Speed and accuracy are the name of the game when it comes to a successful piping installation and a thriving business. Whether you’re installing potable plumbing or hydronic piping, the faster and more precise the job, the more time and money you potentially have to work on other projects. While there are hundreds of tips Read more

Industry Blogs

Speed and accuracy are the name of the game when it comes to a successful piping installation and a thriving business. Whether you’re installing potable plumbing or hydronic piping, the faster and more precise the job, the more time and money you potentially have to work on other projects.

While there are hundreds of tips and tricks out there to make your installs faster, easier, and more effective, I’m going to concentrate on the following three methods almost any plumbing or mechanical contractor can use to bring greater productivity to projects.

Flexible PEX pipe with bend supports

If you’ve never heard of PEX, it’s an acronym for crosslinked polyethylene. It’s a flexible, durable plastic piping product that provides numerous benefits over rigid CPVC or metallic systems, including faster installs, zero corrosion, and freeze-damage resistance.

Many residential contractors are already using PEX (considering it’s the most installed piping system for new-home construction over copper and CPVC combined). However, PEX is still a relative newcomer in the commercial industry.

The biggest benefit of PEX is its flexibility, which allows you to simply bend the pipe with each change in direction. With a tight bend radius of six times the pipe’s diameter, you can practically make 90-degree bends without the need for a fitting.

For times when you do have a tight bend that needs to stay in a particular place, PEX manufacturers offer bend supports. For those of you that prefer to watch rather than read, here’s a video that explains bend supports in detail.

These helpful products are available for ⅜”, ½”, ⅝”, ¾”, or 1″ PEX pipe. They hold the bend in place at the proper angle and take a fraction of the time compared to making a 90-degree elbow.

Most contractors agree that using flexible PEX with bend supports can eliminate most fittings in smaller-diameter pipe sizes 1″ and down, saving up to half the install time of a rigid piping system.

Expansion tools

When it comes time to make a connection with PEX pipe, the professionals’ choice is PEX expansion. Note that expansion connections are only designed for PEX-a pipe. If you’re using PEX-b or PEX-c pipe, you’ll need to use a different fitting type as PEX-b and PEX-c pipes aren’t made to expand like PEX-a pipe, and they will experience microcracking during expansion.

Expansion connections require one simple tool that expands the pipe and an expansion ring before inserting a fitting. As the pipe and ring shrink back down around the fitting, it creates a solid, strong seal that can withstand up to 1,000 pounds of radial force. It’s quick and easy to do and simple to learn, so it’s highly beneficial with the skilled-labor shortage that’s challenging the trades. Here’s a quick, 20-second video on how to make a connection.

Now, to make installs even faster, expansion tools have advanced to make connections even quicker. For up to 1″ connections, the Milwaukee® M12 FUEL™ ProPEX® Expander with RAPID SEAL™ Heads is the fastest tool yet — with up to 65% faster sealing times compared to previous models.

For larger-diameter pipe connections, the new Milwaukee M18 FUEL™ ProPEX Expander with ONE-KEY™ is taking commercial installs to a new level by offering 3X faster 2″ connections. To watch how much faster, check out this video from Milwaukee Tool.

Prefab

Finally, let’s talk about prefabrication. This is becoming a big trend for national residential builders or large commercial projects that have a lot of repeatability on the project. By prefabbing certain sections of a project, it can shave days, weeks, or even months off a timeline, depending on how big the project.

Prefabricating piping assemblies in a controlled factory environment not only adds more efficiencies, it also provides an additional benefit of greater accuracy. By doing a job repeatedly, it hones the skill and gives installers greater confidence in their work.

Plus, having rows and rows of prefabbed piping assemblies in a shop environment makes it a lot easier to perform quality checks. Instead of walking for miles on a job site, a supervisor can save significant time simply walking a shop floor.

And here’s another area where flexible, durable PEX provides additional benefits. Transporting prefabbed PEX piping assemblies is much easier than transporting rigid assemblies that can crack or break. Because PEX is super flexible, it can withstand the rigors of being transported to a job site without worry.

So, there you have it…just a few ideas to keep in mind the next time you have a project with a tight deadline, and you’re squeezed on time and skilled labor. Every little bit helps when it comes to adding productivity to projects. If you have other ideas, I’d love to hear them. Feel free to email me at kim.bliss@uponor.com.

Kim Bliss is the technical and marketing content manager at Uponor. She can be reached at kim.bliss@uponor.com.

Kim Bliss is the technical and marketing content manager at Uponor. She can be reached at kim.bliss@uponor.com.

Technology, and the advancement of technology, affect the mechanical industry in a pretty substantial way. Machines become more efficient, humans need to put less time into supervising machine lead tasks, and automation is getting better all of the time. So, how will the field of mechanics and mechanical materials be further changed (for better or Read more

Technology, and the advancement of technology, affect the mechanical industry in a pretty substantial way. Machines become more efficient, humans need to put less time into supervising machine lead tasks, and automation is getting better all of the time.

So, how will the field of mechanics and mechanical materials be further changed (for better or worse) going forward into the future? Although Gary Coleman has said “the fourth industrial revolution is in its nascent state,” there has already been a fair amount of change in the industry. Some think change can be hazardous, while others say it’s necessary.

Internet Of Things

IOI has changed the way people live their lives, but it also has implications for the mechanical industry. Imagine controlling machines via your smartphone. Products will be able to communicate with their manufacturer like never before. Software-driven controls are becoming more advanced all of the time, leading to mechanical engineers and other operators having to constantly update their supplier base in a rush to access the latest software.

The internet of things gives those in the industry a higher degree of productivity. Machines are now having a higher degree of autonomy over various controls than ever before, leaving mechanics and operatories more time to allot to other areas of work. While some think this isn’t necessarily good and could end up costing them their jobs, others believe it’s great because they’re not spread as thin, and there are fewer chances for accidents to occur.

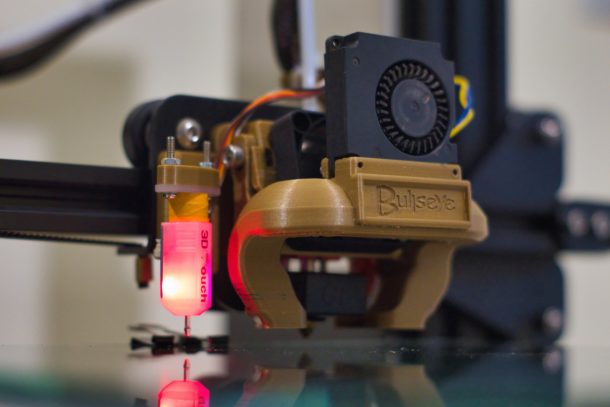

3D Printing

3D printing was spoken about for years before it became properly commercially viable. But as soon as it did, it blew up. 3D printing makes product and material creation extremely easy and immediate (no more waiting for shipping). The upsurge in 3D printing has brought about many firms offering a 3D printing service for other businesses and end-users. Some purely print products are then customized and sold, whereas others print bespoke components for broader usage across the mechanical and manufacturing sector.

There are mechanical engineers out there who have managed to create amazing things in 3D printers. Think about prosthetic limbs or walking aids. These were usually pretty complex to create, but 3D printing has allowed their application across the world in poorer countries.

Nanotech

Nanotech, or nanotechnology, has been touted by many as the future. Its usage covers a wide range, and many people can be forgiven for thinking about science fiction when first coming across the term. In reality, it simply involves the study of materials and structures which are between 1 nanometer and 100 nanometers. It’s supremely useful in the scientific field, where it was originally developed. However, nanotech has vast implications for the mechanical industry.

Pinpoint measurements, fluid mechanics and enhanced robotic controls are but a few potential applications for nanotech. While the study into nanotechnology is still at the outset, it’s clear that it could completely revolutionize multiple industries and open up a whole new way of looking at mechanical engineering.

Machine Learning (and A.I)

It’s another term that could walk straight out of a science fiction novel. AI is basically a machine or program trying to simulate human behavior. It’s getting better all of the time. Machines are becoming more accurate, and able to make human-like decisions (or better than human decisions). Just look at driverless cars as an example. Tesla’s learn as they’re driven. There are still accidents from time to time and many countries are hesitant to adopt driverless as a full feature, but it’s clear that in the not-so-distant future, cars will be driverless.

This applies to mechanical machinery too. Better production outcomes and timetables, robotic designs becoming believable and realistic, virtual reality being far more believable, and much more. With AI in charge, it’s believed that the production of material and anything from an industry standpoint can become far more efficient.

Solar Everything

The sun touches a lot of manmade material, so it makes sense to have it double as solar panels to generate clean energy. Instead of attaching solar panels to certain materials, material itself will be a solar panel. Take for example a window. It gets a lot of sun. Imagine if it could harness the energy from the sun and redistribute it as energy while still functioning as a transparent window. Look at roads. Imagine if they were made out of solar panels. Panels that can hold the weight of cars but still manage to collect and distribute energy.

With constant pivots towards green energy, it’s extremely likely that more materials will be built and geared towards the harnessing of natural energy.

Becoming a trade professional is a straightforward decision for many of us. We have a certain skill set, are interested in a certain industry or simply want to get involved in a trade that can secure a stable career and income. However, things aren’t always as simple as picking up your tools and heading out Read more

Becoming a trade professional is a straightforward decision for many of us. We have a certain skill set, are interested in a certain industry or simply want to get involved in a trade that can secure a stable career and income. However, things aren’t always as simple as picking up your tools and heading out to work. If you work for someone else, this is fine and will work. But if you want to work for yourself, you’re going to have to put in the work of securing clients and customers on a routine enough basis to generate a consistent income.

Nowadays, this means having a good quality website. Think about it – if you’re looking for a tradesperson, what would you do? Chances are, you’d type a few keywords like “plumber” or “roofer” into a search engine and click one of the first results to put up. You’d learn what you needed from their website and would make a decision on whether you want to use their services or not based on this. So, if you’re going to make a success of yourself, here are a few suggestions that can help you to create the website you need to secure your sales!

Use Web Designers and Developers

First, you’re going to need to reach out to a web designer and developer. They’ll be able to create the actual website for you. When talking to these professionals, it’s good to discuss things like the color scheme you’d like, creating a logo, how the pages are laid out and so much more. You may also want to reach out to a UX designer, who will be able to make sure that the pages are easy to use and direct people, step by step, to actually getting in touch with you. Once your website is up and running, you’re going to need to use specialists in SEO to help it rank in search engine results. This means when people search for the services you’re providing, your site will appear at the top of the list of links.

Get a Photographer

A photographer will be able to take pictures of your work to secure further sales going forward. It’s a good idea to get a few photos of you at work, doing whatever trade you might do, as well as your tools and equipment. This will give you some content for the website itself, such as on your “about me” or “services” pages. Then, you could do with some quality pictures of the work you’ve completed, which is ideal for a portfolio page, where potential clients can browse your work and see how good you are at what you do! Most photographers will edit and resize images to perfectly fit your site in their post-production processes. If you’re unsure, check whether this is a part of their package or a service that they offer. If it’s not included, you can easily find online tools or software that offer a photo size converter to ensure your images are optimized for your website.

Use a Copywriter

If you’re not too good with words, you should reach out to a copywriter too. This professional will be able to write all of the text on your website. They’ll be able to explain what you do and advertise it well. This can help people to get a good idea of your skill sets, how long projects could take and can work as a form of advertising and marketing, showing you in the best light possible. Many freelancers or agencies will complete this work for a reasonable price. Make sure to have a consultation with them to ensure they know everything that you have as a selling factor, from qualifications to specialist skill sets or experience and how far you’re willing to travel. You can write a list for them to refer to and check the copy over once it’s complete. If anything’s missing, or anything comes to mind later, you can always request edits.

Get Reviews

It’s a good idea to dedicate a part of your site to reviews from previous and existing clients. This is a form of social proof that will give new customers confidence in actually using your services. Ask previous customers to write up a short review and submit it on your page. This can really enhance your reputation and secure a lot more bookings or sales.

As you can see, there are a fair few steps you’re going to need to take when it comes to creating a website for your services and securing the sales you need to keep your business up and running. Hopefully, some of the information above should help you to experience as much success as possible.

There’s no denying that worker safety is a top priority for many companies. All trade professionals need to ensure safe job sites, whether working on home improvement projects or other contractor positions. Safety needs to be paramount — no company wants to see a maintenance employee get severely injured or face any life-threatening situations. Thankfully Read more

There’s no denying that worker safety is a top priority for many companies. All trade professionals need to ensure safe job sites, whether working on home improvement projects or other contractor positions.

Safety needs to be paramount — no company wants to see a maintenance employee get severely injured or face any life-threatening situations.

Thankfully, technology can be leveraged to enhance safety measures on any job site. New technologies for safety are emerging, and no matter the job performed, workers should consider implementing tech to achieve high safety standards.

1. Virtual Reality (VR)

Generally speaking, VR is becoming a widely used technology across various industries, from consumer electronics to health care. VR is used in many sectors, especially for training purposes — construction, plumbing and HVACR work is no exception.

For example, the Air Force has recently adopted VR systems to train workers responsible for aircraft. In addition to training in a controlled environment, which is safer than working on the actual plane, processes were made easier. The technology helps employees achieve a sense of realism when performing tasks, and they can better understand all the variants of the systems that keep planes running at a high level.

2. Wearables for Fall Detection

Many trades require people to work on elevated surfaces. Performing maintenance on equipment in higher locations can increase the risk of a worker experiencing a fall, leading to severe injury or even death.

