By Eric Aune, Aune Plumbing LLC

The Cadet modulating/condensing boiler is relatively new to the market as a low-cost alternative to its big brother, the Knight heating boiler. Lochinvar has produced this model to target a specific need for a no-frills installation/replacement. By no-frills I would have to say any contractor looking for a simple, capable boiler with quality components that the Cadet will likely fit your bill.

This boiler utilizes a Giannoni heat exchanger. Anyone familiar with this stainless steel heat exchanger will know that it presents a high head loss and requires (at the least) primary/secondary piping with a properly sized boiler circulator to hydraulicaly se parate the boiler from the system piping and satisfy the flow requirements through the heat exchanger. This piping requirement is not only commonplace with most mod/con boilers but also a simple concept to understand, even for the less experienced installer.

parate the boiler from the system piping and satisfy the flow requirements through the heat exchanger. This piping requirement is not only commonplace with most mod/con boilers but also a simple concept to understand, even for the less experienced installer.

What drew me to the Cadet was the low input rating of the “smallest” model [CDN040] offered up by Lochinvar. The project where this is installed had a heat load of only 30K Btu/hr at design, a combination of two separate heating zones (garage & basement). The owner was most interested in a high efficiency boiler, the Cadet is rated at 94.0% AFUE (natural gas). With a minimum 9K Btu/hr input rating the Cadet most closely fit the requirements for the job.

The Expanded Polypropylene Jacket that houses the heat exchanger and controls is lightwieght and seems sturdy. Upon opening the crate for unpacking I was leary of the jacket material at first but once it was hanging on the wall I quickly realized the engineers intentions and the materials cost savings provided verses the standard sheet metal housing we are more familiar with. The cover is friction fit via nicely molded attachement points and secure when properly “snapped” into place. All the interior components are supported by a continuous metal frame making up the top, back and bottom of the enclosure.

The control (one heating zone input) with push-button functionality and constant display of actual output temperatures is simple and includes ODR (sensor included) functions. The boiler installation manual does an okay job taking you through the control adjustment procedures for installers that are experienced. I did read through the manual prior to actual installation but when going through the set-up perameters in the control I found myself searching for the proper combination of button pushing to access the space boiler settings. I feel the manual could highlight this procedure a little better for ease of use in the boiler room. I would like to note the easy access to the wiring connections. The access to and nice open area where the board is located in the cabinet is a nice feature when compared to some other wall hung boilers.

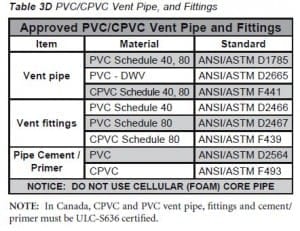

Right out of the box this model is set up for 2” vent piping. The max distances allowed for combination vent & intake piping for the CDN040 is an impressive 100 equivalent feet. As with any power vent system an account of fittings as they equate to feet of pipe must be taken. An optional room air kit is available for the intake to the boiler but is recommended for commercial applications only. A chart included in the installation manual provides information on approved vent materials.

There are a couple things I did take issue with while installing the boiler though, nothing major but I think they are worth noting.

There are a couple things I did take issue with while installing the boiler though, nothing major but I think they are worth noting.

First, and I talked about it above, the manual like all others is written by the designers/engineers and key information (like control access functions) can easily be missed if the installer is not enitrely familiar with the Lochinvar program. Maybe it was just me or the fact that it was the end of a long day but I found myself paging back and forth having missed this bit of info when needed. That being said, I feel my situation represents the norm for most installers in that this procedure will be happening after a long day on the job and the annoyance it presented was unwelcomed. Seems like and easy fix. The information is there, I am not implying it is not, maybe a “quick-start” control supplement would be more helpful?

Second, and last. The supply and return piping provided out of the bottom of the boiler jacket is situated too close to one another in my opinion. Both are bare-ended ¾” copper tubing but are spaced so that immediate redirection is needed to provide enough space fot eh recommended fittings such as unions, tee for temp./pressure gauge and isolation valves. The tubing is sturdy and secured nicely as it exits the cabinet but spacing was a key issue for me. I would like to see another inch or two for allowing the direct fittment of any fitting needed. This would definitely be welcomed in a more limited space installation, also the reduction in one or two joints/fittings will lessen the labor and materials on each install.

Overall I would say the Cadet is a solid, no frills boiler. My experience with Lochinvar products in the past has been positive, mostly due to build/material quality and feature functionality. I expect the same from this new model.

Join the conversation: