Hundreds of details must come together to build any type of residential structure. For a new apartment community, increase the hundreds of details found with a single-family home by a factor of 10—maybe more. Some of those details are non-negotiable: code requirements, local zoning rules and energy-efficiency mandates, to name just a few. Others fall into what can be called the optional category: aesthetic considerations, plan modifications, product specifications or construction schedules.

In an ideal world, the nonnegotiable and the optional do not conflict. But anyone ever involved in a building project knows the “ideal” rarely—all right, never—makes even a cameo appearance. Every detail, negotiable or not, impacts the schedule and the bottom line for builder and subcontractor alike.

At Vintage Crossing, Portrait Homes and Plumbing Concepts originally specified the NR66s for all three different plans, but SV venting didn’t work with the B and C plans. So they shifted to the larger NR83 model whose concentric venting permits zero clearance. “Venting drove our decision to upgrade the heaters in this project,” explains Greg Paulino, Plumbing Concepts Engineering department manager.

The construction team at Vintage Crossings, a 92-unit affordable apartment community in Anaheim, Calif., puzzled together countless details to plumb each living unit with an individually metered, gas-fired tankless water heater, for a total water heater count of 98. Three different Noritz models, the NR66-SV, the NR83-DVC, and the NRC98-DV, ultimately replaced the tankless water heaters included in the original specification.

The team of trade professionals behind the spec changes includes project superintendent Bob Pitsenberger of Portrait Homes; estimator Jay Hoke and engineer Greg Paulino of Plumbing Concepts; and builder sales manager Craig Burns of Noritz. This quartet worked together to select models that better met tough, mandatory energy-efficiency goals, while also solving numerous aesthetic considerations that mattered to the owners of Vintage Crossings and their future residents.

Putting together all the puzzle pieces at Vintage Crossing were (from right) Noritz Builder Sales Manager Craig Burns, Portrait Homes Project Superintendent Bob Pitsenberger and Plumbing Concepts Engineering Department Manager Greg Paulino.

“We broke new ground on this project with the tankless water heater installation,” explains Paulino, who heads the Plumbing Concepts engineering department. “The over-used line, it’s a ‘win-win situation,’ really applies here.”

Problem-solvers: At the forefront of innovative solutions at Vintage Crossings was Plumbing Concepts’ new-construction services team, a group that blends decades of hands-on plumbing experience with a commitment to provide the highest-quality, residential plumbing systems.

Plumbing Concepts Engineering Department Manager Greg Paulino devoted countless hours to engineer an installation plan the solved Portrait Homes’ aesthetic concerns that also provided for venting the tankless heaters in an efficient and code-compliant way.

Collaborative efforts began in spring 2011 during the early stages of product development, with Hoke and Paulino meeting with the builder, architect and other sub-contractors in value engineering focus groups. In these early meetings, the project scope was defined: seven, three-story walkup buildings that offer three different apartment configurations: Floor Plans A, B and C. The project breaks down as follows:

Building 1: 21 apartment units;

Building 2: 10;

Buildings 3 and 4: 12 each;

Building 5: 18;

Building 6: 18, plus an apartment for the building manager, a community room and a laundry facility;

Building 7: a single-story preschool, a second laundry facility and a room that houses the equipment for the community pool.

From the outset, the publicly funded Vintage Crossings had to exceed most energy-efficiency standards. In addition, the owners told the construction team that they intended to apply for LEED Silver Certification from the U.S. Green Building Council. The final specifications combined tankless water heaters with R-19 insulation and many other energy-saving factors to meet both goals.

The two Noritz models installed in the apartments—the NR66-SV (single vent) and the NR83-DVC (direct concentric vent)—more than met the mandated efficiency standards. But the construction team also had to grapple with certain aesthetic issues.

For example, the cedar-clad siding on all seven structures at Vintage Crossings did not mesh terribly well with the vent terminations originally recommended. These terminations “looked like a shiny metal muffler sticking out the front of an earth-tone building,” says Pitsenberger. “It was just ugly, so I challenged the Plumbing Concepts team to come up with something better.”

And they did, as we will detail toward the end of this article. But their challenges were not confined to vent terminations. Paulino devoted countless hours to engineering a multifaceted installation plan that resolved all of Portrait Homes’ aesthetic concerns while also venting the tankless heaters in an efficient and code-compliant way. Sounds like something an engineering department manager does every day, right? Perhaps. But no one involved in this effort describes the Vintage Crossings installation puzzle as “routine.” A few more examples of the complexities Paulino faced:

Buildings 1 through 5 contain similarly sized apartment units, but they are pieced together differently.

As a result, Floor Plans A, B and C each locate the water heater in a different place.

The mix of apartments with functional spaces in Building 6 required a separately engineered installation solution.

The preschool in Building 7 had decidedly different water heating needs, especially with regard to venting, than its residential counterparts.

