If you’re like many other business owners in the trades, you know that recruiting is a constant challenge. In fact, for some businesses, recruiting and keeping talent is the top issue in the company! Finding people to maintain your company’s current size or to grow is vital; after all, even if your company is overwhelmed Read more

Guest Blog

If you’re like many other business owners in the trades, you know that recruiting is a constant challenge. In fact, for some businesses, recruiting and keeping talent is the top issue in the company! Finding people to maintain your company’s current size or to grow is vital; after all, even if your company is overwhelmed with calls, you can only do the amount of work you have employees for.

When will this situation end? I have bad news for you: it won’t. As older technicians age out and retire, they’re not being replaced by younger technicians as quickly as they’re needed. The only road to salvation is acknowledging that society will not fix your problem. YOU are going to have to save yourself!

Here’s the good news, however: you can train your own employees and solve your recruiting woes. And it’s not as hard as it sounds. Plenty of businesses are training their own workforce and finding great success!

Why attempt an in-house training program?

The benefits of creating your own technicians far outweigh any challenges that an in-house training program might foster. Training someone from the ground up eliminates bad habits that most experienced new hires carry in the door. Homegrown techs are prepared to do things the way you want them done. Best of all, there’s no shortage of training options for any trade. Online and virtual reality training curricula have come a long way.

Refine your search

Years ago, a hiring manager could list specific skills, traits, or abilities they were looking for in candidates and then choose from a variety of applicants. While that was once an effective staffing strategy, it doesn’t necessarily work in these challenging recruiting times.

Hiring today is about attitude, behavior, character, and work ethic. Think about this: you can probably teach anyone technical skills, but attitude? Character? These characteristics are more challenging to instill. Removing the technical aspect from a candidate search then leaves you open to individuals who have great character and simply need to be taught technical skills.

Opportunities everywhere

If you’re looking to fill your training rolls, you should always be recruiting, and there should be opportunities everywhere. If you went about your day with the keywords “attitude, behavior, character, and work ethic,” how many individuals might you encounter who embody some or all of those words? You might be surprised. Think about a service desk clerk you saw dealing with a difficult situation. Consider the hustle of the barista at your coffee shop or the stocker at your local grocery store. You can spot talent when you see it. What if those people could be your next great technicians? They could be!

Build relationships with local youth

The service and replacement industry is about building and maintaining relationships with customers. Why not apply the same principles to creating and maintaining your talent pipeline? What relationships do you have with your local high schools? Have you participated in any recent career days? How about offering to be a guest speaker?

If your local high school doesn’t have any shop classes, it doesn’t matter! STEM (Science, Technology, Engineering, Math) has seen an enormous push in nearly every level of public instruction in the last decade. The plumbing, HVAC, and electrical trades are involved in all aspects of STEM. Imagine a discussion that explains scientific principles the kids are learning about in class and a demonstration of real-world applications inside the trades. Talk about a fertile ground to grow your workforce!

Clubs and organizations are significant pipelines for talent as well. Think about the 4H or FFA chapters near you, or Scouts troops.

Now, you might be saying, “But I need someone now, not kids!”

Let me ask you this: Where would you be now if you had started doing all this five years ago? Kids grow up and graduate, and not all of them are going to want to enter a four-year college. Some of them might be a great fit for your company’s training program; some of those kids might become some of the best technicians you have.

Consider veterans and career jumpers

Veterans moving from active duty to reserve status, or those discharged into civilian life can be good candidates to fuel your company’s growth. Another group of people to look at are career jumpers. Career jumping is when those already established in a career decide they want something else and move in a different direction. You already know what the trades can offer – great pay, great work environment, and a great career. Your company might be exactly what someone who wants to change careers is looking for!

When you open in-house technical training to a wider pool of potential candidates, you help yourself solve the challenge of today’s recruiting environment. The time to start is today. You’ll never know the vast opportunities surrounding you if you don’t start taking action.

Guest Blogger: Jeff Atwell started in the plumbing trade the first business day after his high school graduation. He has more than 30 years of experience with residential and commercial service, as well as with residential new construction, and discovered a passion for teaching as an instructor at his local apprenticeship school. Jeff was the first technical coach hired to work on Nexstar Network’s NexTech Academy program. Since then, he has been working to create the best program focused on residential plumbing service. He can be reached at jeffa@nexstarnetwork.com.

Guest Blogger: Jeff Atwell started in the plumbing trade the first business day after his high school graduation. He has more than 30 years of experience with residential and commercial service, as well as with residential new construction, and discovered a passion for teaching as an instructor at his local apprenticeship school. Jeff was the first technical coach hired to work on Nexstar Network’s NexTech Academy program. Since then, he has been working to create the best program focused on residential plumbing service. He can be reached at jeffa@nexstarnetwork.com.

Valves play an essential role in plumbing systems. They control water flow by limiting or stopping the flow based on placement. But one quick trip down the plumbing aisle, and you’ll quickly find that PVC valves come in various styles. Knowing what valve is needed for which purpose takes some skill. As a general rule Read more

Valves play an essential role in plumbing systems. They control water flow by limiting or stopping the flow based on placement. But one quick trip down the plumbing aisle, and you’ll quickly find that PVC valves come in various styles. Knowing what valve is needed for which purpose takes some skill.

As a general rule, if you’re looking for a non-corrosive plumbing option or you have specific needs to meet hygiene standards or green building goals, PVC valves check all the right boxes. While they are technically made from a plastic polymer, these valves have become a preferred option over most metal alternatives.

What is a PVC Valve?

Traditionally, plumbing valves are made from different types of metals. Brass, cast iron, bronze, stainless steel, alloys, galvanized metals, and others serve different purposes. For example, salt water is highly corrosive and requires stainless steel or PVC fittings as other metals will easily rust.

PVC, or polyvinyl chloride, is not a metal. It’s a synthetic plastic polymer that provides a highly durable and cost-effective option for plumbing fixtures. PVC has been around the plumbing world a little longer than you may have realized. Pipes made from this polymer were first introduced in 1932. By the 1970s, pipes and valves made from PVC had found their way to mainstream use.

These valves are some of the most versatile, fitting appropriate uses across many applications. PVC valves can be utilized for:

- Domestic Irrigation: PVC is the top choice for providing water for landscaping maintenance.

- Water Treatment: PVC is a chemical-resistant, non-corrosive material ideally suited for water treatment facilities.

- Water Features and Wellsprings: The same properties that make PVC a smart choice for irrigation systems also make it a natural choice for garden water features.

- Aquariums: PVC is one of the few materials aside from stainless steel that can resist the corrosion of salt water, making it a good choice for aquariums.

- Landfills: Any plumbing systems in landfills need to tolerate various chemicals, making chemical-resistant PVC a natural choice.

- Swimming Pools: This same chemical-resistant property makes PVC the best choice for chlorinated swimming pools.

- Chemicals: PVC is the best choice for a wide variety of corrosive chemicals.

- Food: The same properties that make PVC environmentally friendly also lend themselves well to food safety. PVC valves are a common choice in residential and commercial kitchens.

- Healthcare: More than 10 million quality-control tests prove that PVC plumbing fixtures are sterile and hygienic.

Benefits of Using PVC Valves

PVC plumbing valves are common across nearly every application, from residential construction to healthcare and manufacturing. It provides a lower-cost option to most metal valves with comparatively similar properties.

For starters, PVC is manufactured with energy-efficient practices so choosing this material over other options is a good step towards greener building practices. PVC also promotes cleaner water, keeping the supply free from sediment contamination.

Plus, most contractors appreciate the lower material cost of PVC fittings. PVC valves offer a durable, chemical-resistant, and corrosion-resistant plumbing option that is lightweight and easy to install.

Types of PVC Valves

As the popularity of PVC valves has grown, there is no shortage of options on the market. Even within each basic type of PVC valve, you’ll find different sizes for different uses. Here are a few of the most common valves.

PVC Ball Valves

A ball valve is a simple on or off-style valve frequently used in landscaping applications. It provides a water-tight seal using a ball to restrict or allow the flow of water. Ball valves are recognized for speed and efficiency. They’re a great option for emergency shut-off valves. If you’re choosing between a ball valve and other styles of on-off valves, speed of operation should be the primary consideration.

PVC Gate Valves

A gate valve is an on-off style valve best suited for low-pressure flows in larger diameter pipes. Gate valves become challenging to operate under higher pressures. Gate valves essentially do the same thing as a ball valve, but with a few more problems down the road.

PVC Check Valves

A check valve is a specialty valve that is designed to prevent backflow. While most valves are controlled by an external handle, a check valve is specifically designed to function internally based on the flow of material.

PVC Butterfly Valves

Butterfly valves are flexible control valves that allow the user to have precise control over water flow. These valves can function to restrict flow or entirely shut it off. A butterfly valve uses a disc to block water flow. Butterfly valves are used for variable control with a quick response.

PVC Diaphragm Valves

A diaphragm valve is a little less common than many of the other options on our list. These valves also serve a very specific purpose. A diaphragm valve is a regulatory valve that is used to control pressure.

PVC Foot Valves

A foot valve is a particular type of check valve fitted with a strainer. It’s placed at the end of a pipeline and assisted by a spring that opens and closes the valve when a pump turns on or off. A foot valve is designed to prevent fluid from draining out of a pump so that the pump remains primed and functional.

Final Thoughts on the Different Types of PVC Valves and Their Benefits

Polyvinyl chloride, or PVC, is commonly found in plumbing systems ranging from residential to commercial and industrial. While some pipes are still made from various metals, PVC has proven to be a durable and cost-effective alternative. Plus, as an added bonus, PVC offers several environmentally friendly benefits ranging from eco-friendly manufacturing processes to cleaner water.

Choosing the correct valve requires a thorough understanding of your needs and application, along with your options. In most cases, there is a PVC valve option that can save you money with a lower ticket price and long-lasting durability, providing clean water for a variety of commercial and residential applications.

Author Bio: Mark Ligon is the marketing manager at Commercial Industrial Supply, a supplier of commercial PVC and CPVC pipe, fittings and valves. Mark’s experience in industrial filtration has provided valuable relationships with suppliers, manufacturers and vertical resources online. CFS has more than a decade of experience providing name brand/quality products to the industrial filtration market. He enjoys educating businesses on the parts of piping systems so plumbing managers can make informed decisions.

Author Bio: Mark Ligon is the marketing manager at Commercial Industrial Supply, a supplier of commercial PVC and CPVC pipe, fittings and valves. Mark’s experience in industrial filtration has provided valuable relationships with suppliers, manufacturers and vertical resources online. CFS has more than a decade of experience providing name brand/quality products to the industrial filtration market. He enjoys educating businesses on the parts of piping systems so plumbing managers can make informed decisions.

By: Erin Woodward, Resideo Global Sustainability Leader Scientific evidence is clear: human impact on our world is increasing global warming trends. Reports of our impact on the planet pour in citing mega droughts, severe wildfires and the United Nation’s “code red” status. At Resideo, we’re focused on protecting what matters most. In the simplest sense, that means your home Read more

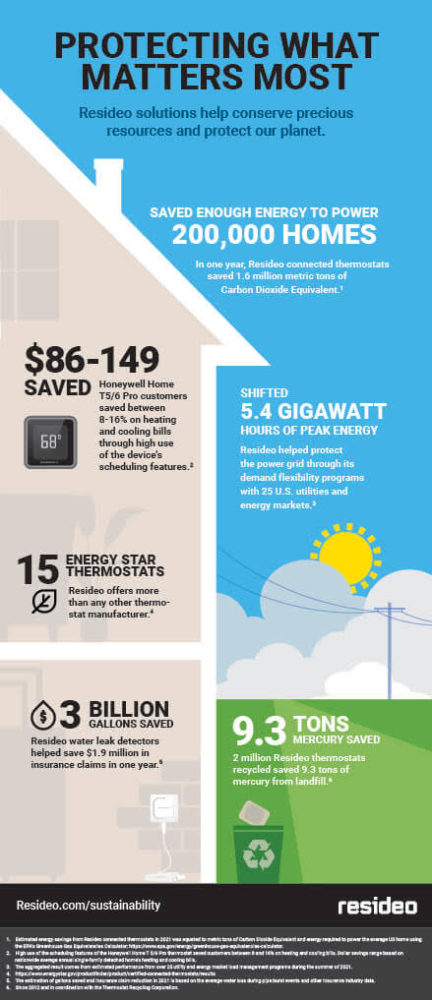

By: Erin Woodward, Resideo Global Sustainability Leader

Scientific evidence is clear: human impact on our world is increasing global warming trends. Reports of our impact on the planet pour in citing mega droughts, severe wildfires and the United Nation’s “code red” status.

At Resideo, we’re focused on protecting what matters most. In the simplest sense, that means your home, family or business, and in the richest sense – what matters most is our collective home: planet Earth.

We’re doing our part to help deliver a more sustainable future, and our customers are also following suit. For example, more than 40% of Resideo’s revenue** comes from sustainable solutions, meaning those solutions with the capability to contribute to energy savings in your home or building.

We know that sometimes the smallest things – such as a thermostat – can make the biggest impact on a home’s energy use, and even the planet. Everyday actions can add up to big change, and Resideo is committed to helping our customers be part of the solution.

Resideo’s global employees showcase their commitment to sustainability for Earth Day 2022.

RESIDEO EARTH DAY STATS

- Fifty percent of energy costs come from heating and cooling your home and 44% of U.S. Internet households say they actively work to reduce energy consumption at home. (Parks Associates, February 2022)

- More than 40% of Resideo’s revenue** comes from sustainable solutions, meaning those solutions with the capability to contribute to energy savings in your home or building.

- With more ENERGY STAR-rated products than any other thermostat manufacturer, Resideo’s Honeywell Home thermostats are energy efficient and can help save 8% of heating and cooling or $50 per year.

- According to the U.S. Department of Energy, you can save as much as 10% a year on heating and cooling by simply turning your thermostat back 7-10 degrees Fahrenheit from its normal setting for eight hours a day.

RESIDEO’S COMMITMENT TO SUSTAINABILITY

Each day, I’m proud to work for an organization that treats every day like Earth Day. We strive to advance comfort, safety and well-being with solutions that can benefit the planet and people living on it. Our goal is to deliver products and services that limit their impact on the environment and the people who manufacture, distribute, and use them during their life cycles.

We have a responsibility to our employees and customers to manufacture responsibly, which is why we set a goal of reducing our company’s greenhouse gas (GHG) emissions 20% by 2025, compared to the 2019 baseline. We’re well on our way with reductions in GHG emissions and energy and water consumption, and half of our sites operate on a strong environmental management system.

Once our products are in distribution, our strong community partnerships, help support the next generation of skilled trades men and women through Resideo Academy and Building Talent Foundation. Our partnership with Habitat for Humanity International allows us to deploy our solutions that can help save energy and water.

Our solutions are designed to help ensure people have a comfortable, safe and efficient home. Internally, we are bringing diverse voices to the table to unlock new sustainable innovations. In use, we are proud that our solutions help alert homeowners to more potential water leaks, help save them energy and water, and help prevent costly insurance claims.

FOUR WAYS YOU CAN HELP MAKE A DIFFERENCE

Fifty percent of energy costs come from heating and cooling your home and 44% of U.S. Internet households say they actively work to reduce energy consumption at home. Resideo suggests several ways to create a more earth-friendly home.

- Perform a Home Energy Audit. Learn where and how you consume energy in your home and make corresponding adjustments to help save money each month. Resideo created this home energy audit checklist with additional tips.

- Upgrade to Energy Star Appliances. With more ENERGY STAR-rated products than any other thermostat manufacturer, Resideo’s Honeywell Home thermostats are energy efficient and can help save 8% of heating and cooling or $50 per year.

- Leverage Thermostat Technology. One of the biggest mistakes you can make is keeping your thermostat set at the same temperature all day, every day. Instead, you can deliver comfort when at home and energy savings when you’re away. According to the U.S. Department of Energy, you can save as much as 10% a year on heating and cooling by simply turning your thermostat back 7-10 degrees Fahrenheit from its normal setting for eight hours a day. Don’t forget to also unlock rebates from your local utility.

- Recycle Old Technology. Whether you’ve just uninstalled your previous thermostat, or you’re looking to do so in the future, we recommend safely recycling your outdated thermostat. Responsibly recycling the old is as important as upgrading to a new efficient product in terms of its impact on the environment.

**Based on Resideo sustainable offering criteria of products that have the capability to directly (primarily) contribute to energy savings.

Speed and accuracy are the name of the game when it comes to a successful piping installation and a thriving business. Whether you’re installing potable plumbing or hydronic piping, the faster and more precise the job, the more time and money you potentially have to work on other projects. While there are hundreds of tips Read more

Speed and accuracy are the name of the game when it comes to a successful piping installation and a thriving business. Whether you’re installing potable plumbing or hydronic piping, the faster and more precise the job, the more time and money you potentially have to work on other projects.

While there are hundreds of tips and tricks out there to make your installs faster, easier, and more effective, I’m going to concentrate on the following three methods almost any plumbing or mechanical contractor can use to bring greater productivity to projects.

Flexible PEX pipe with bend supports

If you’ve never heard of PEX, it’s an acronym for crosslinked polyethylene. It’s a flexible, durable plastic piping product that provides numerous benefits over rigid CPVC or metallic systems, including faster installs, zero corrosion, and freeze-damage resistance.

Many residential contractors are already using PEX (considering it’s the most installed piping system for new-home construction over copper and CPVC combined). However, PEX is still a relative newcomer in the commercial industry.

The biggest benefit of PEX is its flexibility, which allows you to simply bend the pipe with each change in direction. With a tight bend radius of six times the pipe’s diameter, you can practically make 90-degree bends without the need for a fitting.

For times when you do have a tight bend that needs to stay in a particular place, PEX manufacturers offer bend supports. For those of you that prefer to watch rather than read, here’s a video that explains bend supports in detail.

These helpful products are available for ⅜”, ½”, ⅝”, ¾”, or 1″ PEX pipe. They hold the bend in place at the proper angle and take a fraction of the time compared to making a 90-degree elbow.

Most contractors agree that using flexible PEX with bend supports can eliminate most fittings in smaller-diameter pipe sizes 1″ and down, saving up to half the install time of a rigid piping system.

Expansion tools

When it comes time to make a connection with PEX pipe, the professionals’ choice is PEX expansion. Note that expansion connections are only designed for PEX-a pipe. If you’re using PEX-b or PEX-c pipe, you’ll need to use a different fitting type as PEX-b and PEX-c pipes aren’t made to expand like PEX-a pipe, and they will experience microcracking during expansion.

Expansion connections require one simple tool that expands the pipe and an expansion ring before inserting a fitting. As the pipe and ring shrink back down around the fitting, it creates a solid, strong seal that can withstand up to 1,000 pounds of radial force. It’s quick and easy to do and simple to learn, so it’s highly beneficial with the skilled-labor shortage that’s challenging the trades. Here’s a quick, 20-second video on how to make a connection.

Now, to make installs even faster, expansion tools have advanced to make connections even quicker. For up to 1″ connections, the Milwaukee® M12 FUEL™ ProPEX® Expander with RAPID SEAL™ Heads is the fastest tool yet — with up to 65% faster sealing times compared to previous models.

For larger-diameter pipe connections, the new Milwaukee M18 FUEL™ ProPEX Expander with ONE-KEY™ is taking commercial installs to a new level by offering 3X faster 2″ connections. To watch how much faster, check out this video from Milwaukee Tool.

Prefab

Finally, let’s talk about prefabrication. This is becoming a big trend for national residential builders or large commercial projects that have a lot of repeatability on the project. By prefabbing certain sections of a project, it can shave days, weeks, or even months off a timeline, depending on how big the project.

Prefabricating piping assemblies in a controlled factory environment not only adds more efficiencies, it also provides an additional benefit of greater accuracy. By doing a job repeatedly, it hones the skill and gives installers greater confidence in their work.

Plus, having rows and rows of prefabbed piping assemblies in a shop environment makes it a lot easier to perform quality checks. Instead of walking for miles on a job site, a supervisor can save significant time simply walking a shop floor.

And here’s another area where flexible, durable PEX provides additional benefits. Transporting prefabbed PEX piping assemblies is much easier than transporting rigid assemblies that can crack or break. Because PEX is super flexible, it can withstand the rigors of being transported to a job site without worry.

So, there you have it…just a few ideas to keep in mind the next time you have a project with a tight deadline, and you’re squeezed on time and skilled labor. Every little bit helps when it comes to adding productivity to projects. If you have other ideas, I’d love to hear them. Feel free to email me at kim.bliss@uponor.com.

Kim Bliss is the technical and marketing content manager at Uponor. She can be reached at kim.bliss@uponor.com.

Kim Bliss is the technical and marketing content manager at Uponor. She can be reached at kim.bliss@uponor.com.

Technology, and the advancement of technology, affect the mechanical industry in a pretty substantial way. Machines become more efficient, humans need to put less time into supervising machine lead tasks, and automation is getting better all of the time. So, how will the field of mechanics and mechanical materials be further changed (for better or Read more

Technology, and the advancement of technology, affect the mechanical industry in a pretty substantial way. Machines become more efficient, humans need to put less time into supervising machine lead tasks, and automation is getting better all of the time.

