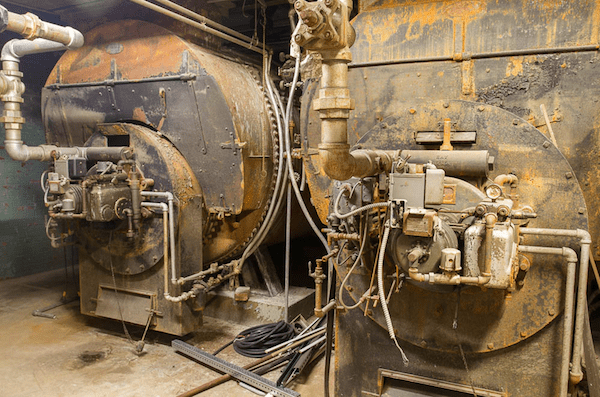

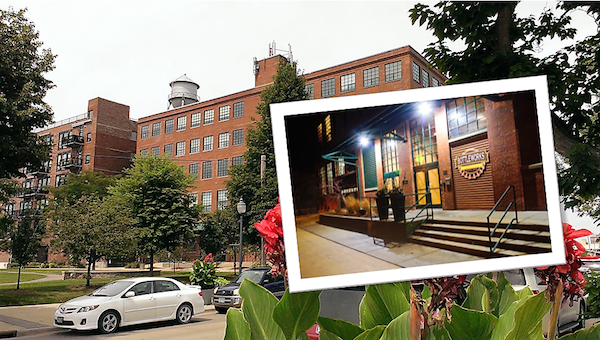

As I was finishing up an 18-month consulting project, I took the opportunity to visit the basement boiler room. The room sits cold now with two huge boilers that have been replaced by a modern state-of-the-art distributed geothermal heat pump system.

In my mind, I could see the boiler fired and operating, providing heat for the building’s occupants and operation. I could see the heating technicians in the space, working under treacherous conditions to ensure the boilers where providing optimum performance. In case you have any trouble believing that these old boilers are still in operation, watch this from the Wall Street Journal on the Flat Iron building in NYC; you’ll get to hear an interview with the building engineer, and see the boiler, dated March 31, 2015. https://youtu.be/9WXNjYuS2zY

In my mind, I could see the boiler fired and operating, providing heat for the building’s occupants and operation. I could see the heating technicians in the space, working under treacherous conditions to ensure the boilers where providing optimum performance. In case you have any trouble believing that these old boilers are still in operation, watch this from the Wall Street Journal on the Flat Iron building in NYC; you’ll get to hear an interview with the building engineer, and see the boiler, dated March 31, 2015. https://youtu.be/9WXNjYuS2zY

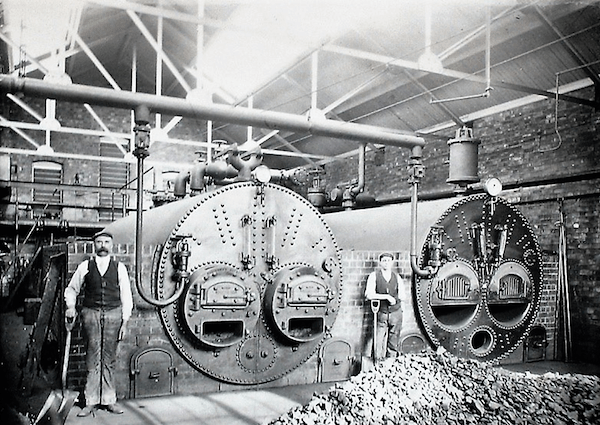

Technicians in the heating and air-conditioning trades are truly the most knowledgeable and toughest out there. They work under rigorous conditions (both hot and cold), and must have a good working knowledge of high and low voltage electrical circuits, Plumbing of all types (hydronic and steam piping systems), combustion heating (coal, oil, natural gas, etc.) and operational understanding of the Carnot refrigeration cycle. I think that those mentioned cover every trade except structural, roofing and painting, and they even have to do quite a bit of that. We are in the job from day one until the grilles and thermostats go in.

Technicians in the heating and air-conditioning trades are truly the most knowledgeable and toughest out there. They work under rigorous conditions (both hot and cold), and must have a good working knowledge of high and low voltage electrical circuits, Plumbing of all types (hydronic and steam piping systems), combustion heating (coal, oil, natural gas, etc.) and operational understanding of the Carnot refrigeration cycle. I think that those mentioned cover every trade except structural, roofing and painting, and they even have to do quite a bit of that. We are in the job from day one until the grilles and thermostats go in.

