Armstrong Fluid Technology recently held an “International Engineers Visit” and “Media Days” at its world headquarters in Toronto where more than 200 engineers and trade media from around the world attended. Several major product and strategic announcements were made that dealt with helping specifying engineers, contractors, maintenance engineers and building owners operate installations more cost effectively. More efficiently from an energy standpoint. Recently, Mechanical Hub caught up with Lex van der Weerd, CEO, Armstrong Fluid Technology.

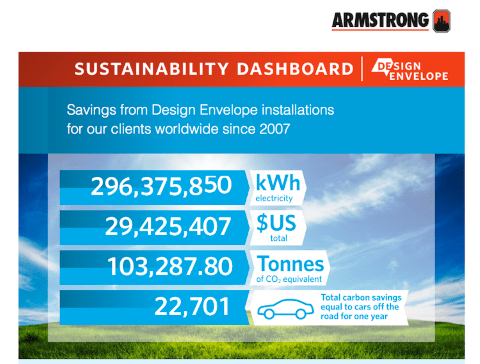

Located on the company’s website, the Armstrong Sustainability Dashboard presents a highly visual summary of Armstrong’s environmental accomplishments worldwide. The dashboard presents customer savings in the form of electricity and tons of CO2 equivalent, as well total carbon savings equal to cars off the road for one year.

MH: Tell us about some of the exciting news recently announced.

Lex: The announcements made include:

• Armstrong Rebranding – S.A. Armstrong Limited announced a global re-branding which will unite the entire group of Armstrong companies under a single name – Armstrong Fluid Technology. The new company name will be used by the group’s businesses around the world, creating a unified brand that will more effectively represent Armstrong to its customers, suppliers, partners and employees. Armstrong now operates manufacturing facilities in Canada, US, UK, India and China and has developed a network of sales offices, supplying solutions and services to homes and businesses in more than 50 countries.

The new COMPASS circulator helps contractors and wholesalers with easy selection, fast installation and extremely broad performance capabilities for application to a wide variety of installations

The new COMPASS circulator helps contractors and wholesalers with easy selection, fast installation and extremely broad performance capabilities for application to a wide variety of installations

• Armstrong Design Envelope – An innovative technology that ensures more energy-efficient HVAC systems and integrates the latest selection, control, and hydronic tools into heat transfer solutions that naturally accommodate changes in building design and demand to ensure that system performance is at an optimum at any given time.

• Global launch of the Armstrong Parallel Sensorless technology with the introduction of the Parallel Sensorless Pump Controller – An innovative add-on control device that coordinates the output of multiple pumping units in a parallel configuration to achieve significant energy savings.

• Armstrong ECO*PULSE™ HVAC Health Management Service – The ECO*PULSE™ combines industry-leading diagnostic technology with expert review to help keep central cooling systems operating at optimal performance. ECO*PULSE™ will be offered as a subscription based service with the Armstrong’s Integrated Plant Controller and OptiVisor™ products.

IVS Series Design Envelope Pump – Armstrong Design Envelope technology integrates the latest selection, control, and hydronic tools into heat-transfer solutions that naturally accommodate changes in building design and demand to ensure that system performance is at an optimum at any given time.

IVS Series Design Envelope Pump – Armstrong Design Envelope technology integrates the latest selection, control, and hydronic tools into heat-transfer solutions that naturally accommodate changes in building design and demand to ensure that system performance is at an optimum at any given time.

• Armstrong Sustainability Dashboard – The Sustainability Dashboard is designed to display savings in energy and associated carbon emissions related to both Armstrong’s innovative Design Envelope installations around the world and the continuous improvements in energy performance of the company’s own global operations.

MH: That’s quite a line-up of very impressive new products and announcements. Where can people learn more?

Lex: Interested HVAC and building services professionals can contact their local Armstrong representative and visit the Armstrong website at www.armstrongfluidtechnology.com for more information.

MH: What training opportunities does Armstrong offer contractors?

Lex: Armstrong has assembled a valuable collection of training videos. We are in the process of deploying those videos to a new online education platform. Armstrong representatives are also available for on-site training in a “lunch and learn” format. Given the value of Armstrong solutions to contractors, and the importance of a complete understanding of the technical aspects of our solutions, Armstrong is quite willing to prepare and deliver educational materials for contractors.

MH: What exciting plans and products can U.S. contractors look for in the coming months?

Lex: Armstrong has a lot to offer contractors, including products and solutions that offer the lowest first cost, lowest life cost and reduced risk. Two products in particular that will be of interest to contractors are the new Compass circulator, for residential heating applications, and the new Parallel Sensorless Pump Controller for commercial installations. Both of these products offer an opportunity for contractors to provide great value to the end customer and at the same time benefit from low installed costs and fast installation.

Join the conversation: