Mechanical Hub continues its series of exclusive Q & A sessions with industry leaders and players to get their views on the future, and living in a COVID world, and an insight into the market in 2021. The American Supply Association released its annual sales report for 2020 and the ASA Pulse sales report shows Read more

Featured Articles

Mechanical Hub continues its series of exclusive Q & A sessions with industry leaders and players to get their views on the future, and living in a COVID world, and an insight into the market in 2021.

The American Supply Association released its annual sales report for 2020 and the ASA Pulse sales report shows member distributor respondents enjoyed an average sales growth of 4.4% and a median growth of 6% during the fourth quarter of 2020; however, distributor respondents doing business primarily in the industrial pipe, valves and fittings channel continued to report declines.

Total ASA distributor respondents reported a median 1.4% sales growth for the full year 2020 vs. 2019, and inventory levels rose 4.9% in the fourth quarter of 2020 compared to the fourth quarter of 2019.

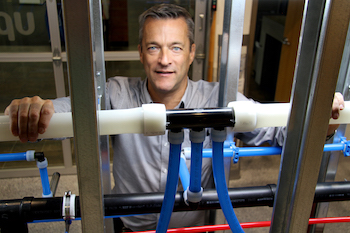

Bill Gray

This week, Mechanical Hub features Bill Gray, president, Uponor North America to get his company’s pulse for 2021. You get the sense that it’s time to move forward and the time is now to take full advantages of the opportunities that lie ahead.

MH: While putting together the Mechanical Hub annual forecast last year, you were one of the only ones to go on record who took COVID into account in the short-term up until that point in mid-January 2020. What were you hearing?

GRAY: We were starting to hear “noise” in the supply chains. You have to understand, I have a mother in the background who was reading all the articles, warning me about traveling to Europe and Hawaii. What sounds like wisdom from me is actually deriving from my mother yelling in the background to stay home.

MH: Most of the residential guys are doing fine, but there are hiccups with commercial and industrial sectors. What does the short-term economy look like for Uponor? What are the economic indicators telling you?

GRAY: This is a question we try to answer on a weekly or bi-weekly basis with our European parent company. We are currently enjoying a very healthy level of business. In 2020, we hit the brakes in April after a great first quarter. By the end of May, it was all back in a big way. All that demand that fell off, people decided to get that work done. Through Q3, it was good volume.

We knew there was more volume going into residential. For commercial, no one was stopping projects already coming out of the ground. I don’t know when we will see commercial projects begin to tail off. As you know, 12, 18, or 24 months is nothing to get a commercial project rolling. What I am told is that there are fewer projects to quote in commercial order books. Certain segments are more adversely impacted than others. For example, it is hard to imagine you are going to build a new hotel if you haven’t already broken ground.

I am one of those guys who normally spends 75 to 100 nights a year in a hotel. In 2020, I spent maybe 20, and all of those were at the beginning of the year. So that challenge to commercial will keep getting pushed forward. They will still need to perform retrofits, and that might open up some opportunities.

Residential is on fire, supported by demographic demand that has been held back. We often speak of “natural” household formations coming in at 1.5 million annually. We never achieved that level coming out of the past recession, so the demand gets pushed forward. Meanwhile, existing homes valued between $250,000 and $500,000 are going for the asking price or higher and don’t last very long at all on the market. Builders of new homes are building into their 2022 and 2023 land plans currently.

One of the factors that may bring down that activity is that builders cannot get land fast enough, as they burn up all of their lots now. So, we are in a window now, and everyone is building homes as fast as they can, and prices are slowly climbing. Input prices are crazy. Truss packages—nobody builds trusses on the job site anymore—are going for 3X or 4X vs. 2020 levels. Insulation deliveries are crazy; all the HVAC and mechanical stuff—crazy. Our friends over at Bradford White are at six to eight weeks currently.

