Heating oil doesn’t have the market share of some of the other fuels, but it’s used in about 4.5 million homes in U.S. Most of these homes are concentrated in the Northeast, but heating oil is in use to some degree in almost every state in the country. And the heating oil’s market share has Read more

Featured Articles

Heating oil doesn’t have the market share of some of the other fuels, but it’s used in about 4.5 million homes in U.S. Most of these homes are concentrated in the Northeast, but heating oil is in use to some degree in almost every state in the country. And the heating oil’s market share has been shrinking over time in the face of climate change and a growing global awareness of environmental issues. The home heating oil industry is undergoing a remarkable transformation.

A quiet renaissance is taking place in the industry as communities, companies and individuals turn to a cleaner and more sustainable alternative to keep their homes warm during the cold winter months, while reducing their carbon output. That alternative is renewable liquid fuels. Electrification is often touted as the only decarbonization solution when there are many viable options, including renewable liquid fuels. Utilizing all options is the prudent approach to a worldwide problem of such immense scope.

The Need for Change: From Fossil Fuels to Renewable Liquid Fuels

For decades, homeowners have relied on traditional heating oil derived from fossil fuels to combat the chill of winter and provide abundant domestic hot water. However, with the environmental impact of these fuels becoming increasingly apparent, and with government mandates for carbon reduction, the need for a greener alternative has never been more pressing. Enter both biodiesel and renewable diesel—renewable energy sources that offer a solution to reduce carbon emissions and create a more sustainable future rapidly and economically.

The Rise of Renewable Liquid Fuels

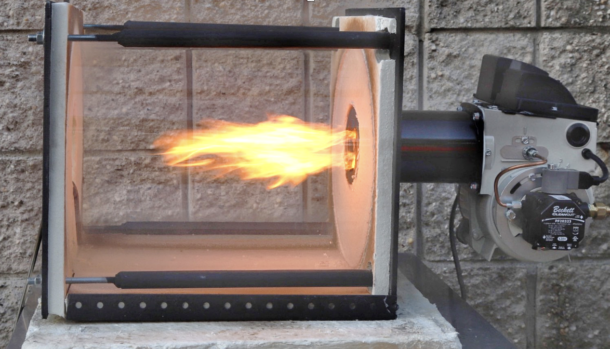

Biodiesel, made from organic materials such as plant oils, animal fats or recycled cooking oil, is emerging as a game-changer in the heating industry. Unlike traditional heating oil, biodiesel produces up to 90% less greenhouse gas emissions, making it a cleaner and more environmentally friendly option. The shift toward biodiesel aligns with the global push for renewable energy sources and a reduction in dependence on fossil fuels.

Renewable diesel is derived from the same biomass feedstocks as biodiesel but undergoes a different production process. Renewable diesel is gaining popularity as a low-carbon alternative to traditional heating fuels. Unlike conventional fuel, which is derived from crude oil, renewable diesel significantly reduces greenhouse gas emissions and promotes a more sustainable energy future. Renewable diesel is in wide use in Europe for space and domestic water heating, particularly in the UK where renewable diesel incentives and mandates are upcoming.

During the transitional phase, renewal liquid fuels are commonly blended with each other and conventional petroleum. These blends are referred to as BXX, the XX representing the portion of renewable fuel. For example, B20 would be 20% biodiesel and 80% petroleum. Blends of biodiesel and petroleum are often referred to as Bioheat®.

Initiatives Leading the Way

Manufacturers, as well as national and state associations, are taking the lead in this transition. Forward-thinking fuel dealers and individuals are driving change from the ground up. These initiatives focus on producing new burners, appliances and accessories that are rated for renewable liquid fuels, education, outreach, and the development of infrastructure to support the adoption of renewable liquid fuels for home heating.

In many cases, these initiatives are not only reducing the carbon footprint of communities but also contributing to local economic development. Renewable liquid fuel production often involves repurposing waste materials, creating new jobs, and supporting local businesses engaged in the sustainable energy sector. Utilizing waste products from agricultural production helps both the American farmer and the economy.

