“Any day building custom mechanical rooms is a great day,” says Tyler Dynes (@dyneshvac), lead installer—with a specialty in hydronics—for Farr Mechanical Corp., greater Toronto area. You see, for Dynes, the most rewarding part of his work is seeing the finished install and hearing the customer say, “this is the nicest room in the house.” Read more

Featured Articles

“Any day building custom mechanical rooms is a great day,” says Tyler Dynes (@dyneshvac), lead installer—with a specialty in hydronics—for Farr Mechanical Corp., greater Toronto area. You see, for Dynes, the most rewarding part of his work is seeing the finished install and hearing the customer say, “this is the nicest room in the house.”

In fact, Dynes loves what he does so much, one of his bucket list items is building his own home with a custom hydronic system.

Dynes’ rise into the trades started right out of high school where he began a career in automotive mechanics. After a few years in the field, he soon realized it just wasn’t for him. After speaking to someone at a local fuel/HVAC company, Dynes decided to give working for them a try. Several of his friends were in the industry already and encouraged him to enter the trade. “I worked with that company for about 11 years, learning everything I could in the residential HVAC field. It was here I became a gas fitter, oil burner and started my AC apprenticeship,” says Dynes.

Tyler with Brandon Farr (l), owner of Farr Mechanical.

One of my Dynes’ first mentors was a seasoned tech named Chris who Dynes trained under for five years at that first HVAC company. I also follow the careers of Eric Aune (@mechanicalhub), Mike Flynn (@flynnstone1), Don Taylor (@dontaylor53) and Aaron Bond (@bond_aaron) closely on Instagram. “They inspire me to push myself and learn more about all the different aspects of the trade. I still look up to them and chat with them from time to time,” says Dynes.

Dynes hadn’t considered himself a role model, just someone who takes a lot of pride in what he does. “I hope that I can encourage people to join the trade, and for those already in it, to push themselves to learn new skills. I would love for people to look at my work and be able to ask questions to help them learn everything I have and beyond,” says Dynes.

And with that, social media has allowed Dynes to grow professionally and personally as he loves the relationships that he’s built through it. Dynes is amazed at the support and encouragement he’s received over the last few years through his Instagram posts and stories. “It has such a great community of people from all trades supporting each other,” says Dynes.

And with that, social media has allowed Dynes to grow professionally and personally as he loves the relationships that he’s built through it. Dynes is amazed at the support and encouragement he’s received over the last few years through his Instagram posts and stories. “It has such a great community of people from all trades supporting each other,” says Dynes.

Yet social media can become addicting, says Dynes, and it can be hard to step away. “After I get home, there are usually questions or conversations that happen through Instagram about my posted installs or other people looking for advice. I try to help when I can, but I know it’s important to put my phone down and spend time with my family, which can be going to the cottage with his family and riding his dirt bike,” says Dynes.

Over the past decade, there is no debating social media has become a place where contractors can show off their work and wares, and connect. This should help enhance the trades. “We need to showcase the fun side of trades and that no day is ever the same. There are so many areas that you can excel or specialize in, and we need to make that more known to people. It’s a hard work, fast-paced environment, but it’s so rewarding when you get the freedom to be creative,” says Dynes.

Over the past decade, there is no debating social media has become a place where contractors can show off their work and wares, and connect. This should help enhance the trades. “We need to showcase the fun side of trades and that no day is ever the same. There are so many areas that you can excel or specialize in, and we need to make that more known to people. It’s a hard work, fast-paced environment, but it’s so rewarding when you get the freedom to be creative,” says Dynes.

Engineer’s ERV static-plate enthalpy cores specification eliminates need for conventional defrost systems and saves city energy and maintenance costs The new $12 million Wasilla (Alaska) Police Station employs many innovative HVAC designs that will save the city energy and provide occupants with unprecedented indoor air quality (IAQ). The recently completed 20,000-square-foot building designed with aesthetic Read more

Engineer’s ERV static-plate enthalpy cores specification eliminates need for conventional defrost systems and saves city energy and maintenance costs

The new $12 million Wasilla (Alaska) Police Station employs many innovative HVAC designs that will save the city energy and provide occupants with unprecedented indoor air quality (IAQ).

The recently completed 20,000-square-foot building designed with aesthetic post-modern industrial architecture by MCG Explore Design, Anchorage, doubles the police department’s previous building, which was an old, converted bank. The sustainable mechanical HVAC design features dedicated outdoor air systems (DOAS) with energy recovery, hydronic radiant floor heating and packaged rooftop units (RTU) with heat recovery that all contribute to energy efficiency.

For example, ERVs were specified without defrost coils, which are commonly used for Alaska’s frigid winters, but are costly in upfront capital, operational and maintenance costs. Instead, DN Series DOAS units manufactured by RenewAire, Waunakee, Wis., use static-plate enthalpy cores. The units are designed to operate down to -10°F ambient temperatures without requiring defrost cycles, because they don’t transfer H2O between supply and exhaust air. If temperatures drop lower (Wasilla temperatures rarely drop below -20°F), the DN-Series’ onboard controller activates a bypass damper and introduces space heat to prevent heat exchanger frost accumulation, if needed, according to Christian Dougherty, P.E., mechanical engineer and the project’s manager at consulting MEP engineering firm, AMC Engineers, Anchorage, Alaska.

“The energy recovered by the DOAS units, and the fact they don’t require conventional defrost cycles and equipment, is saving the city a large amount of money,” said Dougherty, whose firm has specified core-based units on previous projects. “We’ve had mixed results in the past with energy recovery alternatives, such as enthalpy wheels, that require defrost cycles and maintenance for moving parts that cores don’t require.”

“Cores aren’t subject to cross contamination, which is potentially problematic in critical spaces, such as garages and evidence rooms, where contaminants can potentially infiltrate occupied spaces,” added Jordan Privoznik, systems sales leader at Trane, Anchorage, Alaska. “DOAS units with static-plate cores are often an ideal solution in our environment as they can be more reliable than other energy recovery methodologies due to less moving parts, while still achieving very high efficiencies.”

Installed by project mechanical contractor Mechanical Specialists Inc., Wasilla, Alaska, the two DN Series ERVs provide 3,000-CFM and 1,700-CFM of 100% outdoor air in the facility’s 3,100-square-foot garage and the 750-square-foot evidence room, respectively. Both spaces are under negative pressure to prevent garage vehicle emissions and evidence room odors, such as bodily fluids or confiscated drug off-gassing, from infiltrating common walls shared with occupied spaces. The two units are also outfitted with sensors, an onboard controller, a manual wall switch and a smoke detector, the latter which complies with Alaska building code. The facility’s building management system (BMS), a Trane Tracer Control System, monitors the ERVs.

While evidence material off-gassing was the prime motivation, 100% outdoor air will also dilute any airborne contaminants that could degrade stored evidence. The evidence room is also closely monitored to minimize any potential degradations from wide temperature and humidity variances.

The garage’s 100% outdoor air is critical in preventing CO and NO2 accumulation and maintaining indoor air quality for employees using and servicing city vehicles. The ERV uses energy recovery to help maintain a year-round 70°F set point. On extreme cold days, which according to ASHRAE guidelines is -23°F locally, the ERV can preheat air to as high as 40°F. A 70°F leaving air temperature can be reached on extreme days by using the integral hydronic reheat coil supplied by the boiler circuit’s glycol heat exchanger.

Other project equipment includes a 25-ton, 8,500-CFM Trane Intellipak™ RTU that supplies the building and includes DX cooling, hydronic heat, and variable airflow, serving several Trane variable air volume (VAV) boxes with hydronic reheat coils to provide precise zone control. A 15-ton, 5,000-CFM Trane Voyager™ RTU was also specified. Radiant floor heating, and snow melt duties are provided by a 2Mbh gas-fired boiler manufactured by Riello, Mississauga, Ontario. Secondary glycol heat exchangers for air handlers were provided by Bell & Gossett, Morton Grove, Ill.

Additional efficiency was created by a Dougherty and Privoznik collaboration that configured the radiant floor heating into zones (rooms) controlled by the Trane BACnet Building Automation System. While VAVs and radiant heating can operate concurrently, there exists a challenge when combining VAV technology’s quicker space comfort achievement with radiant tubing embedded in a thermal mass that takes longer to react. “Meticulous programming and strategic commissioning were required to ensure both systems operated seamlessly and synergistically,” explained Privoznik. “This process, combined with Trane’s advanced Trim and Respond control strategies as prescribed in ASHRAE Guideline 36, allowed us to maximize energy efficiency, maintain control stability and achieve optimal space comfort for the occupants.”

Another energy efficient design was Dougherty’s collaboration with Trane for designating one air handler for operation only during standard business hours, while the other unit operates for 24/7 occupied areas. When a large portion of the building is unoccupied, and outdoor air isn’t required, the less efficient VAV System is disabled and space temperature is maintained solely thru radiant floor heating.

Although the project didn’t apply for Leadership in Energy and Environmental Design (LEED®), Dougherty said the HVAC design would have significantly helped the building accumulate enough credits if the city had chosen certification.

Regardless, the police station is delivering 21st century comfort, IAQ and energy savings, within a strict construction budget.

https://youtu.be/46yc2caCGzo A quick Hub on the Road takes us to Grasser’s Plumbing & Heating in McNabb, Ill., to visit with Tim Kuhlman to talk about the company, its new showroom, inventory and supply, and a plumbing truck tip Read more

A quick Hub on the Road takes us to Grasser’s Plumbing & Heating in McNabb, Ill., to visit with Tim Kuhlman to talk about the company, its new showroom, inventory and supply, and a plumbing truck tip.

I know it’s the start of summer and you’re thinking, “who is thinking snow and cold temps?” But it could be the best time to ramp up your snowmelt game for the upcoming winter season. Once upon a time, commercial snowmelt systems lived independently, with little concern about the larger mechanical environment they were often a Read more

I know it’s the start of summer and you’re thinking, “who is thinking snow and cold temps?” But it could be the best time to ramp up your snowmelt game for the upcoming winter season. Once upon a time, commercial snowmelt systems lived independently, with little concern about the larger mechanical environment they were often a part of. Typically, a boiler provided heat and a smart tubing layout, properly circulated, offered thermal distribution.

Voila! As if by magic, tropical warmth gently melted away midwinter precipitation from parking lots, walkways, ramps and driveways.

All good things change, and occasionally for the better. As for modern snowmelt systems, their renaissance has come in the way of—you probably guessed it— improved and more sophisticated controls. Now, snowmelt systems can integrate with BAS (building automation systems).

It only makes sense that snowmelt systems would eventually cross that bridge. Getting there, however, wasn’t without challenge.

BAS networks, by design, are largely “inclusive.” That is, their purpose in life is to integrate, control and monitor as many of a building’s key functions as possible, including heating, cooling, ventilation, lighting and other important operations.

Yet, because snowmelt systems operate outside a building, and are exposed to ambient conditions outside the envelope—with conditions that change quickly, often requiring far more than simple on/off function—BAS systems are challenged by their limitations. The key frustration expressed by design engineers, installers and building owners alike is that the ever-changing nature of outside, ambient conditions defies the constraints of most automated controls.

For this reason, anyone attempting to tie commercial snowmelt function with a BAS confronted a giant hurdle.

Fortunately, those impediments may now be things of the past.

The nature of the beast

For the longest time, achieving proper connection to and communication between snowmelt controls and a BAS was the seemingly impossible task. The two key parts of that puzzle were a.) sensors didn’t want to communicate digitally with the BAS, and b.) controls were mostly incapable of anything more than on-off operation. Maintaining idle operation, controlling gradual increases in temperature, or especially measured deactivation—these became the key challenges.

After all, if snowmelt system deactivation happens too soon, winter accumulations may pile up, or snow may melt prematurely, turning into treacherous ice. Or, if a system demands too much heat, or stays on too long, it punishes the building owner with unexpected operational costs.

For many years, there were many reverse-engineered attempts to connect snow and ice sensors with building automation systems. However, more recently, new technology has been developed to meet this challenge.

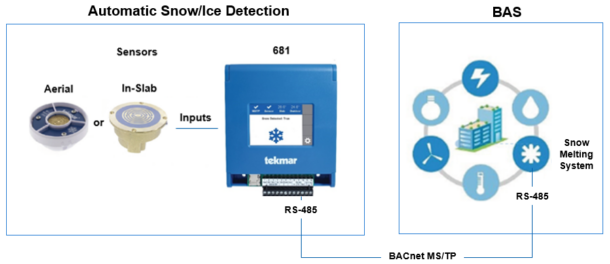

This new technology helps connect these two previously disconnected functions by receiving input data and sending information from sophisticated sensors directly to the building automation system, which ultimately tells the snow melting system to turn on or off.

A snow and ice sensor interface communicates directly with a BAS controller through BACnet MS/TP protocol, letting the BAS know to engage the on and off function of a snowmelt system when the outside sensors detect snow or ice. This unique piece of technology has quickly turned a traditionally inefficient process into a smart and truly automated system.