There is demand out there. RWC just released their numbers, but had great sales growth last year with more exposure to DIY through Home Depot and Lowe’s. We know the latter pair are doing very well. We are seeing a lot of switch-in-spend right now. “I cannot go on vacation, so I am going to work on my house and yard.” Many cannot get a contractor to do the work, and if they do, the pricing can be very high. “I’m willing to take the work, but it will cost you.”

MH: As far as inventories and supply, how is Uponor faring?

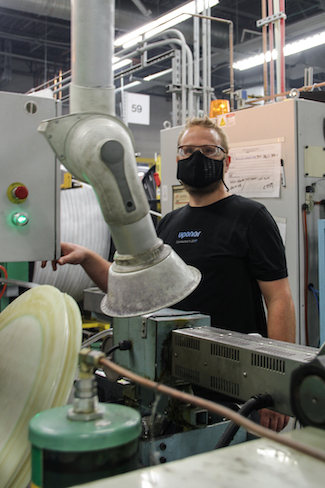

GRAY: We shut down the plant for eight days in April and laid off some staff in distribution and manufacturing. We have them back, plus. We are up to a month behind right now against a strong order volume. We were famous for delivering our product on time and in full. The problem definitely relates more to residential—smaller-diameter pipe.

It is what it is right now, but I question how long this activity can be sustained. Most companies, from what I have read, are saying like the first half, maybe through Q3 2021. But there is no election this year. We will see what happens with the stimulus packages. Do they finally do something on infrastructure? We need infrastructure work—now is the time to do those projects. Money will never be cheaper, nor labor more plentiful. But if you wait until a full economy, the challenges will be much greater.

I think if the federal government plays this right, understanding the dynamics of the market today—like in 2008-09, shovel-ready projects that will keep the economy going—I think construction could be really good—or really challenging. A lot of variables have not played out yet.

MH: How are you steering the ship to deal with COVID? You have gotten through 2020, is it all systems go? Anything different?

GRAY: What we did as well as or better than anyone else—not just in our industry, but in other industries too—is that we got on top of the problem early with our COVID Task Force. Originally, we were focused on problems in the supply chain, but that transitioned very quickly to our employees’ health and safety, as COVID hit the United States. We started looking at where our employees were traveling for work, creating an awareness, telling them if you are going to an area that may be compromised, be sure you are taking the proper precautions for yourself and your colleagues.

We were able to keep the plants open, because we were designated—along with most of new-construction markets and building products—as essential services. We have been promoting health and safety first, then the continuity and integrity of our factories, making sure we are able to ship products to customers. That is how we cascaded these priorities.

At Uponor, we went virtual on Friday, March 13, 2020, with the idea that we should test our systems in case we must work from home at some point, and everything worked out well from an IT perspective. As it turned out, ironically, the mandate to work from home came down over that weekend.

Next, we did a live migration to Microsoft Teams, which was a huge improvement over our previous platform.

As the situation has “stabilized” now—as much as it can be stabilized—we are continuing monthly calls with all employees. The leadership team and I continually explore what’s new, what’s different? When can we expect to come back to the office? What’s coming back going to look like? We try to manage all that.

From my perspective, we won’t be coming back to anything normal probably until 2022. My boss from Finland visited the United States the week before the AHR Expo in 2020. I don’t expect to see him in the United States at all in 2021. It’s been spotty in that part of the world, although with their stronger central governments, they seem to have managed COVID more effectively. Their countries haven’t had the same levels of infection. My next trip to Europe may be Q1 of 2022. By then, I should have the vaccine, I am confident.

The big unknowns on the horizon are the variants of COVID and whether the vaccines will help prevent their spread. Or is our future more pandemics? I don’t know right now.

MH: Last month, Uponor launched its new Complete Polymer Solution for commercial-piping applications in the U.S. How do you manage a launch like this in the midst of a pandemic and the cancellation of a major trade show?

GRAY: We did a soft launch around the announcement of the relationship with Pestan at the AHR Expo in 2020. We understood the amount of work that lay in front of us. For a company like Uponor to launch a product line of this magnitude, it is a major endeavor.