How to Transition?

Most fuel dealers and homeowners don’t jump immediately from heating oil to 100% biodiesel, they slowly transition the blend level upwards over time. This slow transition makes it a non-event; the homeowner and technician observe no noticeable differences and no changes in equipment are needed. As filters, gaskets and other components are replaced over time, they should be upgraded to versions rated for use with biofuels.

The same holds true for appliances—when they reach the end of their lifespan or are upgraded for efficiency purposes, renewable fuel rated boilers and furnaces should be installed. The Inflation Reduction Act (IRA) recognizes the advantages of renewable fuels and authorizes a $600 tax credit for a new liquid fuel furnace or boiler rated for at least B20.

Success Stories: Homes Heated by Biodiesel

There are more than 300,000 companies and consumers that have already made the switch to B20 or higher blends, and are experiencing firsthand the positive impact on both the environment and their wallets. Jacqueline Hart, Executive VP of Hart Home Energy in Oakdale N.Y., remarked, “Our family began injection blending biofuel more than 20 years ago because we felt it was the right thing to do to decrease our dependency on foreign oil sources and to make the environment cleaner for future generations.

Since that time, we have increased our blends, participated in every local field study conducted in our area, and have used B100 in our own homes and business. We have seen a large reduction in service calls. The Hart Family remains committed to providing the cleanest and most sustainable carbonless fuel of choice for our customers and neighbors.”

These benefits require little to no upfront capital investment unlike many other decarbonization options and provide immediate carbon reduction, not at some future time as other solutions promise.

Challenges and Future Prospects

While the transition to renewable liquid fuels presents numerous benefits, it is not without some minor challenges. Infrastructure updates, technician education and public awareness are hurdles that the industry must overcome. However, as technology advances and support grow, these challenges are becoming increasingly manageable. Technician education will play a vital role in this transition. Just as some were resistant to PEX and PVC replacing copper and cast-iron pipe or press technology replacing sweat, there will be those opposed to this future fuel.

Looking ahead, the future of the home heating oil industry seems destined for a renewable rebirth. Governments, businesses and individuals are recognizing the urgency of addressing climate change, and the home heating sector is a crucial battleground in this environmental struggle. In the pursuit of a greener warmth, the transition to renewable liquid fuels is not just an industry shift, it’s a collective effort to preserve the planet for generations to come.

As communities unite in this endeavor, the home heating oil industry, soon to be renewable liquid fuel industry, is proving that sustainable choices can keep us warm and comfortable while protecting the world we call home.

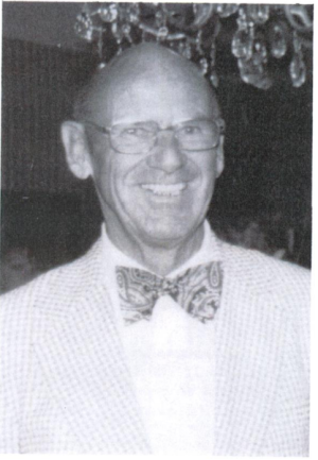

Robert O’Brien is Director of Education, National Oilheat Research Alliance (NORA).

This past October, a select group of social media influencers that represent small or mid-sized, light commercial plumbing contractors attended a Watts two-day “Social Media Summit” at the company’s North Andover, Mass. and Franklin, N.H. locations. Guests included Mechanical Hub’s very own Eric Aune @mechanicalhub; Paige Knowles @plumber_paige; Travis Abaire @t.a.p.plumbingandheating; Matt Fleming @allstarplumbinginc; Evan Read more

This past October, a select group of social media influencers that represent small or mid-sized, light commercial plumbing contractors attended a Watts two-day “Social Media Summit” at the company’s North Andover, Mass. and Franklin, N.H. locations. Guests included Mechanical Hub’s very own Eric Aune @mechanicalhub; Paige Knowles @plumber_paige; Travis Abaire @t.a.p.plumbingandheating; Matt Fleming @allstarplumbinginc; Evan Berns; and Chris Sbrocco @chris_sbrocco.