Assembling the pieces: Plan A presented the greatest installation challenge. Located above every Plan A unit, which is always situated on the ground floor, are two Plan C units on the second and third levels. As a result, it was impossible to vent the water heaters inside the Plan A units vertically from the ground floor through the roof — and through the two Plan C apartments in between — and still achieve the required clearances. “Clearance” here refers to the minimum spacing stipulated by the National Gas Code between the tankless unit, its venting and nearby windows, doors and walkways.

The years of experience Paulino and Pitsenberger brought to the project, combined with Burns’ product knowledge, resulted in a highly original installation solution. Outside each Plan A apartment is a 2-foot by 2-foot column that inspired Paulino to “get creative” by housing a tankless heater inside the column in a specially built cabinet with a louvered door (to provide adequate air flow for combustion). Venting terminates to the side of the column, which also supports the deck of the Plan C apartment above. “That column was the only place I could actually install and vent the Plan A water heaters, given the clearance requirements,” says Paulino.

Because this solution isn’t covered in any manual, plumber and builder involved city inspectors early to get their approval. “We hung up a model during the rough framing phase and showed the inspector what we proposed,” explains Pitsenberger. “It took awhile, but we finally got the city’s blessing to proceed.”

The engineering for Plan B required nearly as much creativity as Plan A. Plan B is a single-level unit that occurs on both the second- and third-story of each building. Each Plan B apartment has a covered balcony where a specially built closet with a louvered door houses its water heater, which vents vertically through the roof.

Whenever there is a Plan B on the second floor, there’s another B unit directly above on the third floor. Consequently, the second-floor water heater must vent through an identical third-floor closet on its way to a rooftop termination point. Using concentric venting, Paulino split the two vents from one another in the attic to maintain the required clearance between terminations.

Plan C is a two-story unit, spanning both the second and third floors. The water heater solution here was relatively straightforward: Each C unit has an NR83-DVC heater housed inside a hallway closet on the upper level and vents vertically through the roof.

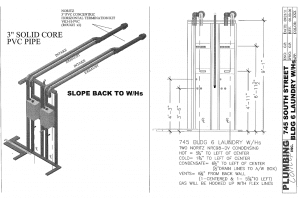

Condensing alternative: While the community room in Building 6 and the preschool in Building 7 also are equipped with NR83-DVC tankless units, the laundry room in each building required a third solution: a condensing-type water heater. Each laundry facility draws hot water on demand from a pair of tankless units, but because of space limitations, a through-the-roof vertical vent run was not possible. Instead, Paulino had to design a horizontal run of approximately 15 feet in each space.

Fifteen feet of five-inch/three-inch, concentric Category III Stainless Steel carries a fairly hefty price tag, both in materials and labor. Noritz’s Burns recommended that Paulino switch to a higher-efficiency condensing model that would permit venting with less-expensive, installer-friendly PVC piping. Condensing tankless water heaters use a secondary heat exchanger to boost efficiency by capturing heat from combustion gases before they escape up the flue. This heat-absorption process, in turn, cools these gases enough to allow venting with plastic instead of metal.

The four NRC98-DV condensing units were more expensive than the NR83-DVC models, says Paulino. “But I still saved between $200 and $300 on material costs for each of the two installs by using PVC rather than stainless. We probably saved on labor as well, be-cause the PVC is easier to handle and faster to install.”

Water heater selection: In the end, because of all the venting variations, the Vintage Crossings project proved to be “one of the most complex projects I have ever done,” says Paulino. Tankless water heaters may appeal to builders because of their efficiency and compact size, he notes, “but when it comes to system design, which is my primary professional concern, venting is always the main focus. That was certainly the case at Vintage Crossings where venting issues drove the final choice of water heater models.”

Portrait Homes and Plumbing Concepts originally specified the smaller, single-vent NR66 units for not only Plan A, but Plan B and C as well. With inputs up to 140,000 Btuh and a maximum flow rate of 6.6 gallons per minute, this model was sufficient to meet the needs of these one-bathroom apartments. Then Paulino discovered that Plans B and C had clearance issues that precluded the use of a single-vent water heater. His attention soon shifted to the larger NR83, whose concentric venting permits zero clearance. “Noritz’s broader product offering helped save us on this one, and the manufacturer stood behind the innovative solutions we devised for the venting.”

Venting and aesthetic considerations actually intersected at Plan A. If the NR66 was a no-go for Plans B and C, why not specify the NR83 for Plan A as well and use the same model throughout the entire project? “Seeing how we positioned the Plan A water heaters in the columns, the builder preferred the look of domed, ‘eyebrow’ design of the single-vent termination of the NR66 over the concentric vent termination of the NR83,” he explains. “So, because of better visuals, we went with the SV option in those cases.”

Join the conversation: