Infusion laboratory managers seek additional ‘layer’ of protection against airborne bacteria and other contaminants

Managers at a Texas-based medical infusion laboratory recently took proactive steps to protect the laboratory environment from airborne pathogens using ultraviolet germicidal irradiation technology (UVGI or UV-C), which kills or inactivates infectious diseases.

Since the 1940s, UV-C light has been used to mitigate the risk of nosocomial infections in health care settings—including clinics, surgical suites, emergency room waiting areas and patient rooms—for its ability to kill all known microorganisms, including bacteria, viruses, molds and other pathogens – even those that are antibiotic resistant.

Since the 1940s, UV-C light has been used to mitigate the risk of nosocomial infections in health care settings—including clinics, surgical suites, emergency room waiting areas and patient rooms—for its ability to kill all known microorganisms, including bacteria, viruses, molds and other pathogens – even those that are antibiotic resistant.

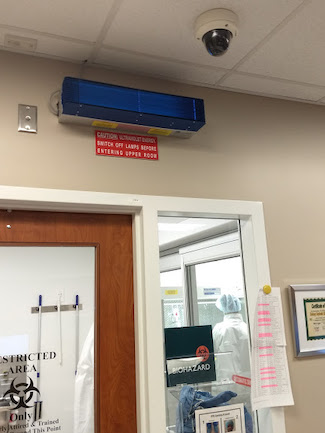

At the infusion laboratory, facility managers selected two UV-C technologies to control microbes and bio-aerosols: 1) upper-room UV-C disinfection units in the laboratory common area and anteroom and 2) UV-C fixtures in the HVAC supply air units to clean airstreams and cooling coils.

The UV-C devices, along with higher efficiency air filtration were implemented to supplement the center’s already rigid infection-control protocols for disinfection and sterilization. The 24/7 pathogen-killing, germicidal wavelength provides an extra level of protection for the infusion laboratory.

IAQ Energy Solutions, a Texas-based UV-C equipment distributor, was called in to meet with managers to see how UV-C would ensure the greatest practical control of microbes and airborne microorganisms in the laboratory area. Dan Young, Sales Manager at IAQ-Energy, contacted Dean Saputa, Vice President of Sales for UV Resources, who has extensive experience with UV-C in upper air applications. Saputa, who has also served on the ASHRAE technical committee TC 2.9, Ultraviolet Air and Surface Treatment since its inception, supported Young’s recommendation to add four high-output GLO™ upper-room UV-C fixtures to protect the laboratory and anteroom. Airborne microorganisms generated by people and materials entering and exiting the area are reduced as the microorganisms are carried, via the natural rise-and-fall of air convection currents, into the irradiation zone created by the upper air/room fixture.

IAQ Energy Solutions, a Texas-based UV-C equipment distributor, was called in to meet with managers to see how UV-C would ensure the greatest practical control of microbes and airborne microorganisms in the laboratory area. Dan Young, Sales Manager at IAQ-Energy, contacted Dean Saputa, Vice President of Sales for UV Resources, who has extensive experience with UV-C in upper air applications. Saputa, who has also served on the ASHRAE technical committee TC 2.9, Ultraviolet Air and Surface Treatment since its inception, supported Young’s recommendation to add four high-output GLO™ upper-room UV-C fixtures to protect the laboratory and anteroom. Airborne microorganisms generated by people and materials entering and exiting the area are reduced as the microorganisms are carried, via the natural rise-and-fall of air convection currents, into the irradiation zone created by the upper air/room fixture.

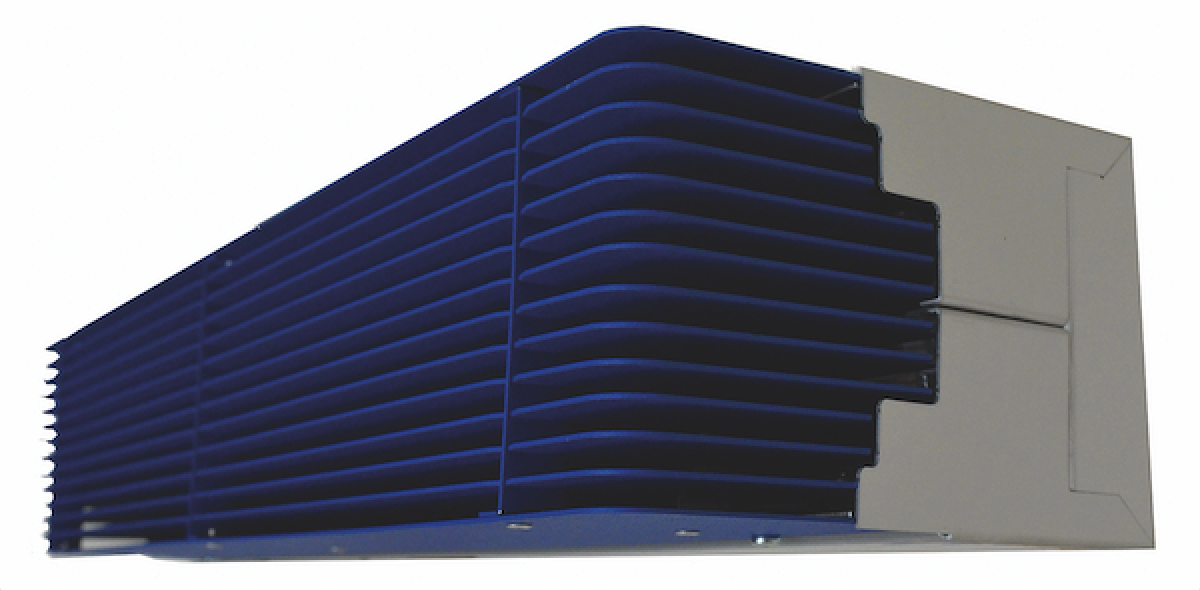

The GLO fixture delivers the industry’s greatest amount of upper room UV-C dosage – up to 350 percent more irradiance than conventional upper air UV systems. This increase in irradiance levels translates to greater germicidal coverage, enabling infection control specialists to treat more square foot area with fewer fixtures, saving both cost and energy.

