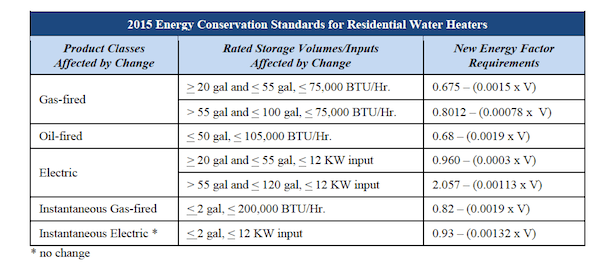

The new 2015 DOE (Department of Energy) Final Rule energy efficiency mandates will require higher Energy Factor (EF) ratings on virtually all residential gas, electric, oil and tankless gas water heaters, completely altering the water heater landscape. These changes will have an impact on how water heaters are manufactured, distributed and installed, affecting manufacturers, wholesalers, installers and customers alike. These higher Energy Factor (EF) ratings will go into effect on April 16, 2015.

Based off information provided by Bradford White, an American-made water heater manufacturer, the DOE mandates the standards, but not the manner in which manufacturers must meet them. Any actual changes to water heater products will vary depending on capacity and class. Product changes will be minor in some cases and more radical in others, particularly the larger volume water heaters.

Based off information provided by Bradford White, an American-made water heater manufacturer, the DOE mandates the standards, but not the manner in which manufacturers must meet them. Any actual changes to water heater products will vary depending on capacity and class. Product changes will be minor in some cases and more radical in others, particularly the larger volume water heaters.

For example, based on today’s technology, gas products > 55 gallons (< 75,000 BTU/Hr.), would likely be condensing units, which would make the water heaters larger and heavier and require a more sophisticated installation than their non-condensing counterparts.

Energy Factor (EF): Energy Factor is the ratio of useful energy output from the water heater to the total amount of energy delivered to the water heater. The higher the EF is, the more efficient the water heater.

Similarly, electric water heaters > 55 gallons (< 12 kW input) would likely utilize integrated heat pump technology, making these water heaters larger and heavier and more complex to install than their standard electric counterparts.

Good for Manufacturing?

Standards that drive true energy-saving efficiencies can be good when all affected parties are part of creating the appropriate solution, including the energy companies, manufacturers, contractors and consumers. On the surface, it looks as though the 2015 energy standards are a good thing. Who doesn’t like better efficiency, right? But if you peel back the layers of this, there are undertones that this could become hurtful to American manufacturing and contracting.

According to a conversation with Bradford White’s Carl Pinto, some standards can have an adverse reaction on manufacturers and consumers alike if the projected benefit is not commensurate with the true costs and other “side effects” that might occur when attempting to achieve a particular goal. One of the side effects is that it can drive manufacturing from U.S. to overseas (tankless from Asia and Europe, HP components only cost effective from Asia). Regulators need to consider technologies readily manufacture-able in the U.S.

The following is a conversation with Bradford White’s Pinto on the upcoming 2015 efficiency standards.

MH: In relation to the Final Rule, government over-regulation is never a good thing. Can you talk to how much some government policies may be hurting American businesses?

Pinto: Government and industry must work together in order to achieve the best policies for all involved. In general, policies with a singular focus that don’t consider all facets of a new regulation can be dangerous. The big issue is with the constant barrage of regulations and the pace at which they are promulgated.

MH: As a leader in water heating manufacturing (Bradford White), why are you so adamant about these upcoming changes?

Pinto: These changes will have an impact on how water heaters are designed, manufactured, distributed and installed, affecting manufacturers, wholesalers, installers and customers alike. And due to the significance of these changes, all affected parties must be prepared in order to insure a smooth transition to these new standards.

MH: Do the new regulations have steps in place for enforcement? Or it will be a matter of suppliers will not offer outdated equipment?

Pinto: Yes. Manufacturers cannot make non-compliant product as of 04/16/15. The same enforcement and penalties will exist as they do now. Theoretically, wholesalers and contractors can buy as much of the “old” product as they want, but they need to consider that local or state codes may change and disallow the sale and installation of “old” product.

MH: Why should contractors care about this upcoming legislation?

Pinto: Contractors need to understand the implications to their business due to the changes in product that will result from these new standards. With the size and weight of products changing, costs, transportation, storage, and installation will be affected. The new technologies will require additional product and installation training, and when on the job, new space, venting and condensate removal requirements may exist.

On the positive side, when products become more complex, it is less likely that they will be purchased and installed by the do-it-yourself consumer. Therefore, a potential impact of the 2015 water heater changes will be an increase in the share sold through wholesale distribution, thereby, increasing installer opportunities.

MH: Does Bradford White offer training/education on this?

Pinto: Bradford White has been sharing information at a variety of tradeshows and is hosting meetings throughout the country on this topic. We are also accepting invitations to speak at local meetings hosted by industry organizations. There is information about these changes on our website and we discuss this transition to the new standards during meetings with our wholesaler and contractor customers.

We are also in the middle of our largest plant expansion in Bradford White’s history to meet growing demand and to accommodate the production of additional 2015 ready products. The plant expansion includes the installation of the most advanced manufacturing equipment, giving us the capability and flexibility to produce an even wider variety of 2015 compliant products than what we offer today. In addition, we opened iTEC, our International Technical Excellence Center, to help educate customers and business partners on the 2015 DOE regulations and the new products that will be required.

MH: How can contractors and suppliers become better versed in this new law?

Pinto: As far as the specifics of the new regulations, they are available on the DOE’s website. The new standards also can be found at www.bradfordwhite.com.

Join the conversation: