RectorSeal, a leading manufacturer of quality HVAC/R and plumbing tools and accessories, introduces GulfCoat Spray Applied Corrosion Coating – Gallon. GulfCoat Corrosion Coatings products, manufactured by Modine Coatings, provide outstanding corrosion protection from salt spray, UV rays, humidity, and other potentially harmful elements that can cause premature failure of HVAC system coils. Available in Blue Read more

Product News

RectorSeal, a leading manufacturer of quality HVAC/R and plumbing tools and accessories, introduces GulfCoat Spray Applied Corrosion Coating – Gallon. GulfCoat Corrosion Coatings products, manufactured by Modine Coatings, provide outstanding corrosion protection from salt spray, UV rays, humidity, and other potentially harmful elements that can cause premature failure of HVAC system coils.

Available in Blue and Clear, GulfCoat Spray Applied Corrosion Coating is water-based and environmentally friendly. GulfCoat sprays evenly without concern for excessive buildup or oversaturation, which can clog vital portals and air passages and reduce the system’s energy efficiency. When correctly applied, GulfCoat products penetrate coil fins deeply to provide outstanding protection. After application, a smooth, high-gloss finish limits the damaging effects of dirt and debris buildup on the coil, allowing for easy, routine equipment cleaning.

“By adding a convenient gallon-size of GulfCoat Corrosion Coating to our lineup, we provide customers with flexibility and another way to protect HVAC coils and equipment effectively,” said Karina Eureste, Product Marketing Manager at RectorSeal. “Now it’s easier than ever to have long-lasting protection for projects of any size.”

Since 1937, RectorSeal has offered products that have built a steadily growing and loyal following among contractors due to differentiated and proven product performance. Further, the company is often the first to tackle and solve challenges professional trade contractors face. In 2015, RectorSeal became part of CSW Industrials, Inc. (Nasdaq: CSWI) and leads CSWI’s Contractor Solutions segment.

Please visit www.rectorseal.com for additional details, and follow us on LinkedIn, Facebook, YouTube, Instagram, and X for the latest product enhancements and news.

RectorSeal, a leading manufacturer of quality HVAC/R and plumbing tools and accessories, is now a master distributor for HAP System pipe hangers and supports. Combining a pipe hanger and stud guard protection in one product allows HAP System products to offer substantial installation and protection benefits. The innovative hold-and-protect HAP System pipe and support hangers Read more

RectorSeal, a leading manufacturer of quality HVAC/R and plumbing tools and accessories, is now a master distributor for HAP System pipe hangers and supports. Combining a pipe hanger and stud guard protection in one product allows HAP System products to offer substantial installation and protection benefits.

The innovative hold-and-protect HAP System pipe and support hangers protect pipes from costly nail penetrations, and they are reusable if the pipe location needs to be changed. Designed for vertical or horizontal installations, HAP System hangers are compatible with PVC, CPVC, copper, PEX, cast iron, stainless steel, and more.

HAP System products are IAPMO-listed and cUPC certified, and they offer quick and consistent installation with two screws. The durable, one-piece HAP System products suit residential, commercial, or industrial applications. Constructed of heavy gauge steel with automotive grade powder coating, HAP System products are usable indoors or outdoors.

“HAP System products can save a substantial amount of time for installers,” said Jeff Ponce, Product Marketing Manager at RectorSeal. “Our installers consistently tell us that the HAP System is their first and only choice. They’ll likely never use anything else—it’s just that good.”

Since 1937, RectorSeal has offered products that have built a steadily growing and loyal following among contractors due to differentiated and proven product performance. Further, the company is often the first to tackle and solve challenges professional trade contractors face. In 2015, RectorSeal became part of CSW Industrials, Inc. (Nasdaq: CSWI) and leads CSWI’s Contractor Solutions segment.

Please visit www.rectorseal.com for additional details, and follow us on LinkedIn, Facebook, YouTube, Instagram, and X for the latest product enhancements and news.

The updated Low Water Cut Off solutions streamline operations and elevate existing product lines, coincide with the company’s 100th anniversary McDonnell & Miller, a Xylem brand, is proud to introduce updates to its electronic Low Water Cut Off (LWCO) product line, including the GuardDog® RB-24SE Low Water Cut-Off and RB-122E Low Water Cut-Off for. Arriving Read more

The updated Low Water Cut Off solutions streamline operations and elevate existing product lines, coincide with the company’s 100th anniversary

McDonnell & Miller, a Xylem brand, is proud to introduce updates to its electronic Low Water Cut Off (LWCO) product line, including the GuardDog® RB-24SE Low Water Cut-Off and RB-122E Low Water Cut-Off for. Arriving during McDonnell & Miller’s centennial, these product line enhancements signify the company’s legacy as an industry leader committed to reliable engineering and manufacturing and continuous innovation.

The GuardDog® RB-24SE and RB-122E share a variety of features, including an exclusive, patented McDonnell & Miller self-cleaning probe—the only low water cut-off equipped with one. Saving time and money, the self-cleaning probe minimizes scale build-up and protects users from potential boiler shutdowns or water overfill, while extending the recommended cleaning interval. The updated LWCO line also features a leak-free metal-to-metal seal and a push-to-test button that quickly confirms proper operation, enabling low water cut-off protection to be verified without draining any part of the system.

“Upgrading the LWCO line positions Xylem to further meet growing industry demands and reflects McDonnell & Miller’s 100-year-old commitment to engineering efficient and reliable solutions that strengthen user experience and simplify operations,” said Jarek Berezowski, product manager, steam specialties, Xylem Inc. “In addition to a more accessible experience, the enhanced GuardDog® RB series promotes easy integration due to its reduced size and backwards compatibility, meaning that new offerings can easily replace current installations in the market.”

GuardDog® RB-24SE key features and benefits:

- Universal wiring harness fits most of today’s hot water boilers

- Small compact size that fits high efficiency boilers, optimized design ensures reduced footprint, making it the ideal choice for space-conscious installations

- 15,000 ohms probe sensitivity

- Exclusive self-cleaning probe

- Designed per UL353/1998 standard

GuardDog® RB-122E key features and benefits:

- Primary cut-off for residential hot water boiler applications

- No blow down required

- 20,000 ohms probe sensitivity

- Designed per UL353/1998 standards

- Exclusive self-cleaning probe

McDonnell & Miller is marking a century of innovation, celebrating 100 years of dependability in the engineering and manufacturing of boiler controls, liquid level controls and flow switches for steam and hot water boilers.

For more information about McDonnell & Miller’s LWCO offerings, product details are available at the following links: GuardDog® RB-24SE, GuardDog® RB-122E. To place an order, contact your local McDonnell & Miller representative at https://mcdonnellmiller.com/findarep.

To learn more about Xylem’s commitment to future-proofed solutions in the commercial buildings space, visit https://bellgossett.com/buildingbetter.

Mueller Steam is helping facility engineers detect when strainer maintenance is needed to prevent production downtime. New differential pressure monitoring technology now comes standard on our duplex strainers and is optional on our wye strainers. With the purchase and activation of an add-on connection kit, the pre-installed pressure sensors at the inlet and outlet of Read more

Mueller Steam is helping facility engineers detect when strainer maintenance is needed to prevent production downtime. New differential pressure monitoring technology now comes standard on our duplex strainers and is optional on our wye strainers.

With the purchase and activation of an add-on connection kit, the pre-installed pressure sensors at the inlet and outlet of the strainer monitor the pressure drop that occurs over time when a strainer screen becomes clogged by foreign particles.

Alerts are triggered via an existing BMS connection or cellular gateway when the strainer basket is 75% full and 100% full.

These sensors do not change the operation of the strainer – they still comply with all the necessary certifications and do not interfere with the normal function of the strainer.

“This is the first smart strainer technology of its kind,” says Jennifer Carlino, Sr. Product Manager at Mueller Steam Specialty. “Facility engineers will now be able to perform strainer maintenance proactively, rather than reactively, which will help protect costly equipment from damage as well as maintain consistent flow and efficient system performance.”

For more information, visit watts.com/smartstrainer.

Legend Valve, a leading manufacturer and supplier of high-quality plumbing, valves, and fittings, is excited to announce the launch of its latest innovation, the ClearLOC™ push to-connect Fitting System. ClearLOC™ offers the fastest installation method among push-to-connect fittings systems. Simply cut the tube, insert it into the fitting, and push to confirm the connection. This Read more

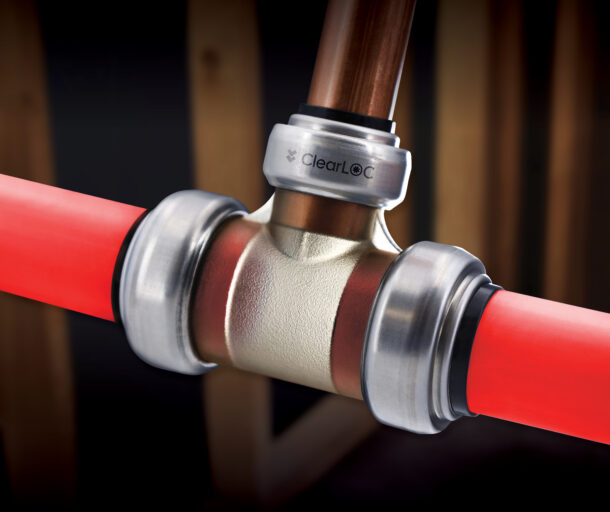

Legend Valve, a leading manufacturer and supplier of high-quality plumbing,

valves, and fittings, is excited to announce the launch of its latest innovation, the ClearLOC™ push to-connect Fitting System.

ClearLOC™ offers the fastest installation method among push-to-connect fittings systems. Simply cut the tube, insert it into the fitting, and push to confirm the connection. This streamlined method ensures efficiency and reliability for plumbing professionals.

The ClearLOC™ Fitting System features an advanced engineered transparent PPSU (polyphenylsulfone) resin, the same as standard plastic PEX fittings. However, ClearLOC sets itself apart with its transparent body and Stainless-Steel end connection points. The transparent body lets plumbers visually verify the connection point, ensuring the tube reaches the integrated stop.

ClearLOC installs 50% faster by eliminating the need to measure tube insertion depth. ClearLOC is compatible with PE-RT / PEX, CPVC, and Copper tube sizes from 1/2”, 3/4”, to 1”. The fittings system is a fully removable and reusable. Use a standard push-fit removal tool to push the release collar inward to remove the fitting. Once depressed, the collar allows for easy removal of the tube.

ClearLOC is available starting May 21st, 2024, at your nearest plumbing wholesaler.

With over 35 years of experience, Legend Valve is renowned for its commitment to innovation, quality, and customer satisfaction. The company continues to be an industry leader in developing new products that meet the evolving needs of plumbing professionals.

“We are thrilled to introduce the ClearLOC™ Fitting System to the market,” said Jeff Shreiner, VP Sales for Legend. “This product represents a significant advancement in plumbing technology, with a 50% faster installation than traditional push-fit fittings.”

For more information about ClearLOC™, please contact:

Wade A. Tennant

Director of Marketing,

Wade.tennant@legendvalve.com

248-630-7400