So, how will the field of mechanics and mechanical materials be further changed (for better or worse) going forward into the future? Although Gary Coleman has said “the fourth industrial revolution is in its nascent state,” there has already been a fair amount of change in the industry. Some think change can be hazardous, while others say it’s necessary.

Internet Of Things

IOI has changed the way people live their lives, but it also has implications for the mechanical industry. Imagine controlling machines via your smartphone. Products will be able to communicate with their manufacturer like never before. Software-driven controls are becoming more advanced all of the time, leading to mechanical engineers and other operators having to constantly update their supplier base in a rush to access the latest software.

The internet of things gives those in the industry a higher degree of productivity. Machines are now having a higher degree of autonomy over various controls than ever before, leaving mechanics and operatories more time to allot to other areas of work. While some think this isn’t necessarily good and could end up costing them their jobs, others believe it’s great because they’re not spread as thin, and there are fewer chances for accidents to occur.

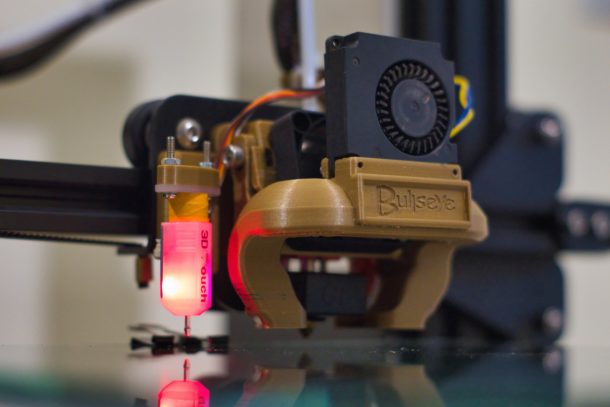

3D Printing

3D printing was spoken about for years before it became properly commercially viable. But as soon as it did, it blew up. 3D printing makes product and material creation extremely easy and immediate (no more waiting for shipping). The upsurge in 3D printing has brought about many firms offering a 3D printing service for other businesses and end-users. Some purely print products are then customized and sold, whereas others print bespoke components for broader usage across the mechanical and manufacturing sector.

There are mechanical engineers out there who have managed to create amazing things in 3D printers. Think about prosthetic limbs or walking aids. These were usually pretty complex to create, but 3D printing has allowed their application across the world in poorer countries.

Nanotech

Nanotech, or nanotechnology, has been touted by many as the future. Its usage covers a wide range, and many people can be forgiven for thinking about science fiction when first coming across the term. In reality, it simply involves the study of materials and structures which are between 1 nanometer and 100 nanometers. It’s supremely useful in the scientific field, where it was originally developed. However, nanotech has vast implications for the mechanical industry.

Pinpoint measurements, fluid mechanics and enhanced robotic controls are but a few potential applications for nanotech. While the study into nanotechnology is still at the outset, it’s clear that it could completely revolutionize multiple industries and open up a whole new way of looking at mechanical engineering.

Machine Learning (and A.I)

It’s another term that could walk straight out of a science fiction novel. AI is basically a machine or program trying to simulate human behavior. It’s getting better all of the time. Machines are becoming more accurate, and able to make human-like decisions (or better than human decisions). Just look at driverless cars as an example. Tesla’s learn as they’re driven. There are still accidents from time to time and many countries are hesitant to adopt driverless as a full feature, but it’s clear that in the not-so-distant future, cars will be driverless.

This applies to mechanical machinery too. Better production outcomes and timetables, robotic designs becoming believable and realistic, virtual reality being far more believable, and much more. With AI in charge, it’s believed that the production of material and anything from an industry standpoint can become far more efficient.

Solar Everything

The sun touches a lot of manmade material, so it makes sense to have it double as solar panels to generate clean energy. Instead of attaching solar panels to certain materials, material itself will be a solar panel. Take for example a window. It gets a lot of sun. Imagine if it could harness the energy from the sun and redistribute it as energy while still functioning as a transparent window. Look at roads. Imagine if they were made out of solar panels. Panels that can hold the weight of cars but still manage to collect and distribute energy.

With constant pivots towards green energy, it’s extremely likely that more materials will be built and geared towards the harnessing of natural energy.