Having the ability to interface snow and ice sensors directly with any BACnet controller is not only creating more efficient snow melting systems for facility and building owners, it’s making it easier for contractors to have a simple, standard solution that can be easily applied to any snowmelt job—without custom coding or complex installation.

Having the ability to interface snow and ice sensors directly with any BACnet controller is not only creating more efficient snow melting systems for facility and building owners, it’s making it easier for contractors to have a simple, standard solution that can be easily applied to any snowmelt job—without custom coding or complex installation.

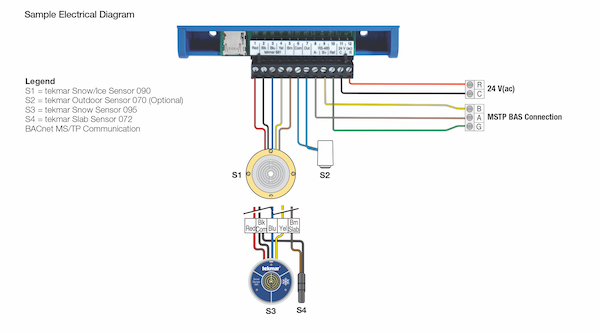

Despite its simplicity, connecting a snow and ice sensor interface to a BAS should incorporate many functions, also known as objects (see bullets below). The device itself is designed to be installed in a mechanical room, or at any remote location on site—perhaps in a service room closer to the snow melting area.

The list of data objects shared with the BAS controller should ideally include:

- Snow or ice has been detected

- Snow or ice has not been detected

- Outdoor air temperature

- Slab temperature

- Slab target temperature

- Snow/ice sensor sensitivity

- Warm weather shut down (WWSD)

- Cold weather cut off (CWCO)

- Error codes

As is often the case—and especially when new technology is introduced—questions arise. Here are some common questions from professionals in the field:

What happens if ambient conditions are too cold, or too warm?

Interface features such as warm weather shut down (WWSD) and cold weather cut off (CWCO) are particularly useful in ensuring the snow melting system is only running when needed. For instance, with CWCO, when outdoor air temperature is too cold (below CWCO setting), the BAS heat source is not able to increase the slab temperature to melt snow or ice. Features like this create critical efficiencies and save loads of energy.

With the right technology in place, the interface sends a signal to the BAS to turn off the snow melting system. Once the outdoor air temperature increases above the CWCO temperature setpoint, the interface will communicate to the BAS to turn on the snow melting system and resume its operation.

Of course, if conditions are too warm for the formation of snow or ice, the systems will use the opposite logic (WWSD) and tells the BAS to deactivate the system.

What types of alert functions are available to building managers?

Ideally, a snow and ice sensor interface will use error codes to signal the BAS controller if there are operational problems with the sensors.

This would allow the BAS to have feedback on the system and determine if any action needs to be taken.

Can contractors use the BACnet Sensor Interface with any snowmelt application controlled by BAS controllers?

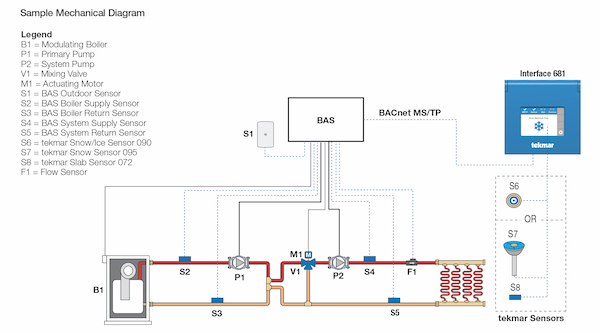

Here, too—a versatile snow and ice sensor interface should be compatible with any snowmelt system application. After all, BAS controllers use BACnet MS/TP protocol for communication. The technology should be capable across many types of installations, such as snowmelt applications with a simple dedicated boiler, or more complex multi-boiler plants with multiple zones and mixing valves. And, the right technology should be BTL certified, providing the confidence of seamless integration.

Here, too—a versatile snow and ice sensor interface should be compatible with any snowmelt system application. After all, BAS controllers use BACnet MS/TP protocol for communication. The technology should be capable across many types of installations, such as snowmelt applications with a simple dedicated boiler, or more complex multi-boiler plants with multiple zones and mixing valves. And, the right technology should be BTL certified, providing the confidence of seamless integration.

Why is it important to control the slab temperature?

Controlling slab temperature is crucial to have an efficient snowmelt system. If the slab temperature is too low, the snow will not melt off. If the temperature is too high, the slab could be damaged and will waste a lot of energy.

Information = power

So, if you’re faced with the need to install—or retrofit—a commercial snowmelt system, and BAS is in the cards, you’re now equipped with new information and ready to reenter winter warfare. But this time, better prepared.

Cleber Alves is product manager for tekmar.

Mechanical Hub continues its conversation regarding heat pumps and heat pump technology. Electrification and carbon reduction is core to the emergence of heat pump technology. We recently spoke with Mark Chaffee, VP Governmental Affairs and Commercial & Industrial Product Management, Taco Comfort Solutions. MH: What are some of the driving forces behind heat pump technology? Chaffee: The Read more

Mechanical Hub continues its conversation regarding heat pumps and heat pump technology. Electrification and carbon reduction is core to the emergence of heat pump technology. We recently spoke with Mark Chaffee, VP Governmental Affairs and Commercial & Industrial Product Management, Taco Comfort Solutions.

Mechanical Hub continues its conversation regarding heat pumps and heat pump technology. Electrification and carbon reduction is core to the emergence of heat pump technology. We recently spoke with Mark Chaffee, VP Governmental Affairs and Commercial & Industrial Product Management, Taco Comfort Solutions.

MH: What are some of the driving forces behind heat pump technology?

Chaffee: The key, driving factor is a desire for CO2 reduction by using less fossil fuel. The world’s leading cultures and political forces have chosen to pursue beneficial electrification as a key component to achieve reduction goals. So, how is it that we can most quickly, substantively reduce our dependence on fossil fuels—a key contributor to carbon emissions? Heat pump technology is the HVAC industry’s best foot forward in achieving this today.

The effort to accomplish decarbonization is broken into two primary camps: a.) at the grid (source) level, and b.) equipment (local).

At the grid level, our 50 states are all at different places in implementing this. And, for the technology that’s involved residentially, and commercially, the ability of heat pumps to deliver COP’s (coefficient of performance) of 3, 4 and 5—meaning operational efficiencies of 300, 400 and 500 percent, or more— can’t be ignored. In comparison, fossil fuel burning equipment can achieve efficiencies of maybe 92 to 98 percent at best.

The goal: clean, efficient grid energy in combination with the highest efficiency HVAC solutions possible. Then install some solar panels on your house or commercial building (distributed green energy) for another win. Heat pumps measure up effectively as viable equipment solutions to keep people comfortable year-round.

MH: What are the benefits of heat pump technology?

Chaffee: At Taco Comfort Solutions, we believe that the best, no-compromise product offering comes from air-to-water systems; we want to be sure they have a seat at the table. They offer extreme energy efficiency, and the finest heating and cooling solutions with the greatest options and flexibility for delivery of that comfort—such as low-temperature radiant heat and towel warmers, etc. And: cooling, too. Hydronic technology is the undisputed king of comfort for humans.

With so many other heat pump technologies (for instance, mini splits, VRF or split system HVAC equipment), refrigerants are the means of thermal exchange across all facets of the distribution network. Refrigerant lines may pierce roofs, and course their way through attics and walls from condensing units to air handlers or terminal units. We prefer the much improved means of using water as the primary source of distribution; it’s safer, less expensive and more efficient. We know water to be the cleanest and most efficient medium of thermal exchange. Simply, more BTUs can be transported by water than by refrigerant compounds or by forced air.

With so many other heat pump technologies (for instance, mini splits, VRF or split system HVAC equipment), refrigerants are the means of thermal exchange across all facets of the distribution network. Refrigerant lines may pierce roofs, and course their way through attics and walls from condensing units to air handlers or terminal units. We prefer the much improved means of using water as the primary source of distribution; it’s safer, less expensive and more efficient. We know water to be the cleanest and most efficient medium of thermal exchange. Simply, more BTUs can be transported by water than by refrigerant compounds or by forced air.

We aren’t comparing heat pumps with boilers here. For generating high temperature water, there’s nothing better than a sturdy boiler. On the other hand, we are comparing air-to-water heat pumps with forced air systems and traditional ground-sourced geothermal systems, the latter of which can also consistently provide efficient, decarbonized comfort, though with substantial up-front costs to accomplish geoexchange.