Which is why I have such an appreciation for our team and their ability to pivot at every opportunity, figuring out just how we would get all the work done. We knew the objective; we knew the amount of work we had to do. But there was a tremendous amount of creativity to making it all happen. Working with our health and safety people, our team developed a protocol for how we would do all this work internally while maintaining proper social distancing.

Then, with the launch itself, there is a lot to going virtual. It may look like it’s going rather smoothly. But when you see the machine behind the people, and how it makes this all work, you can’t help but be impressed. I did my on-camera interview a couple of weeks ago, and at the time it feels like a disparate collection of takes and cuts. But they brought it all together through an editing process that makes even me look good. That’s a pretty tall order!

MH: The market for this PP-RCT launch right now: Is it targeted for domestic water as well?

GRAY: We believe the best opportunity is mechanical. Pursuing domestic water would fragment our efforts. If we focus on mechanical and get really good at that, we can start taking on plumbing. Plumbing is more complex than mechanical; there are different dynamics at play. We think this is the best strategy for us right now. If you are a small company without much of a brand, you can do a lot more across more markets without much risk. If Uponor puts its name on something, we want to make sure we have it right, so our customers are confident it will work.

That is part of the leverage we are providing. If Uponor is offering these products with the full bundle of support—the national rep network, our knowledgeable sales force, on-site training and technical support—the customer can feel better about getting involved. We just felt plumbing would fragment our efforts too much.

Bill Gray is president, Uponor North America.

Bill Gray is president, Uponor North America.

The National Science Foundation’s Daniel K. Inouye Solar Telescope in Maui, Hawaii, uses the largest mirror of any solar telescope in the world. Thanks to its 13-foot-wide mirror, it collects seven times more sunlight than any other solar telescope, producing the clearest, highest-resolution images ever taken of the sun. Not surprisingly, a solar telescope of Read more

The National Science Foundation’s Daniel K. Inouye Solar Telescope in Maui, Hawaii, uses the largest mirror of any solar telescope in the world. Thanks to its 13-foot-wide mirror, it collects seven times more sunlight than any other solar telescope, producing the clearest, highest-resolution images ever taken of the sun.

Photos courtesy of NSO/AURA/NSF

Not surprisingly, a solar telescope of this size produces a lot of heat. With a working lifespan of about 50 years – after more than two decades of planning by the National Solar Observatory and its partners – there is a lot that goes into keeping the telescope cooled so it can provide groundbreaking scientific insights.

And that’s where Viega comes to the table.

An enormous, unique project

Eventually, there will be more than seven miles of thermal piping within the telescope and support buildings, explained Lou Szabo, Facility Thermal Systems Site Coordinator for the National Solar Observatory. He spends his days helping to finish construction and commissioning the equipment that recently began collecting images of the sun.

Much of the piping was prefabricated years ago, as various parts of the facility and telescope were being built (construction has taken about 10 years). Traditional methods, mainly welding, were used. But then the project came to a crossroads.

“As the various science instruments are installed and other devices added to the telescope, the final piping needs to be completed or modified, and oftentimes in close proximity to optics or one-of-a-kind electronics that are worth millions of dollars – things that would take many years to reproduce if damaged,” Szabo said. “We can’t have any joining methods that use heat or fumes. It has to be a very clean process.

“The only way to install these remaining piping runs is with a joining system that meets the ‘no heat, no fumes, no dust’ requirements – and Viega hit that mark. We can go into these critical areas with very little equipment and complete press joints within inches of sensitive equipment, and the crews don’t have to worry about damaging it.”

As the need for a press-fitting solution surfaced, Szabo was already aware of Viega. He’s been in the piping trades for more than three decades and had previously used Viega.

He also knew that Viega had a large variety of fitting choices and, more importantly, offered plenty of technical support.

“When I presented the press system to the lead engineers and the decision-makers, I had to bring the best system I knew of,” he said. “Viega had been around the longest and had the best technical support if we had a question or got into a bind. We knew we had the reliability of the system behind us. It was really the only choice. I wouldn’t have been comfortable with others.”

