydronic product selection software by Bell & Gossett, now offers a powerfully intelligent functionality called System Designer. Users simply answer four questions online in the Systemwize interface and, within minutes, System Designer generates a complete hydronic system design that includes all supporting documentation and details, making quoting jobs faster and easier than ever.

“We are excited to launch this unique capability in Systemwize, which allows customers with a registered account to design a complete heating or cooling system in just minutes,” said Mathias Bullmer, Global Product Manager, Bell & Gossett. “The new System Designer feature also ensures ESP-Systemwize remains the most advanced online selection tool on the market.”

Introduced in 2017, ESP-Systemwize incorporates Bell & Gossett’s expansive product portfolio, applications expertise and hydronic systems knowledge, resulting in an intuitive, easy-to-use tool for selecting highly efficient pumps and compatible system accessories. It’s the industry’s only online selection tool that provides the ability to choose all system components from a single interface.

With a registered account, System Designer is readily accessible at esp-systemwize.com/system_designer. Other advanced features are also available, such as saving project schedules, generating submittals and sharing submittals with a Bell & Gossett manufacturer’s representative in the user’s area. In addition to System Designer, intuitive features of ESP-Systemwize designed to assist engineers in system design include:

- Side-by-side product comparisons

- Express select button narrows search

- Searchable by groups of products

- Analyze pump speeds in real time

- Ability to choose pumps and accessories

- Customizable project schedules

- Warning system for potential selection problems

- 24/7 technical assistance

For more information on System Designer, visit xylem.com/designfaster. For more information about Bell & Gossett, visit bellgossett.com or locate a B&G representative at bellgossett.com/sales-service.

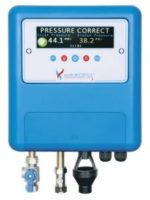

Mikrofill 3 pressurization unit for LPHW/CHW applications of any size makes successful debut at the 2022 AHR Expo in Las Vegas. The only technology of its kind, Mikrofill 3 eliminates the need for pumps and RPZ valves, saving energy and maintenance costs. Mikrofill Systems Ltd. recently brought its thoroughly time- and application-tested Mikrofill 3 hydronic Read more

- Mikrofill 3 pressurization unit for LPHW/CHW applications of any size makes successful debut at the 2022 AHR Expo in Las Vegas.

- The only technology of its kind, Mikrofill 3 eliminates the need for pumps and RPZ valves, saving energy and maintenance costs.

Mikrofill Systems Ltd. recently brought its thoroughly time- and application-tested Mikrofill 3 hydronic system pressurization unit to the North American HVAC market. Originally unveiled in the mid-1990s in the United Kingdom, the product made its debut on this side of the Atlantic at the recent AHR Expo in Las Vegas (Jan. 31-Feb. 2).

As a result, U.S. and Canadian mechanical engineers and contractors are now able to experience first-hand what their U.K. counterparts have known for the past quarter-century: that the unique Mikrofill 3 is the most advanced, “direct-type” pressurization unit available for sealed, low-pressure hot-water (LPHW) and chilled-water (CHW) commercial and multifamily residential applications. Able to fill any heating or chilled water system from empty without the use of a pump, the product also delivers commercial backflow protection with no RPZ valves, while also providing comprehensive electronic pressure management.

The Mikrofill 3 has been tested and approved in accordance with ASSE LEC 2009-2021.

The Mikrofill 3 has been tested and approved in accordance with ASSE LEC 2009-2021.

Fills any heating/chilled water system: Unlike conventional pressurization installs, the Mikrofill 3 connects directly to a commercial building’s incoming water supply (main or boosted), leveraging that line pressure to fill any heating or chilled water system — again, completely dispensing with a conventional circulating pump. By eliminating the pump, the Mikrofill 3 not only helps building owner-managers avoid the expense and hassles of periodic maintenance, but it also saves them substantial energy costs.

The most energy-efficient unit of its kind, the Mikrofill 3 consumes only 30 watts per hour when filling a LPHW/CHW system and only 10 watts per hour when monitoring the system while on standby. That performance results in an energy savings more than 95 percent, compared with pump-type pressurization units.

Provides commercial backflow protection: The Mikrofill 3 integrates ASSE-approved (American Society of Sanitary Engineering), commercial backflow prevention, eliminating the need for RPZ (reduced pressure zone) valves to avoid contaminating a building’s potable water supply. Once the required system pressure is achieved, the internal solenoid valves default to the closed position. This automatic deactivation drains internal waterways, resulting in commercial backflow protection (Fluid Risk Category 4).

Delivers electronic pressure management: The Mikrofill 3 continuously monitors system inlet and operating pressures through a series of pre-commissioned sensors that automatically maintain system presets. By recognizing a change in cold-fill water pressure, these sensors open the Mikrofill 3 valves to top off the system, stopping the fill once the required pressure has been reached.

This comprehensive electronic pressure management protects the system and the building by alerting owner-management to potential issues and providing leak and flood protection:

- Small leaks will prompt continual topping off. Once a preset number of refills has been reached (say, 25 refills over a 24-hour period), the integral color-screen display on the top-front side of the Mikrofill 3 will indicate a problem.

- Larger leaks may prevent proper replenishment. If the Mikrofill 3 does not detect the expected pressure increase over a preset period, the unit will shut down to prevent further water damage.

- In the case of catastrophic leaks, the Mikrofill 3 will quickly close off the main water supply to prevent further damage.

The fill rate for the Mikrofill 3 is 3.8 gallons per minute, based on an incoming pressure of 30 pounds per square inch (psi). The built-in fill volume indicator aids water-treatment calculation.

The base requirement is a water-supply pressure 4.5 psi greater than the cold-fill requirement. For example, a cold-fill requirement of 22 psi would need a main-supply pressure of 26.5 psi to completely fill or top off the system. Maximum inlet pressure is 100 psi, allowing a maximum cold-fill pressure of 95.5 psi.

Plug-and-play installation: The wall-mounted Mikrofill 3 weighs only 11 lb. and measures 9¾ inches wide x 10½ inches high x 4½ inches deep. This compact design facilitates installation by a single, trained technician. No onsite commissioning by the manufacturer is required.

“The ready-to-install Mikrofill 3 is essentially plug-and-play,” says Mikrofill Managing Director Dominic West. “The product’s highly innovative approach to monitoring and maintaining hydronic systems has served the commercial mechanical market in the U.K. exceptionally well for more than 25 years. We see no reason why it cannot do the same in North America.”

For more information on the Mikrofill 3 or technical assistance, visit mikrofill.us or telephone 312.761.5826.