The Watts and social media crew

The purpose of the summit was to develop Watts’ own “rolodex” of online influencers who could help build Watts product excitement and awareness. Hosting a social media influencer summit provided the potential to deepen Watts’ social media influencer connections, assist in digital marketing, and gain contractor-level voice of customer. “Watts welcomed the group plumbers to discuss how social media can play a role in learning and collaborating within the plumbing and piping industry,” said Aune.

Guests were initially greeted to a hearty welcome from Watts CEO, President, and Chairperson of the Board, Bob Pagano. “We were greeted warmly by members of the Watts social media and marketing team, and heard a message from CEO Pagano about his vision for what’s coming next at Watts,” said Berns.

Watts CEO Bob Pagano

Following the opening remarks from Pagano, by an open dialogue on influencer benefits was held hosted by Ryan Kiscaden, Manager, Sales Enablement, with a quick breakdown of the Watts family of products from Shashwat Nath of the Watts Product Team. “After touring their state-of-the-art facility, we were able to ask questions and get our hands on products in their training room,” said Berns.

Abaire continued, “I’ve always liked the products that Watts put out, but to see firsthand the level of care, precision, and pride that actually goes into making their products gave me a whole new level of respect and trust in the Watts brand.”

Director of Training, Greg Gyorda, gives the group a tour of a working Watts mechanical room.

In the afternoon of that first day, the group toured the mechanical rooms and learning center and met with Greg Gyorda, Director of Training, and members of the Watts training team, including Kari Stocks, Training Campaign Manager. “Watts has built a world-class training facility at their headquarters where hands-on technical training is a main focus,” said Aune.

The gang at the Sam Adams brewery

Moreover, “I was impressed with the training facility, as I didn’t realize how many brands are under the Watts umbrella. They had a bit of everything at the training facility to check out and with which to get hands-on,” said Fleming.

Day one concluded with some authentic Boston flavor. “The Watts team showed us some of what Boston has to offer with a tour of Sam Adams brewery and a Boston Bruins game,” said Berns.

On the second day, the group took a one-hour trip to Watts’ Franklin Manufacturing Facility in Franklin, N.H. This facility is a center of excellence in manufacturing Watts’ specialty products that require some level of fabrication. This includes Watts-branded plumbing flow control products. The products that are manufactured at this state-of-the-art, lean facility are used worldwide in various residential and commercial applications. “We were able to tour their incredible manufacturing facilities, and got a look at the many steps that the Watts products go through before we see them on the shelf. It was great to see some of the smiling faces behind the products that we all know and love,” said Berns.

The Hub’s Eric Aune talks with Franklin Manufacturing Facility tour guide Pete Bertagna.

Tour guide Pete Bertagna captivated the group with some of the foundry’s processes, including how the world-renowned backflow preventers are made. “The Franklin factory tour gave us the opportunity to assemble our own backflow preventer from the parts manufactured on site; it was so cool to see the whole process from start to finish,” said Aune.

Fleming assembles his very own backflow preventer.

Fleming concurred, “The factory was also cool seeing all the backflow preventers that I’ve installed for years actually come to life.”

There is a need to continue to simplify plumbing systems and experiences over time. Online social media influencers are a “cog in the wheel” to positively influence the next generation and change perceptions. The Social Media Summit and those content creators that participated are cogs on the Watts messaging wheel. There is a growing need for training programs and education and Watts is taking training very seriously and believe it is key to its success.

The social media crew from l to r: Chris Sbrocco, Eric Aune, Matt Fleming, Travis Abaire, Paige Knowles, and Evan Berns

Overall impressions from the Social Media Summit:

- Eric Aune @mechanicalhub:

“Watts has been present in the industry for decades longer than my 25-year plumbing and heating career. Connecting with people who make, design and distribute the products was a special experience of which I’m thankful to have taken part.”