Another factor to account for is the ozone conditions. The telescope is located at Haleakalā Observatories, at 10,000 feet in elevation, on the island of Maui. This location allows for great conditions for observing the sun but brings with it other unique elements, too.

“There is a high ozone content in the atmosphere here. Ozone was attacking a lot of rubbers and things, so we use HNBR sealing elements in all of our fittings,” Szabo said. “Some of the coolants we use are more exotic, and the HNBR holds up.”

The bulk of the coolant used is Dynalene HC20. The manufacturer lists both HNBR and EPDM as compatible materials, but the EPDM seal isn’t as resilient with the ozone presence, so Viega’s HNBR sealing elements are the right fit.

Inner workings of the telescope site

A series of primary loops come from the main mechanical/utility building, where all the chillers are located. The loops run to heat exchangers, followed by secondary and tertiary loops. There are dozens of pumps and tanks involved in the complex setup.

Piping in the system includes everything from 6” carbon steel piping to ½” copper tubing. Stainless steel is also used. The miles of piping run coolants and air to keep the telescope project at an appropriate temperature and to keep everything working smoothly. Viega ProPress fittings up to 3” in diameter and MegaPress fittings as large as 2” are used throughout the site.

The mirrors and transfer optics are cooled in a variety of ways, including cooled liquid and air. For example, air a few degrees below ambient temperature is typically blown on the back of the mirror cells.

The Dynalene coolant runs at a very low temp, some as low as –2 degrees F, some around 45 degrees. The coolant is also environmentally friendly, which was important for the culturally sensitive site that carried with it many environmental guidelines. Propylene glycol mixtures are also used in some of the scientific chillers.

“A challenge we have in the middle of the Pacific is having fittings available, and that’s why we try to keep our setup as simple as we can,” Szabo said. “It’s also why we went with MegaPress and ProPress. Much of it is available on the islands, whereas other systems are more difficult to get.

“We try to keep a stock of certain fittings and materials on hand and stay ahead of the game. Oftentimes we’re looking at a two- to four-week lead time to get less-common fittings to the island. Thankfully our supplier, PACE Supply, can often get us common fittings within a couple of days.”

Szabo said they strive to keep the piping runs as simple as possible to both limit flow restriction and allow the use of standard elbows, adapters, tees and couplings, which are more readily available on the island.

One-of-a-kind solar research

Plans for the Inouye Solar Telescope (named for the late Daniel Inouye, the U.S. Senator from Hawaii who played a crucial role in getting finances approved for the project and was a big advocate of STEM and science) started 25 years ago. Dr. Claire Raftery, Head of Education, Outreach and Communication for the National Solar Observatory, said innovating how to build something so complicated – and then get it funded – was a massive undertaking.

There was an extensive survey done to determine the location of the telescope. A few hundred sites worldwide were reduced to a short list of 72, which was whittled down to a six. From there, only three met the specific requirements that scientists were looking for, and the location in Maui was chosen.

The Inouye Solar Telescope’s unique location combines clear and vivid blue skies needed to observe the faint corona of the sun with a high elevation and low air turbulence of the atmosphere above the telescope. Thanks to all these things, the telescope can produce the best images of the sun ever taken so that scientists can learn more about the dynamic star.

“We’re studying an object that there’s still a lot of mystery around. Many questions remain unanswered because we don’t yet have the capability to answer them,” Raftery said. “We need more detail, higher resolution – and these are things this telescope will bring to the table. It’s really a fortuitous time to be working in the solar physics industry.”

The telescope is expected to be operational for at least 44 years – four solar cycles – which is one of the benefits of ground-based astronomy, Raftery explained.

“We can expand the abilities of this project much longer than we could from space,” she said. “It’ll never really stop being finished. We can adapt and improve. The team will continue to bring new science experiments online through the life of the telescope.”

