If you are running a manufacturing business, it’s important to ensure that your company is able to cope with some of the common issues in this industry. One of the major issues is always going to be heavy costs that aren’t sustainable. Let’s look at some of the key examples of manufacturing costs and the best ways to handle them head on.

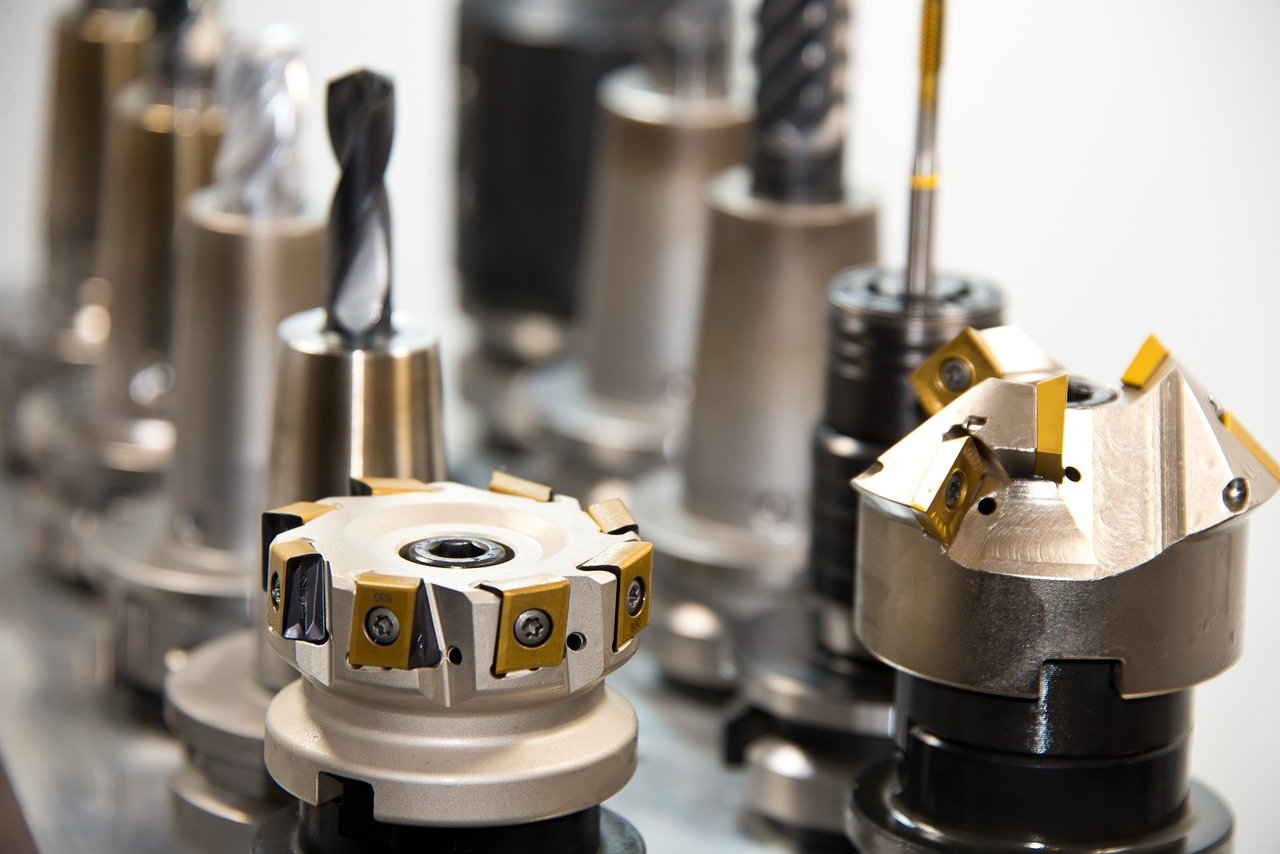

Equipment

The first cost to consider is equipment. Equipment costs are always going to be one of the most expensive upfront costs for your business. You will need to purchase all the equipment as a starting point. For this reason, some manufacturing companies will buy second-hand equipment to avoid problems here. However, this does increase the chances of downtime. You can also get an equipment loan. This could be useful if you require new equipment to expand and grow your company overtime.

Energy

Next, you should think about issues with energy. It’s important to ensure that every business today is limiting energy usage. This isn’t just about saving money either. It could help prevent blackouts through the winter months if the energy stores start to run dry. You might think that it’s difficult to ensure that a manufacturing plant is as green as possible. However, there are steps that you can take here. For instance, you may want to think about investing in renewable power. You can add solar panels to a property. This will help you save a fortune through the winter months and you can also store energy generated so it is available when you need it the most.

Downtime

Depending on your business and the model that you are using, even an hour of downtime could end up costing your business thousands. That’s why you need to ensure that you are taking steps to eliminate any potential issues with downtime. One of the ways that you can do this is by completing regular checks on your systems. System checks will ensure that an issue can be dealt with before it turns into a headache for your company.

You should also have the right IT security. Manufacturing firms can be exposed to hacks and attacks similar to any other type of business.

Team

Finally, you should think about your team. On top of equipment costs, you’ll also need to manage labor expenses as well. Ideally, you should aim to keep your manufacturing team as small as possible. This is an option if you explore equipment that requires less man power to function. You should also avoid additional costs that are associated with having a large business team. One example of this would be injury claims. It’s important to keep your manufacturing plant as safe as possible so that you can avoid a steady influx of PI claims. These can easily cripple your company financially, even over a short period.

We hope this helps you understand some of the key costs of manufacturing companies and the best way to manage them effectively. In doing so, you can ensure that your business is flexible enough to withstand some of the key changes in the industry or even the economy as a whole.

Join the conversation: