Smoke ’em if you got ’em. Or something to that effect. The new Crowne Plaza Copenhagen Towers, one of the greenest hotels in the world, sits on a natural aquifer in which the hotel “mines” for a sustainable passive HVAC system, a similar methodology to geothermal here in the States. “In order for energy consumption Read more

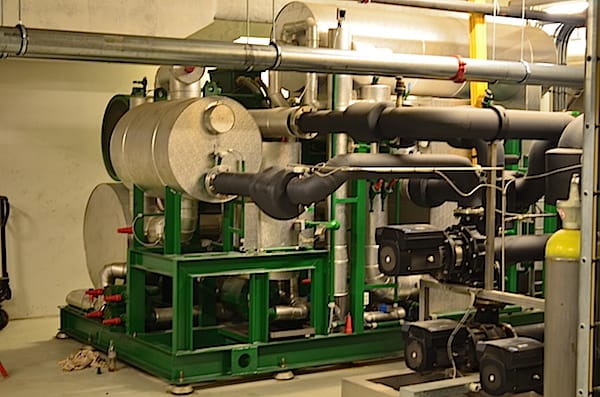

plumbing hub

Smoke ’em if you got ’em. Or something to that effect. The new Crowne Plaza Copenhagen Towers, one of the greenest hotels in the world, sits on a natural aquifer in which the hotel “mines” for a sustainable passive HVAC system, a similar methodology to geothermal here in the States.

“In order for energy consumption and CO2 emissions to be as low as possible, the hotel insisted on the most innovative energy technology throughout the building,” says Jens Norgaard, application manager for Grundfos Commercial Building Services. With the aid of one of the most advanced ATES (Aquifer Thermal Energy Storage) systems, cold groundwater is used for the cooling of the guest rooms in the summer. Conversely, the heat rejected from this process is reused for heating in the winter.

Combined with the building’s variable airflow volume (VAV) ventilation system, the hotel is ensured that guest rooms, lobby and conference facilities are cooled, heated and ventilated individually, and in accordance with the actual load. The system delivers 4.1 MW of cooling and 2.4 MW of heating.

The ATES system delivers cooling and heating system represents one of Denmark’s first groundwater-based cooling and heating systems, and its total annual energy is 51 kWh per square meter for heating, air conditioning, domestic hot water and ventilation. The system has a projected payback of approximately six to seven years.

Ground water from a 46 F cold well is circulated through a heat exchanger that cools water in the hydronic air-conditioning system. In the process, the groundwater is heated and returned to a warm well in the aquifer. The warm well and the surrounding groundwater heats up to approximately 60 F during the cooling season.

During this process, no active refrigeration is required, and the COP is as high as 41. The “free cooling” process covers up to 60% of the building’s total cooling need. Two ammonia chillers remain on standby to cover peak loads between 60% and 100%. Heat rejected from the chiller’s condenser is stored in the warm groundwater well. By reversing the flow, the warm groundwater is available for heating during the winter season.

Groundwater pumps and all other pumps, both in the ATES system and in the hydronic air conditioning and heating systems, are provided with frequency converters in order to let the pumps adapt to variations in flow requirements.

Grundfos delivered all pumps for the building’s air conditioning, heating and water boosting. The following products were supplied specifically for the ATES system:

• 3 pcs. NB 65 200/129 end-suction pumps w/external frequency converters — primary hydronic heating pumps.

• 3 pcs. NB 125 315/290 end-suction pumps w/external frequency converters — primary hydronic cooling pumps.

• 2 pcs. NBE 65 250/254 end-suction pumps w/internal frequency converters — dedicated to the chiller’s condenser circuits.

• 2 pcs. NBE 100 200/195 end-suction pumps w/internal frequency converters— dedicated for the chiller’s condenser circuits.

• 1 TPE 80 340/4 inline pump w/internal frequency converter — serves primary cooling tower circuit.

• 1 TPE 80 370/4 inline pump w/internal frequency converter —serves secondary cooling tower circuit.

All sun-facing facades are equipped with ultra-thin solar panels, and the installation constitutes Northern Europe’s largest private array of solar cells, producing annually more than 200,000 kWh. This constitutes around 15% of the hotel’s annual power consumption. The total solar cell capacity is 270 kWh. The remaining 85% is bought as green energy produced by wind turbines.

In late April, leaders from the plumbing industry gathered in Washington, D.C. for the Plumbing Industry Leaders Coalition (PILC). Every year the group gets together to chart progressive action for the industry: Legionella standards, skilled worker shortage, dry drains research, U.S. water strategy, etc. The plumbing industry think tank gathers every year to seek collaboration Read more

In late April, leaders from the plumbing industry gathered in Washington, D.C. for the Plumbing Industry Leaders Coalition (PILC). Every year the group gets together to chart progressive action for the industry: Legionella standards, skilled worker shortage, dry drains research, U.S. water strategy, etc. The plumbing industry think tank gathers every year to seek collaboration on industry initiatives.

In late April, leaders from the plumbing industry gathered in Washington, D.C. for the Plumbing Industry Leaders Coalition (PILC). Every year the group gets together to chart progressive action for the industry: Legionella standards, skilled worker shortage, dry drains research, U.S. water strategy, etc. The plumbing industry think tank gathers every year to seek collaboration on industry initiatives.

Harmony, balance, unity, common ground. Terms I kept hearing again and again at the PILC meeting and at the the International Emerging Technology Symposium (IETS). You see we are at a crossroads of sorts — at the intersection of where energy efficiency, energy and water conservation, and cost effectiveness meets sanitation and the health.

A guest speaker at the PILC meeting certainly opened my eyes on some issues that had me waxing Axl Rose prophetic and asking, “Where do we go now?” Seriously, though, it did me leave me asking, “What are the answers?” Marc Edwards, Charles Lunsford Professor of Civil Engineering at Virginia Tech, talked about unleaded brass performance, hexavalent chromium, green building water quality, Legionella and changes in water chemistry.

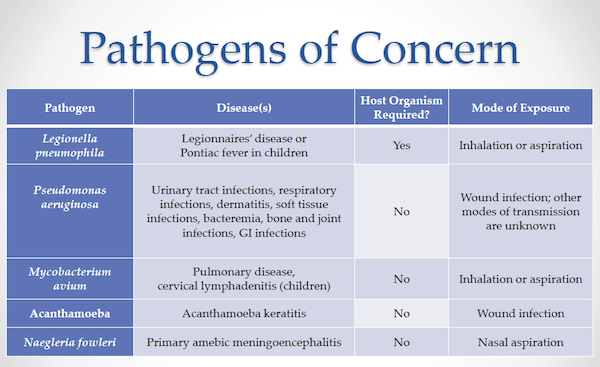

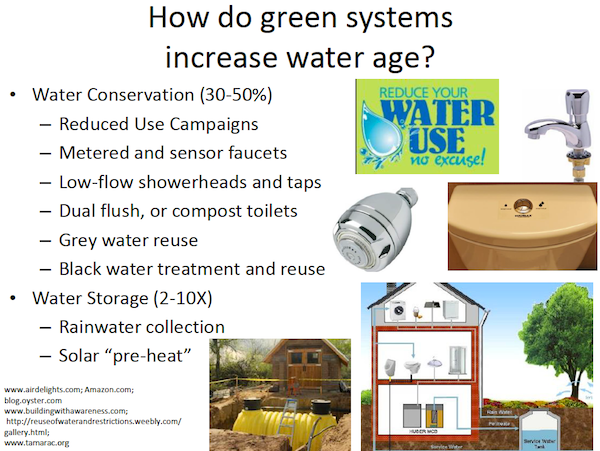

Of particular interest, here are some of Edwards’ points:

• Green Buildings — What’s different about green water systems asks Edwards and co-researcher William Rhoads in a recent report Green Building Premise Plumbing: Identifying Public Health and Aesthetic Concerns. The answer: New sources of potable water/onsite water treatment and water age, the amount of time that passes from the time water enters a system to the time it is used. Does water need an expiration date? Green systems increase water age by reduced use campaigns, metered and sensor faucets, low flow showerhead and taps, dual-flush or compost toilets, greywater reuse and water storage — rainwater and solar pre-heat. There are concerns associated with higher water age: lower and no chlorine residuals, microbial growth, taste and odor, opportunistic pathogen growth and more problems with copper and lead corrosion. “Even if a given building does not reduce water consumption, water quality will still be affected by the cumulative savings of other buildings,” states the report.

The report concludes the we are at the earliest stages of a green building revolution and there is some cause for concern that current strategies might create potable water that tastes bad, has high Pb/Cu, and perhaps high levels of harmful pathogens. The large-scale impact of water conservation has been to increase the water age for all consumers with implications for taste and odor control and human health. In pursuit of obtaining “net zero” buildings or energy efficiency, impacts of some design elements, including water storage and green plumbing fixtures, deserve increased scrutiny.

• Legionnaire’s Disease — In a report by Edwards, Amy Pruden and Randi Brazeau, Microbial Ecology of Residential Hot Water Heater Systems: Role of Hot Water System Type/Design on Factors Influential to Pathogen Re-growth: Temperature, Chlorine Residual, Hydrogen Evolution and Sediment, key findings included increased pathogen growth in electric water heaters vs. gas and incidence higher in buildings with hot water recirculation systems. Conclusion includes temperature is important, but it is more complicated than deciding on a set point; recirculating systems have more H2, less chlorine, less oxygen, higher turbidity and higher metals than standard systems; and design and operation of hot water systems is important for comfort and health.

• Hexavalent chromium [Cr(VI)] is known to cause cancer, and targets the respiratory system, kidneys, liver, skin and eyes. In time, stainless steel in water raises chromium levels. Current plumbing systems in reaction with water can promote HEX chromium.

In addition to Edwards’ findings, it seems that as technology advances we need to be more cognizant the effects of these systems have on human health. For example, it has been advertised, by utility companies no less, that lowering the set-point temperatures on water heaters will reduce electricity costs. This only provides a petri dish for Legionella to grow. What about rainwater harvesting? The more these systems catch hold, the more they need to be examined for treatment and disinfectant of the water they are collecting and holding. Finally, low flow toilets are great for the water conservation cause, but are they adding the complex issue of dry drains?

So here we are at a crossroads of the water conservation vs. health debate: damned if we do, and damned if we don’t.

Visitors to BB&T Ballpark, the new home of the Charlotte Knights, will enjoy great baseball and outstanding skyline views of the city. What you find behind the walls is pretty impressive too — a world-class plumbing system from Charlotte Pipe and Foundry Company. The system includes Charlotte Pipe’s cast iron pipe and fittings, which are Read more

Visitors to BB&T Ballpark, the new home of the Charlotte Knights, will enjoy great baseball and outstanding skyline views of the city. What you find behind the walls is pretty impressive too — a world-class plumbing system from Charlotte Pipe and Foundry Company.

The system includes Charlotte Pipe’s cast iron pipe and fittings, which are manufactured at Charlotte Pipe’s foundry, just minutes away from the ballpark. Charlotte Pipe FlowGuard Gold® and PVC pipe and fittings are also included. This is not the first time Charlotte Pipe products have been selected for use in premier stadiums — both Yankee Stadium and Citi Field in New York City feature Charlotte Pipe plumbing systems.

The system includes Charlotte Pipe’s cast iron pipe and fittings, which are manufactured at Charlotte Pipe’s foundry, just minutes away from the ballpark. Charlotte Pipe FlowGuard Gold® and PVC pipe and fittings are also included. This is not the first time Charlotte Pipe products have been selected for use in premier stadiums — both Yankee Stadium and Citi Field in New York City feature Charlotte Pipe plumbing systems.

The $54 million ballpark project will be home to the Charlotte Knights, a Class AAA team. It has a seating capacity of 10,200 and a natural grass field. Two club areas offer skyline views, 1,050 club seats and 22 luxury suites.

For more than a century Charlotte Pipe and Foundry Company has been manufacturing pipe and fittings. Today the company employs more than 1,200 loyal, hard-working Americans. All of its products are proudly made in the USA. Charlotte Pipe manufactures the industry’s broadest range of standard and specialty DWV products, including cast iron and plastic pipe and fittings. Charlotte Pipe is the only manufacturer that offers a system of ABS, PVC, CPVC, cast iron, FlowGuard Gold®, ChemDrain®, ReUze® and RePVC® pipe and fittings for both residential and commercial plumbing systems.

For more than a century Charlotte Pipe and Foundry Company has been manufacturing pipe and fittings. Today the company employs more than 1,200 loyal, hard-working Americans. All of its products are proudly made in the USA. Charlotte Pipe manufactures the industry’s broadest range of standard and specialty DWV products, including cast iron and plastic pipe and fittings. Charlotte Pipe is the only manufacturer that offers a system of ABS, PVC, CPVC, cast iron, FlowGuard Gold®, ChemDrain®, ReUze® and RePVC® pipe and fittings for both residential and commercial plumbing systems.

Charlotte Pipe is headquartered in Charlotte, NC, and has seven plant locations across the United States. Combining modern technology with a century of craftsmanship and experience, Charlotte Pipe has a proud legacy of commitment to the industry and its customers. The company is guided by the philosophy of its founder — produce the best possible product and provide the best possible service for the customer.

Visit our website at www.charlottepipe.com.

“Litigation” is not a word contractors like to hear. Unfortunately, legal proceedings grow every year, affecting contractors, engineers, architects and manufacturers alike. Often times this is due to value engineering of the plumbing system. Here’s one example. PVC pipe was installed below grade on a new airport in Winnipeg, Canada. Prior to the grand opening Read more

“Litigation” is not a word contractors like to hear. Unfortunately, legal proceedings grow every year, affecting contractors, engineers, architects and manufacturers alike. Often times this is due to value engineering of the plumbing system.

Here’s one example. PVC pipe was installed below grade on a new airport in Winnipeg, Canada. Prior to the grand opening, widespread failures of PVC pipe were discovered.The PVC pipe was bowed, bent, crushed, separated or damaged, and much of it was under thick concrete.

One option was to cut the floor and replace the pipe. Many airports utilize Terrazzo flooring, which typically cannot be patched. Another option was to reline the pipe, which is difficult if the pipe has collapsed. A third option was to dig a subterranean trench and replace the pipe. Each was costly, cumbersome and time consuming. The failed system resulted in a twenty-week delay in the opening of the airport as well as litigation that will require years to resolve.

To help avoid lengthy litigation due to value engineering of the plumbing system, here are a few things to consider.

• Cast Iron Soil Pipe has standard charts for crush rating, so trench preparation and backfilling during installation have minimal instructions. PVC pipe has very specific instructions for the dimensions of the trench as well as the bedding and backfill material of the trench. It also has proper backfill methodologies that are outlined in ASTM D 2321.

• Cast Iron Soil Pipe typically requires an endothermic fire stopping material to fill the annular space between the pipe and any fire rated wall or floor penetrations. Fire caulk products are widely used in the construction industry, inexpensive, simple to install and usually have a long life of useful performance. PVC pipe typically requires an intumescent fire stop, which is significantly more expensive than endothermic fire caulk because of the performance and material requirements.

If there are a small number of fire wall penetrations, value engineering to PVC may be a viable alternative. However, if there are a large number of fire wall penetrations it is less viable because of the more expensive system components required.

• If noise is a concern, cast iron soil pipe is the hands-down better choice. Research has shown that cast iron soil pipe is 750% more effective in silencing plumbing noise when compared to PVC.

• Expansion and contraction is generally not a concern with cast iron soil pipe because it expands ¾” per one hundred feet per one hundred degrees Fahrenheit change (approximately the same as concrete). On the other hand PVC will expand and contract approximately 4.5 to 5 times more, often requiring the need for expansion loops, offsets or changes in directions.

These are difficult to use with gravity systems and the calculations required for installation for compensation are difficult for installers to calculate. The calculation is ΔL = LpC Δ, where: ΔL = Change in length due to change in temperature (in.), Lp = Length of pipe (in.), C = Coefficient of thermal expansion (in./in./°F) = 3.8 x 10-5in./in./°F for PVC ΔT = Change in temperature (°F).

• Another factor to consider when calculating expansion loops is any space limitations your project may have. Often it is very difficult to find the space necessary in order to install properly sized loops and/or offsets. Depending on the project, there may be no space to add the proper loops for expansion and contraction.

• Cast iron soil pipe requires hanger/support within every 18 inches of a coupling or hub. Hanger spacing for PVC and other plastics requires a thoughtful evaluation of pipe size relative to the operating temperature. For instance a four-inch PVC pipe operating at 60⁰ F will require hangers every 7.5 feet and at 140⁰ F every 4 feet.

• Elevated temperatures can cause a PVC system to fail. PVC is rated at a maximum temperature of 140⁰ F while Cast Iron Soil Pipe is rated at 212⁰ F. While many systems have controls limiting the maximum temperature in a system, this is not a guarantee against failure. Consider if the system can be manipulated to override max limits. Also, remember that quick-cure concrete can exceed 140⁰ F and that autoclave or boiler condensate may be errantly drained into the system.

Here’s another case study. The specs for a Midwestern hospital called for cast iron underground, but it was value engineered to PVC. From a budget standpoint this looked like a good idea, since it offered a $5,000 savings on a $20,000 project. Unfortunately, the boiler contractor dumped 180⁰ F condensate into the system causing the PVC to fail. This led to a $29,000 bill to fix the failed piping system.

For more information on value engineering and plumbing systems visit www.charlottepipe.com/value_engineering.

Written by: Paul Riedinger, LEED AP BD+C

By Kris Alderson, Bradley Corporation Some trends in commercial restroom design come and go but those that provide meaningful benefits to both building and facility decision makers – and restroom users – are standing the test of time. Today’s public restrooms feature forward-thinking products and materials that have stylish, sustainable, durable, low-maintenance, hygienic, safety, and Read more

By Kris Alderson, Bradley Corporation

Some trends in commercial restroom design come and go but those that provide meaningful benefits to both building and facility decision makers – and restroom users – are standing the test of time. Today’s public restrooms feature forward-thinking products and materials that have stylish, sustainable, durable, low-maintenance, hygienic, safety, and water- and energy-saving qualities, such as:

Integrated design. The key to commercial restroom design is using products that strike the balance between practicality and attractive styling. Newer quality restroom products, such as lavatory fixtures and washroom accessories that use

.jpg)

finely-crafted, sculptural elements, can create a common aesthetic to integrate the look of the room. For example, when used throughout a restroom, the sleek and modern design of newer stainless steel accessories (towel and toilet paper dispensers, waste receptacles and hand dryers) can create a completely uniform aesthetic.

Sustainable materials. More manufacturers are incorporating sustainable materials into restroom products, which can increase the maintainability and life span of these products. In addition to recycled stainless steel, solid surface lavatory countertops made of recycled materials and rapidly renewable material also help ensure long-term durability, ease of cleaning and long-term maintenance. Likewise, plastic toilet partitions made from 100% post-consumer recycled High Density Polyethylene (HDPE) plastic is another example. The solid plastic material is ideal for heavy usage, especially in wet humid conditions and is easy to maintain.

Touch-free fixtures. There is a continued preference among consumers and building owners for touchless fixtures in restrooms. They are extremely convenient and easy for users to activate and for facility owners to clean and maintain, and they cut down on transmission of germs and bacteria from user’s hands. Some newer touchless fixtures use 0.38 GPM faucets vs. 0.5 GPM, which achieves a 24% water savings.

Safety concerns in restrooms

Wet and slippery floors are all too common in public restrooms. In addition to being a big issue for businesses, they are also a big turn-off too customers and restroom users. Bradley’s annual survey of Americans’ hand washing preferences in public places revealed that wet and slippery floors cause restroom users the highest amount of aggravation. While 68% of Americans say that water collecting on the floor is extremely/very aggravating, almost 50% are extremely/very uneasy about walking across a wet restroom floor.

A new “all-in-one” hand washing fixture – with soap, faucet and hand dryer in the same unit – eliminates dripping water on the floor and safety in commercial restrooms since the user’s hands stay within the sink area until they are dried.

RESTROOM TRENDWATCH:

NEW “ALL-IN-ONE” HAND WASHING FIXTURE ADDRESSES COMMERCIAL RESTROOM TRENDS

.jpg)

The future of hand washing has arrived. Bradley Corporation has just introduced the very first commercial hand washing fixture to provide a sink, soap, faucet and dual-sided dryer all in one touchless and sleek unit: the Advocate® Lavatory System.

Bradley's innovative “all-in-one” touchless design simplifies the art of hand washing — as users intuitively move their hands from left to right using soap, faucet and hand dryer. The design minimizes washroom cleaning and maintenance, and creates a safer restroom environment because water goes down the drain – not on the floor or down the walls.

The Advocate also promotes sustainable restroom design, because it features a 0.38 gpm faucet, which reduces water usage by 24%, a high-efficiency hand dryer, which also cuts paper towel waste, and uses recycled solid surface material, which is GREENGUARD-certified.

For more information, visit www.bradleycorp.com/advocate.

Kris Alderson is a Senior Marketing Manager at Bradley Corporation, a leading manufacturer of plumbing fixtures, washroom accessories, partitions, emergency fixtures and solid plastic lockers. She can be reached at Bradley Corp., W142 N9101 Fountain Blvd., Menomonee Falls, Wis., 53052-0309. For more information, call (800) BRADLEY or visit www.bradleycorp.com.