Part of the federal requirements from the National Science Foundation include returning the site back to the way it was found, so in 50 years they won’t simply turn off the lights and walk away, but instead the project will eventually be removed from the site after it has run its course.

But with that prospect decades into the future, for now everyone involved with the project is exhilarated as the telescope begins recording images of the sun.

“I remind the crews that they are the only ones in the entire world working on this unique system,” Szabo said. “This is truly a one-of-a-kind project.”

Florida-based contractor and YORK Factory Direct join forces with Johnson Controls to support Building Homes for Heroes Recently, Amen Air, Inc. and YORK Factory Direct partnered with Building Homes for Heroes during a Welcome Home ceremony in Lutz, FL. for Army Staff Sergeant Mylee Cardenas. Cardenas joined the military following the September 11th terrorist attacks, citing her devastation over what Read more

Florida-based contractor and YORK Factory Direct join forces with Johnson Controls to support Building Homes for Heroes

Recently, Amen Air, Inc. and YORK Factory Direct partnered with Building Homes for Heroes during a Welcome Home ceremony in Lutz, FL. for Army Staff Sergeant Mylee Cardenas. Cardenas joined the military following the September 11th terrorist attacks, citing her devastation over what occurred as her inspiration to serve. While deployed in Afghanistan, Cardenas found a lump on her breast, but did not seek medical attention as she did not want to abandon her all-female unit and their mission. Upon her arrival home, she was diagnosed with stage three breast cancer.

Army Staff Sergeant Mylee Cardenas

Now, cancer-free, Cardenas is tackling a variety of other missions. She previously worked as a contributing photojournalist for major media outlets. In her role, she returned to war zones to help shed light on the conflicts that affected the areas. Cardenas is a single mother to her 16-year-old daughter, Brianna, and she hopes to adopt more children she met through her former job as a caseworker. Cardenas also is a master’s degree student, public speaker, veteran’s activist, health and fitness coach, model and actor.

To support Cardenas, Johnson Controls and YORK Factory Direct donated a YORK® heating and cooling system with a Wi-Fi® enabled YORK touch-screen thermostat. Amen Air, Inc. donated the HVAC installation services for the veteran’s new home.

“I am not sure my words could appropriately express my gratitude to YORK and Amen Air, Inc. for our new heating and cooling system. I wake up every day with peace of mind,” said Army staff sergeant Cardenas. “I am very grateful for their continued support of the veteran community and Building Homes for Heroes.”

Building Homes for Heroes is a national organization that recognizes those who serve in the United States Armed Forces by supporting the needs of severely wounded or disabled soldiers and their families. The organization strives to build or renovate quality homes and donate them, mortgage-free, to injured veterans nationwide.

“We’re grateful to have gotten the opportunity to give back to this well-deserving local veteran and her growing family alongside YORK and Building Homes for Heroes,” said George Maniates, owner and president, Amen Air, Inc. “Mylee Cardenas is a true hero, and we are honored to offer our services for her new home.”

The YORK brand of Johnson Controls has been a proud sponsor of Building Homes for Heroes since 2014. The company has been recognized by US Veterans Magazine as a top veteran-friendly company. Johnson Controls is also committed to hiring veterans and military spouses. Veteran employees are honored to design, engineer and assemble systems that help improve the lives of fellow veterans.

Building Homes for Heroes invites anyone wishing to volunteer or donate to the organization to contact Building Homes for Heroes at info@buildinghomesforheroes.org. To learn more about Building Homes for Heroes www.buildinghomesforheroes.org.

To learn more about Amen Air, Inc., please visit www.amenair.com and follow them on Facebook.