I could imagine a technician working in the difficult circumstances in this boiler room, and thought of the many injuries that I’d received through the years, and my respect for our fearless HVAC forces was recalled.

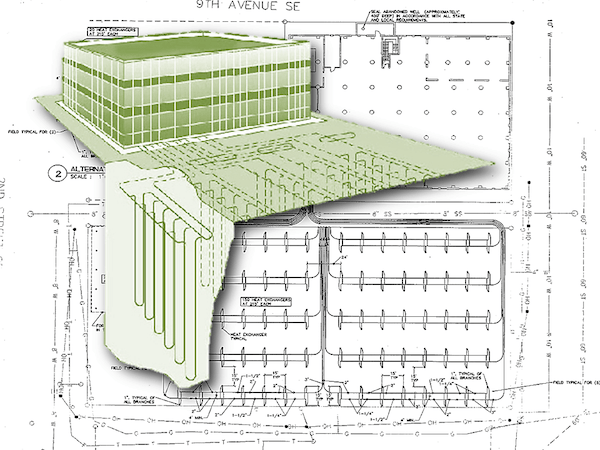

Times are getting better. I mentioned that in this building the basement boiler room sits cold. That’s because 20 years ago, the building was upgraded to a geothermal heat pump system. The boiler was replaced by a geothermal loop field. I was called a year and a half ago, because the owners thought something had gone wrong with the geothermal loops. It turns out, that was the only part that didn’t need attention.

In this case, the main problem revolved around a 100% fresh air system that had some problems, and didn’t get the attention it needed until the damage was done. The common area geothermal heat pumps (GHPs) were overworked in both summer and winter extremes (with the high volume of un-conditioned air being pumped into the building), and the high humidity of the summer took a toll on both the steel piping and the heat pump cabinets.

In this case, the main problem revolved around a 100% fresh air system that had some problems, and didn’t get the attention it needed until the damage was done. The common area geothermal heat pumps (GHPs) were overworked in both summer and winter extremes (with the high volume of un-conditioned air being pumped into the building), and the high humidity of the summer took a toll on both the steel piping and the heat pump cabinets.

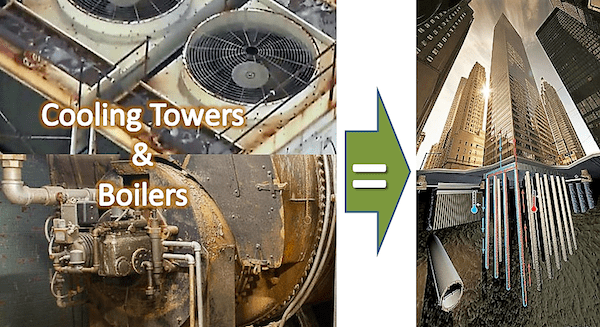

The building owners purchased a new outdoor air unit, and upgraded the GHPs. The hydronic pipe was upgraded to Polyethylene inside the building (the geothermal loops are already constructed of HDPE), and the place is in great shape to serve the next generations with no more down-time. The amazing fact here is that the part that has replaced both the boiler and the cooling tower in this building continues to do its job flawlessly, and it will continue for generations to come.

That is the real beauty of geothermal loop fields. Properly installed and engineered, they’ll last more than a lifetime. One could say with reasonable certainty that they will actually outlast the building. I would bet on it.

That is the real beauty of geothermal loop fields. Properly installed and engineered, they’ll last more than a lifetime. One could say with reasonable certainty that they will actually outlast the building. I would bet on it.

How would you like to be able to tell you customer that you can recommend something that will replace the boiler and the cooling tower, and they’ll never have to worry about either of those pieces of equipment again? Sell them on geothermal, and you’ve got a friend for life.

Learn more about how your company can offer geothermal technology to your customers. Contact the International Ground Source Heat pump Association (IGSHPA) and plan to attend the IGSHPA Conference in Denver this March. You’ll be doing yourself and your residential customers and building owners a huge favor.

Learn more about how your company can offer geothermal technology to your customers. Contact the International Ground Source Heat pump Association (IGSHPA) and plan to attend the IGSHPA Conference in Denver this March. You’ll be doing yourself and your residential customers and building owners a huge favor.

Jay Egg is a geothermal consultant, writer, and the owner of EggGeothermal. He has co-authored two textbooks on geothermal HVAC systems published by McGraw-Hill Professional. He can be reached at jayegg.geo@gmail.com.

Jay Egg is a geothermal consultant, writer, and the owner of EggGeothermal. He has co-authored two textbooks on geothermal HVAC systems published by McGraw-Hill Professional. He can be reached at jayegg.geo@gmail.com.