Family owned and operated, Boston Standard Plumbing & Heating Inc. focuses on residential and light commercial service, repair and installation work. The company performs boiler, furnace, ductless system work, “and plain ol’ no-heat/no-ac calls. We pride ourselves on getting things done right the first time,” says owner, Joseph Wood.

“We operate cleanly and foster a cool team environment where we’re always making sure we’ve got each other’s back—it leads to a nice experience for both our company and our clients and everyone works together, which is great. We do company outings quarterly to make sure we all function as a team at all times, and these vary from Red Sox games to bowling and pizza, or fantasy football drafts,” continues Wood.

“We operate cleanly and foster a cool team environment where we’re always making sure we’ve got each other’s back—it leads to a nice experience for both our company and our clients and everyone works together, which is great. We do company outings quarterly to make sure we all function as a team at all times, and these vary from Red Sox games to bowling and pizza, or fantasy football drafts,” continues Wood.

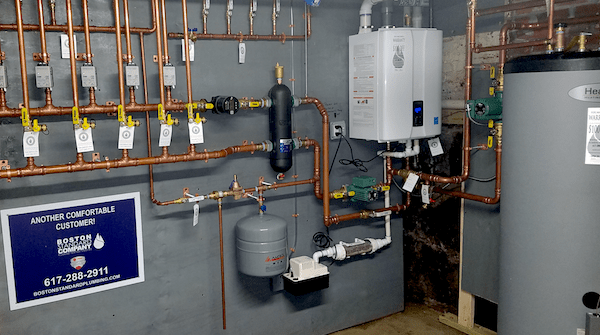

Recently, Wood and a two-man crew encountered an old 4-level, 2,000-sq.-ft. multi-family row house in Boston’s Charlestown neighborhood—near the Bunker Hill Monument—that was converted back to a single family home, which had two failing heating systems and two failing tankless units. (The home is technically a two-family home but has been occupied by the same family since 1960.) It was a great opportunity to transition to one modern system. The two techs, Jose and Ben, worked off of an application drawing that Wood drew for them to ensure they followed manufacturer’s specs or better for each item.

For the 5-zone baseboard system, Boston Standard’s crew installed a Navien NHB-150 to tackle the heating needs due to its superior turndown Ratio of 15:1, meaning it could get down as low as 10,000 BTUs for a mild day, but ramp up if needed to tackle the biggest heating or hot water demand. They paired the NHB-150 with a lifetime warranty 60-gallon Heat Flo indirect water heater so they could get ample hot water and a great lifespan.

The team also installed a Caleffi SEP-4 Magnetic Hydraulic Separator to provide the air elimination, but also to keep the old system debris clean of any remnant debris as it has a manual flush feature to draw iron oxide and similar “crud” from the system. “The SEP-4 also allows us to handle the hydraulic separation in a really clean format,” says Wood.

A Taco Veridian pump was installed to modulate the pump speed based on the number of open zones. “This will allow the client to have an awesome new system that is super-efficient with not only the gas usage, but also with the electrical usage,” says Wood.

In addition, two old HVAC systems were replaced with new Trane Hyperion air handlers and condensers.

Parker fittings along with Viega ProPress using the Milwaukee M12 FORCE LOGIC short throw tool, which presses up to 1.25”, were used for the whole setup to keep things nice and clean and leak free for years to come.

The proof is in the install. “The homeowner loves the new system—it saves space and looks beautiful, and will last the client a good long time,” says Wood.