- Matt Fleming @ allstarplumbinginc:

“At the end of the day, it was great to get to hang out with all my plumbing peers from across the country. I definitely value the friendships I’ve made through social media, and I always look for to an opportunity to hang with everyone.”

- Evan Berns @re.plumb

“The trip was a great opportunity to connect with some of the plumbing and heating industries leading professionals. Overall, it was a great event for Watts to get more involved with the online community and develop their social media presence.”

- Travis Abaire @t.a.p.plumbingandheating

“It was really a great and educational experience, and I’m thrilled I was asked to be a part of it.”

- Paige Knowles @plumber_paige

“I learned a lot about their environment and training opportunities. Seeing how backflow preventers were made, and being able to make one, was awesome!”

Geothermal heating and cooling is a well-established technology; it’s been around in simplistic forms for more than half a century and has developed at an impressive rate to become a technology that is providing real solutions for decarbonization and grid management. In its years of growth and innovative development, geothermal has taken on many different Read more

Geothermal heating and cooling is a well-established technology; it’s been around in simplistic forms for more than half a century and has developed at an impressive rate to become a technology that is providing real solutions for decarbonization and grid management. In its years of growth and innovative development, geothermal has taken on many different forms and variations, all of which have their own unique benefits.

The Vanderbilt Breakers Mansion saves $36,000 a year with Direct Geothermal Exchange.

The first recorded closed-loop geothermal design installed was a water-free direct exchange geothermal system in 1945. Robert C. Webber (1911-1984) is acknowledged by most to be the inventor of the ground-coupled heat pump system. In fact, according to a September 1948 issue of “The Refrigeration Industry,” Webber was the first to heat his seven-room home in Indianapolis by reversing the cycle on his home freezer. The issue featured Webber as The Refrigeration Industry’s “Man of the Month.” Webber’s “freezer in reverse” was also featured in Ripley’s Believe it or Not in 1948.

Caption: Robert C. Webber (1911-1984)

Direct geothermal exchange (DGX) waterless geothermal systems, also known as direct exchange systems, offer an innovative and sustainable way to heat and cool your home without requiring water in the loop for heat exchange. Unlike many other types of systems, DX uses a closed-loop refrigerant circuit to release heat from under our feet, eliminating the need for water that other systems require. One of the most vital benefits of Direct Exchange Waterless Geothermal is how efficiently it produces year-round temperature control using safe, reliable refrigerants.

There are many pioneers within the sustainable and renewable energy field, one of which is Bill Buschur, President of Total Green Manufacturing. Bill is a recognizable figure within the geothermal industry, and within the niche of waterless geothermal, with a history in the development of the technology used today. For reference, back in 1980, EarthLinked Technologies (ETI) established itself as a research company in the geothermal industry, becoming the original direct exchange manufacturer. It continued to have great success over the years as it carved out a niche in the geothermal industry. ETI partnered with Total Green Mfg. for five years, and Total Green acquired the 38-year-old DGX Manufacturing company.

Total Green Crew installs a DGX system.

A little history

“At around 12 years old, I began to ride along with my father in the service truck and I would run back and forth from the truck to get him tools or the parts he needed to make the repairs,” Buschur shared with us, “As I got a little older, I began building geo ground loops. I remember we had two football practices a day, and I would come home and build loops for the rest of the day. Eventually, I began to go to the job site with other crew members and help with the installation process.”

Young Bill Buschur working on site.

One of the keys to innovation is passion, and Bill Buschur has no issue with showing his passion through actions and incredible results. Bill has grown his business from a hard-working crew of only four people to becoming the largest direct exchange geothermal contracting company in the U.S., installing over 100 DX systems on a yearly basis.

Establishing the Waterless® brand was no small feat for Bill, but after earning a degree in Business Management and a refrigeration certification, topped off by 30 years of experience in geothermal heat pump technology, he’s become the driving force behind the biggest name in Direct Geothermal Exchange nationwide.

Quality is vital in any field, but Bill has ensured that his geothermal direct exchange units are to the highest standard, stating, “Dad always taught us that ‘If you don’t do things right the first time, you’ll end up doing it again’”. So we made sure we didn’t cut any corners when it came to Designing and Installing a geothermal system.”. This has been a key factor in how effectively Total Green has kept up with the latest technology.

At the end of the day, the million-dollar question is, “Are direct exchange waterless geothermal systems as efficient as water-based geothermal systems?” The answer is yes. Past criticisms of DX systems have primarily revolved around the question of environmentally friendly refrigerants. Today modern DX systems use advanced refrigerants that are both environmentally friendly and efficient with heat transfer, which will enhance the performance of the system altogether.

Bill Buschur in his younger years learning the trade (right).

We’re fortunate to have so many diverse options when considering which geothermal system to choose from, accompanied by so many industry pioneers behind each system. As we continue to push for the world to embrace and prioritize sustainability and energy efficiency, minimizing negative environmental impact and using the natural resources given to us, we should make a conscious effort to do so as one piece of that ever-forming puzzle. Any and every geothermal system contributes to a brighter, greener, world-changing future for us and generations to come.

We are on the same team, we are in the same boat, and we are a part of the geothermal heat pump revolution, changing the world for the better.

Mimi (Hannah) Egg is a Social Media Marketing Consultant with a passion for writing and researching. She has overseen the social media accounts for multiple private and corporate organizations and is constantly learning new ways to understand and optimize demographic outreach and form beneficial business connections through social networking for her clients. She can be reached at Mimieggshell@gmail.com

Mimi (Hannah) Egg is a Social Media Marketing Consultant with a passion for writing and researching. She has overseen the social media accounts for multiple private and corporate organizations and is constantly learning new ways to understand and optimize demographic outreach and form beneficial business connections through social networking for her clients. She can be reached at Mimieggshell@gmail.com

Just like the scene from the classic movie, “A Few Good Men,” where Tom Cruise says he thinks better with a baseball bat in hand, you gotta believe that for Chris Armstrong, his clarity comes from communicating from the front seat of his service vehicle. Most that follow Chris @pstheplumber on the Gram know that Read more

Just like the scene from the classic movie, “A Few Good Men,” where Tom Cruise says he thinks better with a baseball bat in hand, you gotta believe that for Chris Armstrong, his clarity comes from communicating from the front seat of his service vehicle. Most that follow Chris @pstheplumber on the Gram know that his “van chats,” among many of his other social posts, are can’t-miss.

Nicknamed PS for the past 20 years—or a variation of it like Uncle PS, or for his younger relatives that couldn’t pronounce PS, it morphed into “Uncle Pissy,” to now being called “Pumpkin Spice” by Travis Abaire @t.a.p.plumbingandheating—Armstrong seems to just roll with it. “Whatever floats your boat, I guess.”

Owning his company, Armstrong Pro Services, Hudson Valley, N.Y., since 2004, Chris started his business on accident, really. “I worked for a real high-paced service company making really, really good money and it wasn’t for me. It was just blood money,” says Armstrong with hyperbole. “They were working me like an animal and it wasn’t making me happy. Honestly, I didn’t even have the time to spend the money I made.”

Owning his company, Armstrong Pro Services, Hudson Valley, N.Y., since 2004, Chris started his business on accident, really. “I worked for a real high-paced service company making really, really good money and it wasn’t for me. It was just blood money,” says Armstrong with hyperbole. “They were working me like an animal and it wasn’t making me happy. Honestly, I didn’t even have the time to spend the money I made.”

Having had enough, Armstrong put in a month’s notice to this company and they fired him the next day. Talk about lame …. turns out, Armstrong always had side work and customers that he dealt with so it wasn’t until months later that people were like, “have you found a job yet?” Armstrong says that he had been too busy working, and that’s where the genesis of doing the work for himself and starting on his own really began. “Back then the Internet what it was today, so I put out business cards in the grocery stores, the hardware stores, and just word of mouth so every customer you get, you get their neighbor, their cousin, their sister-in-law, and it branches out.”