Standing in the entryway to the office, I noticed a poster on the door which read, “Write drunk, edit sober.” A quote attributed to Ernest Hemingway, I knew like hell he wanted to, but I don’t think he would ever sacrifice the things he did the best. You see, Bob Mader was the consummate professional Read more

Standing in the entryway to the office, I noticed a poster on the door which read, “Write drunk, edit sober.” A quote attributed to Ernest Hemingway, I knew like hell he wanted to, but I don’t think he would ever sacrifice the things he did the best. You see, Bob Mader was the consummate professional who communicated volumes from the weight of his words. And perhaps that’s why he had that poster on the door. Hemingway was famous for short prose, bereft of too many details, a mirror for Mader’s verbal prowess. Bob was a man of few words, anyone would tell you that. But once you got in, you could feel his warm heart, his hearty laugh, his dry sense of humor and the grace in which he interacted with people. And putting pen to paper, he was the best at his craft—the hard work, the writing, the preparedness and research, and the long hours to be “fair and balanced” to everyone, no matter the circumstances.

Standing in the entryway to the office, I noticed a poster on the door which read, “Write drunk, edit sober.” A quote attributed to Ernest Hemingway, I knew like hell he wanted to, but I don’t think he would ever sacrifice the things he did the best. You see, Bob Mader was the consummate professional who communicated volumes from the weight of his words. And perhaps that’s why he had that poster on the door. Hemingway was famous for short prose, bereft of too many details, a mirror for Mader’s verbal prowess. Bob was a man of few words, anyone would tell you that. But once you got in, you could feel his warm heart, his hearty laugh, his dry sense of humor and the grace in which he interacted with people. And putting pen to paper, he was the best at his craft—the hard work, the writing, the preparedness and research, and the long hours to be “fair and balanced” to everyone, no matter the circumstances.

As I entered his office, I scanned the room and noticed all of the trinkets, the swag from industry events, the trade show name tags strategically located throughout—five decades of experiences in the plumbing and HVAC industry. Stuff that most of us take for granted or throw away as soon we leave an event. Not Mader. He loved every part of being a trade journalist. He lived it.

As I entered his office, I scanned the room and noticed all of the trinkets, the swag from industry events, the trade show name tags strategically located throughout—five decades of experiences in the plumbing and HVAC industry. Stuff that most of us take for granted or throw away as soon we leave an event. Not Mader. He loved every part of being a trade journalist. He lived it.

While Bob was working late that Friday afternoon to finish a story, I sat down and started picking up those experiences. The demo fitting from a trip to Wichita, the beer stein from the trips to Germany, the cowboy hat from a trip to Nashville, the ticket stub from the trip to Fenway and the basket of thumb drives from the countless trade shows. The room was full of experiences, and great memories.

Bob sometimes brought his beautiful wife, Kevyn, to these events, and I was fortunate to meet her and share a laugh with the both of them. While on a trip to D.C., she affectionately referred to him as her “warm biscuit.” Warm, affectionate and caring in every way, I completely understood.

Bob sometimes brought his beautiful wife, Kevyn, to these events, and I was fortunate to meet her and share a laugh with the both of them. While on a trip to D.C., she affectionately referred to him as her “warm biscuit.” Warm, affectionate and caring in every way, I completely understood.

Bob Mader passed away this past Monday, February 22, and it has left a hole in my heart. When Kevyn informed me through a message on Facebook, I couldn’t believe it. I mean, I had just talked with him last week. How could this be possible? I assumed that her account had been hacked. I immediately called his cell and it rang until I heard that familiar voice—that he’d get back to me as soon as he could. But this time, he wouldn’t.

Bob was a gentle giant. Gentle in how treated people with grace, dignity and fairness. Giant not in size but in journalistic stature through the weight of his pen. For nearly five decades, Bob was the consummate professional as he championed for the PHVAC industry, and he went about his business the right way. He was my mentor and my good friend, and I will miss him dearly. I love you, Bob Mader. I hope you know that.