Air-to-water heat pumps are a viable solution and can deliver no-compromise, year-round comfort without wells, deep and grouted boreholes, trenches, or underwater heat exchangers.

Heat pumps offer extreme efficiency, with heating and colling for year-round comfort. Some of them, like ours, also provide super-efficient heating of domestic water—all from a single appliance-like device.

MH: Do you see demand for Heat pumps more on the residential side than commercial? What’s the ratio?

Chaffee: We’ve all seen the explosive growth of mini-splits in the US residential market. To a large extent, homeowners have accepted and appreciate them. In the commercial sector, VRF technology has also seen broad acceptance, but there’s a tougher battle for dominance of the market—including the hydronic technology that we at Taco have invested in heavily.

Air-to-water systems represent a small percentage of both markets—residential and commercial—though with great potential for growth. After all, their superior comfort and technology offerings is matched with the ability to decarbonize. They can also handle the domestic hot water loads as part of a singular system.

Consider, too, that a lot of refrigerant compounds have come and gone in the last couple of decades. As increased regulatory and environmental efforts removed more from the market, the long-term viability of distributed refrigerant-based systems comes into question. Why rip out and replace an existing system just because refrigerant laws change? Hydronics has always been able to adapt and upgrade to environmental, regulatory or technology changes.

I hope we see a great deal more demand for water-based systems in both the commercial and residential markets to help meet the demands for a low carbon society.

A ratio? Right now, the growth trend is affecting both markets equally, though overall—the residential market has seen faster growth initially.

MH: Can the grid support a HP transition?

Chaffee: Probably not, in its current state. But that won’t stop anyone from trying to achieve 100 percent clean energy. But, there’s a lot of work to be done to improve grid conditions before this can accomplished.

MH: Is a different skill set required for installation?

For the most part—no. Most trade professionals in the market today have everything they need—from expertise on tap, skills and tools—to accomplish proper installation of heat pumps. Those who already have a refrigerant license have a step up. Though, what little refrigerant there is within our System M is fully sealed at the factory in the outdoor unit, so no refrigerant license is needed to install the unit.

There are two types of heat pumps as defined by refrigerant technology:

- Monobloc—all refrigerant and the compressor are within the exterior unit, factory-sealed; refrigerant-to-water is the medium for thermal exchange. Only water moves to and from the exterior unit to the home or business for space conditioning.

- Split—these systems move refrigerant from the outside condensing unit to the inside of a structure in the process of air-to-refrigerant, or refrigerant-to-air thermal exchange.

MH: Life expectancy compared to boilers?

Chaffee: Nothing lasts like a boiler. Though many improvements have been made to boilers through the years, chiefly to enhance efficiency, their ability— by design—to heat water and transport it out for distribution, and then back again, is unsurpassed. In round numbers, a boiler’s lifespan is about 30 years.

Now, consider the rate new HVAC technology introductions over the past decade or so. In that same 30 years, a lot of new technology will emerge to supplant any appliance on the market today, and some will see the influence of refrigerant compounds that will be legislated-out, making them obsolete. It’s become broadly accepted that if an appliance lasts 15 to 20 years, its met its expectation.

Essentially, today’s air-to-water heat pump systems are appliances— considering their construction and durability. With proper installation and routine maintenance, they should last 15 to 20 years.

MH: Will you offer training for these products?

Chaffee: Yes. Taco provides training for all of the technology it offers to the market. We’re passionate about the support we offer to installers and system designers, the System M air-to-water heat pump will allow us to continue to educate on products and system design, especially as we look to implement high performance, energy efficient HVAC system.

MH: Other thoughts?

Chaffee: Glad you asked! We’ve heard this question on many occasions from a wide range of trade professionals: “Why does Taco want to offer this technology?”

The answer stems from our combination of expertise in hydronics, thermal distribution and comfort. These different facets meet and combine uniquely in our newest technology—the System M. It’s a single-source, air-to-water, turnkey heat pump system designed and built to meet the comfort and efficiency needs of a low-carbon society.

If we at Taco can help the trade to accomplish this, all the better. After all, that’s been an important part of our makeup dating back more than 100 years now. In the past decade or so, we’ve made a concerted effort to move from our role as a component manufacturer to that of a systems provider. With System M, we’ve combined no-compromise comfort with environmental benefits. And, considering that the technology is easy to size and install, it’s a win-win from many perspectives.