According to Saputa, airborne droplets containing infectious agents from occupants with a cold or flu can remain in room air for six minutes or longer. Upper-air UV-C fixtures can destroy those microbes in a matter of seconds and they operate 24 hours a day for continuous control.

In order to gain the most practical control of the lab environment before implementing more rigorous and expensive measures, UV-C was also installed downstream of the dedicated air handler’s cooling coil to destroy microbes in air and on interior surfaces. A 20-inch UV-C lamp was installed in the unit’s 1,000 CFM fan coil that serves to keep the laboratory under positive pressure. A third UV-C fixture, the Stinger™, was installed, along with reflective material to amplify UV-C energy, in the VAV box that provides the laboratory with supplemental air from the BBU (base building unit).

In order to gain the most practical control of the lab environment before implementing more rigorous and expensive measures, UV-C was also installed downstream of the dedicated air handler’s cooling coil to destroy microbes in air and on interior surfaces. A 20-inch UV-C lamp was installed in the unit’s 1,000 CFM fan coil that serves to keep the laboratory under positive pressure. A third UV-C fixture, the Stinger™, was installed, along with reflective material to amplify UV-C energy, in the VAV box that provides the laboratory with supplemental air from the BBU (base building unit).

Both units, available from UV Resources, are designed to efficiently destroy surface microbes and degrade organic materials that impede HVAC system efficiency, as well as inactivate airborne-transmitted pathogens.

In HVAC systems, mold and bacteria can grow in damp areas around cooling coils, drain pans, plenum walls and filters. This environment also allows viral agents to remain viable for much longer periods. Growth of microbial deposits also leads to coil fouling, which increases coil pressure drop and reduces airflow and heat-exchange efficiency. As HVAC performance degrades, so does the quality, [amount and pressurization capability] of air supplied to conditioned spaces.

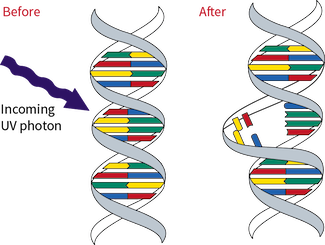

Double Helix dna strand before after UVC-HI

Saputa notes that in addition to inactivating pathogens on HVAC surfaces, a typical coil-irradiation system utilizing 360-degree UV-C irradiation, can kill up to 35 percent of infectious agents moving through the air. UV-C has been shown to be effective against virtually all airborne viruses and bacteria, including chickenpox, measles, mumps, tuberculosis (TB) and cold and flu viruses.

According to Young, facility engineers and healthcare managers are increasingly looking to UVGI technology for its ability to control airborne contaminants in the occupied space, as well as in the HVAC system itself. In the infusion lab measures cited here, UV-C in upper air and HVAC, along with supplemental filtration, were determined to be an integral part of the cost-effective, easy to implement, and most satisfactory microbial control program.

SIDEBAR: HOW TO APPLY GERMICIDAL TECHNOLOGY

There are three primary means of applying UV-C for air and HVAC surface protection against infectious agents: 1) Upper-Room or Upper-Air, 2) HVAC airstream disinfection, and 3) HVAC coil/surface irradiation:

Upper-Room Disinfection: The primary objective of upper-Room UV-C germicidal fixtures is to interrupt the transmission of airborne infectious diseases in communal spaces (e.g., waiting areas, cafeterias, sports facilities, etc.). Airborne droplets containing infectious agents can remain in room air for 6 minutes and longer. Upper-Air UV-C fixtures can destroy those microbes in a matter of seconds including measles, mumps, TB and cold viruses. Kill ratios over 99.9 percent on a first-pass basis have been modeled and, as air is recirculated, concentrations are further reduced by each subsequent pass (“multiple dosing”). The Upper-Room UV-C fixtures utilize the natural rise-and-fall of convection or mechanical air currents to lift airborne infectious agents into the upper room where they are exposed to UV-C irradiation and killed.

HVAC Air- Stream-Disinfection: UV-C air disinfection systems are installed in-duct in air-handling units or air distribution systems to inactivate microorganisms and disinfect moving airstreams “on-the-fly.” UV-C exposure and the resulting dosage is determined by the quantity of germicidal energy absorbed by a pathogen over a specific period of time i.e., disinfection is a function of the time and UV-C intensity a microbe is exposed to UV-C energy, and that microbes’ specific susceptibility to UV-C Predictive-modeling based on scientific studies of each pathogen’s susceptibility to UV-C can assist in designing the recommended dosage rates required to kill individual bacteria, viruses, or spores. Studies have demonstrated that viruses (e.g., influenza, measles, SARS and smallpox) are more susceptible to UV-C inactivation than say bacteria.

Coil-Irradiation Systems: Surface-cleaning UV-C systems provide 24/7 irradiation of HVAC/R components to destroy bacteria, viruses and mold that settle and proliferate on HVAC coils, air filters, ducts and drain pans. UV-C prevents these areas from becoming microbial reservoirs for pathogen growth that will eventually spread into airstreams. A system installed for coil irradiation can also have a secondary benefit of eliminating up to 30% of airborne pathogens on a first-pass basis, with ancillary benefits of restored cleanliness, heat-exchange efficiency and energy use.