I’m sure you all have your stories with Bob, and let’s rejoice in them. Let’s raise a glass and cheer our good friend. And oh, please don’t let Mader know, I don’t think Hemingway ever said that. 🙂

Local contractor relies on RIDGID, part of Emerson’s Professional Tool group, to help crews maximize their time on the new Elyria School construction sites For decades the Elyria City School District (ECSD) and Emerson’s RIDGID® Headquarters have called a small corner of Northeast Ohio home. Now, RIDGID employees are excitedly watching as the school district Read more

Local contractor relies on RIDGID, part of Emerson’s Professional Tool group, to help crews maximize their time on the new Elyria School construction sites

For decades the Elyria City School District (ECSD) and Emerson’s RIDGID® Headquarters have called a small corner of Northeast Ohio home. Now, RIDGID employees are excitedly watching as the school district constructs five new schools for their more than 4,000 Pre-K to 8th grade students – and, several of the tradespeople working on the project are using RIDGID tools to get the job done. In fact, RIDGID tools have been used extensively to help keep construction of the $120 million project on schedule and help contractors maximize their productivity on the job site.

“It’s always a thrill to hear how RIDGID tools are being used to build and maintain infrastructure across the country, but it’s even more exciting when the project is in our hometown and so positively benefits Elyria students,” said John Ruese, vice president and general manager, press connection, RIDGID for Emerson.

“The impact on the community will be very positive and dramatic for many years to come,” said Jim Backs, Elyria City School District Board Member and former RIDGID employee. “To be able to share the benefits of this project with a major, local manufacturer and employer that has supported the ECSD and its students for years is truly gratifying.”

The five new schools, on target to be completed by the end of 2021, is just one more way RIDGID and the ECSD have collaborated to benefit students and the community. Over the years, RIDGID has sponsored many key projects within the district, including a technology lab, new computer equipment for students, and the district’s Maker Space – a learning area dedicated to fostering science, technology, engineering and math (STEM) education. These initiatives, as well as many others, are an extension of RIDGID’s ongoing commitment to education and fostering the skills of the next generation.

The Role of Press Technology

The Role of Press Technology

Wilkes Plumbing & Heating from Huron, Ohio has been installing pipe in the new schools solely using RIDGID press technology. Pressing has helped their teams work efficiently without the need for fire watch. Less equipment on the job site also helps reduce their overall labor costs.

“RIDGID press tools are user-friendly for our crew, and have saved us a tremendous amount of time on the school projects,” said Nick Diederich, vice president, Wilkes Plumbing & Heating. “They’ve allowed us to be efficient – particularly in times like these when timelines get condensed.” Wilkes is a big proponent of using pressing primarily for their jobs, citing the technology’s ability to create watertight seals while reducing labor costs, equipment load and time on the job. Wilkes has also relied on other RIDGID products for this project, including pipe stands, tubing cutters and iconic RIDGID pipe wrenches.

Construction timelines for each school have been tight. Having contractors do quality work the fastest way possible has been vital in keeping the buildings on track.

“I believe the single largest benefit RIDGID press technology has brought to the district’s major construction project is speed,” said Backs. “Joining of copper tubing is accomplished in a few seconds, a small fraction of the time required for conventional soldering.”

The district has also leveraged RIDGID products before for previous construction purposes. Recently, contractors used RIDGIDConnect™ and camera systems to diagnose a significant drainage issue throughout the school’s parking lots.

“It makes me proud to see these local products used on a project that will have an impact on our students for years to come. RIDGID tools are designed and manufactured around the corner from ECSD, and that means something to our community. Elyria is our home and we are doing world-class things – in both our business community and in the learning facilities we offer our students,” said Backs.

“RIDGID invests in its hometown of Elyria and in the children who grow up here. The company has staunchly supported Elyria Schools for decades, not only in bettering the learning environments for its students but in equipping students with tools they need to be successful in school, and in careers,” said Amy Higgins, communications director, Elyria Schools. “It’s exciting for us to walk the job sites of our new schools and see the RIDGID brand on the tools in use to build these modern, beautiful facilities. We’re proud of our partnership with RIDGID and of the new structures their products have helped build.”

To learn more about the project or RIDGID Press tools, visit Elyria’s school YouTube channel or RIDGID.com.