There are new wearables on the market, such as safety vests or hard harts, with built-in sensors, GPS and real-time locating. Some vests even come with an air bag that will deploy if it senses someone is falling. Consider using these new types of wearables to ensure worker safety.

3. Exoskeletons

There are two different types of wearable exoskeletons that can be used on the job. Passive and active versions have various purposes but can be leveraged to ensure employee safety.

Exoskeletons work in tandem with the user. For example, passive exoskeletons prevent stress injuries and help hold essential tools or equipment used for maintenance. Active exoskeletons can help lift heavy objects, something many trade professionals need to accomplish daily. Together, the two types of technology play a key role in keeping workers from overexertion and related dangers like exhaustion, allowing for a healthier and more productive work experience.

4. Inspection Software

Software is being leveraged by every business across sectors, whether it’s to improve operational efficiency or keep track of employee productivity. Inspection plays a significant role in keeping equipment working properly.

Using inspection software to perform routine maintenance is becoming more widespread across the trade industries. Inspection software helps guide human workers while on the job, ensuring their safety and detecting equipment failure that could lead to injury. Automation will likely transform every industry and make daily tasks more efficient.

5. Security Cameras

When nightfall comes and a job site is left unattended, expensive equipment must be kept safe from theft. Aside from maintenance, construction workers have often turned to security cameras for ample job site surveillance to prevent instances of theft or damage, leading to lengthier projects and extra costs.

Using high-end security cameras acts as a deterrent to would-be criminals and can capture anyone who tries to trespass on a job site and cause damage or steal tools. Consider placing cameras in vulnerable areas to improve overall security measures. There are plenty on the market to choose from.

Ensure Workers Safety on Job Sites

Consider these technologies to improve workers’ safety as 2022 approaches. Whether it’s an electrician working on a telephone pole or someone on the roof of a residential building, these jobs require comprehensive safety measures to protect employees.

April Miller is a managing editor at ReHack.com who specializes in engineering and construction technology. You can find her work published on sites like Open Data Science and The Society of Women Engineers.

April Miller is a managing editor at ReHack.com who specializes in engineering and construction technology. You can find her work published on sites like Open Data Science and The Society of Women Engineers.

Your employees are the lifeblood of your business and you will succeed or fail based on their work. That’s why you need to take the time to create a company culture that is positive and encouraging. Alongside good working conditions and other benefits, the best employers also invest in the professional development of their employees. Read more

Your employees are the lifeblood of your business and you will succeed or fail based on their work. That’s why you need to take the time to create a company culture that is positive and encouraging. Alongside good working conditions and other benefits, the best employers also invest in the professional development of their employees.

What is professional development?

Most companies fall into the trap of only training employees when they absolutely have to (when a skills gap is causing problems) or training people only to do the job that’s in front of them. This is a very short-sighted approach and not only devalues your employees but has major consequences for your business too.

By taking a more holistic view of professional development, you can ensure that your employees are skilled, motivated and engaged. A fully rounded development program will take into account skills-based learning, workplace essentials such a lifesaving skills from cprcertificationnow.com and fire training.

The final part is allowing your staff to develop for their future career goals. The leaders of tomorrow may be working for you now but need the chance to develop and expand their skill set.

How can professional development help your company?

Engaged staff who are happy in their jobs can have huge benefits to your company. For example, they provide better service to customers, increasing profits. They also represent your brand well to the outside world.

Employee engagement is a huge issues for a lot of companies. Various studies have shown that up to 70% of the workforce are disengaged.

Your company can also gain a competitive advantage within your sector. Having the best trained and productive employees will soon show when it comes to the competition.

Happier and skilled workers feel supported in their roles and produce better work. You’ll find that errors will decrease and the productivity levels.

Solve company problems

By equipping people with skills outside of their normal job roles, you can encourage a team that can look at any inefficiencies within the company and suggest ways to put these right and make improvements.

Attract and retain top talent

Developing a reputation as a company that values it’s employees can have many benefits. One of these is the ability to keep your best employees and not have them jumping ship to your competitors. Additionally, you’ll find it much easier to attract talented people to your organization when you recruit. Given the upheaval that people leaving your company can cause, then this can save you a lot of money and increase the productivity of your company as you don’t have to wait for new recruits to get up to speed with everything.

Final thoughts

As an employer, you need to think of your employees development needs in a broader sense. The benefits from doing this can benefit your business in so many ways and can repay your investment many times over.

You’ll soon develop a reputation as a great employer and will have your pick of talent in the area.