Armstrong Pro Services specializes plumbing and mechanical—new construction, renovation, some HVAC work, pumps. “I really enjoy the vintage stuff; I’m very passionate about repairing the real early stuff on up through the early ‘60s and ‘70s.”

Yet, making that transition from employee to owner, “I had a good reputation with all the other plumbing companies and other local plumbers. They knew that I was of good integrity so they would basically hire me on sometimes for a job for a week, a day. In between my stuff, I would go do their projects or lead their projects so they didn’t have to lose out. They paid me what I wanted, I got their job done, I didn’t steal their customers. In fact, a lot of these companies helped me start my company,” says Armstrong.

Yet, making that transition from employee to owner, “I had a good reputation with all the other plumbing companies and other local plumbers. They knew that I was of good integrity so they would basically hire me on sometimes for a job for a week, a day. In between my stuff, I would go do their projects or lead their projects so they didn’t have to lose out. They paid me what I wanted, I got their job done, I didn’t steal their customers. In fact, a lot of these companies helped me start my company,” says Armstrong.

As a 20-year veteran of owning his own business, his message to anyone entering the trades? “I would say start young. The more you are interested in learning and soaking up as much as you can, it’s only going to make you better, and earn that much more money that much faster.”

Speaking from experience, an old Frenchman became a good mentor to Armstrong. “When I was 18 years old, he was the first guy I’ve ever seen bend a piece of L copper. He was amazing.”

So how can the industry as a whole in today’s landscape do a better job of attracting young people to the trades? “The industry is already doing better. We’ve got more good people. We’ve got all of these guys that have a big profile on social media and doing really well to not only encourage their own coworkers and their companies and their bosses to do better, but everybody else,” says Armstrong. “The more we show these kids that you can make a good living and you can be proud of what you’re doing, and it’s not just guys out here plunging toilets and getting super dirty, we are doing better at recruitment. You can make a good living in the trades. By continuing to learn, you will be a very critical part of the workforce.”

So how can the industry as a whole in today’s landscape do a better job of attracting young people to the trades? “The industry is already doing better. We’ve got more good people. We’ve got all of these guys that have a big profile on social media and doing really well to not only encourage their own coworkers and their companies and their bosses to do better, but everybody else,” says Armstrong. “The more we show these kids that you can make a good living and you can be proud of what you’re doing, and it’s not just guys out here plunging toilets and getting super dirty, we are doing better at recruitment. You can make a good living in the trades. By continuing to learn, you will be a very critical part of the workforce.”

“Absolute daily go-to tools: the Supco Magjumpers —hybrids and the regular ones—and my Fieldpiece meter are probably two of the most important tools that I’m using on a daily basis.”

Armstrong admits that social media hasn’t helped his business per se, but he’s not presently putting forth the effort on social to do just that. “As far as social media helping my business, it hasn’t, and I’m not trying to make it so,” says Armstrong.

“I’m very busy and I’m definitely a lot more short-handed. We used to have anywhere from 5-7 guys full time for many years. I’m trying to stay smaller, and not that I don’t want more help, but I’m not putting my business out there trying to get business out of social media. I’m do this so I can see people by whom I get inspired—all these guys/gals doing cool shit. I like to see guys like me that are nerdy and passionate about what they’re doing and always striving to get better.”

Bottom line, “I’m on social media so I can see what people are doing. I like helping a lot of people. Sometimes it gets to be a little much but I do like to share what I know to people that need help. It feels good to help people out. I get a lot of people who send me messages and pictures of their jobs. The connections that I’ve made are more important than anything else.

Bottom line, “I’m on social media so I can see what people are doing. I like helping a lot of people. Sometimes it gets to be a little much but I do like to share what I know to people that need help. It feels good to help people out. I get a lot of people who send me messages and pictures of their jobs. The connections that I’ve made are more important than anything else.

All the people I’ve met on social are good people and have become good friends, and I love the connections. That’s the most important thing for sure.”

How does Armstrong balance work life with home life? “That’s a challenging one for me,” says Armstrong. “I definitely get that you need it, and I am getting older. Listen, I have been doing this well over 20 years. It’s tough—I just worked until midnight on a Sunday and 9 pm on a Saturday. I’m trying. My kids are young so I’m trying to spend more time with them and I’ve got things to get done around the house.”

Armstrong stresses that he’s constantly trying to spend more time with the family, but he says that he’s out there trying to help everybody, trying to do as much as he can. Nevertheless, when it comes that precious spare time, “I’m always at my kid’s hockey games. I like working on old motorcycles; basically, I like working on anything old and fun—restoring tools.”

If he wasn’t doing any plumbing and mechanical work, Armstrong says that he would be doing some sort of fabrication. He enjoys building things so he’d probably be doing some type of engineering, tool making. “I like tinkering, I like to make tools and I like to prototype. I’ve made a lot of tools; I didn’t get patents but I like to build. I have little machines at my house, I have a milling machines and lathes, plasma cutters and everything that you can think of—shrinkers, stretchers, benders, rollers.”

If he wasn’t doing any plumbing and mechanical work, Armstrong says that he would be doing some sort of fabrication. He enjoys building things so he’d probably be doing some type of engineering, tool making. “I like tinkering, I like to make tools and I like to prototype. I’ve made a lot of tools; I didn’t get patents but I like to build. I have little machines at my house, I have a milling machines and lathes, plasma cutters and everything that you can think of—shrinkers, stretchers, benders, rollers.”

Finally, any favorite tattoo? “I’ve got this eagle on my arm with a fishing pole in one hand with a fish on it and he’s got a pipe wrench in the other hand. It doesn’t really mean anything; it was just a fun, quick tattoo.”

By joining forces with Uponor, GF is set to become a global leader in sustainable water and flow solutions. To support this ambition, complementary businesses will be grouped together under one roof: the new division GF Uponor will focus on Building Technology, whereas the infrastructure and utility business will move to GF Piping Systems. Michael Read more

By joining forces with Uponor, GF is set to become a global leader in sustainable water and flow solutions. To support this ambition, complementary businesses will be grouped together under one roof: the new division GF Uponor will focus on Building Technology, whereas the infrastructure and utility business will move to GF Piping Systems. Michael Rauterkus will join GF’s Executive Committee and will lead the new division together with his Uponor leadership team.

After all conditions of the tender offer have been fulfilled, GF closes the transaction as of 13 November 2023.

To accelerate the implementation of GF Piping Systems’ Strategy 2025 and to further benefit from global megatrends, GF will start an ambitious value creation program to unleash the full potential of this acquisition. GF Piping Systems will focus on the industrial and utility business, providing its customers with sustainable leak-free piping solutions for numerous end markets such as microelectronics, water treatment, energy, chemical processing, marine, data centers or water & gas utilities. Uponor’s infrastructure business will become part of GF Piping Systems and will further strengthen the division’s portfolio to provide customers with combined solutions.

In the new division, GF Uponor, the building technology businesses will be combined to offer a complementary portfolio for safe and clean water, as well as energy efficient heating and cooling. The consolidation of complementary businesses provides an ideal platform to develop markets with high potential for both divisions. As the brand Uponor stands for high quality and innovation, it will drive growth in intelligent Building Flow Solutions.

These organizational changes will be implemented during the course of 2024 while GF will ensure operational excellence and business continuity to customers.

“We will continue to implement our strategy, and leverage powerful global trends, such as the need for safe and clean water, or more efficient energy use,” GF CEO Andreas Müller said. “On behalf of all my colleagues, I am happy to welcome Uponor employees and start this new chapter together.”